Light-curable adhesive with shock absorption property

A light-curing and adhesive technology, applied in adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve poor shock-absorbing ability, loose bonding of diaphragm and coil, and affect the quality performance of micro-acoustic devices and other problems, to achieve the effect of improved shock absorption performance and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

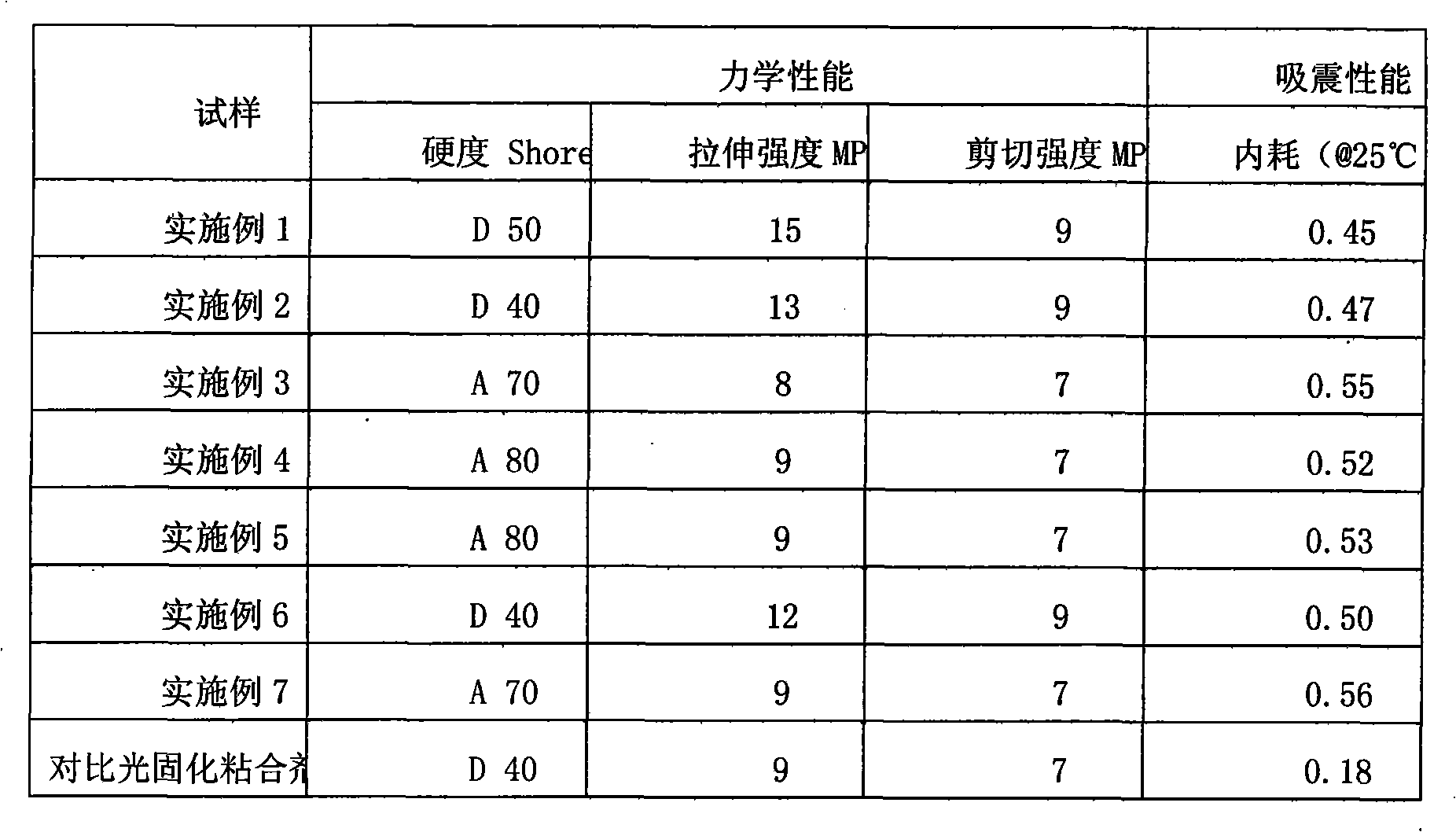

Examples

Embodiment 1

[0016] Example 1, first take 135 g of hydroxyl-terminated polybutadiene diols with a molecular weight between 1500 and 4500 and an average functionality of 2, remove water at 107.5°C for 3 hours under vacuum conditions, and then cool it down to 45°C Then stop vacuuming, add 10.9g of difunctional isocyanate TDI, stir rapidly, after the temperature is stable, slowly raise the temperature and control it to 80°C for 2.5 hours, cool down to 45°C after the reaction is complete, add 5.3g of hydroxyethyl acrylate , and add 0.05g of hydroquinone as a polymerization inhibitor, slowly heat up to 75°C and react for 2.5 hours. After the reaction is complete, vacuum degassing for 0.5h, take the material to obtain polybutadiene type polyurethane modified acrylate, seal and store away from light spare;

[0017] Accurately weigh 45g of the above-mentioned polybutadiene polyurethane modified acrylate, 20g of isobornyl acrylate, 20g of N,N-dimethylacrylamide, 5g of isooctyl acrylate, 5g of photo...

Embodiment 2

[0018] Example 2, first take 100 g of hydroxyl-terminated polybutadiene diols with a molecular weight between 1500 and 4500 and an average functionality of 2, remove water for 4 hours under vacuum at 100 ° C, and then cool it down to 40 ° C Then stop vacuuming, add 5.6g of difunctional isocyanate MDI and 4.3g of IPDI, and stir rapidly. After the temperature is stable, slowly raise the temperature and control it at 75°C for 3 hours. After the reaction is complete, cool down to 40°C and add methyl Add 3.2g of hydroxyethyl acrylate and 2.5g of hydroxypropyl acrylate, add 0.04g of hydroquinone as a polymerization inhibitor, slowly raise the temperature to 70°C and react for 3 hours. Diene type polyurethane modified acrylate, sealed and protected from light for later use;

[0019] Accurately weigh 30g of the above-mentioned polybutadiene type polyurethane modified acrylate, 15g of isobornyl acrylate, 15g of tetrahydrofuran acrylate, 20g of N,N-dimethylacrylamide, 10g of lauryl acry...

Embodiment 3

[0020] Example 3, first take 213 g of hydroxyl-terminated polybutadiene diols with a molecular weight between 1500 and 4500 and an average functionality of 2, remove water at 115°C for 2 hours under vacuum conditions, and then cool it down to 50°C Then stop vacuuming, add 4.5g of difunctional isocyanate XDI, 6.9g of H-MDI and 14.5g of H-TDI, and stir rapidly. After the temperature is stable, slowly raise the temperature and control it at 85°C for 2 hours. After the reaction is complete, Cool down to 50°C, add 4.3g of hydroxyethyl acrylate, 2.5g of hydroxypropyl methacrylate and 5.7g of hydroxypropyl acrylate, and add 0.1g of hydroquinone as a polymerization inhibitor, slowly raise the temperature to 80°C for 2 hours, After the reaction is complete, vacuum degassing for 0.5h, take the material to obtain polybutadiene-type polyurethane-modified acrylate, seal and store away from light for later use;

[0021] Accurately weigh 65g of the above-mentioned polybutadiene type polyuret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com