Power-saving winding using combined ferrite iron core

A ferrite iron, combined technology, applied in transformer/inductor coil/winding/connection, transformer/inductor core, AC network to reduce harmonics/ripple, etc. High-order harmonics cannot be eliminated, etc., to achieve the effect of eliminating high-order harmonics, reducing neutral current, and high magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

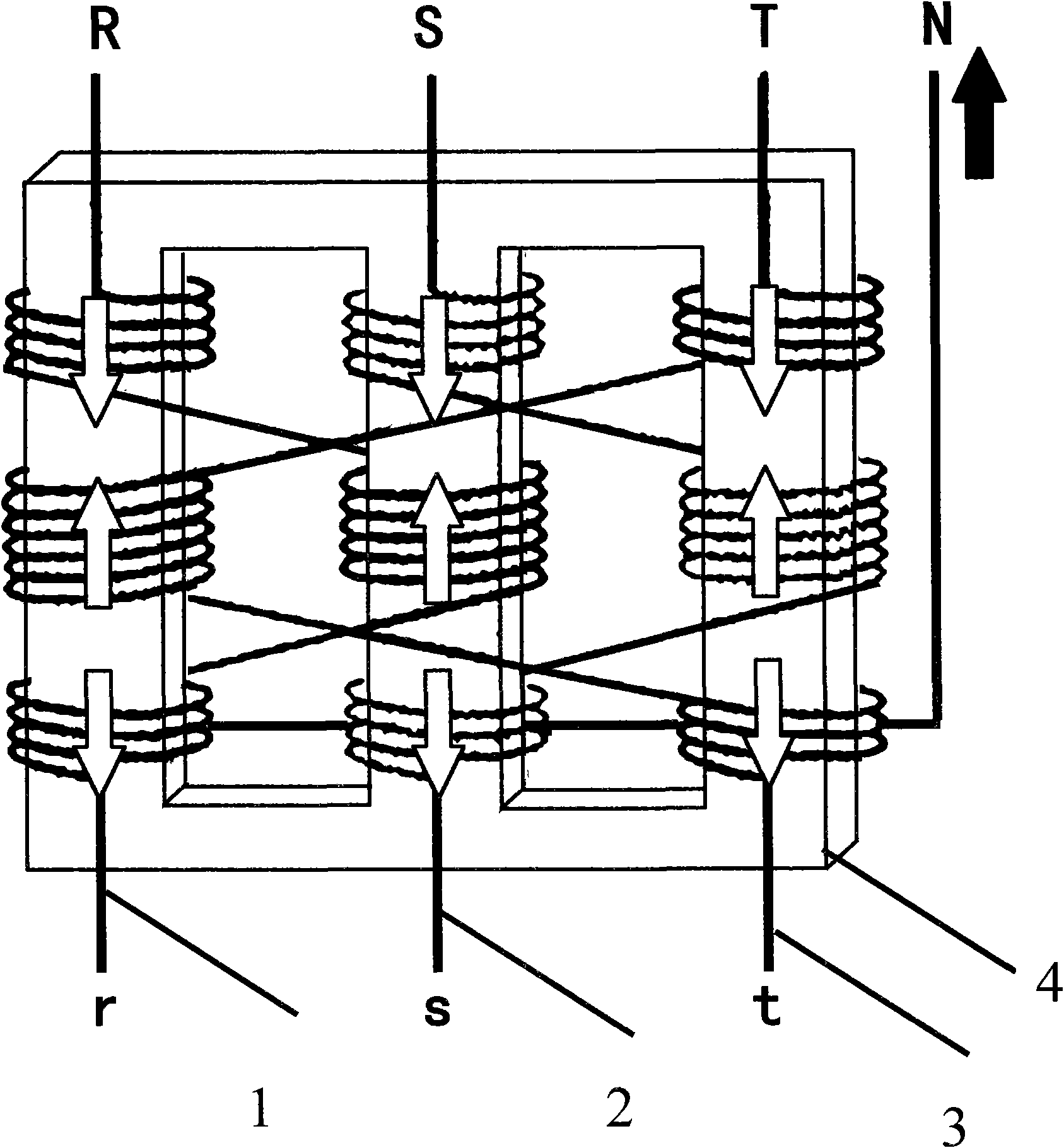

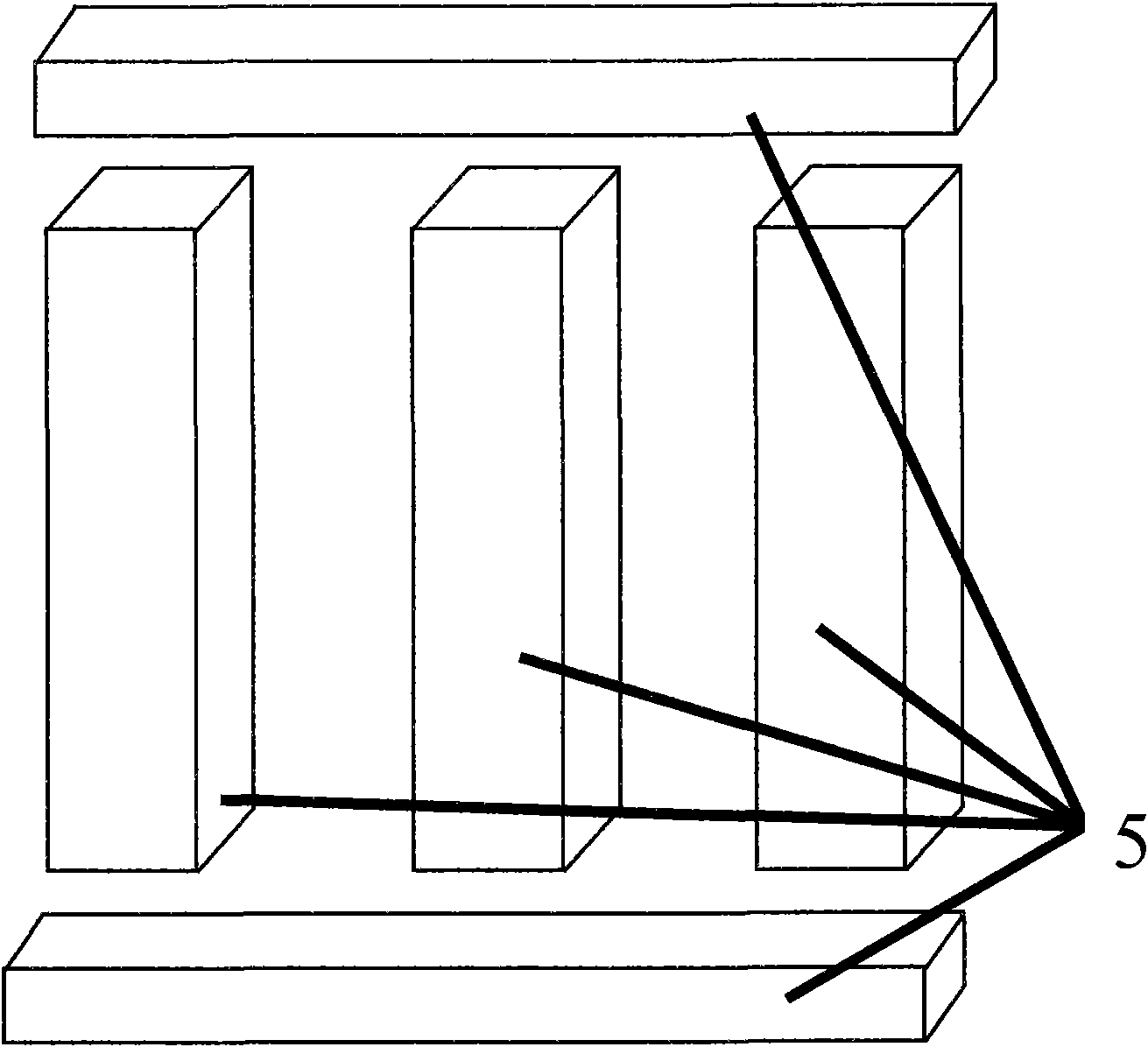

[0014] exist figure 1 Among them, the first coil 1 , the second coil 2 and the third coil 3 are wound on the iron core 4 in a zigzag winding manner. That is, the two ends of the first coil 1 are wound on the left column of the iron core 4, and the middle section is wound on the middle column of the iron core 4; the two ends of the second coil 2 are wound on the middle column of the iron core 4, and the middle section is wound on the iron core The right column of 4; the two ends of the third coil 3 are wound on the right column of the iron core 4, and the middle section is wound on the left column of the iron core 4. They use mutual cross balance to control the coil, generate waveforms that are completely opposite to the phase of the high-order harmonics, and cancel each other out, thereby correcting the crooked waves, reducing the neutral line current, and eliminating high-order harmonics. The effect of phase balance, while saving electric energy, can significantly improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com