Well type air seep carbon stove and improvement of process thereof

A carburizing furnace and tooling technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of extended carburizing cycle time, waste of carburizing agent, long carburizing cycle time, etc., and achieve product The effect of improving quality and product quality, increasing carburizing speed, and shortening carburizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

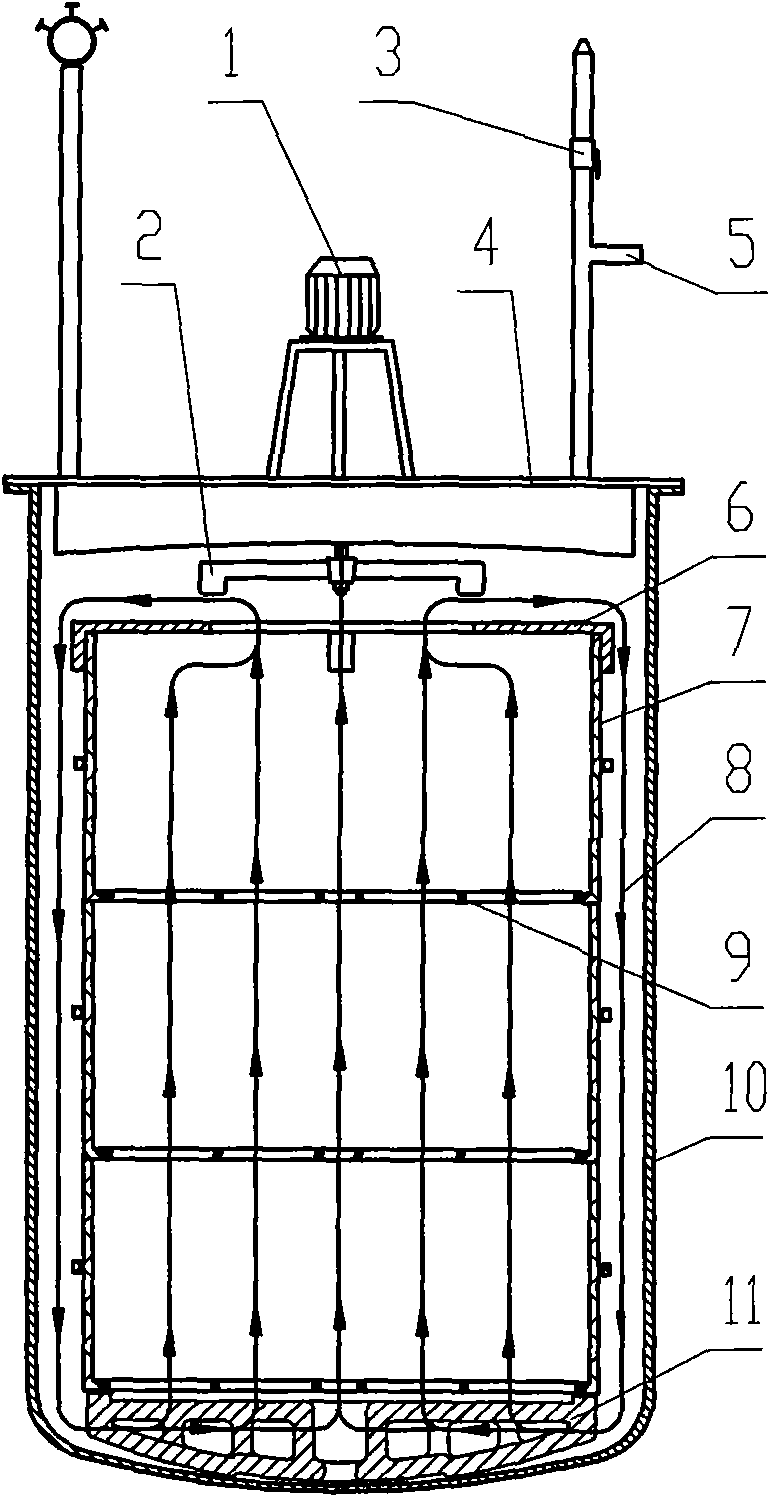

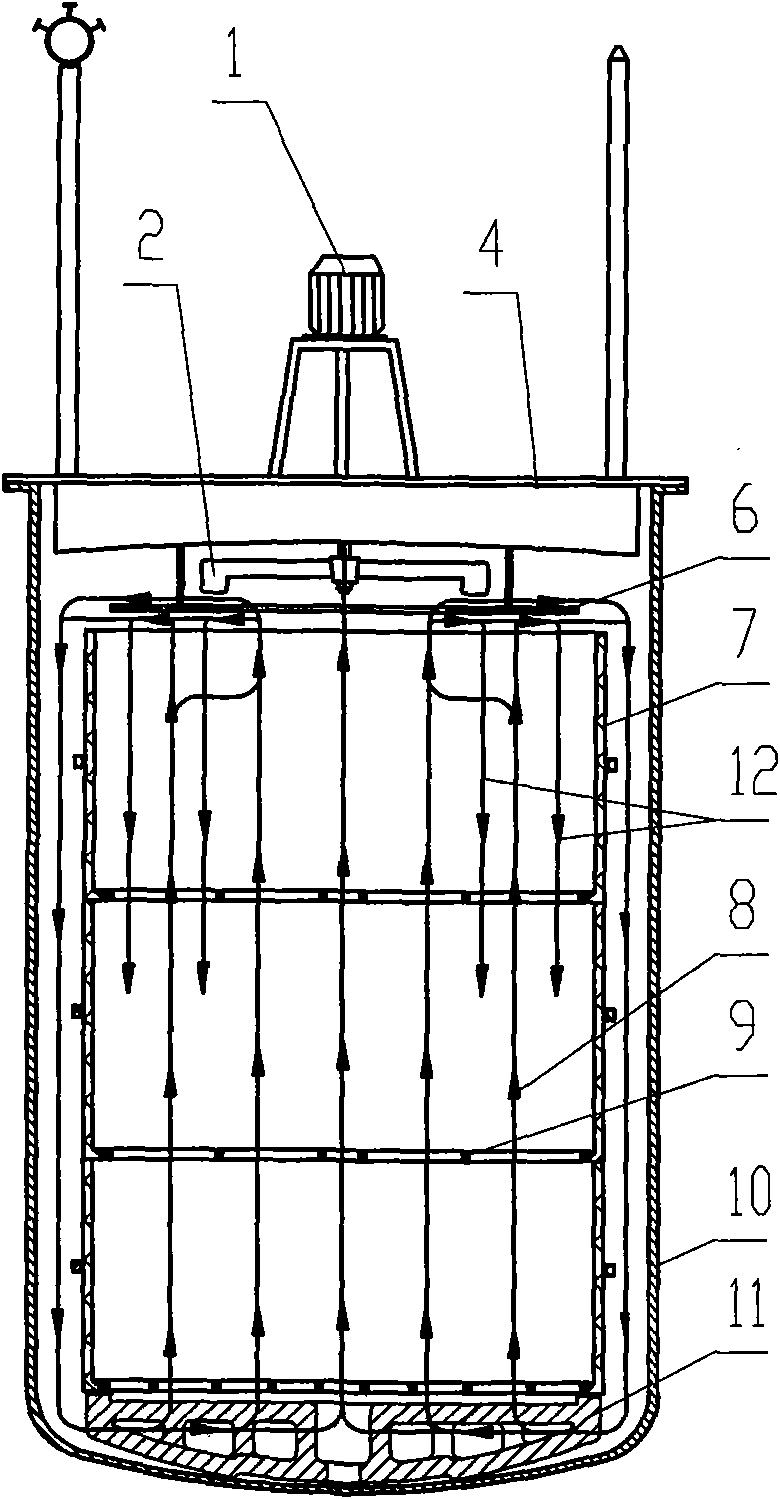

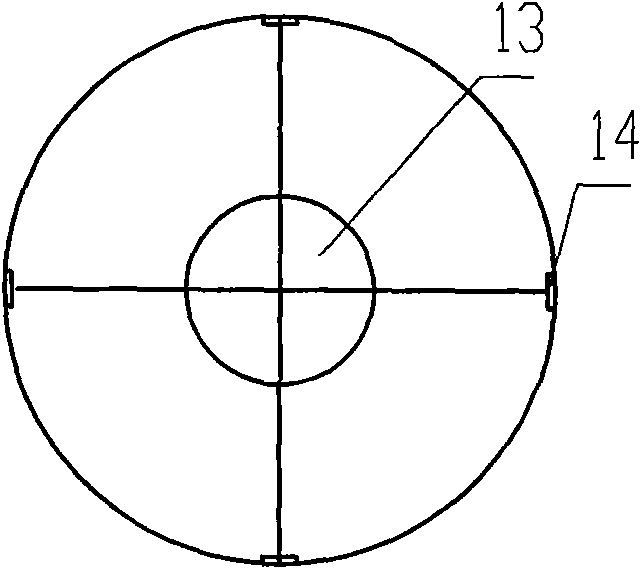

[0028] Such as figure 1 As shown, a well-type carburizing furnace includes a furnace body and heating elements arranged on the inner wall of the furnace, and also includes temperature control devices such as power distribution cabinets. In the furnace body, a retort 10 is arranged, a furnace cover 4 is arranged on the top of the retort 10, a motor 1 is installed above the furnace cover 4, a fan 2 connected to the motor 1 is installed below the furnace cover, and no connection with the motor 1 is installed below the fan. The windshield connected to the furnace cover; the furnace cover 4 is also equipped with an exhaust pipe and a drip injector for dripping carburizing agent, and a pressure regulating valve 3 is installed on the exhaust pipe. The pipe is also provided with a pressure gauge interface 5 connected with a pressure gauge. The pressure gauge here is a U-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com