Method and equipment for controlling growth of quantum dots

A growth control, quantum dot technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of quantum dot material properties, unsatisfactory application, inability to accurately control quantum dot positioning, and inability to control quantum dot positioning, etc. To achieve the effect of positioning controllable growth, cheap equipment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

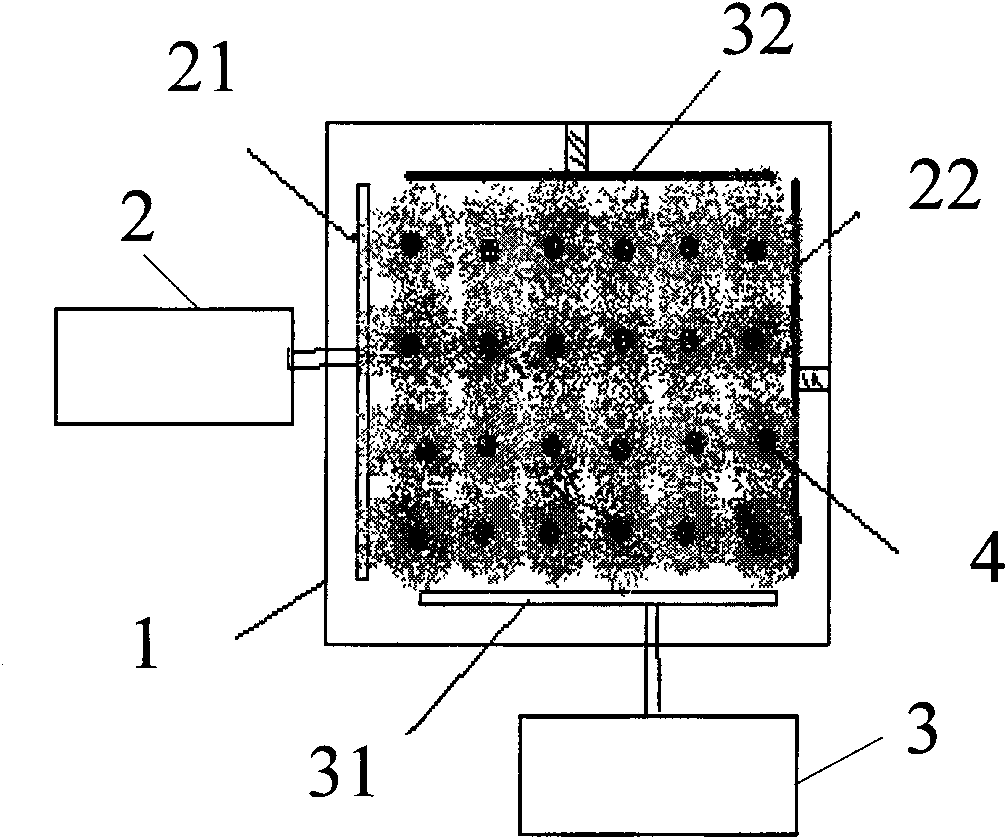

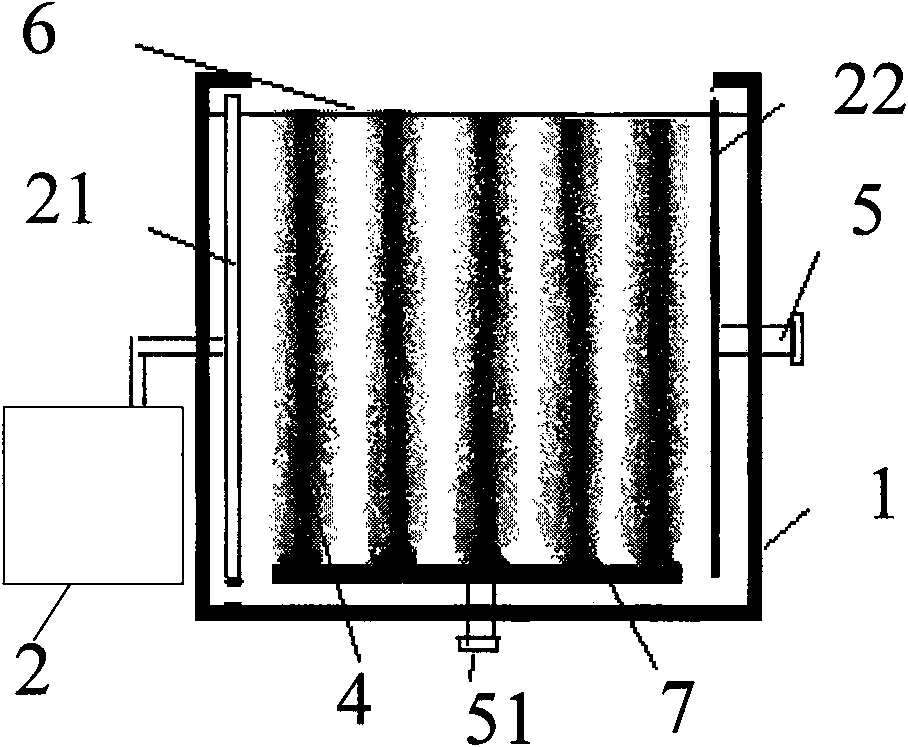

[0031] This embodiment provides a quantum dot growth control method, including:

[0032] The substrate used for growing quantum dots is arranged in a solution in which quantum dot materials are dissolved, and at least two columns of intersecting ultrasonic waves are arranged in the same horizontal plane above the substrate to form ultrasonic standing waves, so that the nodal columns formed by ultrasonic standing waves pointing to said substrate;

[0033] The quantum dot material in the solution settles and grows quantum dots on the substrate through the nodal columns formed by ultrasonic standing waves;

[0034] Adjusting the frequency or wavelength of the ultrasonic waves in the solution (that is, adjusting the spacing between the formed node columns) is used to adjust the growth position of the quantum dots on the substrate (including the row spacing, column spacing and density between the quantum dots). Among them, the frequency range of the ultrasonic wave can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com