Safety syringe structure and manufacturing method thereof

A syringe and safe technology, applied in the field of medical devices, can solve the problems of slow production speed, increased disease, component pollution, etc., and achieve the effects of improving quality and qualification rate, shortening processing time, and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

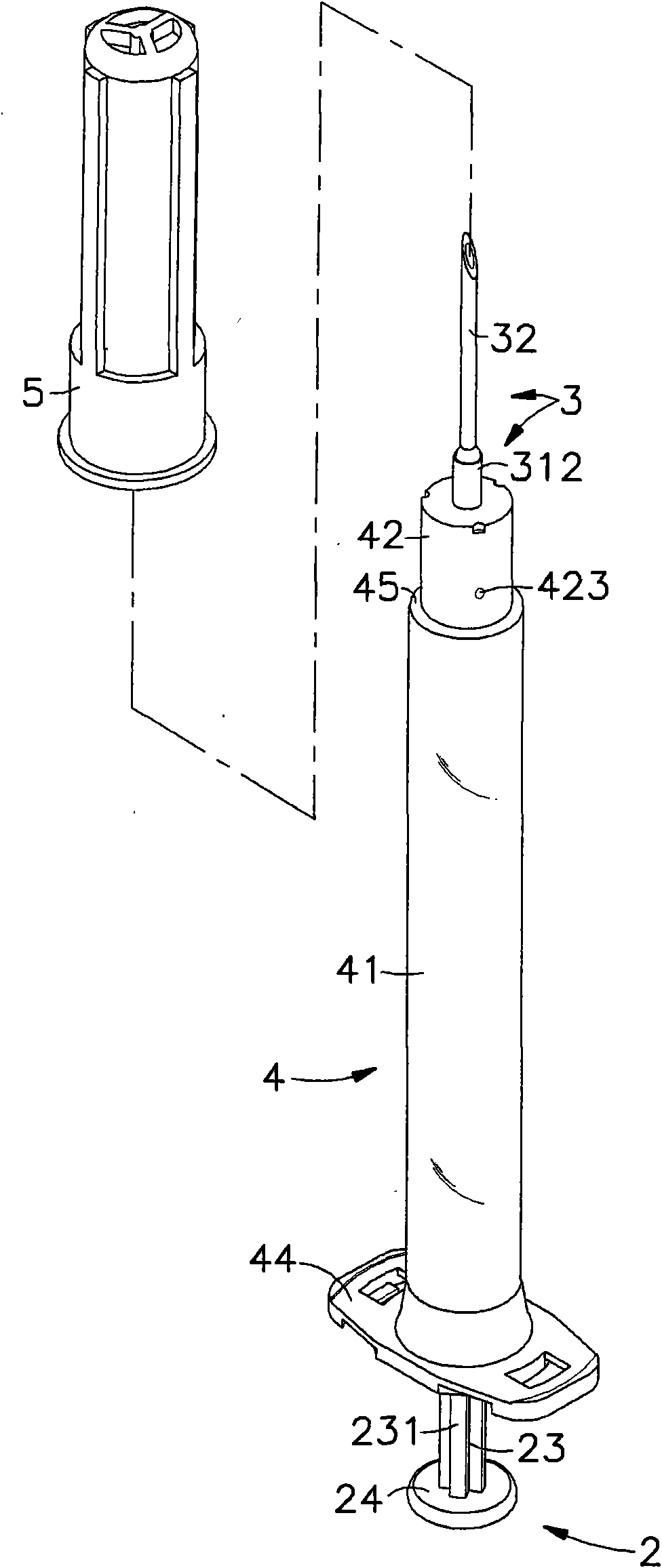

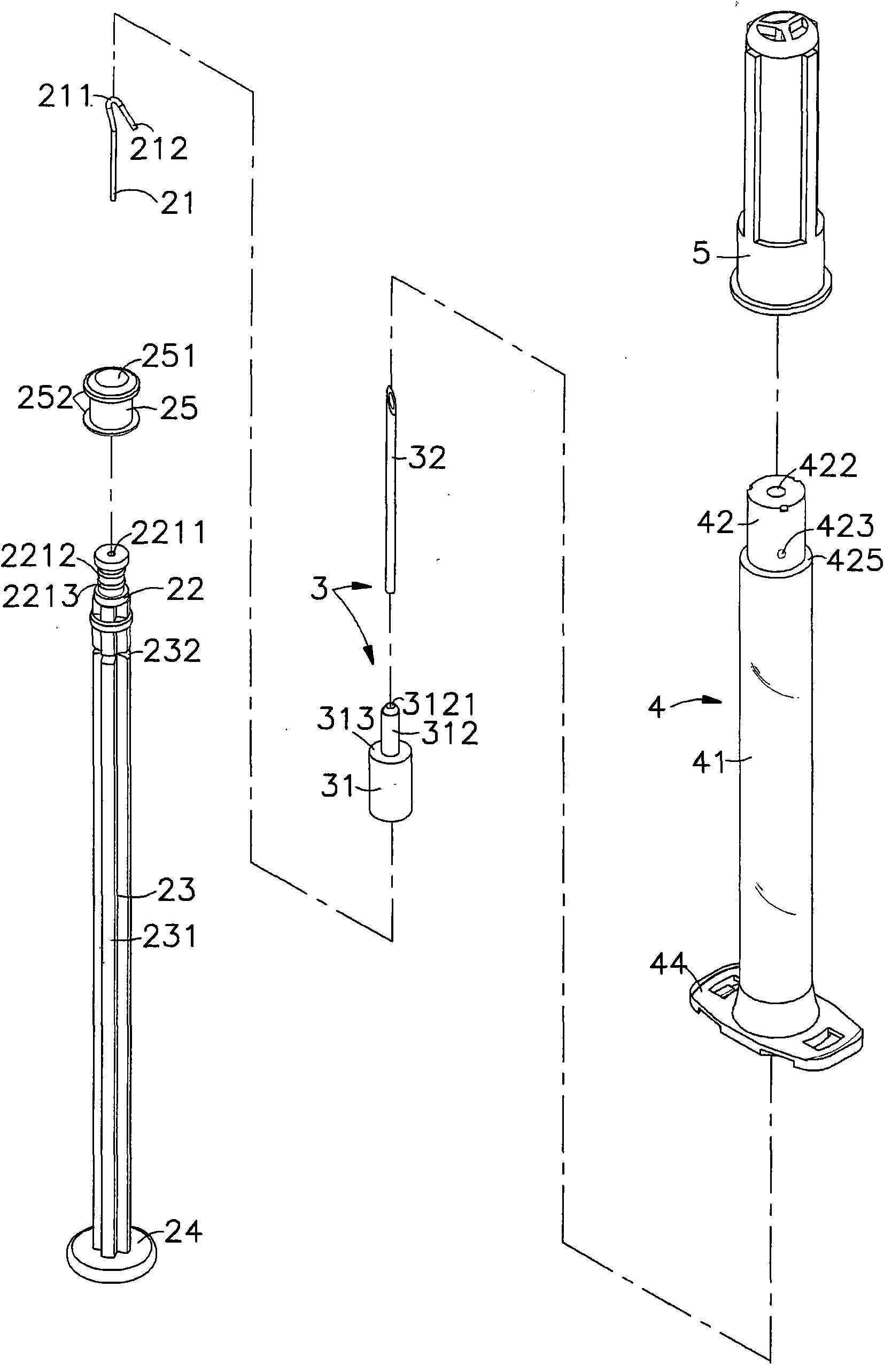

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

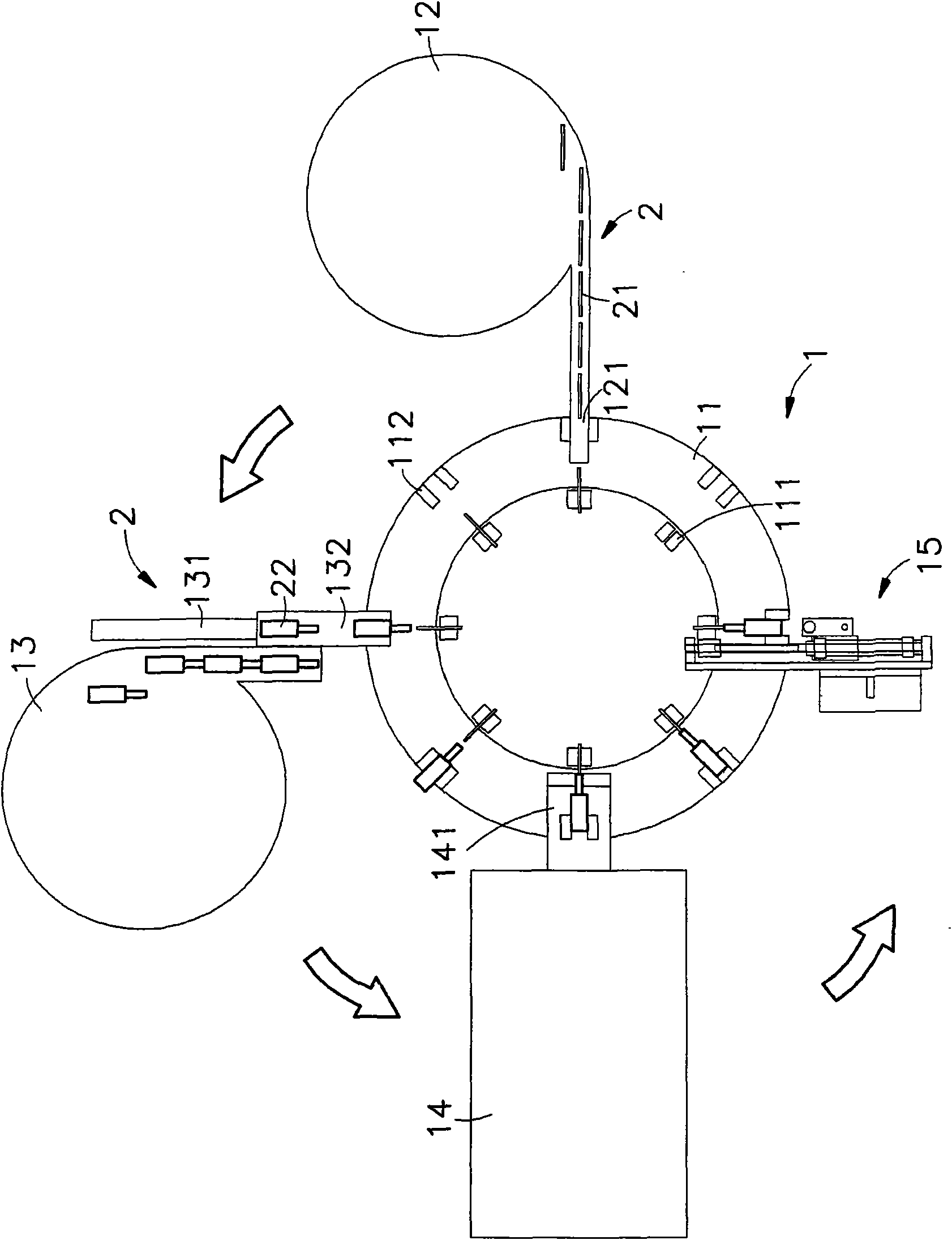

[0021] see figure 1 As shown, the figure shows a schematic top view of the manufacturing process. When using the manufacturing method of the present invention to process the safety syringe, the following steps are followed:

[0022] Step A, the processing mechanism 1 utilizes the metal hook conveying device 12 provided around the outer periphery of the turntable 1 to linearly and continuously convey the metal hook 21 .

[0023] Step B, after the metal hook body 21 passes through the conveying channel 121 , it is clamped and positioned by the fixing device 111 arranged inside the turntable 11 .

[0024] Step C, the turntable 11 is rotated to transport the metal hook body 21 to the position of the docking seat transport device 13 .

[0025] Step D, the docking seat conveying device 13 transports the docking seat 22 through the conveying track 132, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com