Reactor for carrying out a continuous oxide hydrogenation, and method

A technology of reactor and reaction section, applied in the field of continuous oxidative dehydrogenation, to achieve the effect of balancing the temperature of the gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

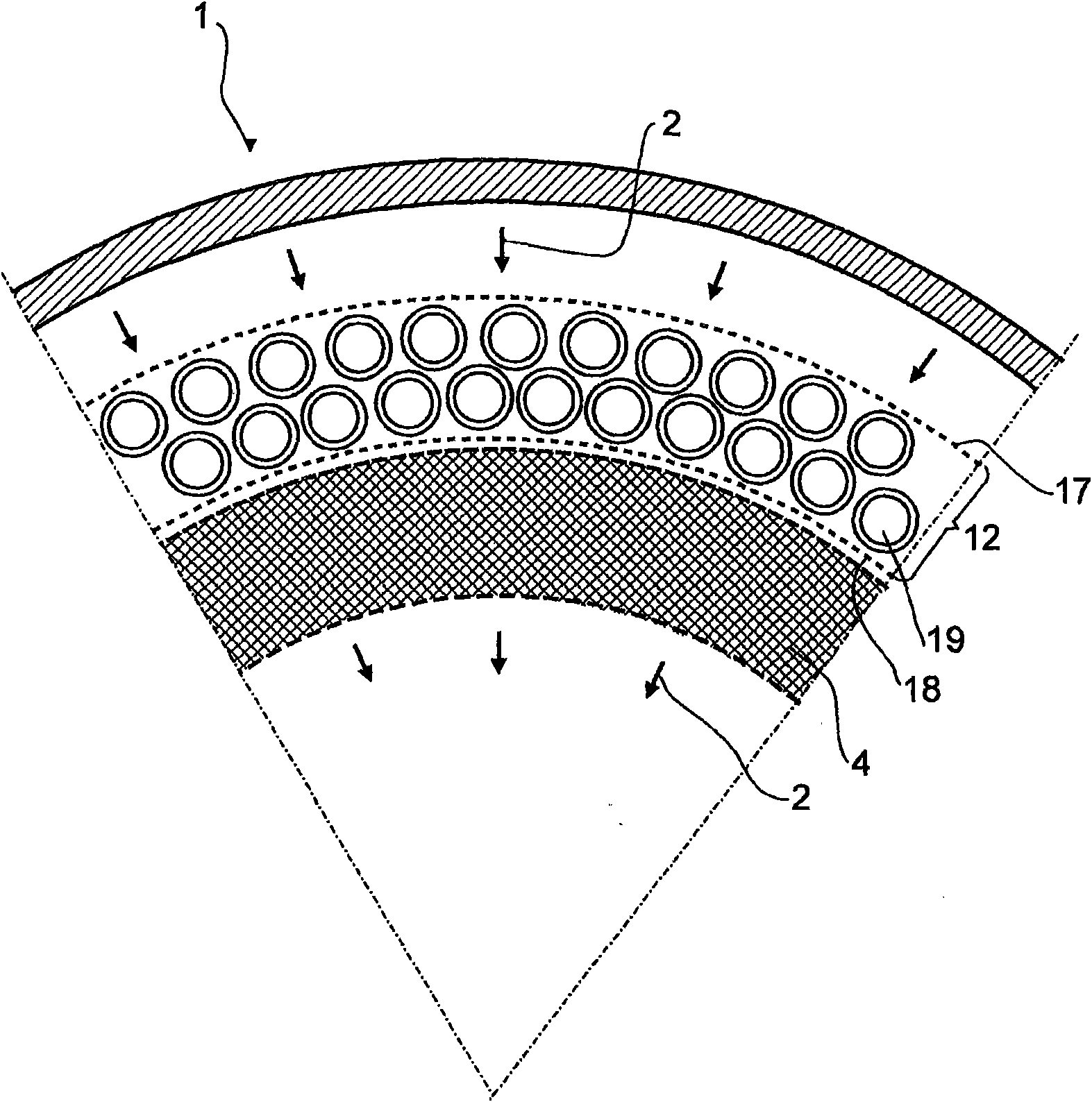

[0076] figure 1 A fan-shaped cross-section is shown through a first exemplary embodiment of a reactor 1 according to the invention, in which the feed gas flow 2 is fed to the reactor outer shell and the feed gas flow is discharged via the reactor interior. The feed gas stream 2 flows vertically to a mixing device 12 comprising two rows of finned tubes 19 arranged such that the finned tubes (in one row) abut the gaps in the other row, where A first orifice plate 17 is provided at the front (upstream) of the two rows of finned tubes along the flow direction, and a second orifice plate 18 is provided at the rear (downstream) of the two rows of finned tubes along the flow direction. Two rows of finned tubes 19, upstream orifice plates 17 and downstream orifice plates 18 are respectively arranged on concentric rings. The reaction gas mixture premixed in the mixing device 12 then flows through the moving catalyst bed 4 .

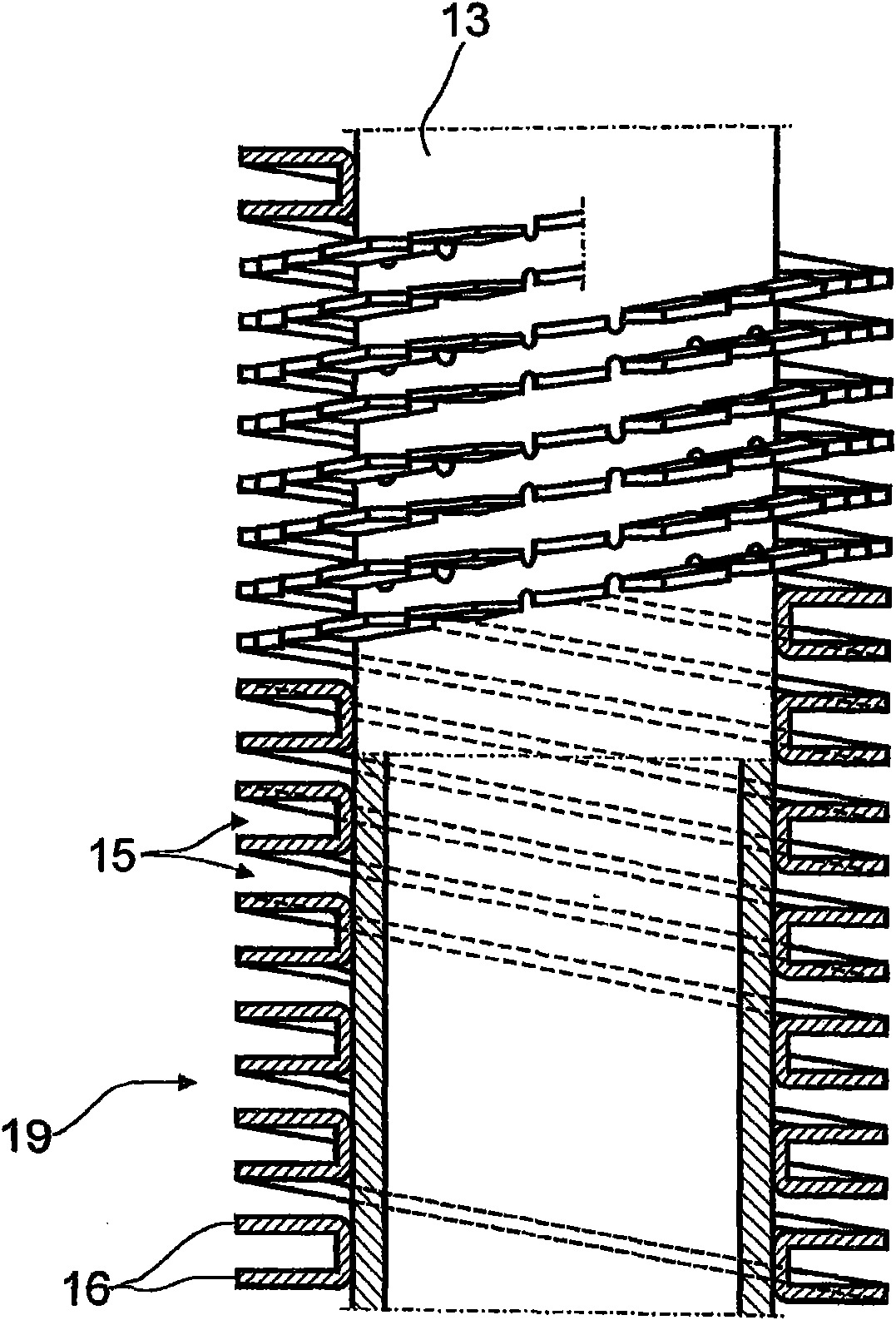

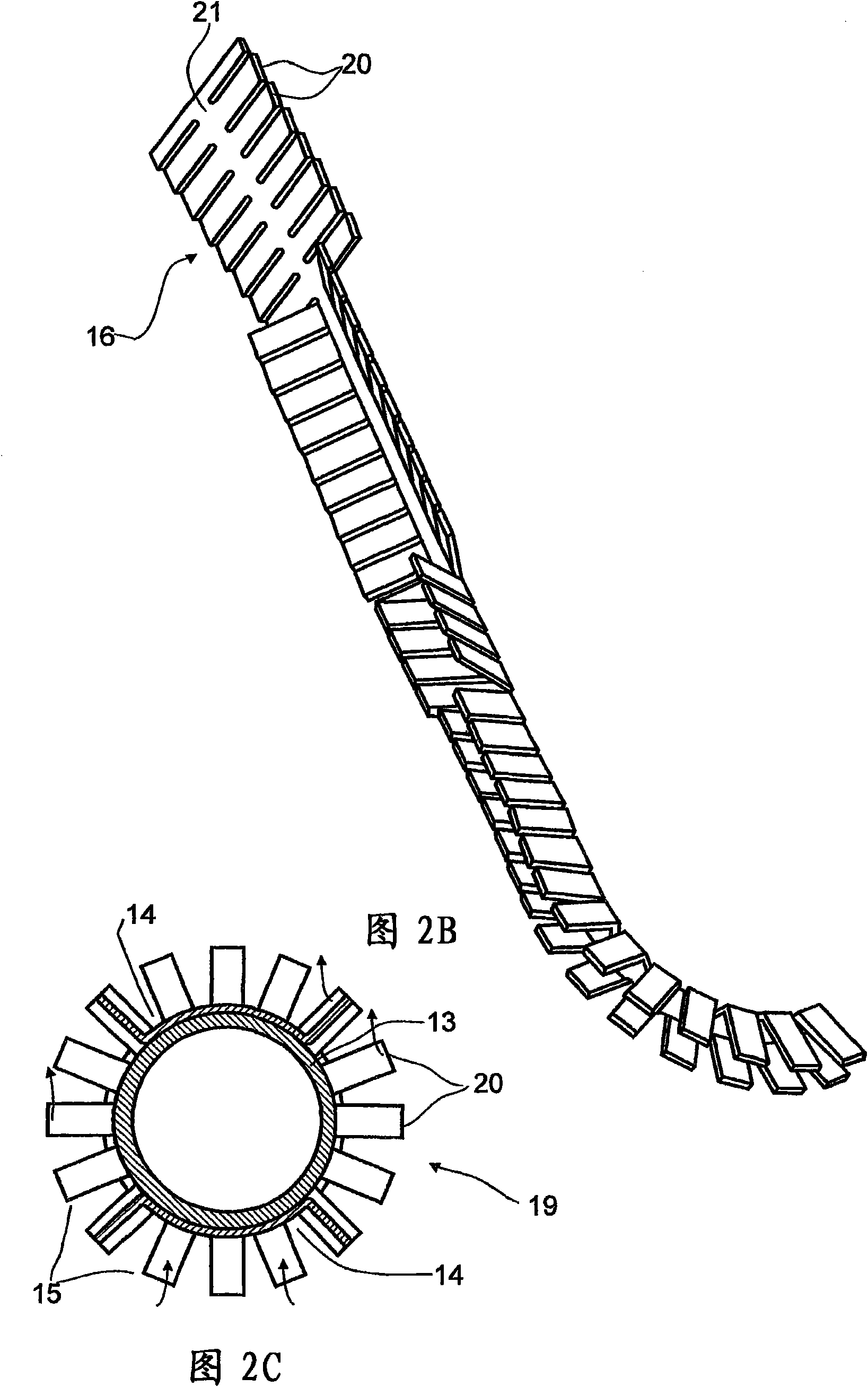

[0077] Figures 2A to 2C A detailed illustration of a fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com