Traction driven cold extrusion diameter reduction molding machine for mineral insulated fireproof cable

A fireproof cable, traction drive technology, applied in cable/conductor manufacturing, insulating conductors/cables, reducing the size of conductors/cables, etc., can solve problems such as the impact of construction progress, and achieve better toughness and elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the technical solution clearer, the technical solution will be further described in detail below in conjunction with specific embodiments. It should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the technical solution.

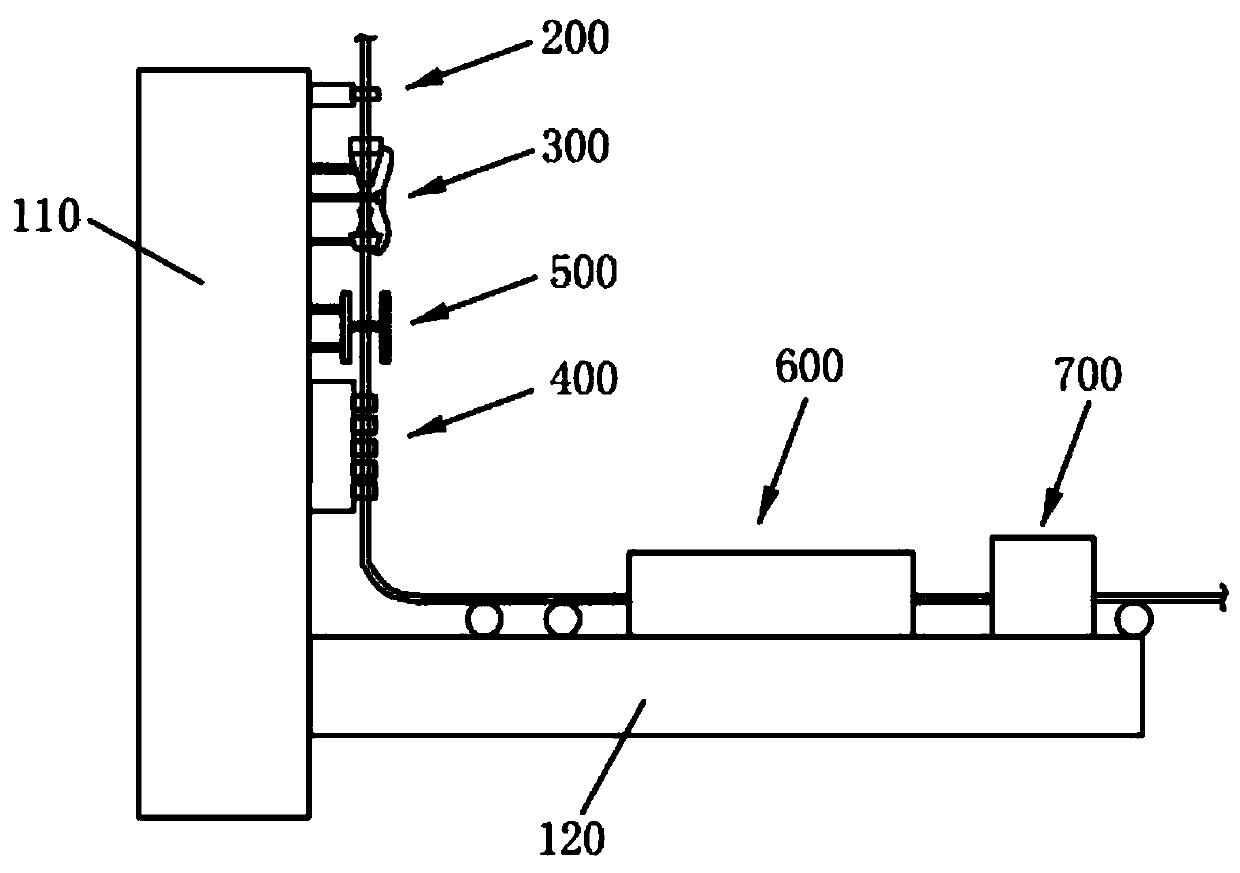

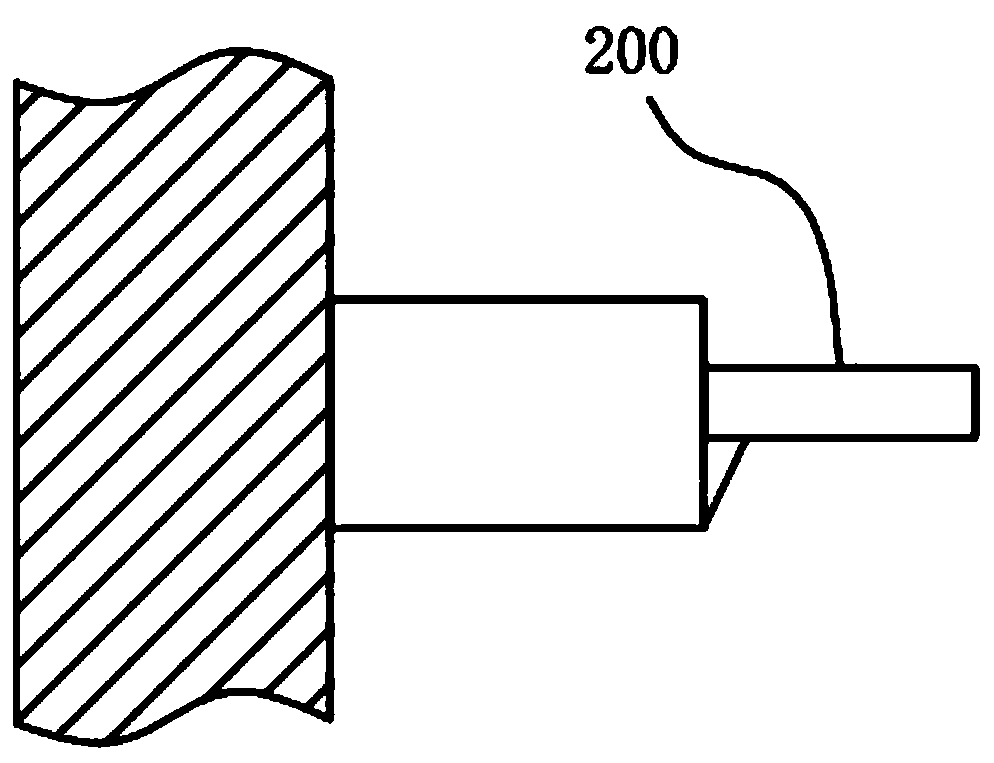

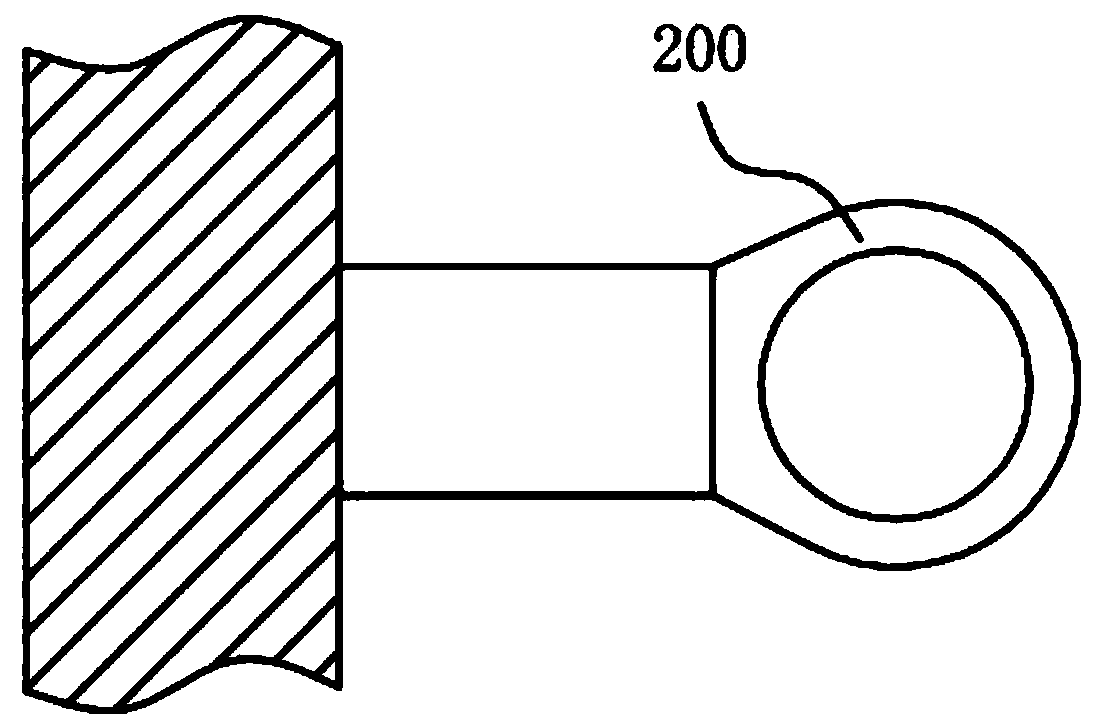

[0041] Such as Figure 1-Figure 11 As shown, the present embodiment proposes a traction-driven cold extrusion compression molding machine for mineral insulated fireproof cables, including a support frame, a guiding device 200, an oiling device 300 and a drawing device 400, a guiding device 200, an oiling device 300 and The drawing device 400 is vertically oppositely arranged on the support frame from top to bottom; the guide device 200 is used to support the cable and guide the cable into the oiling device 300; the oiling device 300 is used to apply lubricating oil On the outer wall of the cable; the drawing device 400 is used to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com