Method for repairing alignment films

An alignment film and alignment liquid technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor cleanliness, material energy loss, and waste, and achieve the effects of avoiding material loss and waste, saving energy, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are exemplified below and described in detail with accompanying drawings.

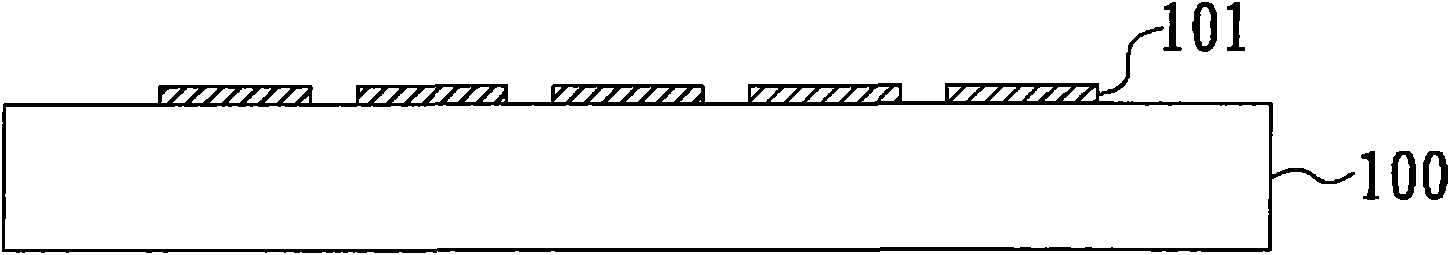

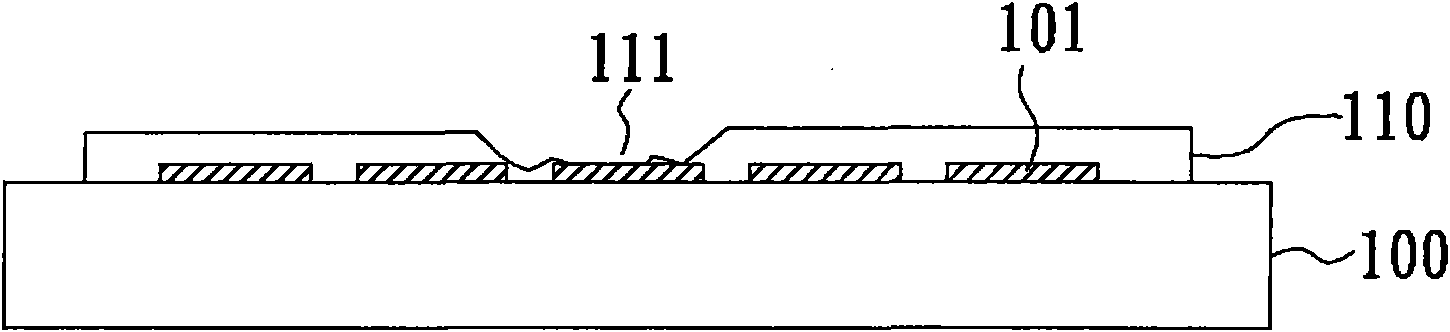

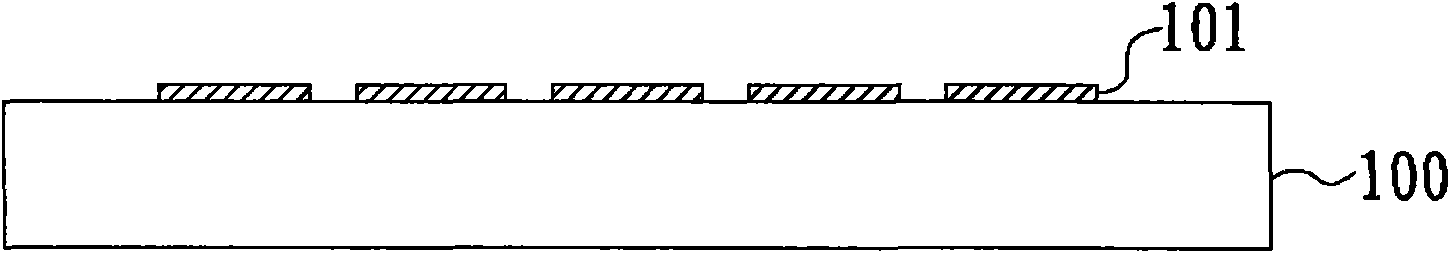

[0041] The alignment film repair method proposed by the present invention is used in the manufacture of liquid crystal display panels. The steps of the alignment film repair method include: first, providing a substrate, and forming a first alignment film on one surface thereof, the first alignment film has a defect. Then, a liquid drop of an alignment liquid is dropped on the defect.

[0042] The method for repairing the alignment film according to a preferred embodiment of the present invention may further include performing a pre-treatment before dropping the alignment liquid onto the defect. The pretreatment is carried out by laser irradiation or UV irradiation.

[0043] The aforementioned method for repairing the alignment film in a preferred embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com