Magnetic suspension spherical electromotor system

A magnetic levitation and motor technology, applied in the field of motors, can solve problems such as complex support structure, mechanical wear, uneven motor air gap, etc., and achieve the effect of reasonable and simple structure, fast response speed and good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

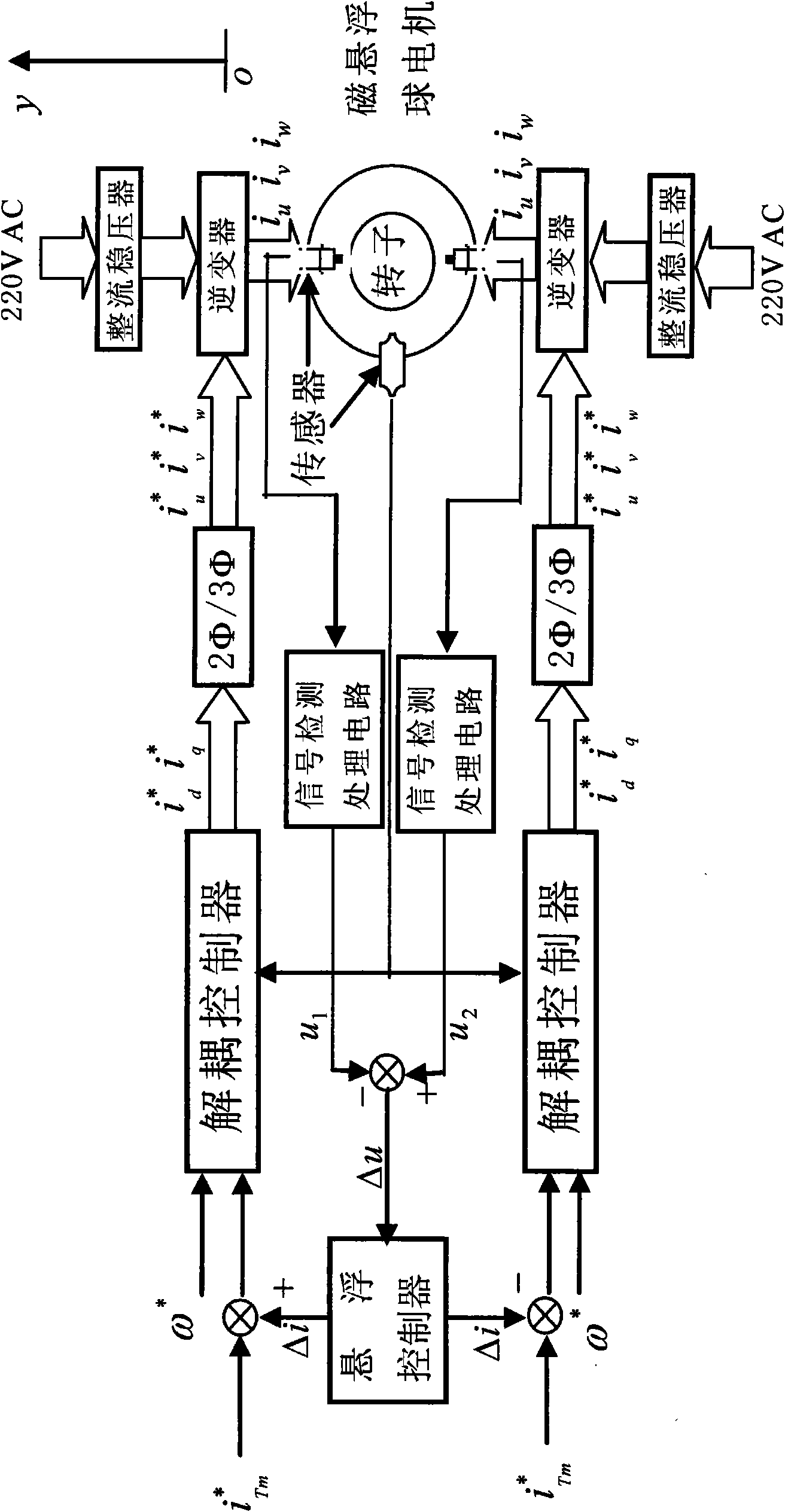

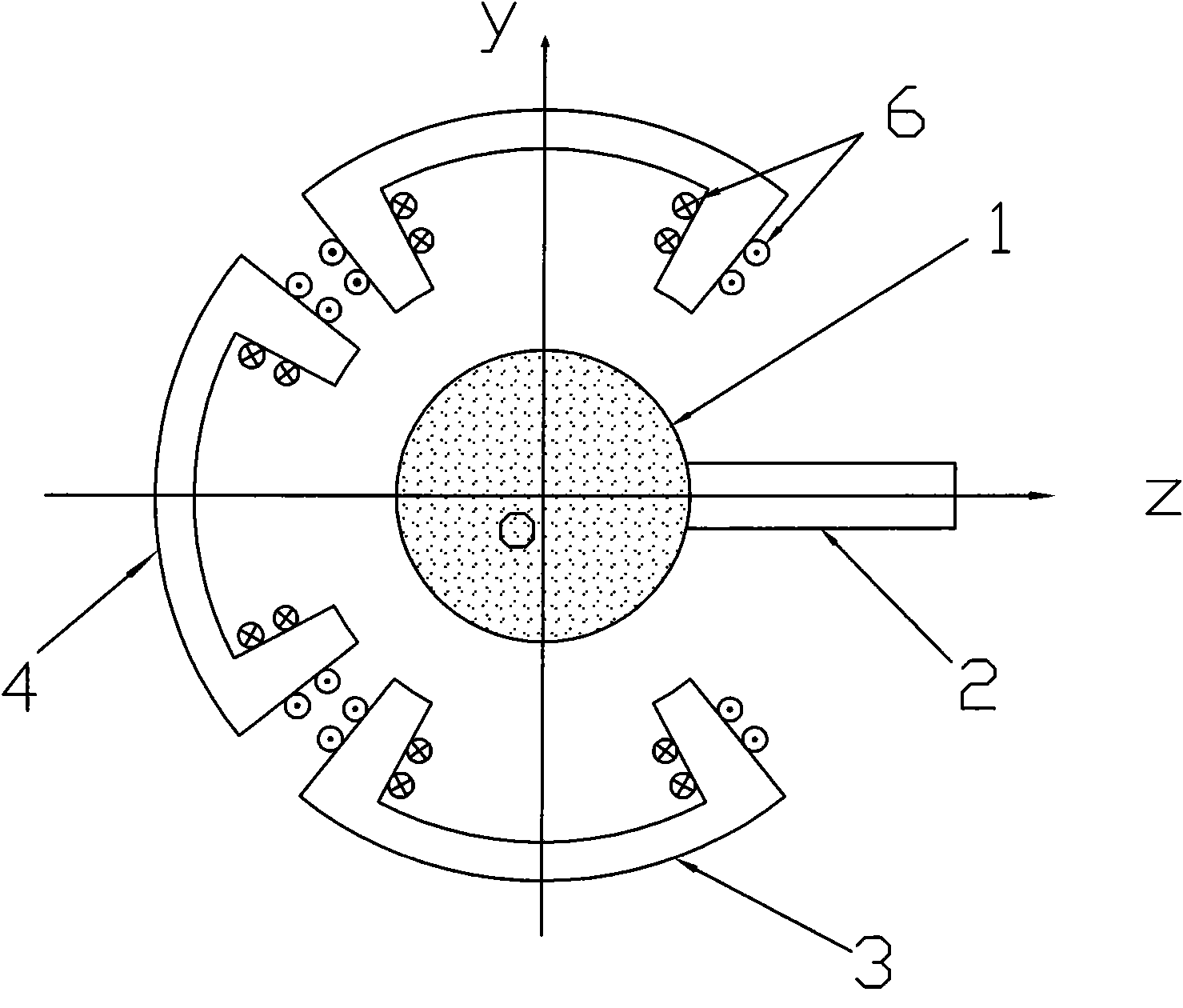

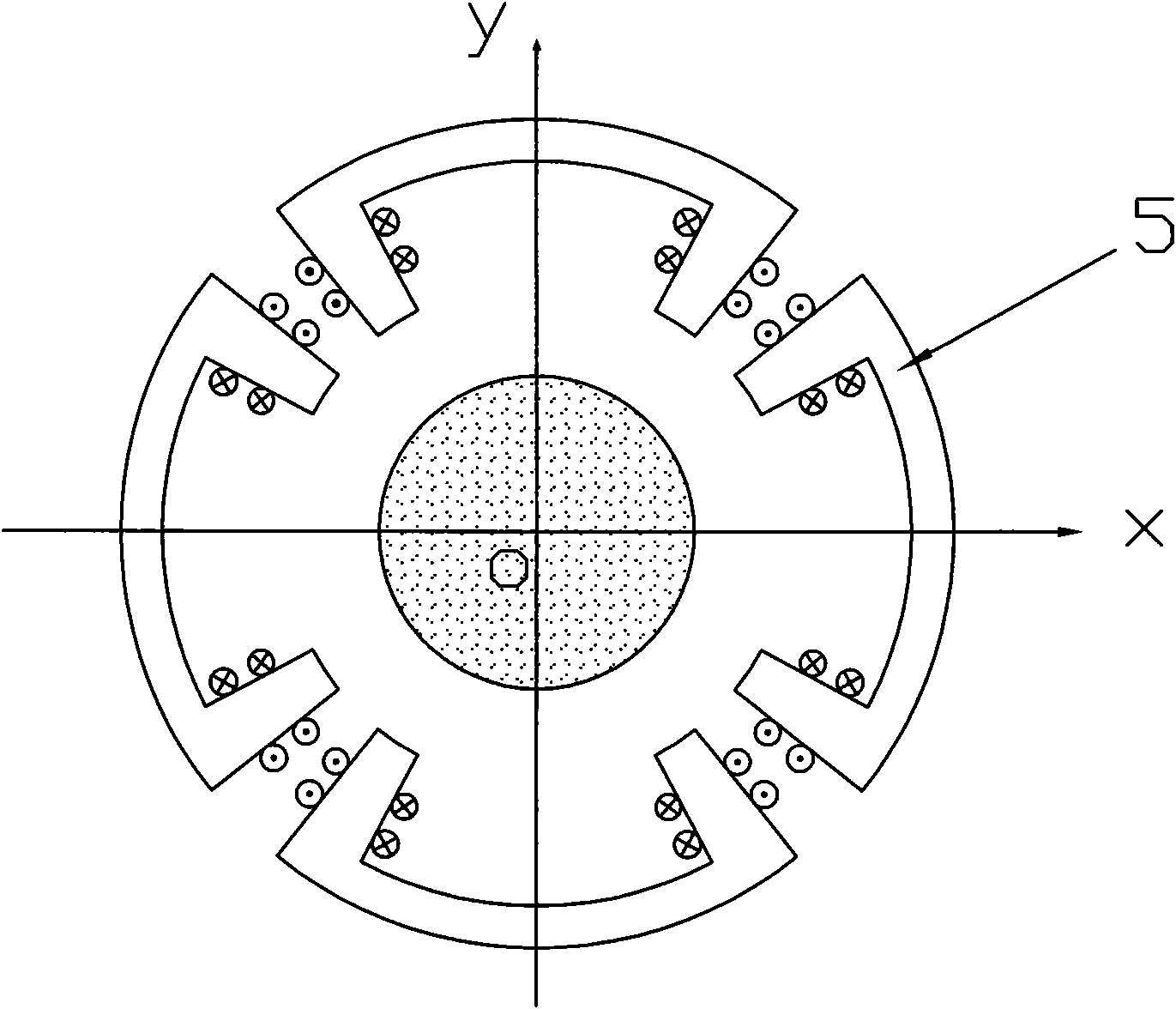

[0022] Combine below figure 1 , Figure 2a , Figure 2b , Figure 3a , Figure 3b , Figure 3c , Figure 4a , Figure 4b , to further describe the embodiments of the present invention.

[0023] The magnetic levitation spherical motor system consists of a magnetic levitation spherical motor body and a detection and control system. The body structure of the magnetic levitation spherical motor is composed of a spherical rotor 1, an output rotating arm 2, a centripetal push (pull) force magnetic levitation spherical motor salient pole stator 3, 4, 5, and a stator energized winding 6. The salient pole stator of the magnetic levitation spherical motor is arranged orthogonally on each side of the spherical rotor 1 according to the three-dimensional coordinate system of x-y-z, with the center of the spherical rotor at the equilibrium position as the coordinate origin. Among them, one motor stator 5 is arranged symmetrically to the coordinate origin (rotor sphere center) in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com