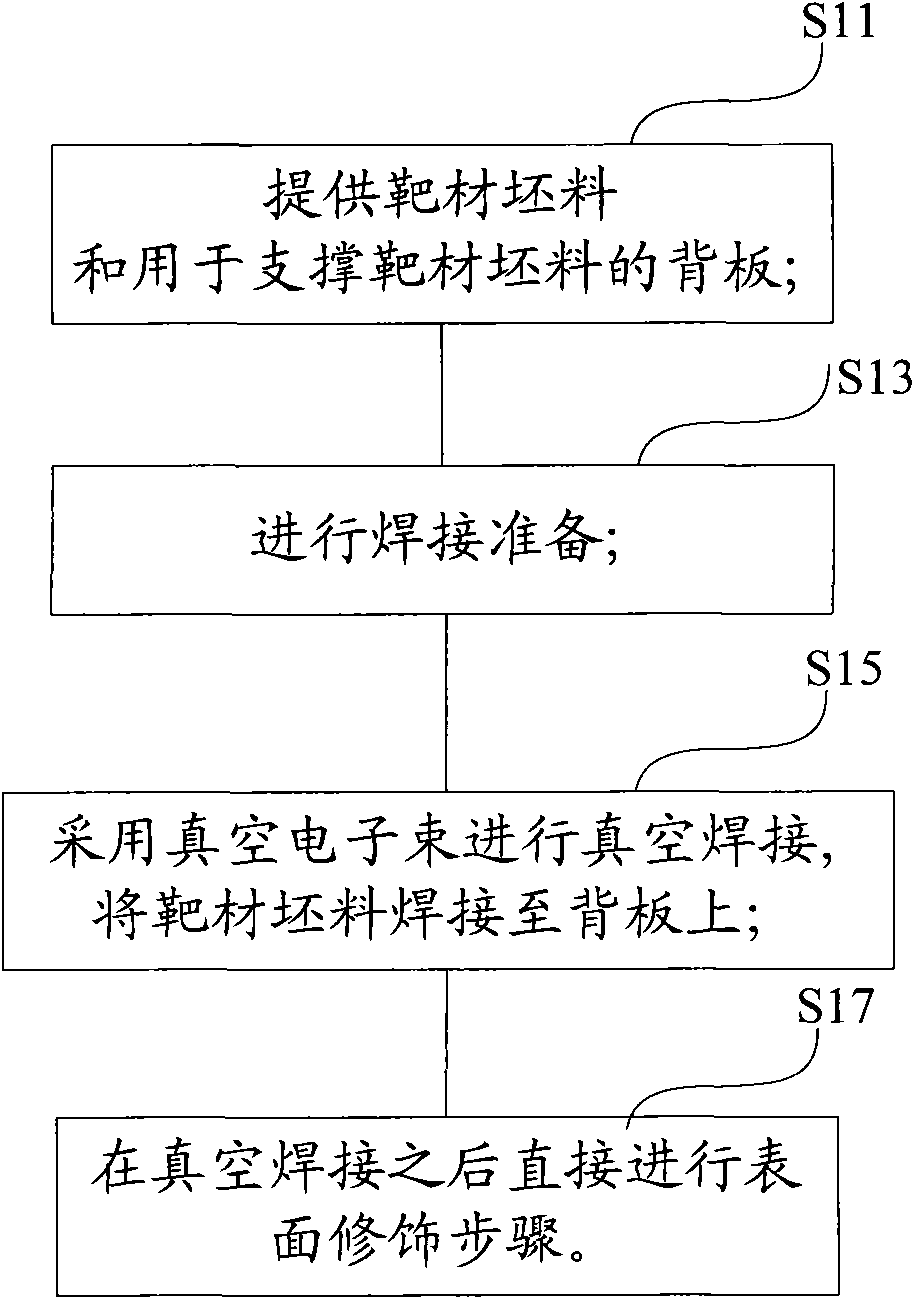

Vacuum electron beam welding method

A technology of vacuum electron beam and welding method, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., which can solve the problems of complex process and long target material cycle, so as to speed up the cycle and avoid cooling or suction Vacuum, the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0040] As an embodiment of the present invention, the target blank 200 and the back plate 100 to be welded are both aluminum, and under the conditions of the corresponding preheating specific example described above, the conditions of the vacuum welding are: the voltage is 60KV, the line speed The current is 10mm / s, the beam current is 90mA, and the focusing current is 650mA.

[0041] As another embodiment of the present invention, the target blank 200 and the back plate 100 to be welded are both copper, and under the conditions of the corresponding preheating example mentioned above, the conditions of the vacuum welding are: the voltage is 60KV, the line speed The current is 15mm / s, the beam current is 85mA, and the focusing current is 640mA.

[0042] As another embodiment of the present invention, the target blank 200 and the back plate 100 to be welded are both titanium, and the vacuum welding conditions are as follows: the voltage is 70KV, the linear velocity is 18mm / s, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com