a clamping device

A technology of clamping device and set, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of limited diameter range, inconvenient replacement of expansion sleeves, and processing constraints of workpieces with different diameters, so as to achieve the effect of ensuring the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

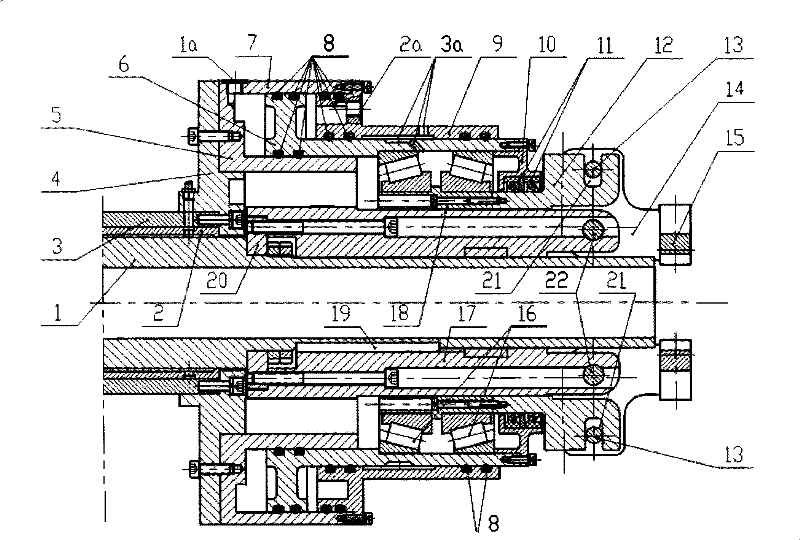

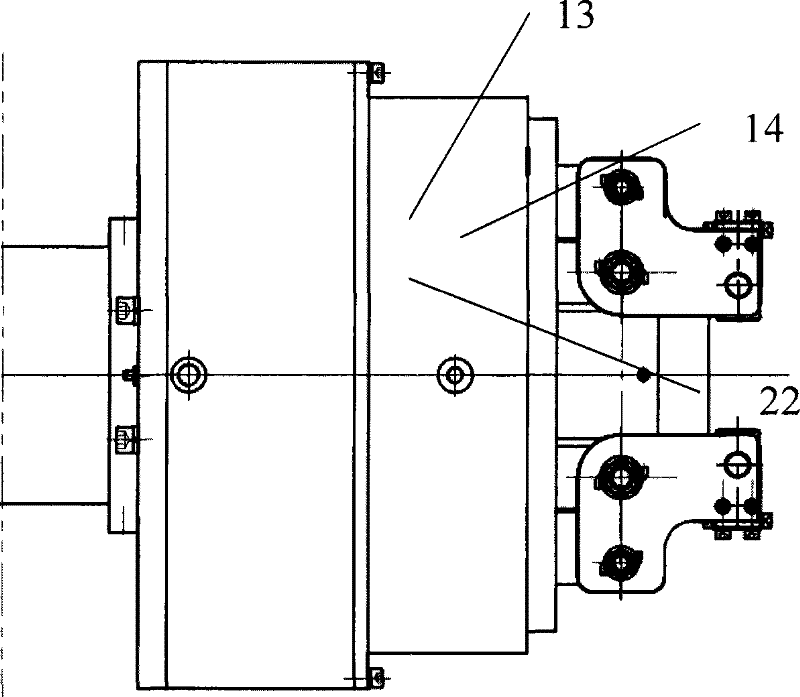

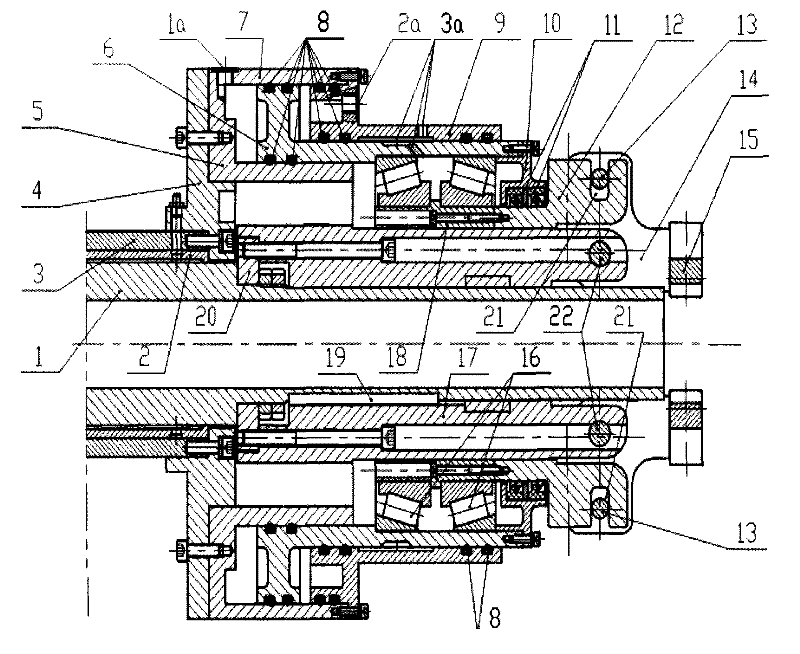

[0054] figure 1 is a cross-sectional view of a clamping device according to the invention. In the following description with figure 1 The right side is the front, and the left side is the back. As shown, the clamping device according to the invention comprises a hollow spindle 1 . During actual processing, the cooling medium—in this embodiment, cooling water—flows through the hollow part of the hollow spindle 1 into the interior of the quenched workpiece, thereby cooling the quenched workpiece from the inside.

[0055] The bearing sleeve 17 is arranged concentrically with the hollow spindle 1 . It can be seen from the figure that due to the needs of processing technology and installation, the supporting sleeve 17 and the sliding sleeve 12 are composed of multiple parts. But in this embodiment, for convenience of description, the combination of these parts is referred to as supporting sleeve 17 and sliding sleeve 12 according to their functions. The support sleeve 17 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com