Circulating fluidized bed boiler for 20t/h efficient burning Fujian anthracite

A circulating fluidized bed and anthracite technology, applied in the field of boiler combustion, can solve the problems of low combustion efficiency, achieve the effect of increasing furnace temperature, increasing oxygen concentration and particle concentration, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

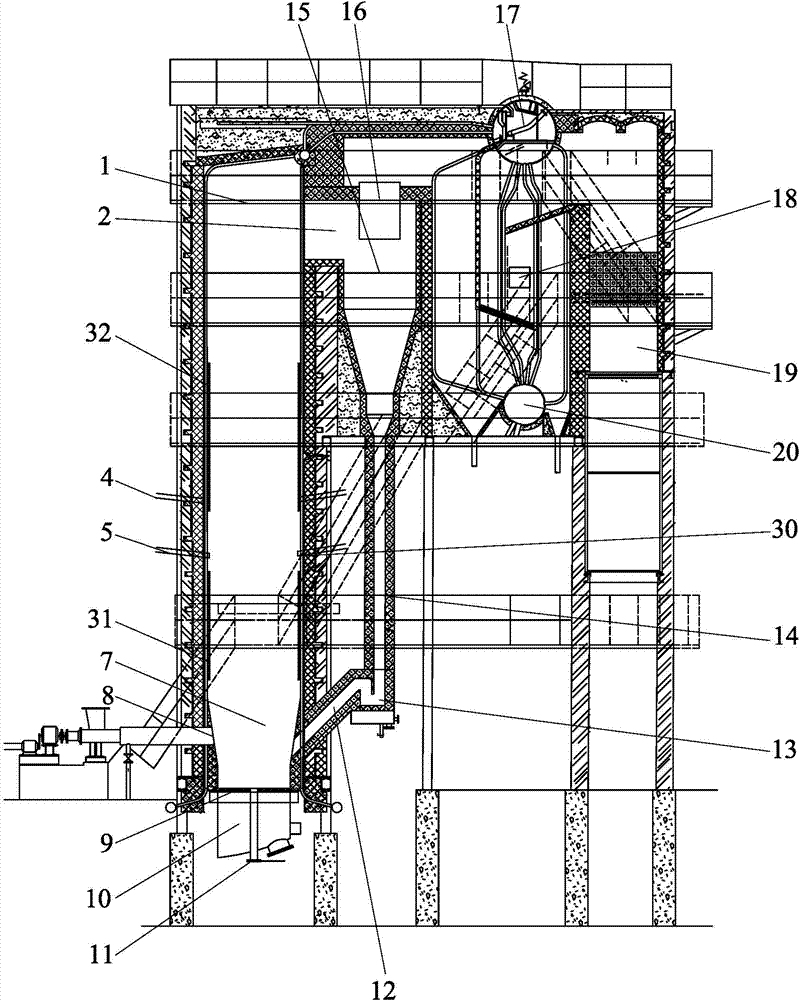

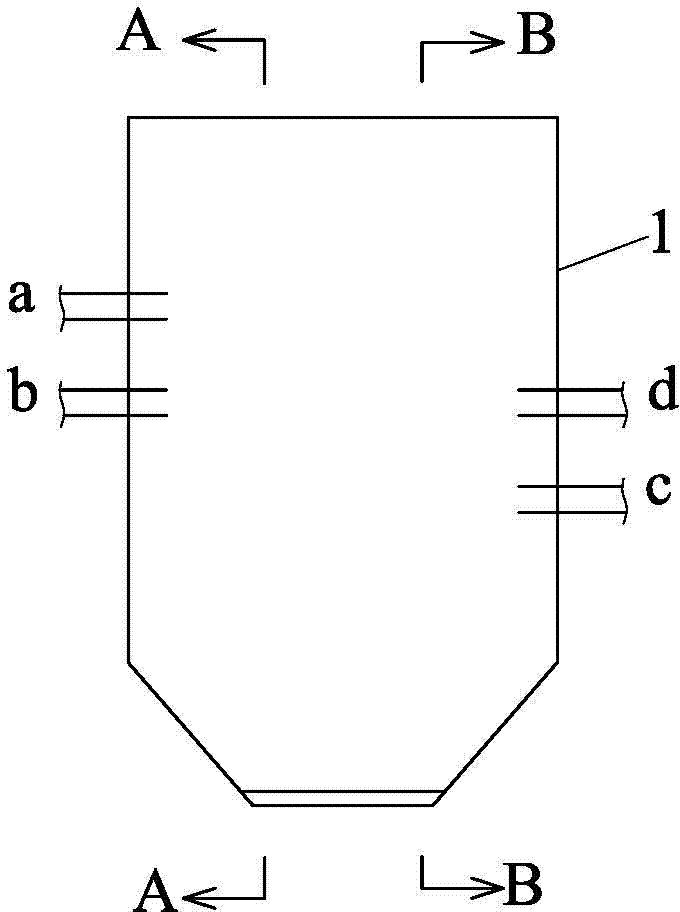

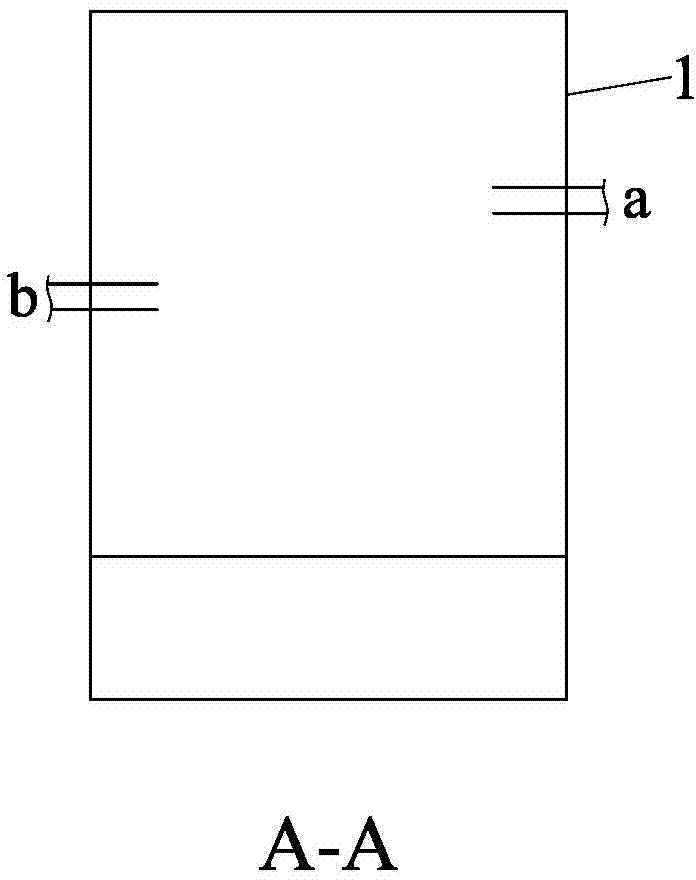

[0028] like figure 1 As shown, the present invention is a 20t / h high-efficiency circulating fluidized bed boiler for burning Fujian anthracite, which includes a membrane water-cooled hearth 1, an adiabatic cyclone separator 15, a feeding system 12, an upper drum 17, and a lower boiler Tube 20, S-shaped flue 18 and shaft flue 19.

[0029] The upper part of the dense-phase area of the membrane-type water-cooled hearth 1 is equipped with a 2m-high hygienic belt 31, and the middle part of the dilute-phase area is equipped with a 2m-high hygienic belt 32 to keep the furnace at a higher temperature. A guard combustion belt 31 is laid on the upper part of the dense phase area of the furnace 1 or a guard combustion belt 32 is only laid in the middle of the dilute phase area. The furnace outlet 2 is connected to the side opening of the adiabatic cyclone separator 15, and its upper central outlet tube 16 communicates with the S-shaped flue 18, and the outlet of the S-shaped flue 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com