Method for preparing high-viscosity silicon-steel grade magnesium oxide

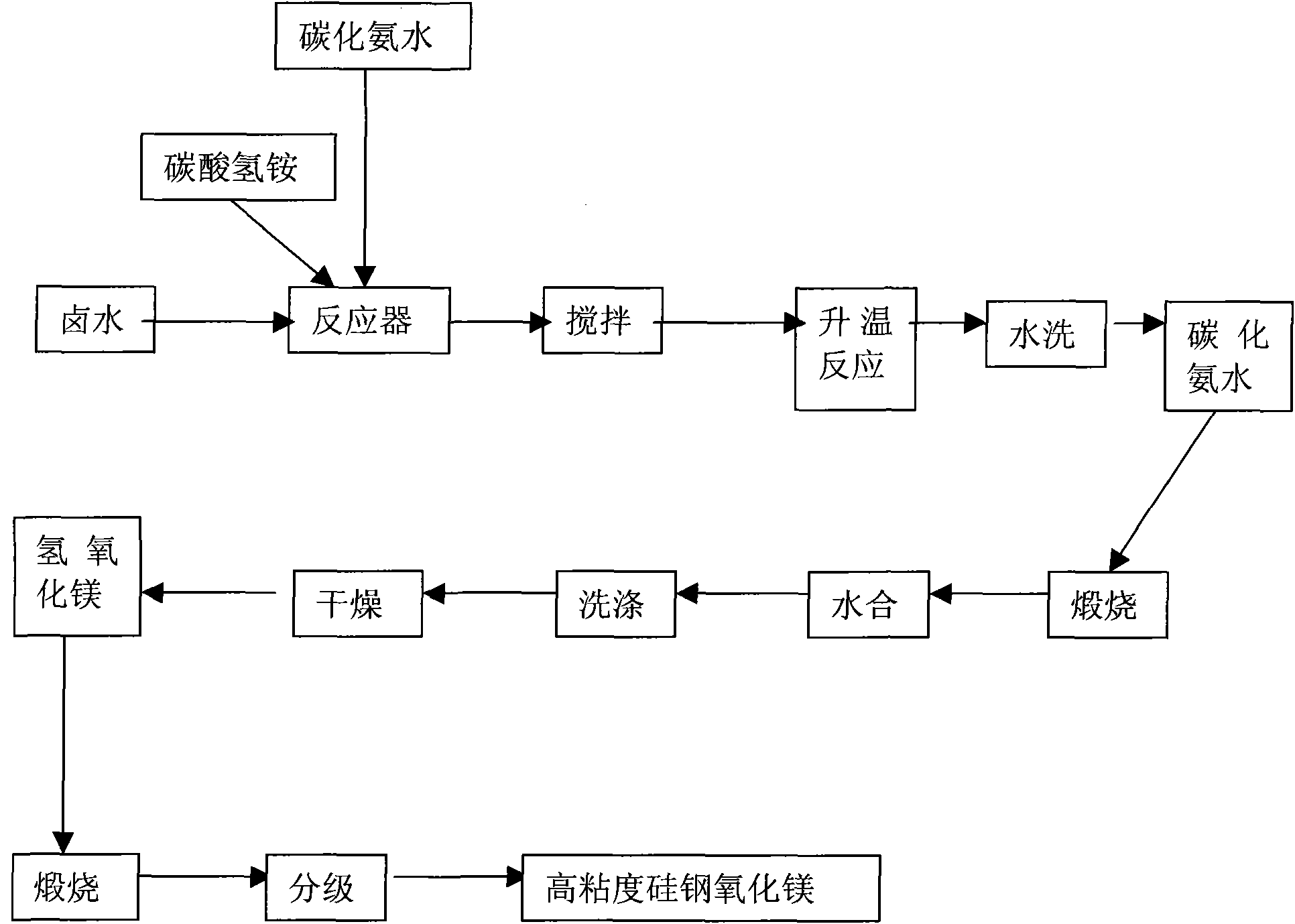

A technology of magnesium oxide and silicon steel grade, applied in magnesium oxide and other directions, can solve the problems of low magnesium content in products, low utilization rate of raw materials, and high production costs, and achieve the effects of ensuring stability, rational design, and improving calcination and pulverization processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Add 6m to the reactor 3 The molar concentration of the volume is 2.0mol / L (as Mg 2+ ) brine, add 200kg of ammonium bicarbonate under normal temperature stirring state, add 1m 3 Carbonated ammonia water (carbonization degree 40-60%), then add 100kg of ammonium bicarbonate, keep stirring and raise the temperature to 40-50°C, the reaction time is 1.5 hours; separate and dry to obtain magnesium compound; calcined at 780°C for 2 hours , to obtain high-activity magnesium oxide with a magnesium oxide content of more than 85%; put high-activity magnesium oxide into pure water at 80-90°C for hydration, stir for 1.5 hours, then separate the solid-liquid mixture, wash and dry to obtain magnesium hydroxide, at 980°C Calcining at low temperature for 4 hours to obtain magnesia particles, crushing and grading and packaging to obtain high-viscosity silicon steel magnesia.

[0023] Table 1

[0024] MgO content

[0025] The production of silicon steel sheets requires a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com