Manufacturing method of self-reset cable winding device

A cable winding and manufacturing method technology, which is applied to electrical components, antennas and other directions, can solve the problems of unable to achieve orderly movement of cables, and achieves the effect of simple structure, low manufacturing cost and solving cable damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

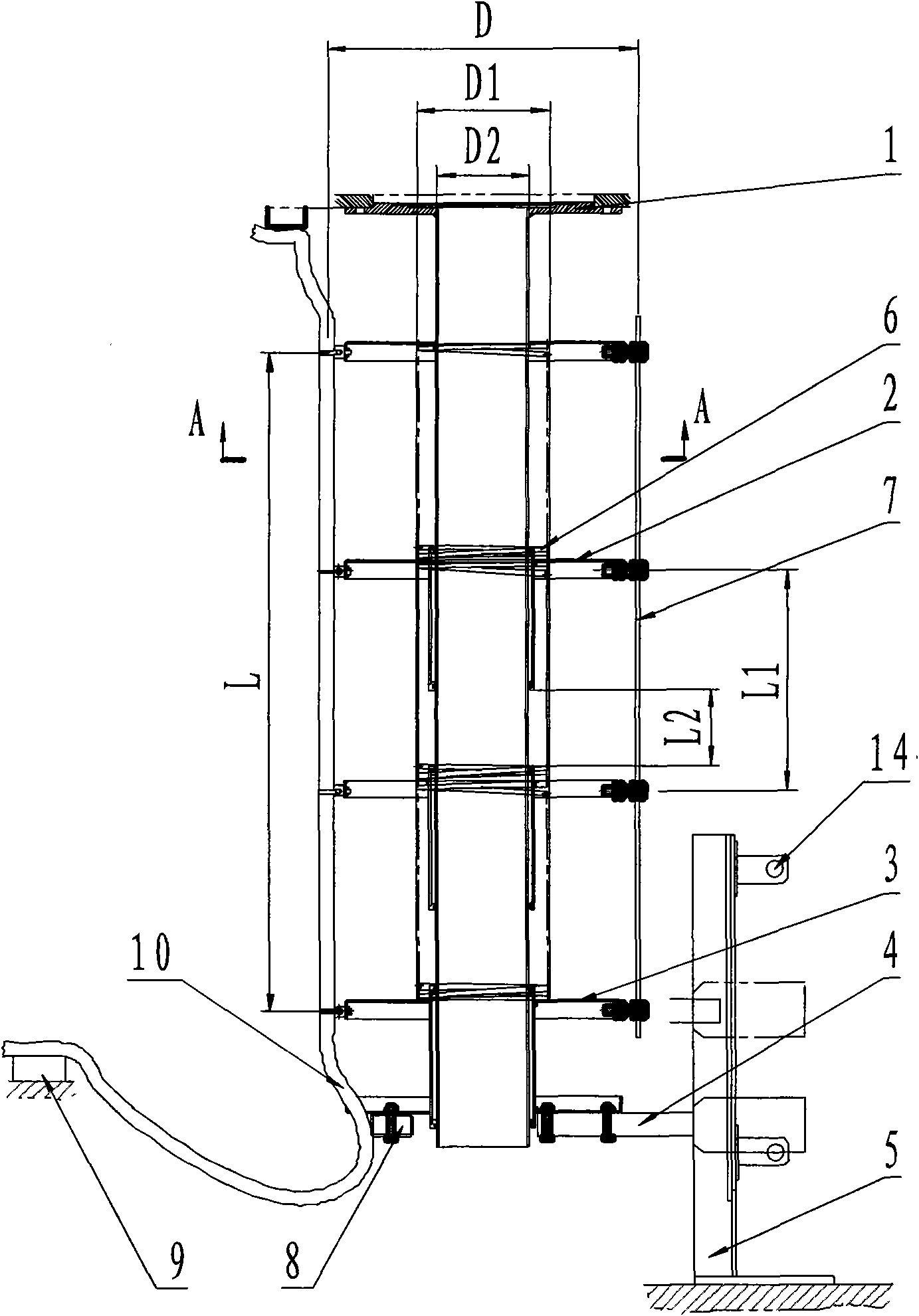

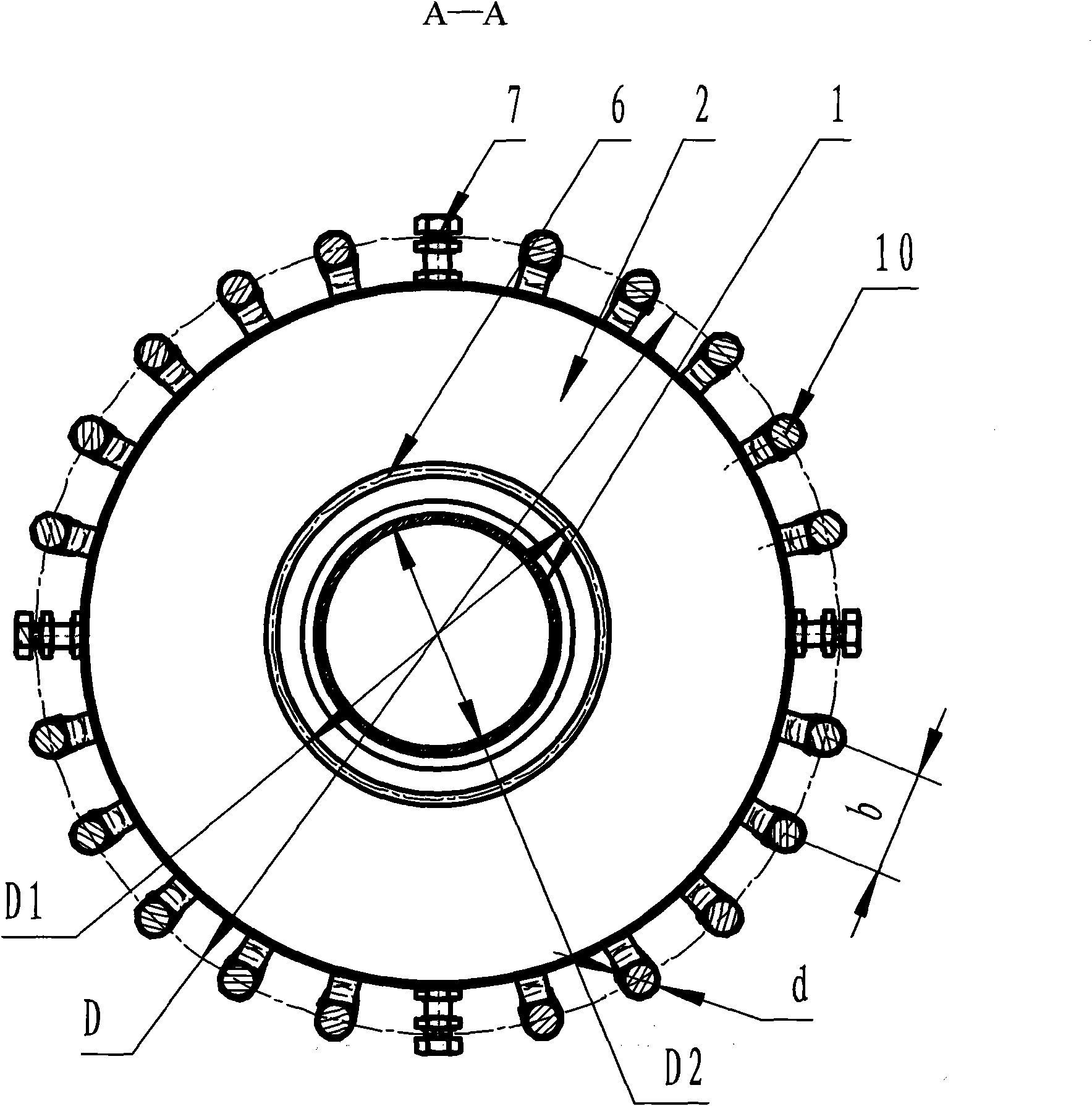

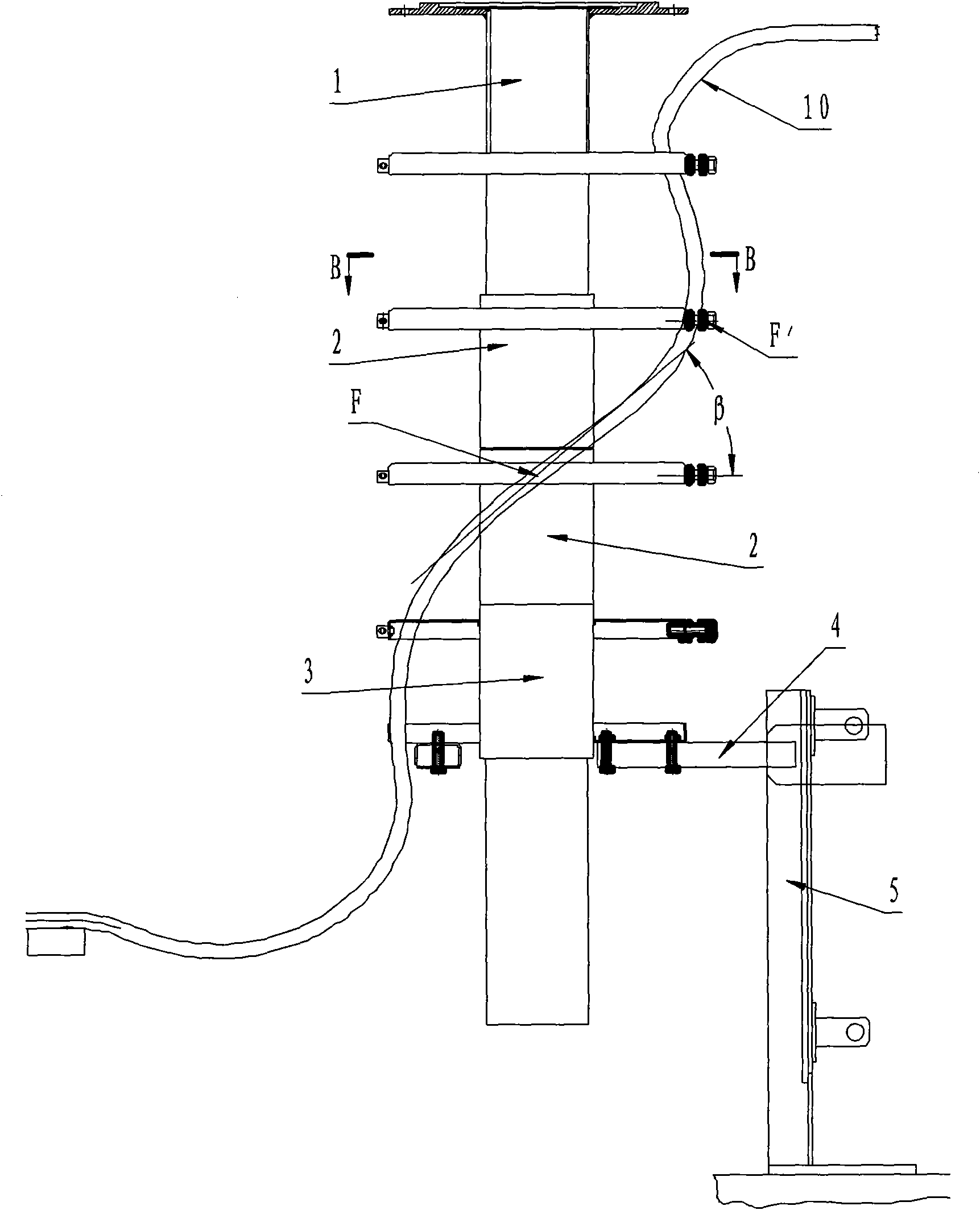

[0029] Refer to Figure 1 to Figure 4 , The present invention consists of a slewing support shaft assembly 1, a cable support assembly 2, an end cable support assembly 3, a rotation stop lever 4, a fixed chute assembly 5, a spring 6, a steel wire 7, a movable cable bracket 8, a fixed cable bracket 9, and a cable 10. The limit switch 14 and other components are composed, such as figure 1 As shown, figure 1 It is a schematic structural diagram of an embodiment of the present invention.

[0030] In the present invention, when the rotary turntable rotates, the rotary support shaft assembly 1 fixed with the rotary turntable rotates together with the rotary turntable. The rotary support shaft assembly 1 drives the steel wire rope 7 to rotate, and the wire rope 7 drives the N cables step by step. The support assembly 2 rotates and slides up and down on the shaft of the rotary support shaft assembly 1. The final cable support assembly 3 slides up and down on the shaft of the slewing supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com