Window anti-seepage installation and construction method

A construction method and anti-leakage technology, applied in the direction of frame fixing, etc., can solve the problems of packing cracking, water seepage, rainwater cannot be drained from the drain hole in time, etc., to achieve the effect of easy operation, overcoming leakage, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

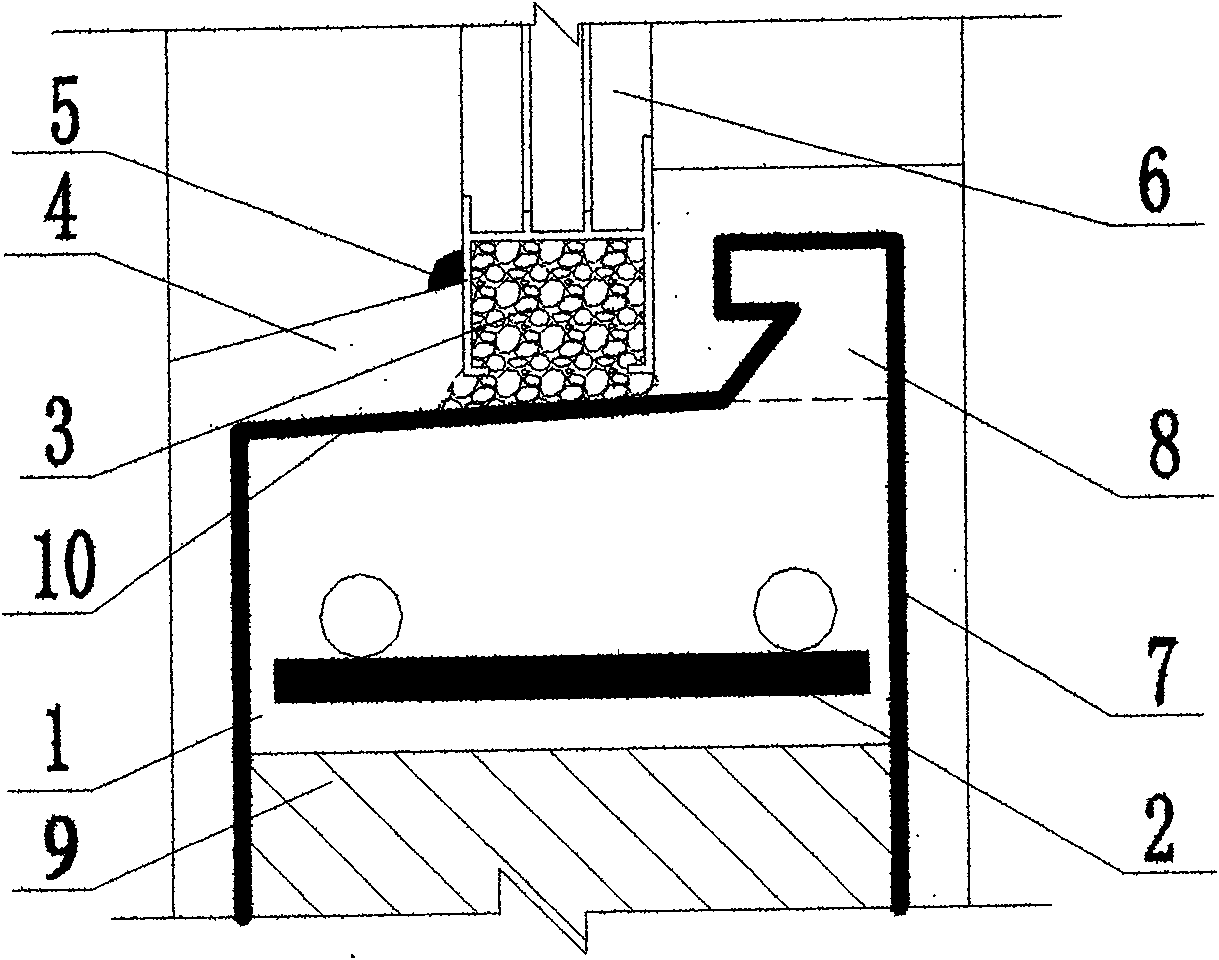

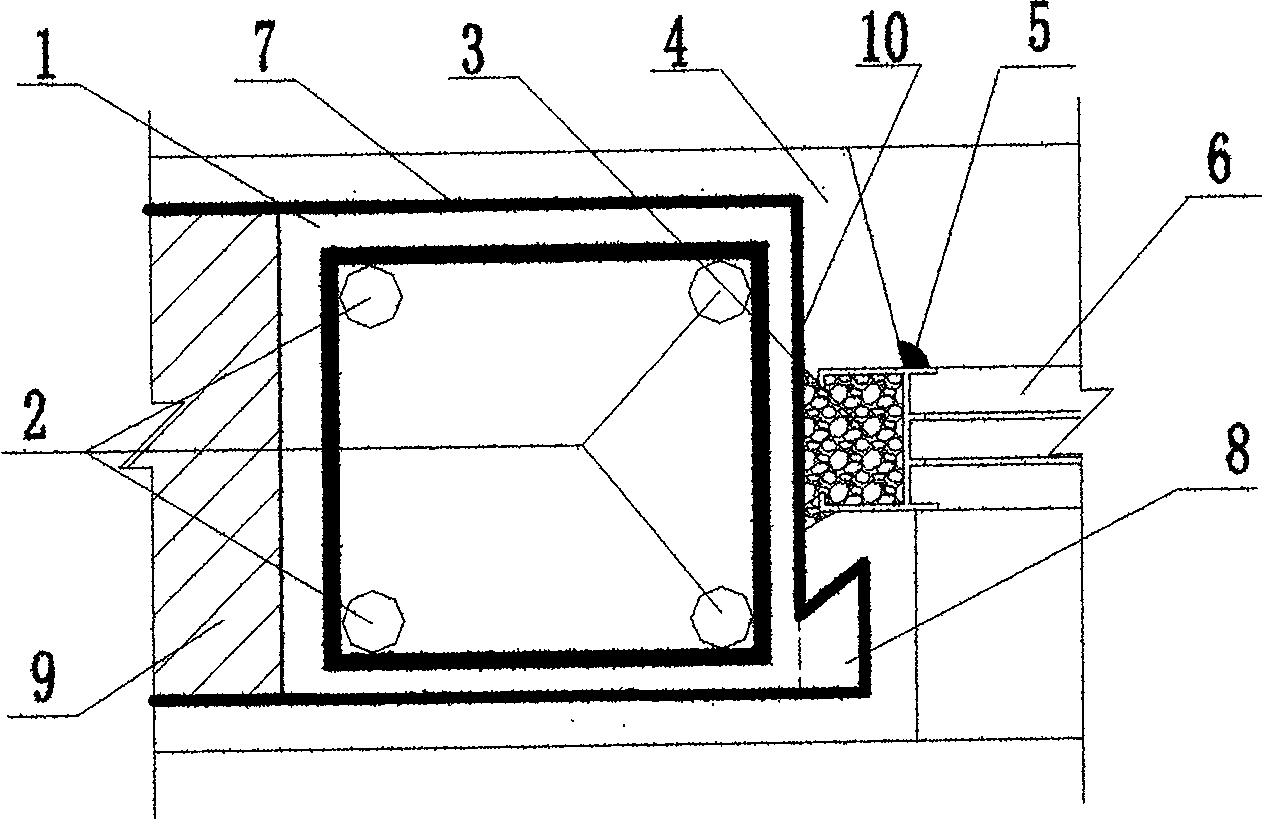

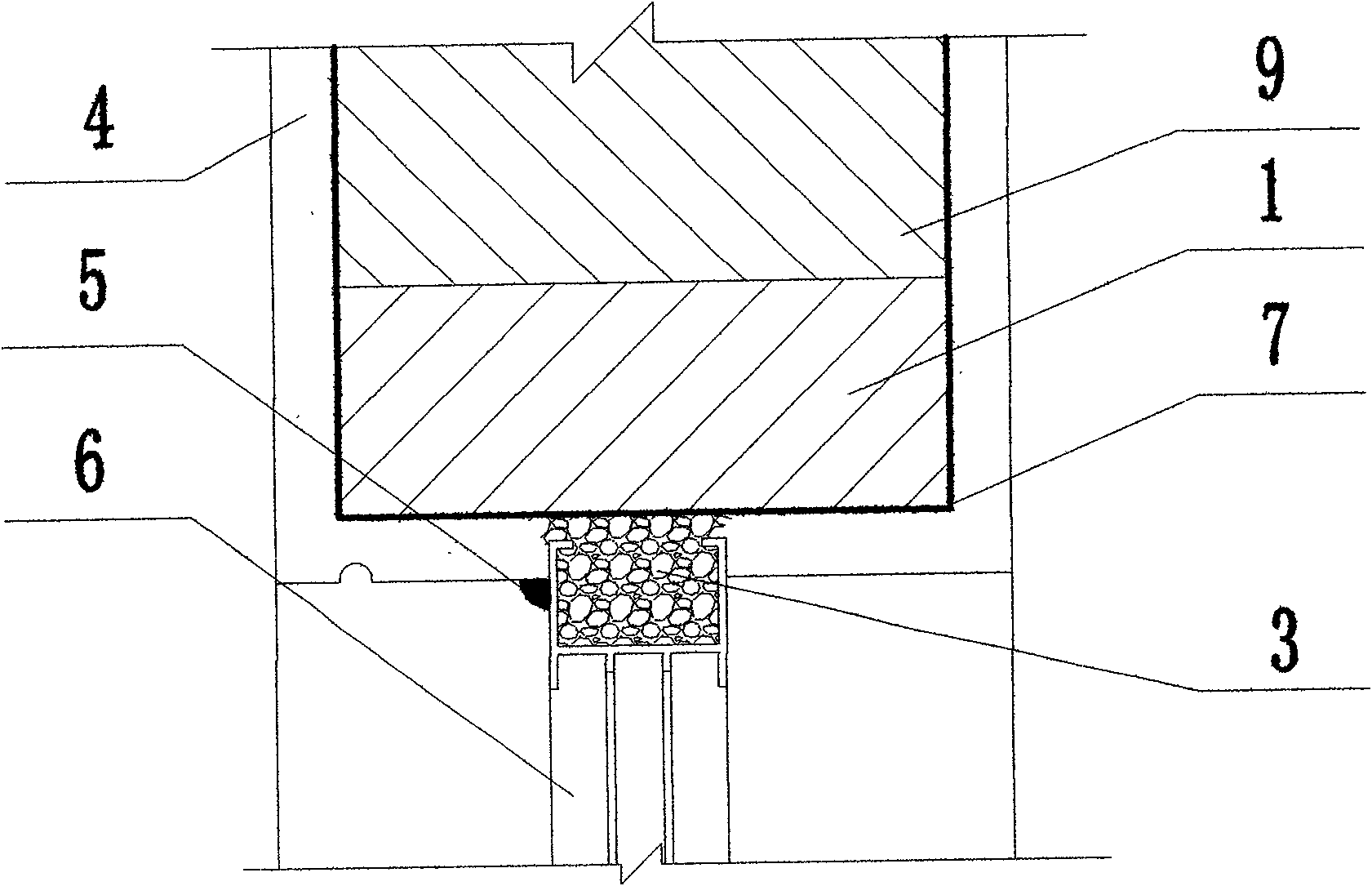

[0018] With reference to the examples given in the drawings, it can be clearly seen that in order to solve the problem of leakage between the window and the wall, the present invention has designed a window anti-leakage installation construction method. An anti-leakage device is set between the window hole of the building body and the finished window frame, and a decorative layer with no visible gap is made of cement mortar and sealant on both sides of the window frame. The technical improvement is that the waterproof device is anti-leakage Frame device 1, a water-retaining sill structure is added to the anti-leakage frame device 1, and polyurethane foam 3 is used as the sealing filler between the window frame 6 and the anti-leakage frame device 1, and polyurethane sealant 5 and cement are used The mortar 4 is used as a finely sealed and gapless decorative layer. The specific steps include:

[0019] I. Set the mold 7 of the anti-leakage frame device 1 with the water-retaining sill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com