Directional orifice oxide material and preparation method thereof

A technology of oxides and directional holes, applied in the field of porous materials, can solve the problems of structural differences of such materials, template structure differences, and limited application range of materials, so as to achieve the effect of improving uniformity and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

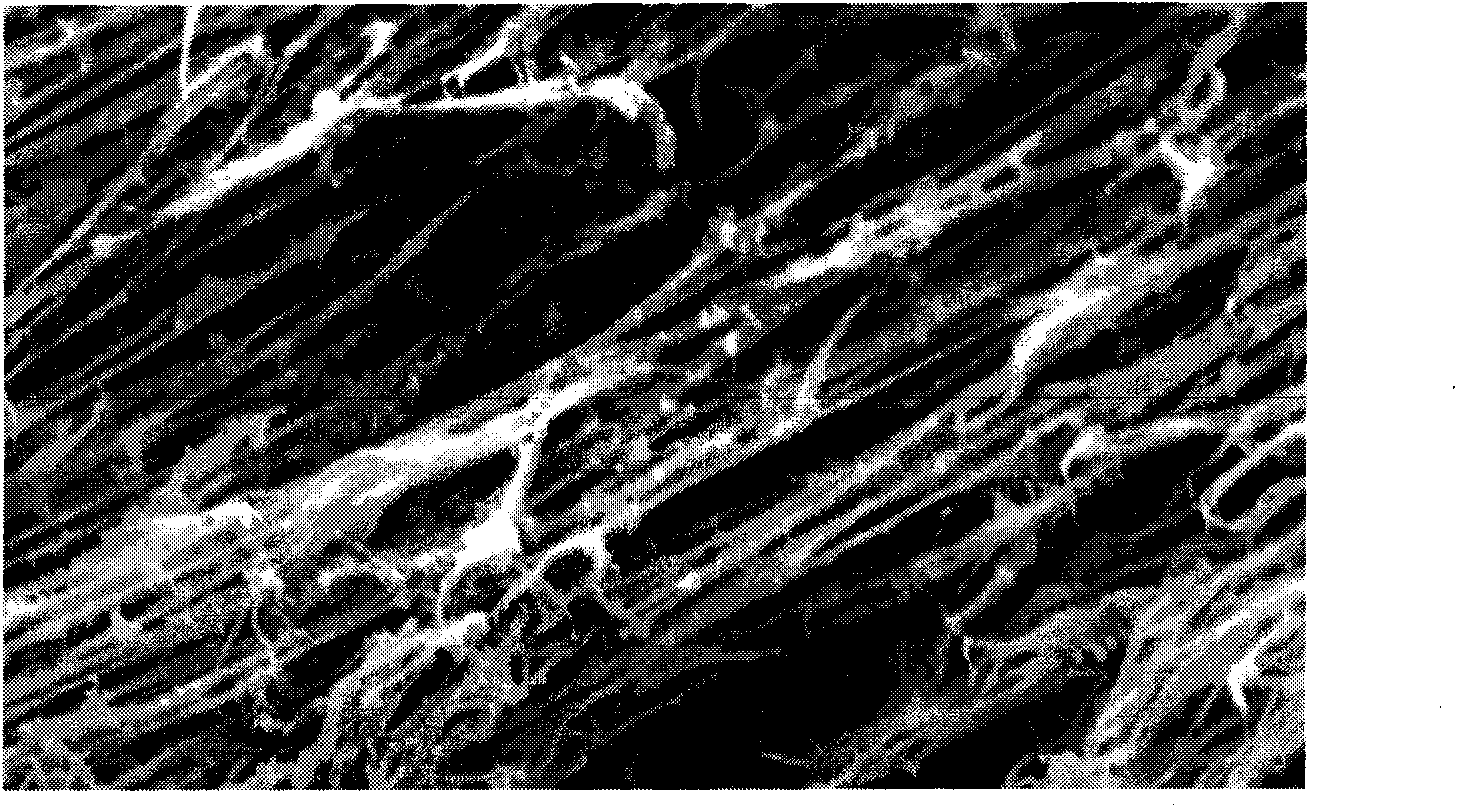

[0026] First press phenolic resin: tetraethyl orthosilicate: p-toluenesulfonyl chloride: water=30%: 50%: 10%: 10% by weight, take respectively phenolic resin, tetraethyl orthosilicate, p-toluenesulfonyl chloride and water , stirred in a 40°C water bath to form a colloid; move the colloid to a commercially available plastic centrifuge tube with a conical bottom, fix the centrifuge tube on a device that can precisely control the lift, and adjust the position of the centrifuge tube so that the bottom of the centrifuge tube reaches Contact with the surface of liquid nitrogen, then lower the centrifuge tube at a rate of 50 mm / hour until the colloid in it is completely submerged in liquid nitrogen, then stop falling and keep it in this state for 3 hours; then put the centrifuge tube in a freeze dryer Freeze-dried in medium temperature for 48 hours, took out the sample, placed in a tube furnace, fed nitrogen gas and raised the temperature to 200°C at a rate of 2°C / min, kept the temper...

Embodiment 2

[0028] First weigh methylcellulose, titanyl sulfate, nitric acid and water according to the weight percentage of methylcellulose: titanyl sulfate: nitric acid: water=30%: 40%: 10%: 20%, and stir in a water bath at 60°C Form a colloid; move the colloid to a commercially available plastic centrifuge tube with a conical bottom, fix the centrifuge tube on a device that can precisely control the lift, adjust the position of the centrifuge tube so that the bottom of the centrifuge tube is in contact with the surface of liquid nitrogen, and then use 30mm / hour descending speed range will drop the centrifuge tube until the colloid therein is completely submerged in liquid nitrogen, then stop falling and keep this state for 3 hours; then place the centrifuge tube in a lyophilizer to lyophilize for 48 hours, Take out the sample, put it into a tube furnace, feed nitrogen gas and raise the temperature to 600°C at a rate of 2°C / min, keep the temperature constant for 5 hours, then feed air, a...

Embodiment 3

[0030] First weigh phenolic resin, butyl titanate, p-toluenesulfonyl chloride and water respectively according to phenolic resin: butyl titanate: p-toluenesulfonyl chloride: water=40%: 40%: 15%: 5% by weight, at 50 Stir in a water bath at ℃ to form a colloid; move the colloid to a commercially available plastic centrifuge tube with a conical bottom, fix the centrifuge tube on a device that can precisely control the lifting, adjust the position of the centrifuge tube so that the bottom of the centrifuge tube is in line with the surface of liquid nitrogen Contact, then drop the centrifuge tube at a rate of 20 mm / h until the colloids in it are completely submerged in liquid nitrogen, then stop the drop and keep this state for 3 hours; then place the centrifuge tube in a lyophilizer to lyophilize for 48 hours, take out the sample, place it in a tube furnace, feed nitrogen gas and raise the temperature to 200°C at a rate of 2°C / min, keep the temperature for 5 hours, then feed air, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com