Production line of inorganic light weight thermal insulation composite mortar drier and production process thereof

A technology of thermal insulation compounding and production technology, which is applied in the direction of chemical instruments and methods, mixing operation control, mixing operation control device, etc., can solve the problems that affect the production quality of thermal insulation mortar dry materials, inaccurate ingredients, and low production efficiency, and achieve anti-corrosion The effects of high compressive strength, guaranteed product quality, and improved labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

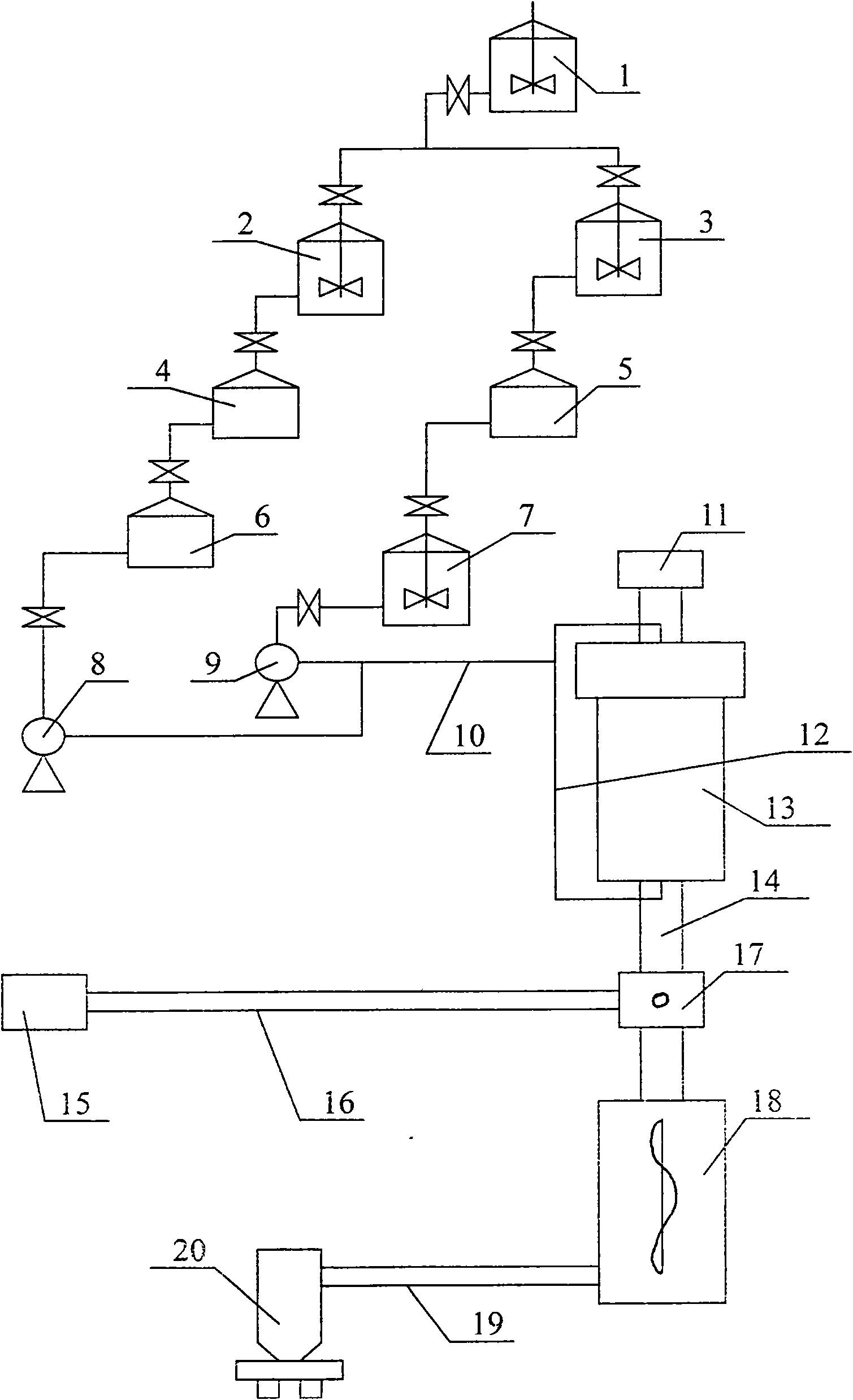

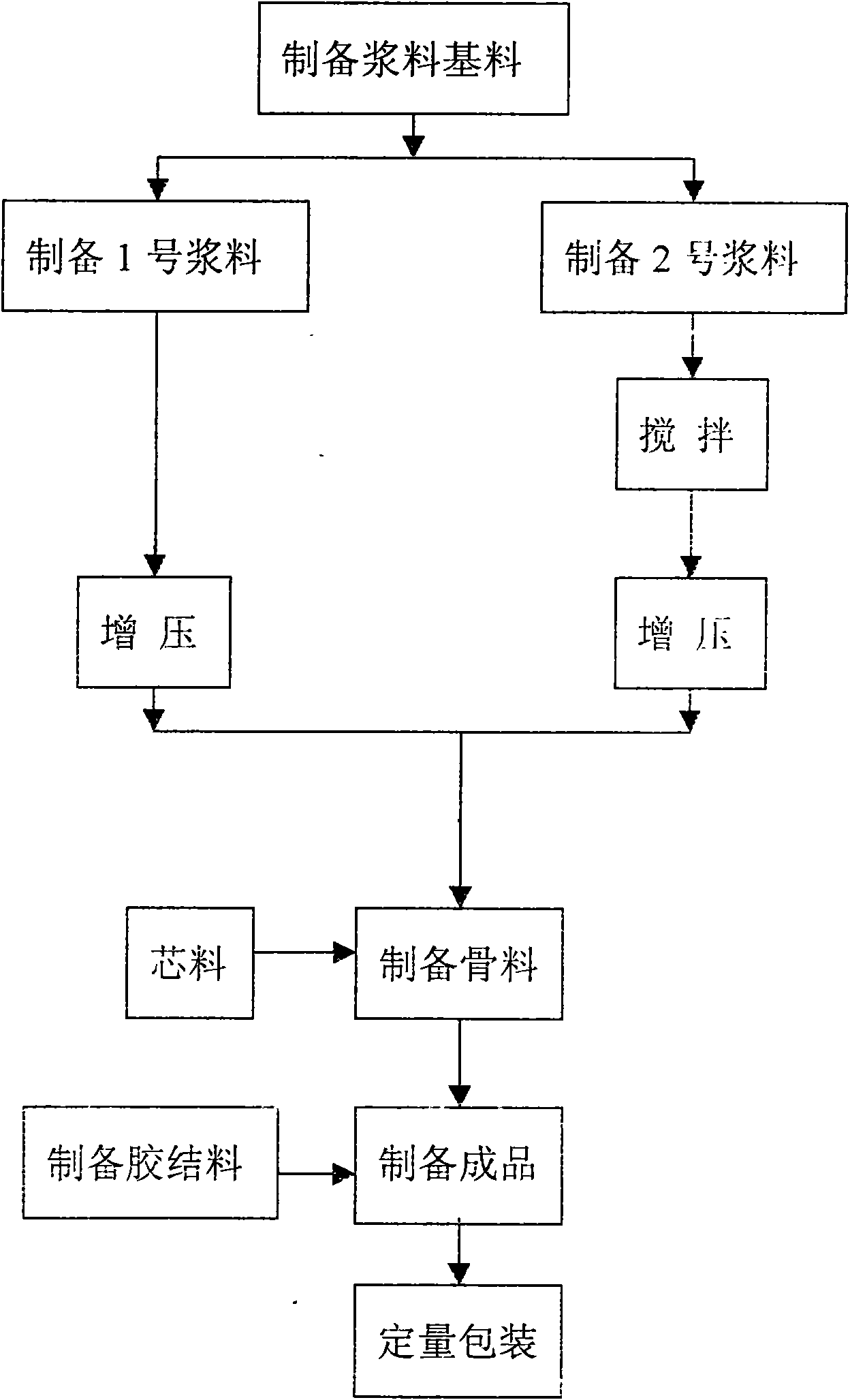

[0026] The aggregate preparation unit is used for the preparation of aggregates in the dry mortar. This unit includes No. 1 slurry feeding tank 6, No. 2 slurry mixing feeding tank 7, No. 1 slurry pressure pump 8, and No. 2 slurry pressure pump. Pump 9, slurry conveying pipe 10, core material feeder 11, aggregate mixing drum 13 and aggregate conveyor belt 14, wherein the feed of No. 1 slurry feeding tank 6 and No. 2 slurry mixing feeding tank 7 The port is connected with the No. 1 slurry storage tank 4 and the No. 2 slurry storage tank 5 in the slurry preparation unit through the feed pipeline and the pressure pump respectively, and the No. 2 slurry agitating feed tank 7 is used to store water in the slurry storage tank. More No. 2 slurry is stirred, thereby avoiding segregation and precipitation of raw material components in the slurry. Aggregate mixing drum 13 is provided with a ring that runs through inside and outside, and the part of slurry feeding pipe 12 inside aggregate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com