Cross transpose fully low pressure low temperature drift cold scanning probe microscope body

A scanning probe and low-temperature drift technology, applied in microscopes, measuring devices, instruments, etc., can solve the problems of noise, speed, accuracy, and power consumption that are not as good as low-voltage operational amplifiers, and are expensive, and achieve temperature drift suppression, low price, and The effect of high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

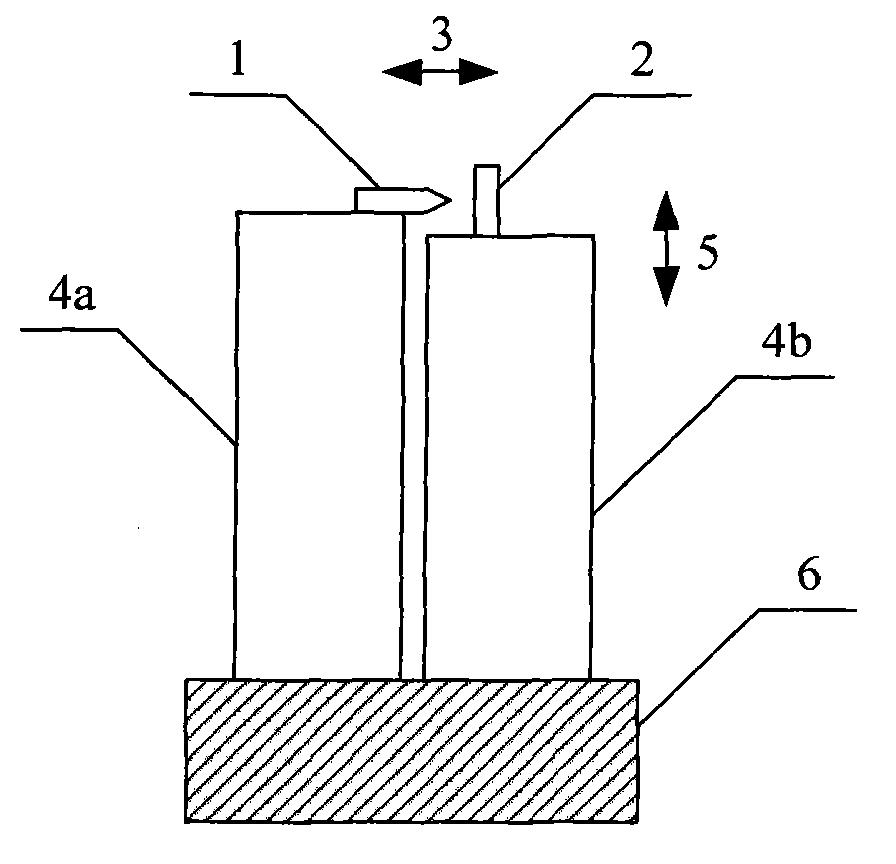

[0030] Example 1: Double piezoelectric tube vertical and horizontal transposition full low-voltage low-temperature drift scanning probe microscope mirror body

[0031] figure 1 It is a schematic diagram of the basic structure of the mirror body of the double piezoelectric tube type vertical and horizontal transposition full low-voltage low-temperature drift scanning probe microscope. Two piezoelectric tubes 4a, 4b stand side by side and are fixed on the base 6, the probe 1 and the sample 2 are respectively arranged at the free ends of the two piezoelectric tubes, and the gap between the probe 1 and the sample 2 is adjusted The direction 3 is perpendicular to the axial direction 5 of the two piezoelectric tubes, and the two piezoelectric tubes at least include one X positioning, one Y positioning and one Z positioning integrally or separately.

[0032] When working, since the first piezoelectric tube 4a and the second piezoelectric tube 4b include at least one X positioning, ...

Embodiment 2

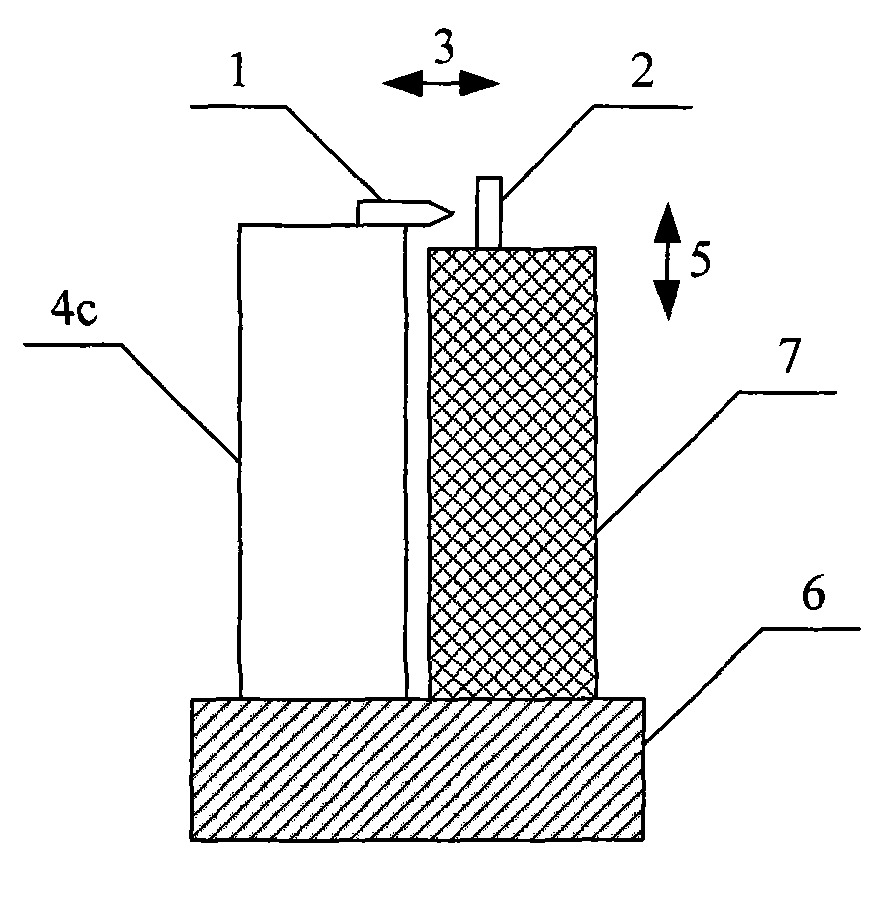

[0036] Example 2: Single piezoelectric tube vertically and horizontally transposed full low-voltage low-temperature drift scanning probe microscope mirror body

[0037]For the two piezoelectric tubes in Embodiment 1, if one of them is selected as an XYZ positioning piezoelectric tube, the other piezoelectric tube does not need to have a positioning function, and can be replaced by any vertical rod 7 to form a single piezoelectric tube type vertical and horizontal rotation. Set full low-pressure low-temperature drift scanning probe microscope body, see attached figure 2 . The specific method is: the XYZ positioning piezoelectric tube 4c and the vertical rod 7 stand side by side and are fixed on the base 6, the probe 1 and the sample 2 are respectively arranged on the free ends of the XYZ positioning piezoelectric tube 4c and the vertical rod 8, and probe The positions of the needle 1 and the sample 2 can also be reversed, and the gap adjustment direction 3 between the probe 1...

Embodiment 3

[0039] Embodiment 3: A vertically and horizontally transposed full low-voltage low-temperature drift scanning probe microscope mirror body with an inertial stepping motor

[0040] A mass block can be added between the free end of the piezoelectric tube described in Embodiment 1-2 and the probe or sample arranged on it to form a probe-sample coarse approximation inertial stepping motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com