Sheet metal laser high-precision hot-bending forming

A metal plate and thermal bending technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of different bending angles of heating wire plates, and achieve the effect of improving forming accuracy and large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

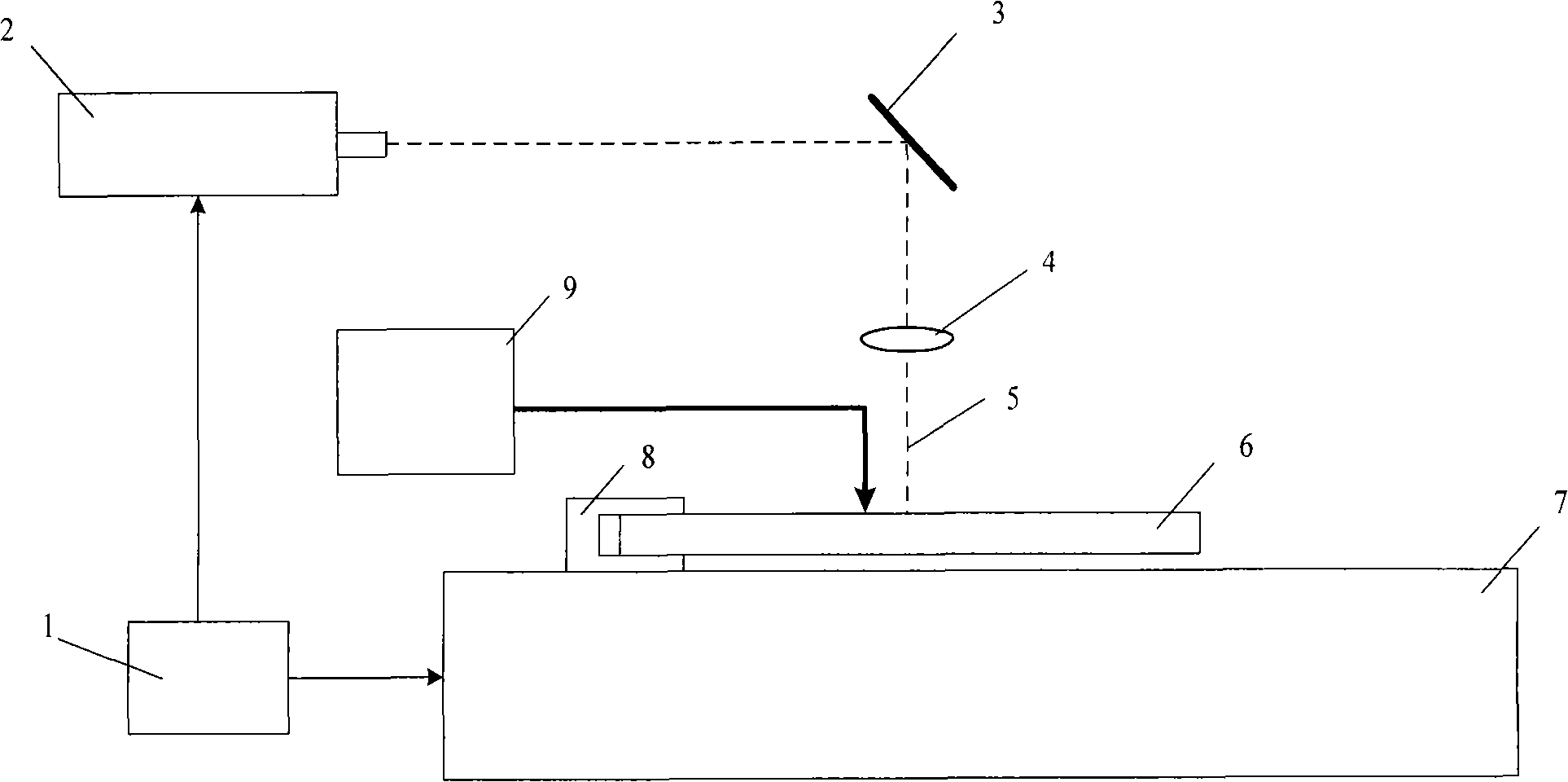

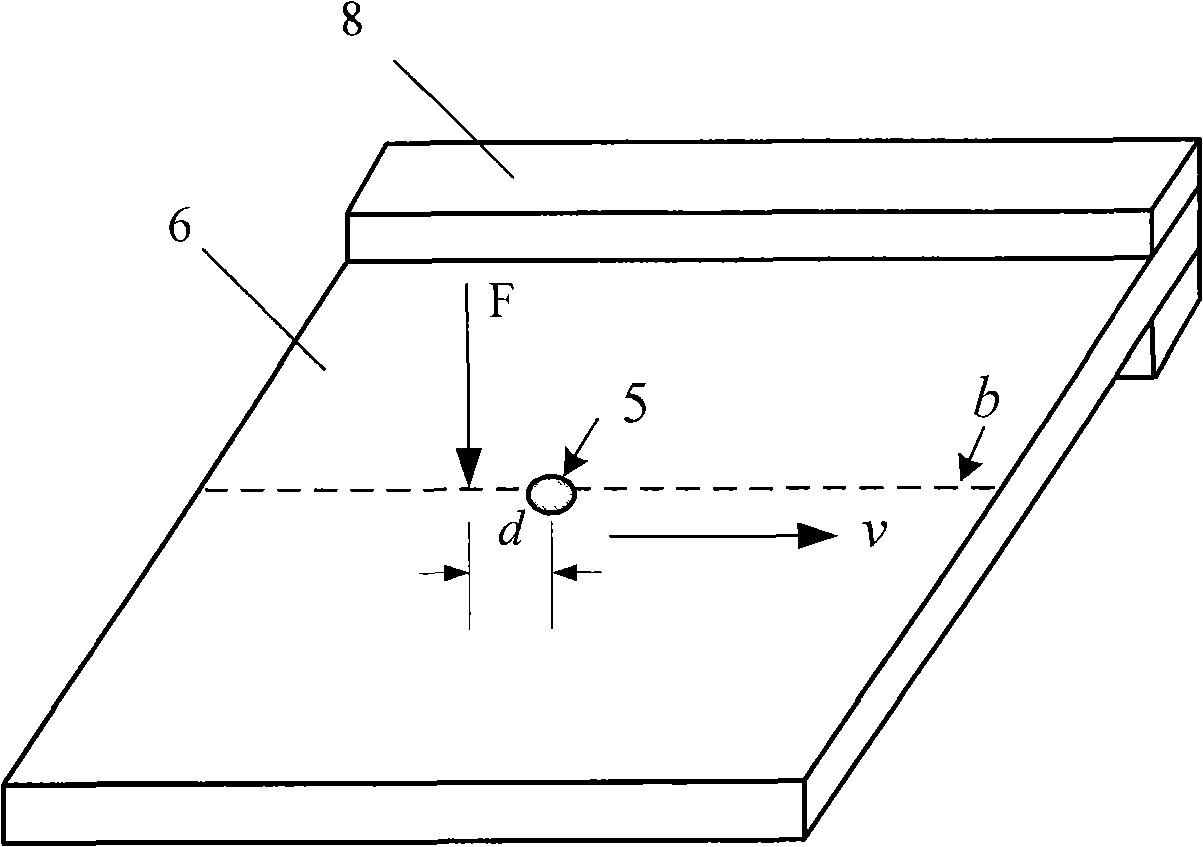

[0010] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. The high-precision laser thermal bending forming device is composed of the control system (1), CO 2 Laser (2), mirror (3), focusing mirror (4), pressure output system (9), fixture (8), three-dimensional numerical control table (7) and formed workpiece (6), such as figure 1 shown.

[0011] The specific forming steps of metal sheet are as follows:

[0012] 1. Clean the surface of the metal plate with acetone;

[0013] 2. Evenly coat a layer of laser adsorption coating on the surface of the metal plate for blackening treatment;

[0014] 3. The formed workpiece (6) is placed on the three-dimensional numerical control table (7), and one end of the formed workpiece (6) is fixed with a clamp (8), and the positions of the laser beam (5) and the pressure applying device (9) are fixed;

[0015] 4. The laser beam is emitted by the laser (2), and a beam with a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com