Method for machining hot-dipped galvanized steel sheet having two faces with different types of spangles

A technology of hot-dip galvanized steel sheet and processing method, applied in hot-dip galvanizing process, metal processing equipment, manufacturing tools, etc., to achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

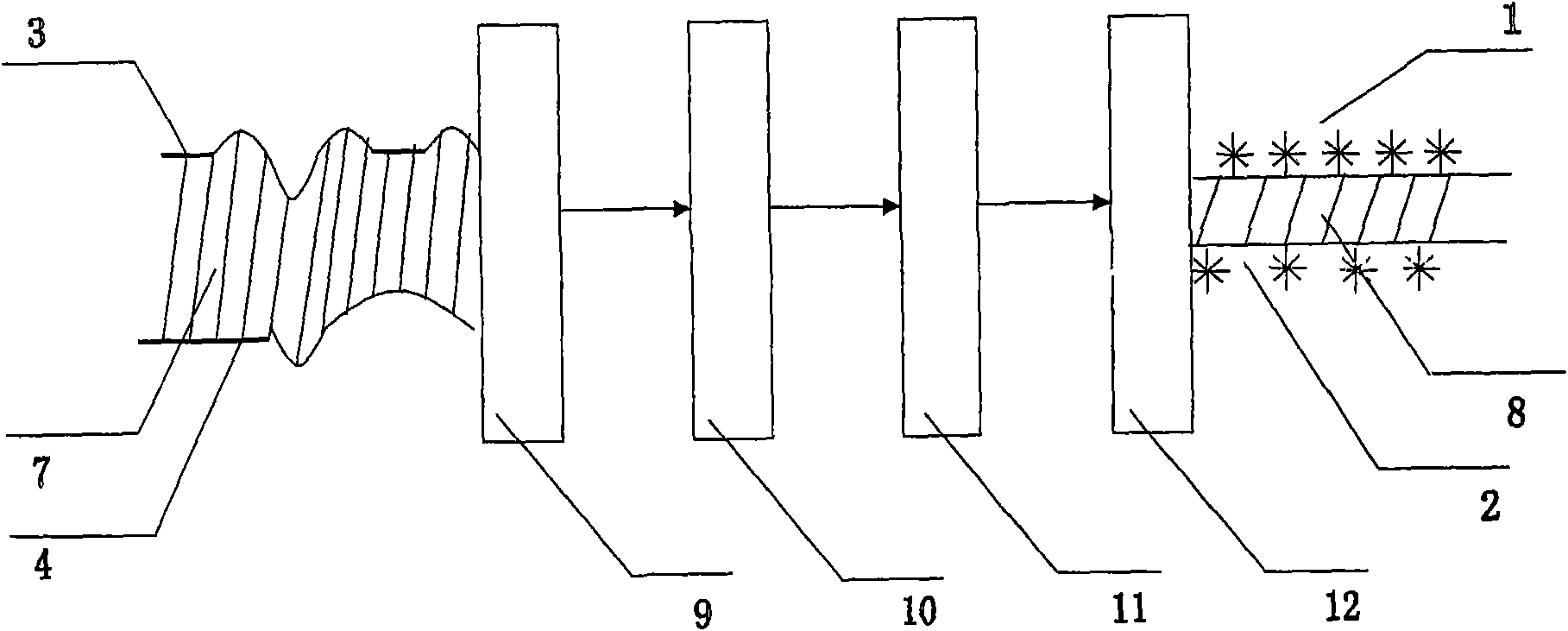

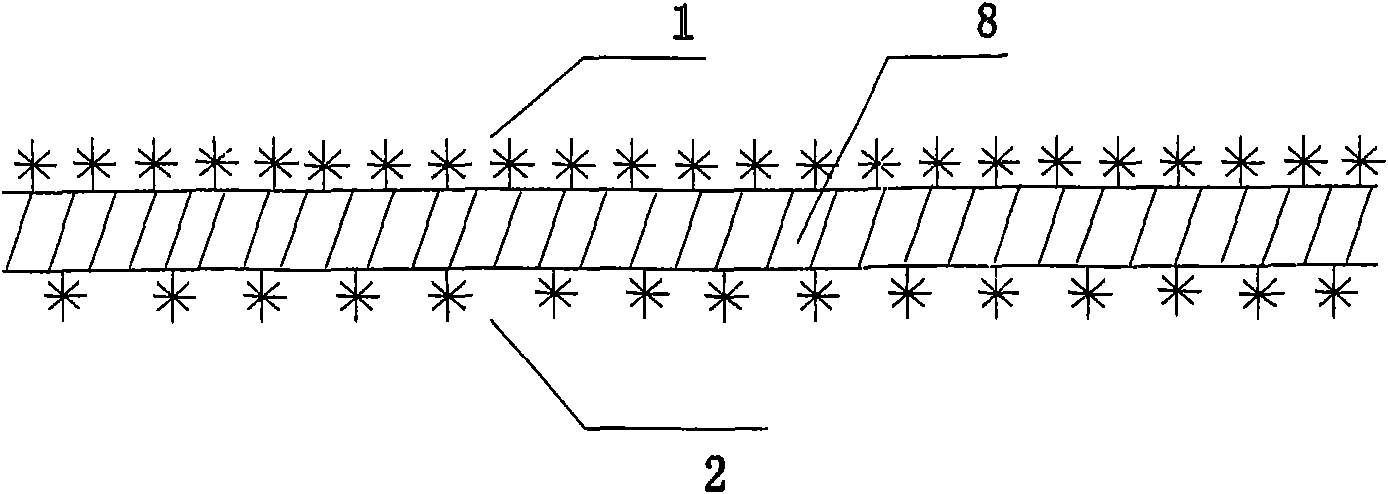

[0019] please see Figure 1 to Figure 4 .

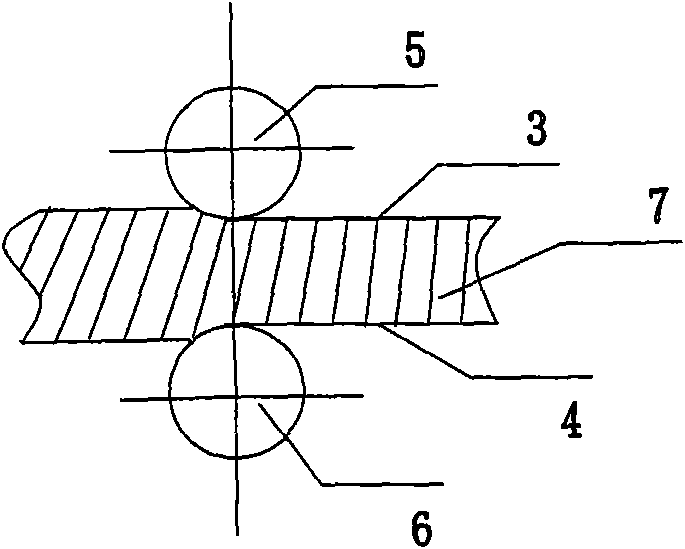

[0020] The method of the present invention includes rolling the substrate 7, cleaning with a cleaning tank 9, annealing in an annealing furnace 10, galvanizing with a zinc pot 11, and smoothing with a skin pass machine 12, thereby obtaining hot-dip galvanizing with different types of spangles on both sides Zinc steel. As the technical gist of the inventive method: for upper and lower work rolls 5,6 ( figure 2 shown) to carry out texturing treatment on the surface so that the surfaces of the upper and lower work rolls 5 and 6 each form a textured surface structure, specifically: use CO 2 Laser texturing technology for texturing treatment, the preferred texturing treatment equipment is the HGL-HAT3500 large-scale roll laser texturing complete set of equipment produced by Wuhan Huagong Laser Engineering Co., Ltd. in Wuhan City, Hubei Province, China. It adopts high-energy, high-repetition frequency of pulsed CO 2 After the laser be...

Embodiment 2

[0028] please see Figure 1 to Figure 4 .

[0029] The method of the present invention includes rolling the substrate 7, cleaning with the cleaning tank 7, annealing in the annealing furnace 10, galvanizing with the zinc pot 11 and smoothing with the skin pass machine 12, thereby obtaining a hot-dip galvanized steel sheet with different types of spangles on both sides . In this embodiment, the roughness of the surface of the upper work roll 5 is controlled to be 2.1 μm, and the number of bosses on the surface of the upper work roll 5 is set to 20 / mm 2 The diameter of the bosses on the surface of the upper work roll 5 is controlled to be 200 μm, and the center distance between adjacent bosses is 45 μm; the roughness of the surface of the lower work roll 6 is controlled to be 0.9 μm, and the number of bosses on the surface of the lower work roll 6 is set to 8 piece / mm 2 , the diameter of the bosses on the surface of the lower work roll 6 is controlled to be 100 μm, and the ce...

Embodiment 3

[0035] please see Figure 1 to Figure 4 .

[0036] The method of the present invention includes rolling the substrate 7, cleaning with the cleaning tank 7, annealing in the annealing furnace 10, galvanizing with the zinc pot 11 and smoothing with the skin pass machine 12, thereby obtaining a hot-dip galvanized steel sheet with different types of spangles on both sides . In this embodiment, the roughness of the surface of the upper work roll 5 is controlled to be 1.5 μm, and the number of bosses on the surface of the upper work roll 5 is set to 15 / mm 2 , the diameter of the bosses on the surface of the upper work roll 5 is controlled to be 155 μm, and the center distance between adjacent bosses is 20 μm; the roughness of the surface of the lower work roll 6 is controlled to be 0.6 μm, and the number of bosses on the surface of the lower work roll 6 is set to 5 piece / mm 2 , the diameter of the bosses on the surface of the lower work roll 6 is controlled to be 52 μm, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com