Device for recording and detecting automatic production line procedures

An automatic production line and detection device technology, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of high control system configuration requirements, information loss, etc., and achieve simple and reliable technology, low cost, and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

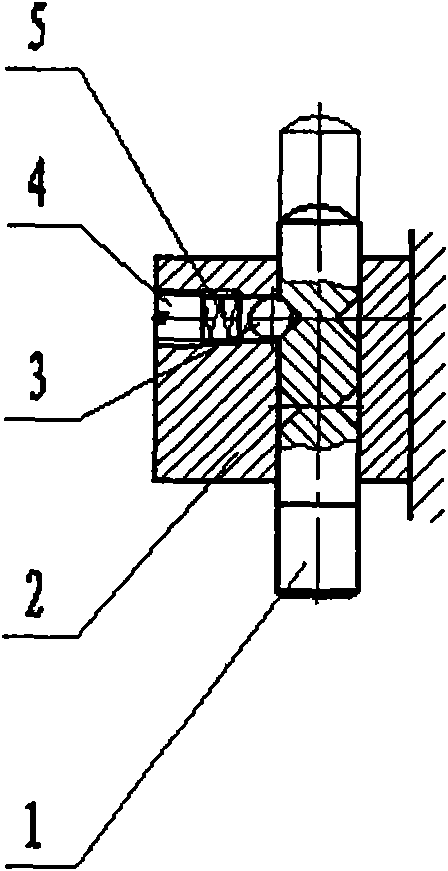

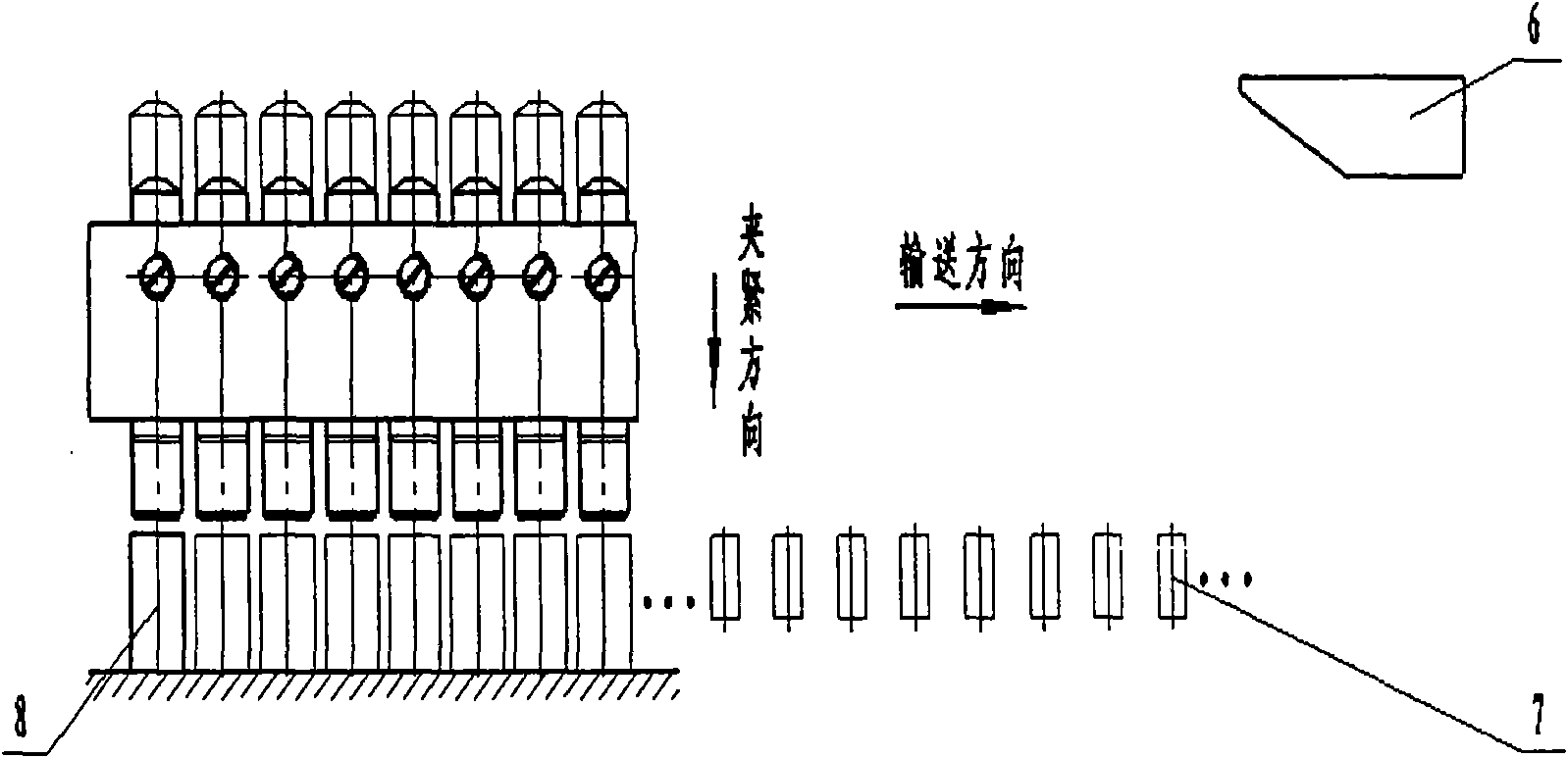

[0016] Embodiment: During specific implementation, the automatic line process recording and detection device generally includes the following three groups of devices: a recorder composed of cylindrical record carrier pins 1 (corresponding to the number of processes) integrated on the same body 2, a group distributed in different The write recording pin 8 (corresponding to the number of processes) and a group of detection proximity switches 7 (corresponding to the number of processes) on the fixed fixture of the process machine tool are equipped with a reset wedge 6 for the record and detection device to work cyclically.

[0017] The recorder is integrated on the same body 2 by a number of record carrier pins 1 corresponding to the number of processes. Each record carrier pin 1 is matched with the body 2 with a cylindrical surface, and can slide axially in the hole. Through the steel ball ring The slot positioning mechanism determines two axial positions of the record carrier pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com