Spraying material for inner surface of electricity channel of diamond type power distribution network and preparation method thereof

A technology for power piping and spraying materials, applied in metal material coating process, coating, melt spraying and other directions, can solve practical application limitations, difficult to apply and other problems, to avoid hidden dangers, excellent mechanical properties, and simple technology reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

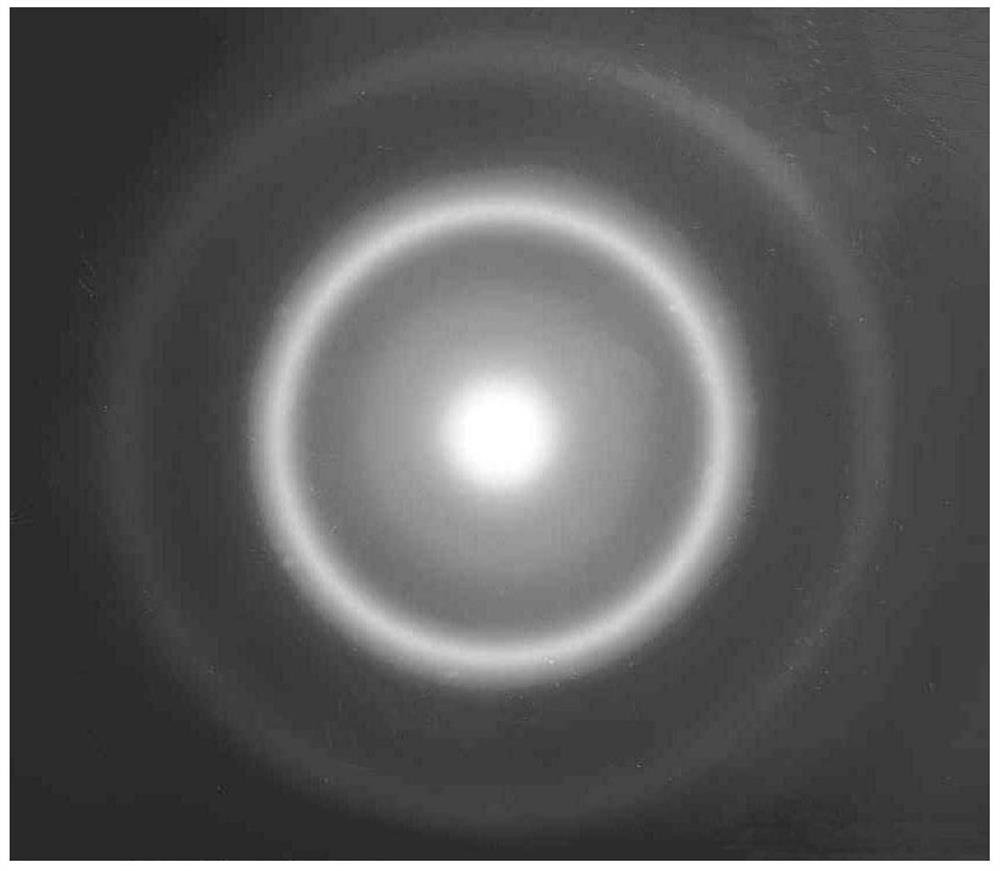

Image

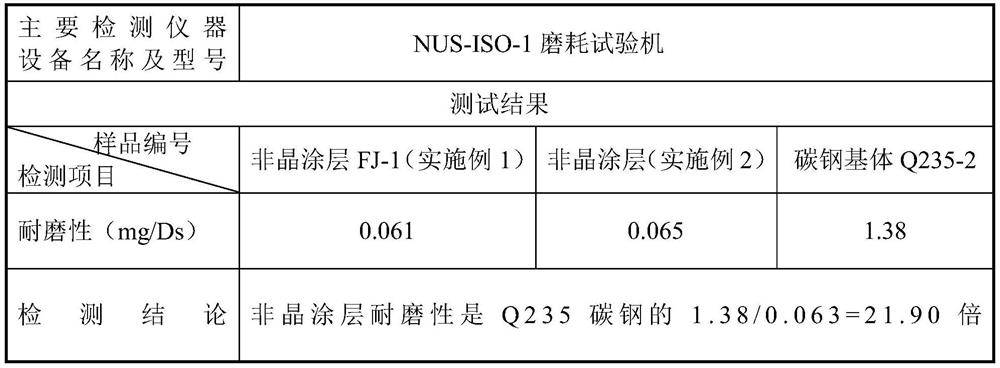

Examples

Embodiment 1

[0034] After weighing the metal block raw materials by electronic balance, 23% Fe was prepared according to the mass percentage. 2 B, 21% Fe 4 N, 18% MnAl 4 , 16% of V 6 Si 5 , 9% AlMo 3 , with a margin of α-Nb 5 Si 3 alloy composition.

[0035] Put the various materials in the above proportions into the chamber of the non-consumable arc melting equipment. After the chamber is evacuated into a high vacuum, it is filled with argon (purity: 99.999wt%) protective atmosphere to stabilize the arc. Adjust the current intensity to control the temperature of arc melting, and obtain a primary alloy ingot with uniform composition after repeated melting.

[0036] Put the alloy ingot into the quartz crucible of the gas atomization powder making equipment, close the equipment and evacuate to 3×10 -2 Pa, filled with argon to normal pressure. In order to ensure the purity of the gas in the equipment, repeat the above process three times. Set the injection pressure to 5MPa and the o...

Embodiment 2

[0039]After weighing the metal block raw materials by electronic balance, 26% Fe was prepared according to the mass percentage. 2 B, 24% Fe 4 N, 19% MnAl 4 , 16% of V 6 Si 5 , 11% AlMo 3 , with a margin of α-Nb 5 Si 3 alloy composition. Next, various materials in the above proportions are put into the chamber of the non-consumable arc melting equipment, and an alloy ingot with uniform composition is obtained by arc melting. Before melting the material, the chamber is evacuated to a high degree of vacuum, and then filled with an argon protective atmosphere to stabilize the arc. Adjust the current intensity to control the temperature of arc melting, and after repeated melting, a block with uniform alloy distribution is obtained. Then, put the alloy ingot into the quartz crucible of the gas atomization powder making equipment, close the equipment and evacuate to 3×10 -2 Pa, filled with argon to normal pressure. In order to ensure the purity of the gas in the equipment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com