Foam drying method of blackcurrant mashed fruit

A technology of foam drying and fruit pulp, applied in the direction of food science, etc., can solve the problem of destroying the quality of blackcurrant fruit powder, achieve the effect of maintaining color and nutritional content, good product quality, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

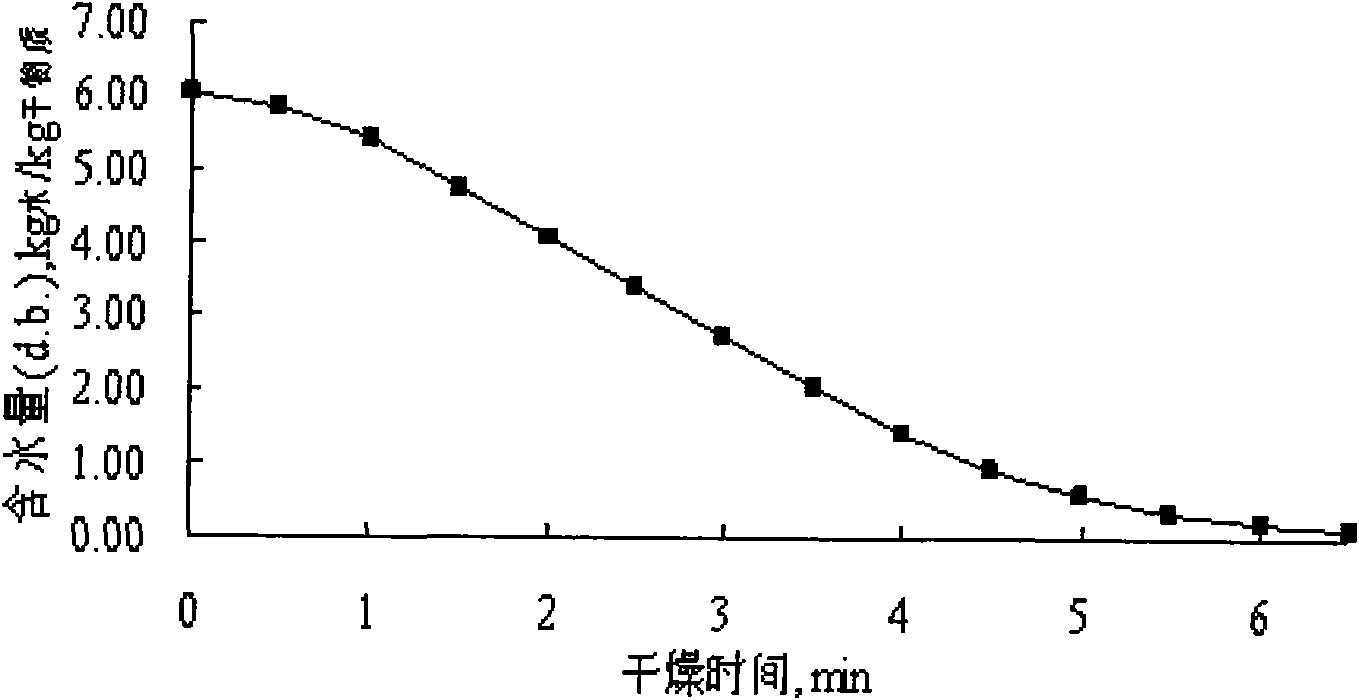

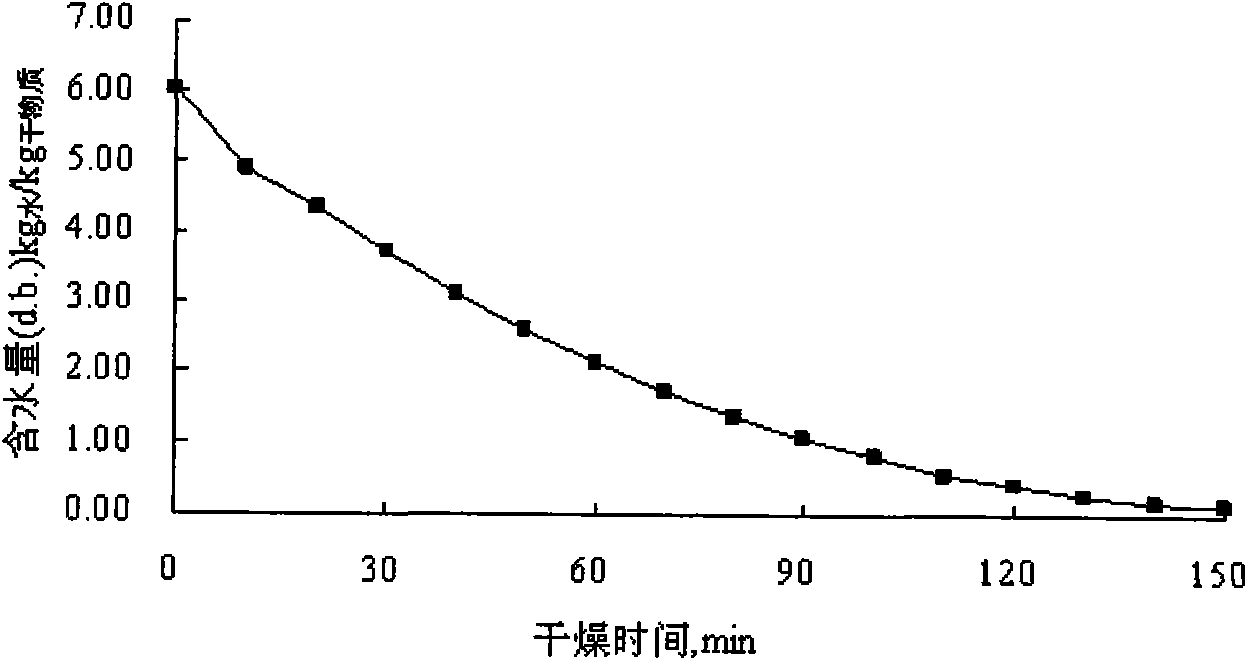

[0010] Specific embodiment one: the foam drying method of blackcurrant pulp in this embodiment is carried out according to the following steps: 1. According to the ratio of parts by weight, 70~80 parts of blackcurrant pulp, 7~15 parts of foaming agent and 7~ Mix and stir 15 parts of stabilizer for 4-15 minutes; 2. Dry the mixture in step 1 by microwave for 5-10 minutes, the mass of the mixture is 2-4kg, the thickness of the mixture is 2-6mm, and the microwave power is 140-700W; Drying of black currant pulp.

[0011] In step 1 of this embodiment, the total mass of blackcurrant pulp, foaming agent and stabilizer after mixing is 2-4 kg.

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the foaming agent is composed of monoglyceride and soybean protein isolate in a mass ratio of 1.5-2.5:1. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stabilizer in step 1 is carboxymethyl cellulose with a mass concentration of 0.5%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com