Device for maintaining overall temperature of working cylinder balanced and control method of device

A technology of overall temperature and working cylinder, which is applied to the improvement of process efficiency, additive processing, and energy efficiency improvement. It can solve the problems of unbonded molded parts, defects, and undifferentiated area control, etc., to achieve the effect of ensuring sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

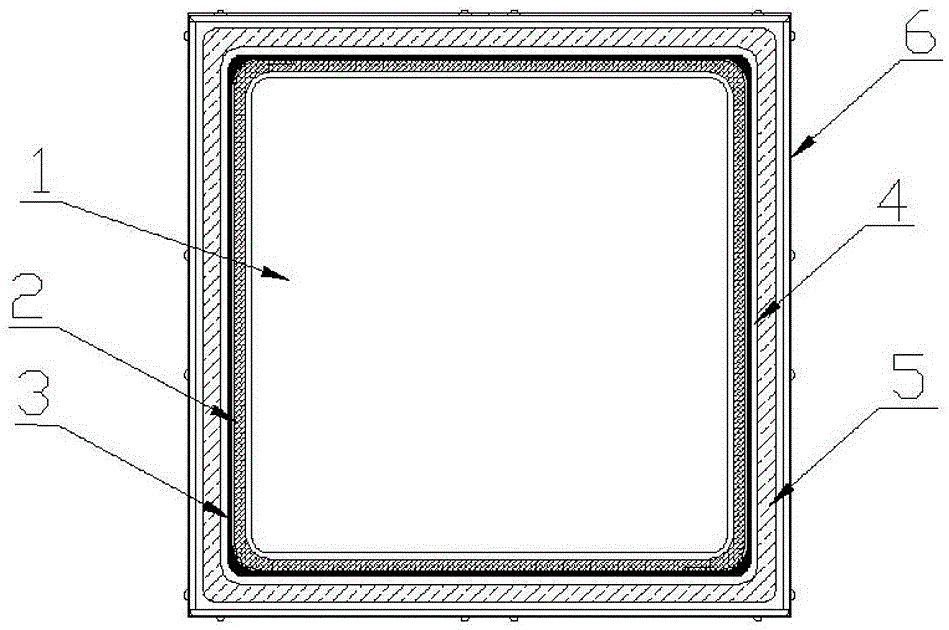

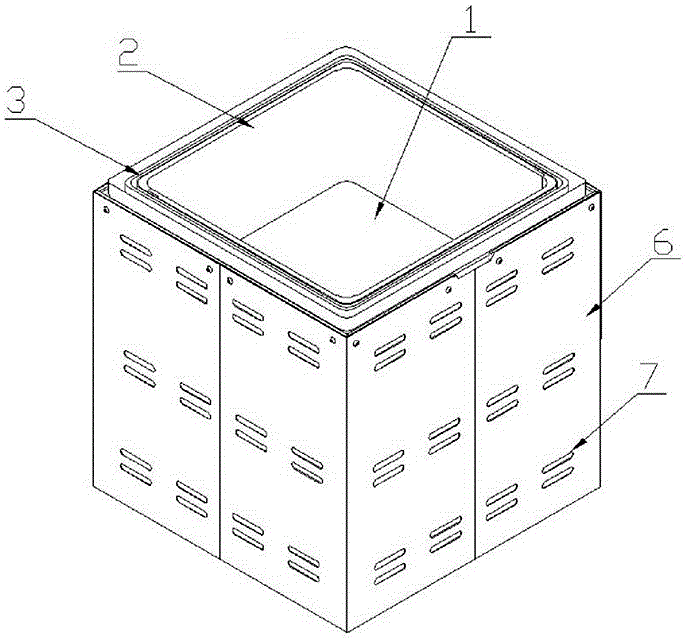

[0034] see Figure 1 to Figure 5 , the names and marks of the components included in the figure are: working cylinder piston 1; working cylinder body 2; heating device 3; ; groove 10 ; control unit 11 .

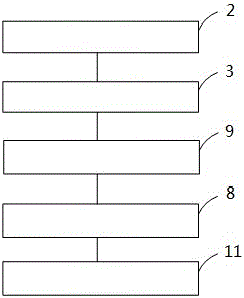

[0035] see Image 6 , 51 means calculating the quantity and position of the molded products in each area, and controlling the power of the working cylinder heating device; 52 means calculating the shape complexity and thickness of the molded products in each area, and controlling the power of the working cylinder heating device; 53 means according to Calculate the temperature change rate from the temperature data fed back by the detection device, and control the power of the heating device with a large change rate in real t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com