Pre-expanded noncrosslinked polypropylene resin beads and in-mold expansion moldings

A cross-linked polypropylene and pre-foaming technology, which is applied in the field of in-mold foaming moldings, can solve problems such as undetermined effects and unexpectable effects, and achieve the effects of excellent weldability, excellent antistatic properties, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

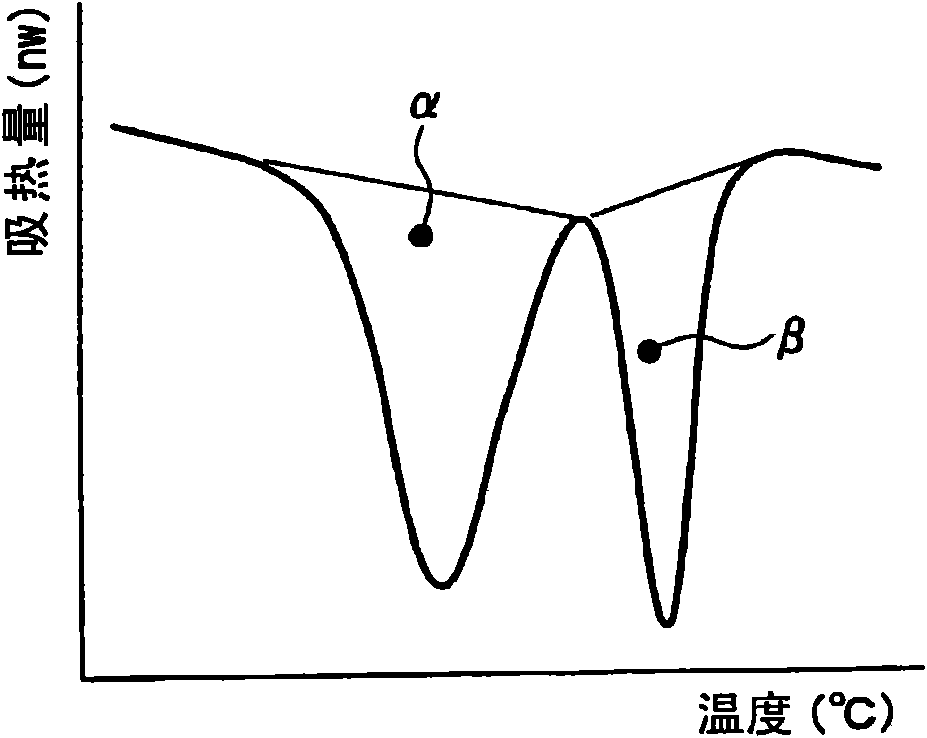

Method used

Image

Examples

Embodiment

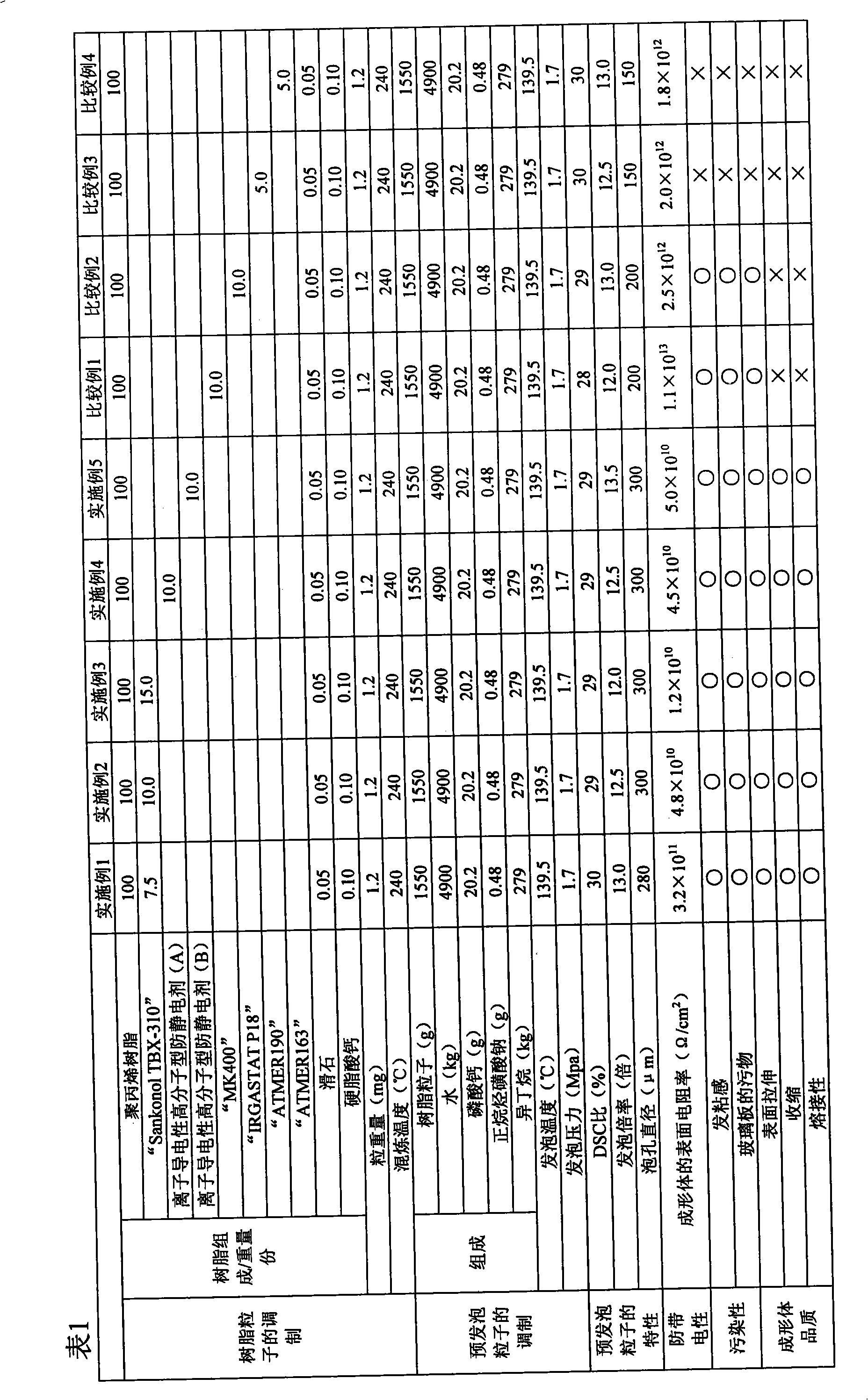

[0068] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto.

[0069]

[0070] Using the "Hirester MCP" tester manufactured by Mitsubishi Chemical Corporation, under the conditions of applying a voltage of 500V to the surface of a molded body of 400 x 300 x 50mm x 1 minute, a measurement temperature of 23°C, and a humidity of 50%RH, according to JIS K 6911 Determination of surface resistivity. The lower the surface resistivity value, the higher the antistatic property.

[0071]

[0072] Evaluation was performed by directly touching the molded body with hands. A sample with a sticky feeling was rated as x, and a sample without a sticky feeling was rated as ○. In addition, a glass plate of 100×100×1 mm was covered on the surface of the molded body, heat-treated in an oven at 80° C. for 1 week, and then returned to room temperature, and dirt adhering to the glass plate was determined. A samp...

manufacture example 1

[0091] A mixture of 90 parts by weight of polyether / polyolefin block copolymer ("Pelestat 300" manufactured by Sanyo Chemical Industries) and 10 parts by weight of lithium bis(trifluoromethanesulfonyl)imide was mixed with a Henschel mixer , was put into a twin-screw extruder, kneaded and extruded while heating at a temperature of 200° C., and then pelletized after water cooling to obtain an ion-conductive polymer type antistatic agent (A).

manufacture example 2

[0093] In Production Example 1, except that lithium bis(trifluoromethanesulfonyl)imide was changed to lithium trifluoromethanesulfonate, the ion-conductive polymer type antistatic agent (B) was obtained by the same method as Production Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Crystal melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com