Radiographic testing weld image management system and auxiliary film viewing method

A technology of ray detection and image management, applied in the directions of image data processing, image analysis, electrical digital data processing, etc., can solve problems such as misjudgment of welding defects, missed judgment, hidden dangers of welding structure quality, and difficulty in retrieval and reference, and reduce coupling , the effect of good expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

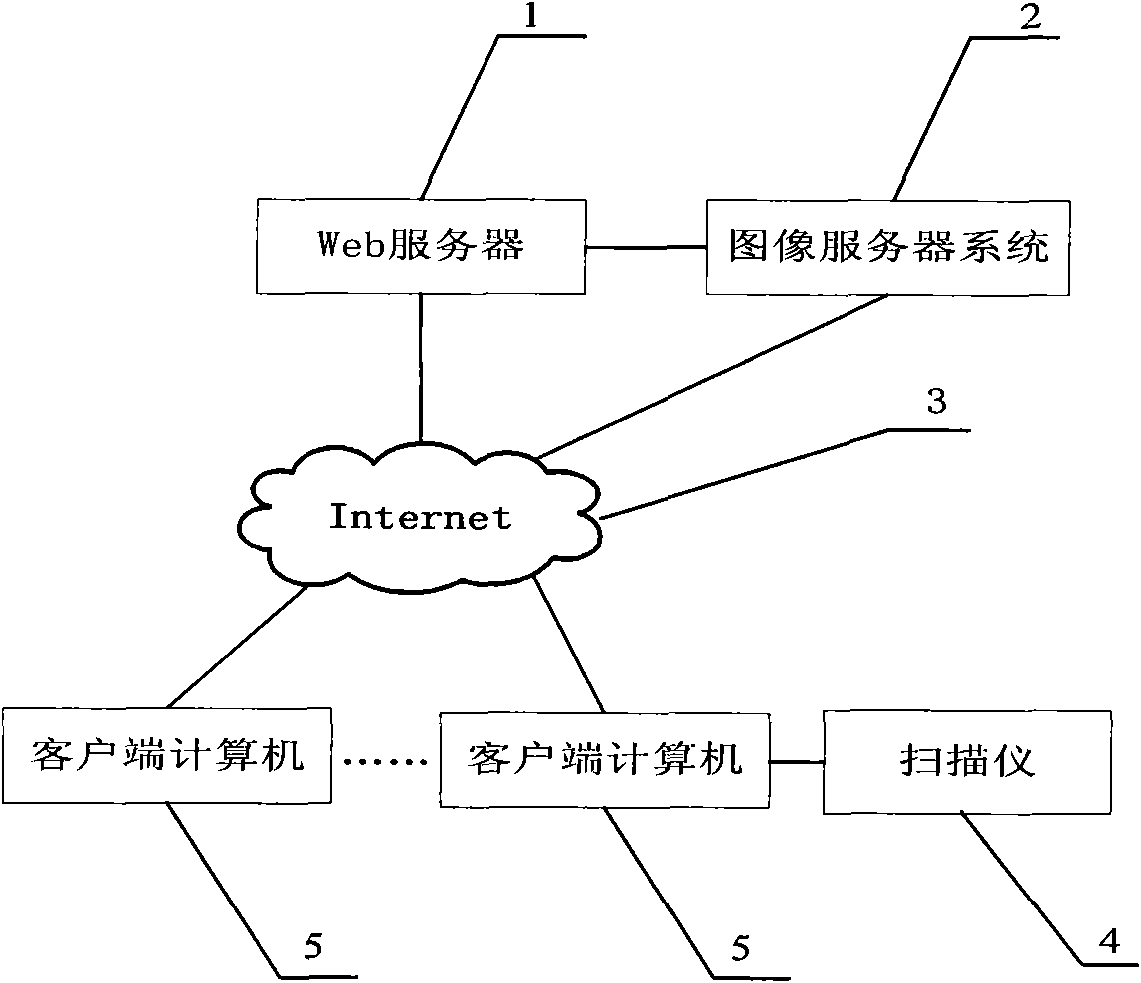

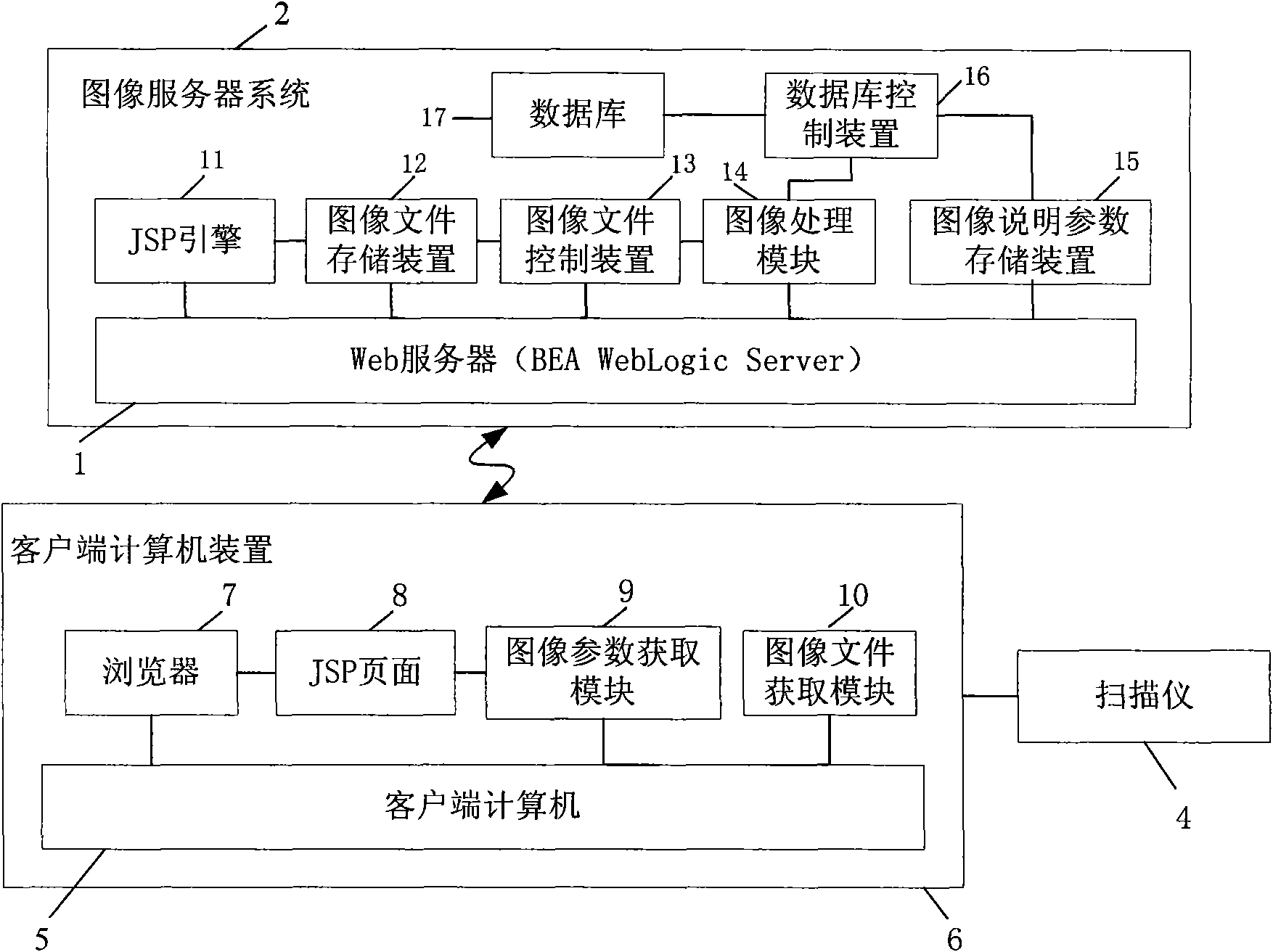

[0029] Embodiment 1: A radiation detection weld image management system:

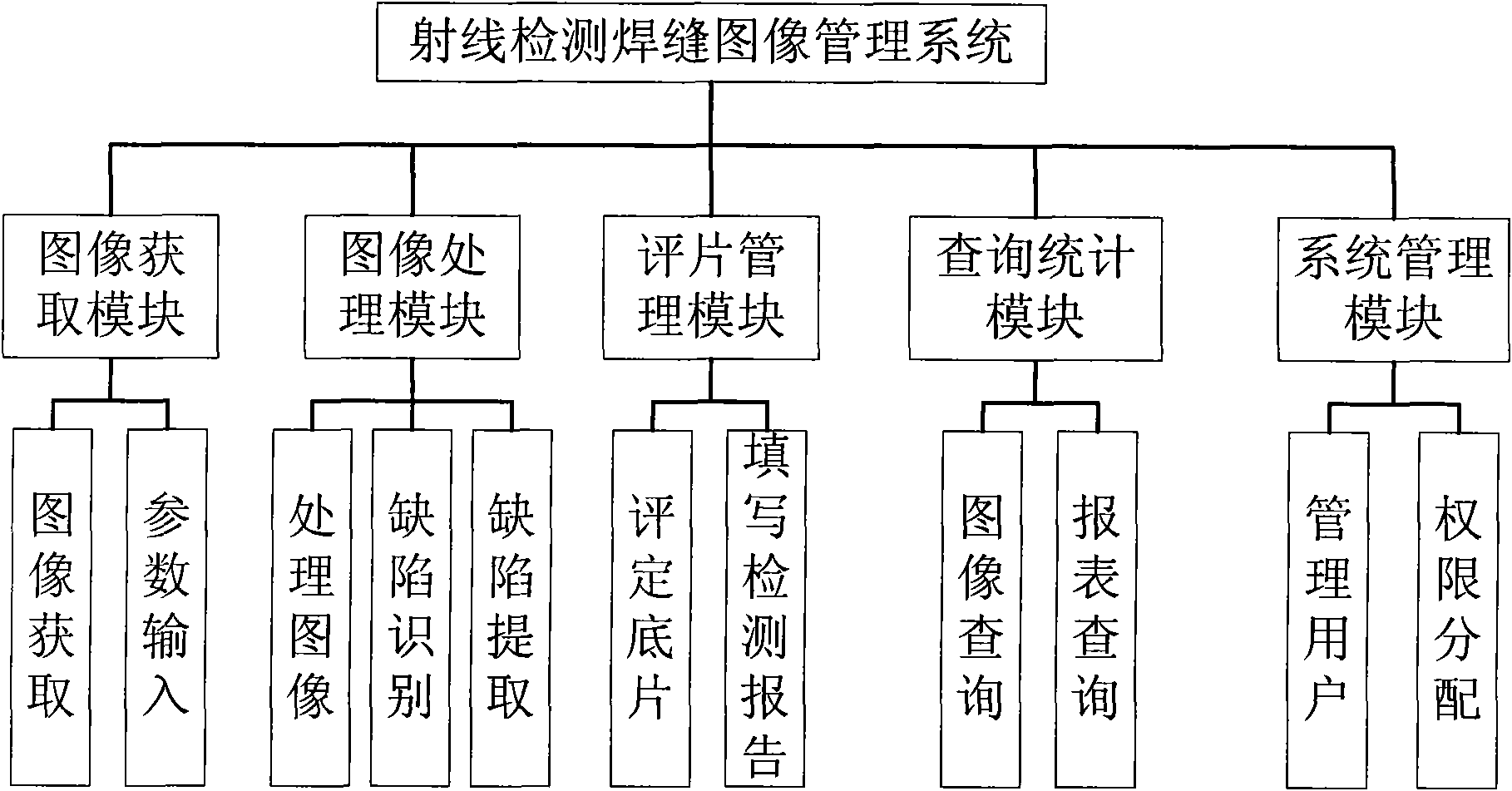

[0030] The image management system is deployed on the server system and accessed through the client computer; the image management system has functional modules, which are designed with a B / S four-tier architecture, including: presentation layer, business logic layer, persistence layer and database layer, and supports remote browsing and film review functions; functional modules include image acquisition module, image parameter acquisition module, image processing module, film review management module, query statistics module and system management module.

[0031] The image acquisition module is used to obtain the image file of radiographic inspection digitalized by the scanner, and input the parameter information description related to the image of radiographic inspection; in the server;

[0032] The image parameter acquisition module is used to obtain description parameters related to image files, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com