Reshaping device for semiconductor laser diode array pumping

A laser diode and shaping device technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., to achieve the effect of focusing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

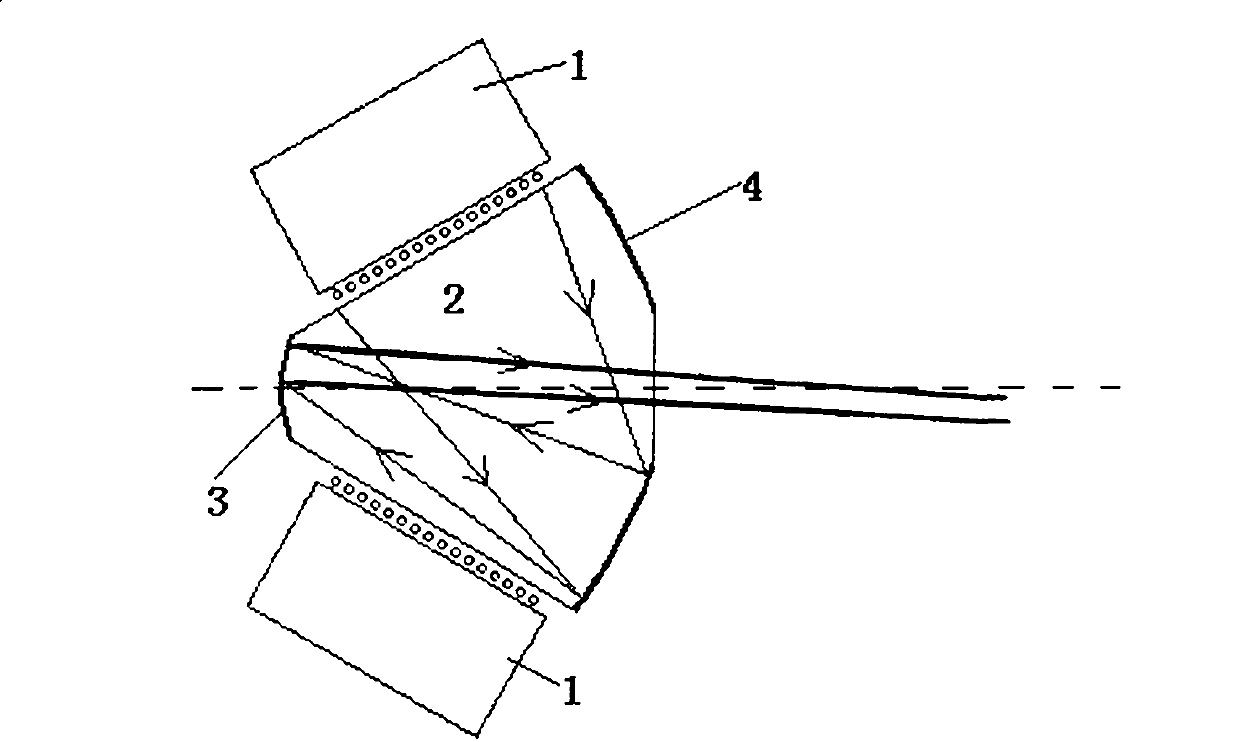

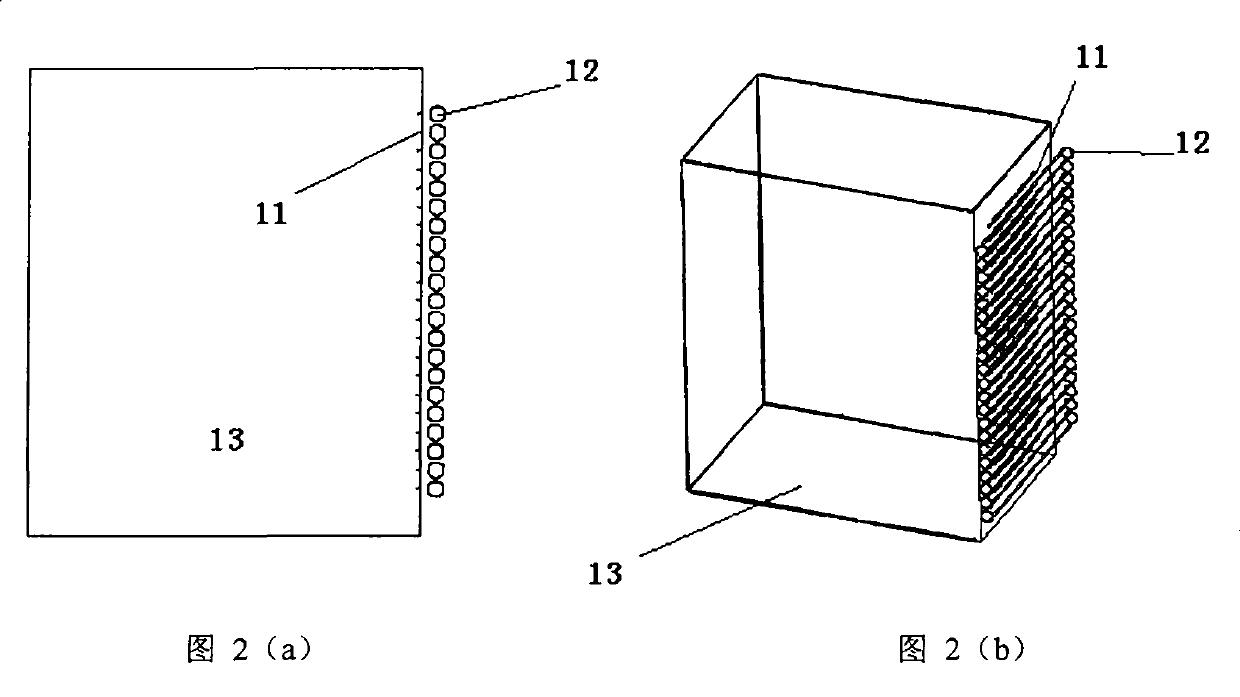

[0045] refer to figure 1 , make a shaping device for semiconductor laser diode array pumping according to the present invention. Two laser diode arrays 1 are used in the device, and the two laser diode arrays 1 are symmetrically placed on both sides of the reflective structure 2. Each array It includes 16 laser diode bars 11 and the same number of optical fibers 12; the light emitting lines of each laser diode bar 11 in the laser diode array 1 are parallel to each other and form a rectangular light emitting surface. The laser diode array 1 is composed of the 16 laser diode bars fixed on one side of the appendage 13, wherein the appendage 13 is a square metal block (as shown in Fig. 2 (a) and Fig. 2 ( As shown in b), and the attachment 13 is provided with a power connection member; it can also be purchased from the market, for example, produced by the Changchun Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences.

[0046] The 16 optical fibers 12 are arra...

Embodiment 2

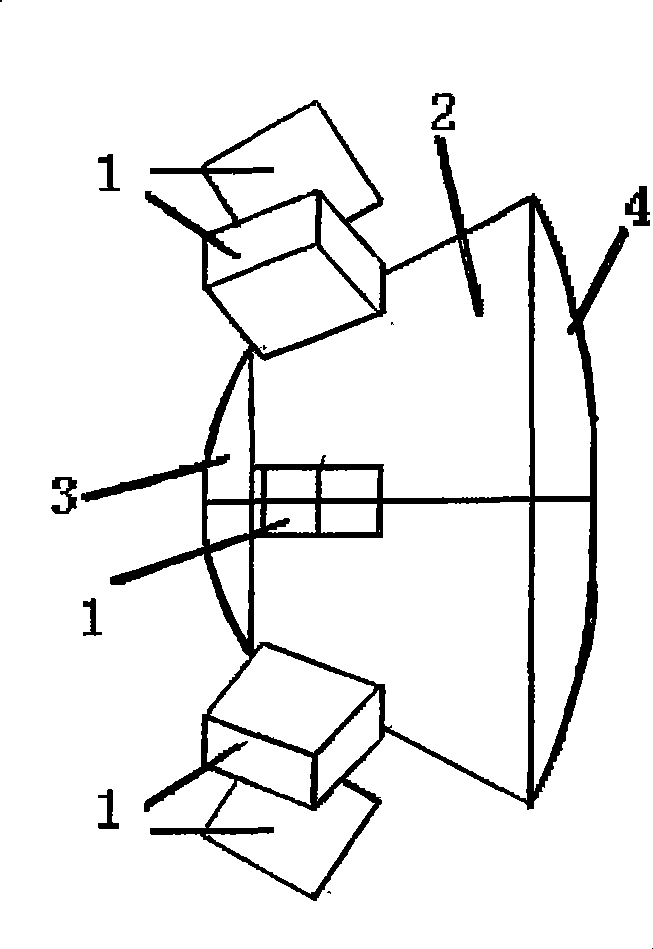

[0048] With reference to Fig. 3 (a) and Fig. 3 (b), make a shaping device for semiconductor laser diode array pumping of the present invention, use 8 laser diode arrays 1 in this device, and 8 laser diode arrays 1 are arranged in a circle Arranged around the reflection structure 2; each array includes 24 laser diode bars 11 and the same number of optical fibers 12. Wherein said laser diode array 1 is made up of said 24 laser diode bars fixed on the side surface of accessory 13, and wherein said accessory 13 is a rectangular copper metal block, and also in this rectangular copper metal block There is a channel for cooling water, and a water inlet and outlet are provided on the upper and lower end faces of the rectangular copper metal block, as well as a power connection member; the light-emitting lines of each laser diode bar in the array are parallel to each other and form a The illuminated face of the rectangle. The optical fiber axis and the corresponding light-emitting lin...

Embodiment 3

[0050] Make a shaping device for semiconductor laser diode array pumping of the present invention, use 18 laser diode arrays 1 produced by the Changchun Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences in this device, and each laser diode array 1 includes 8 laser diode bars strip 11, and the same number of optical fibers 12. The light emitting lines of each laser diode bar 11 in the array are parallel to each other and form a rectangular light emitting surface. The optical fiber axis and the corresponding light-emitting line of the laser diode bar 11 are arranged parallel to each other, with a distance between 0.1 mm and 1 mm. The direction of light emitted by the laser diode bar 11 is perpendicular to the optical fiber axis. The 18 arrays are divided into 9 groups, and the 9 groups of arrays are arranged around the reflective structure 2 in a rotationally symmetrical structure. The two arrays of each group are arranged in parallel with the side surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com