Special fertilizer for Chinese goosebeery and preparation process thereof

A preparation process and kiwifruit technology are applied in the field of fertilizer manufacturing and can solve the problems of low solubility, low fertilizer efficiency and utilization rate, and less obvious synergistic effect of chemical fertilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A special fertilizer for kiwifruit, which contains the following raw materials in weight ratio:

[0047] Humic acid or humate: 5-6, nitrogen fertilizer: 8-10, phosphate fertilizer: 5-5, potassium fertilizer: 5-7.

[0048] Nutrient elements suitable for the growth of kiwifruit are also added, and added according to the following parts by weight:

[0049] Zinc sulfate 1-2, boron 1.5-2.5, magnesium sulfate 5-8, calcium 2-6, ferrous sulfate 2.5-3.5.

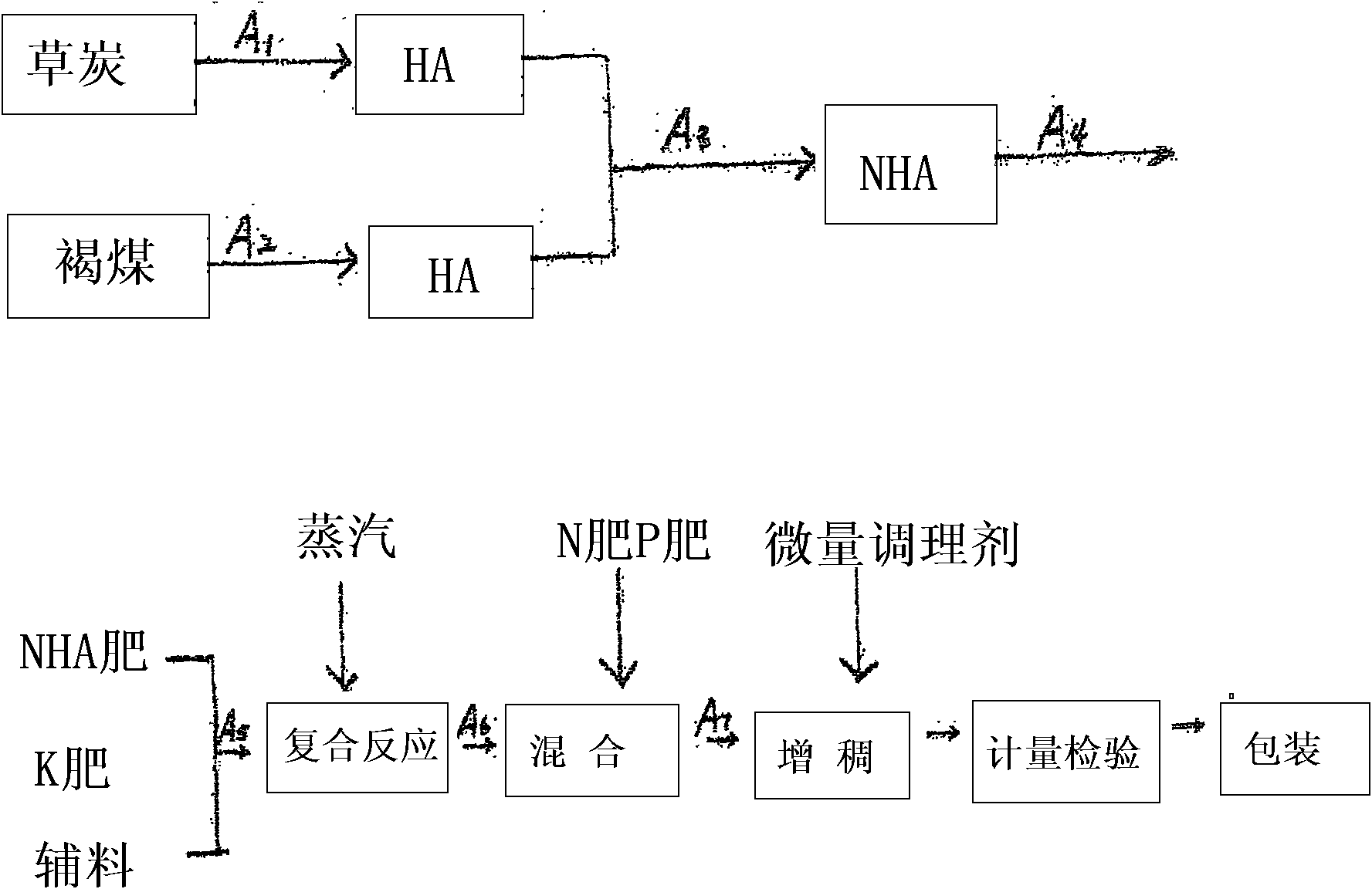

[0050] Above-mentioned kiwi fruit special fertilizer preparation technology, it is to implement according to the following steps:

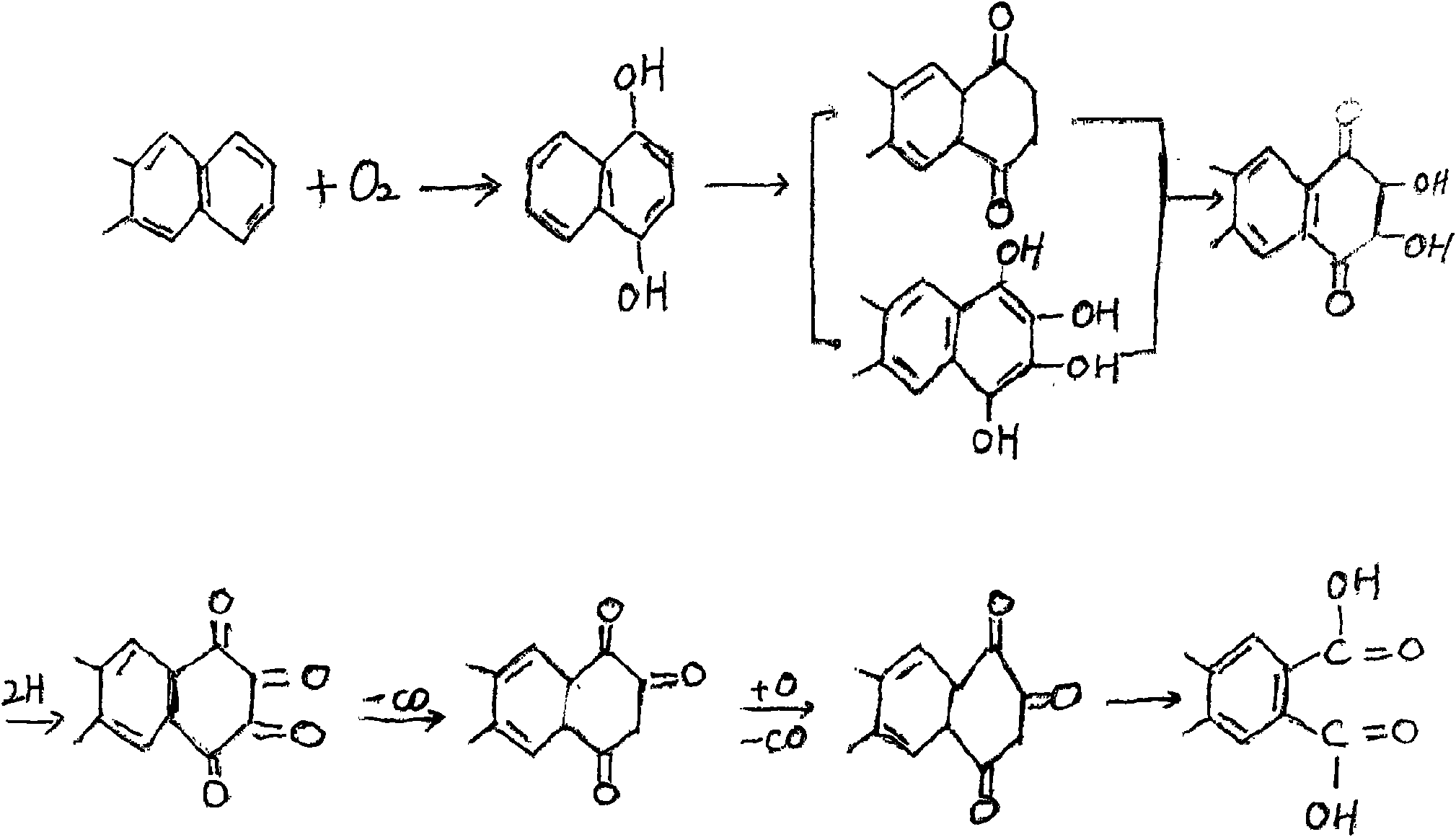

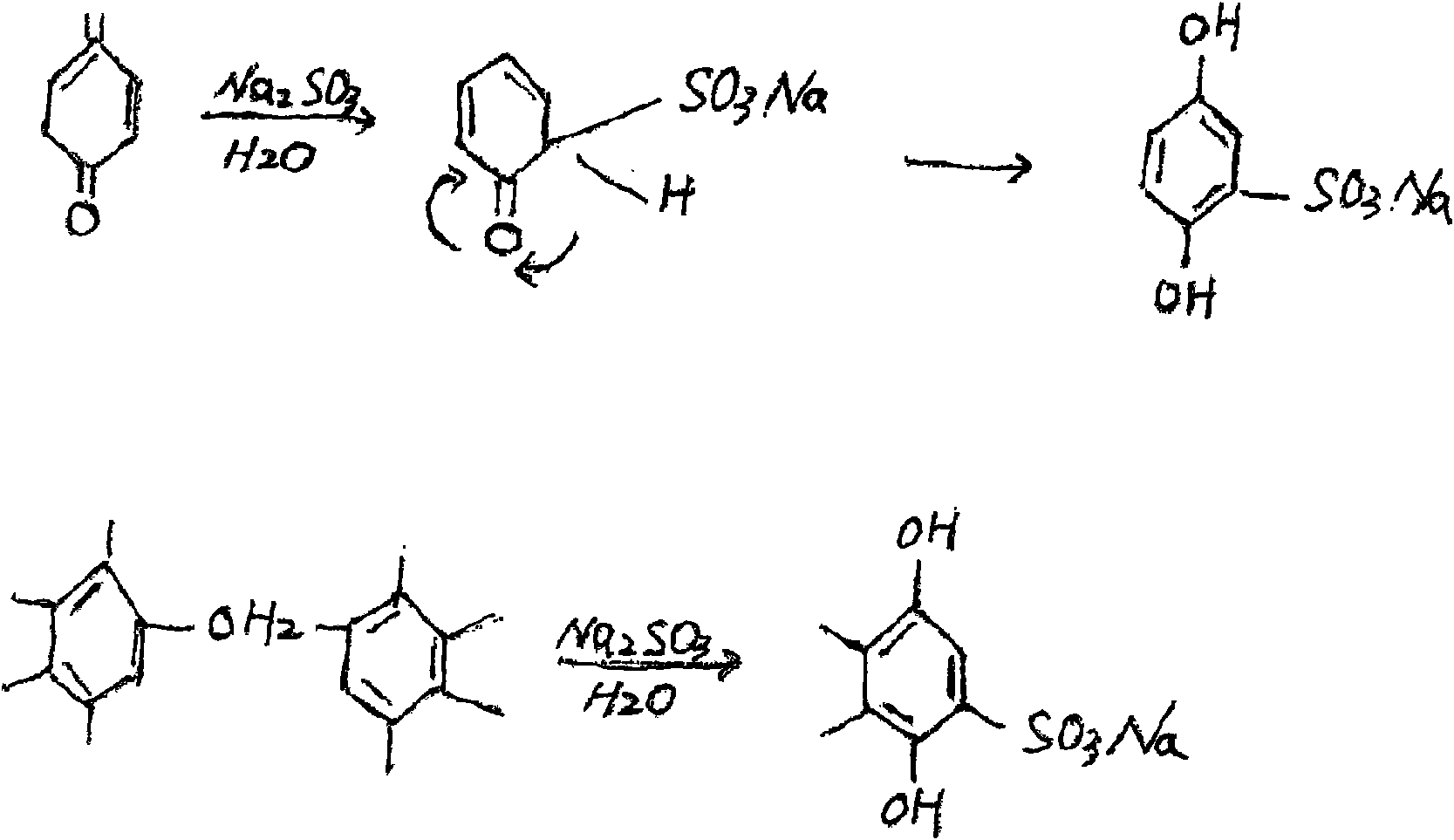

[0051] (1) humic acid modification: after the humic acid raw material is oxidized with an oxidizing acid, sulfite is added to modify it into humate;

[0052] (2) Chelation: Add potassium fertilizer and compound fertilizer auxiliary materials to the humate, feed steam into the reaction kettle and heat it to above 80°C for more than 8 hours of chelation;

[0053] (3) Mixing: add nitrogen fertiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com