Method for sound field separation by double plane vibration speed measurement and equivalent source method

A technology of equivalent source and sound field, applied in the field of noise, which can solve the problems of low calculation efficiency, low precision of normal particle vibration velocity, especially obvious error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

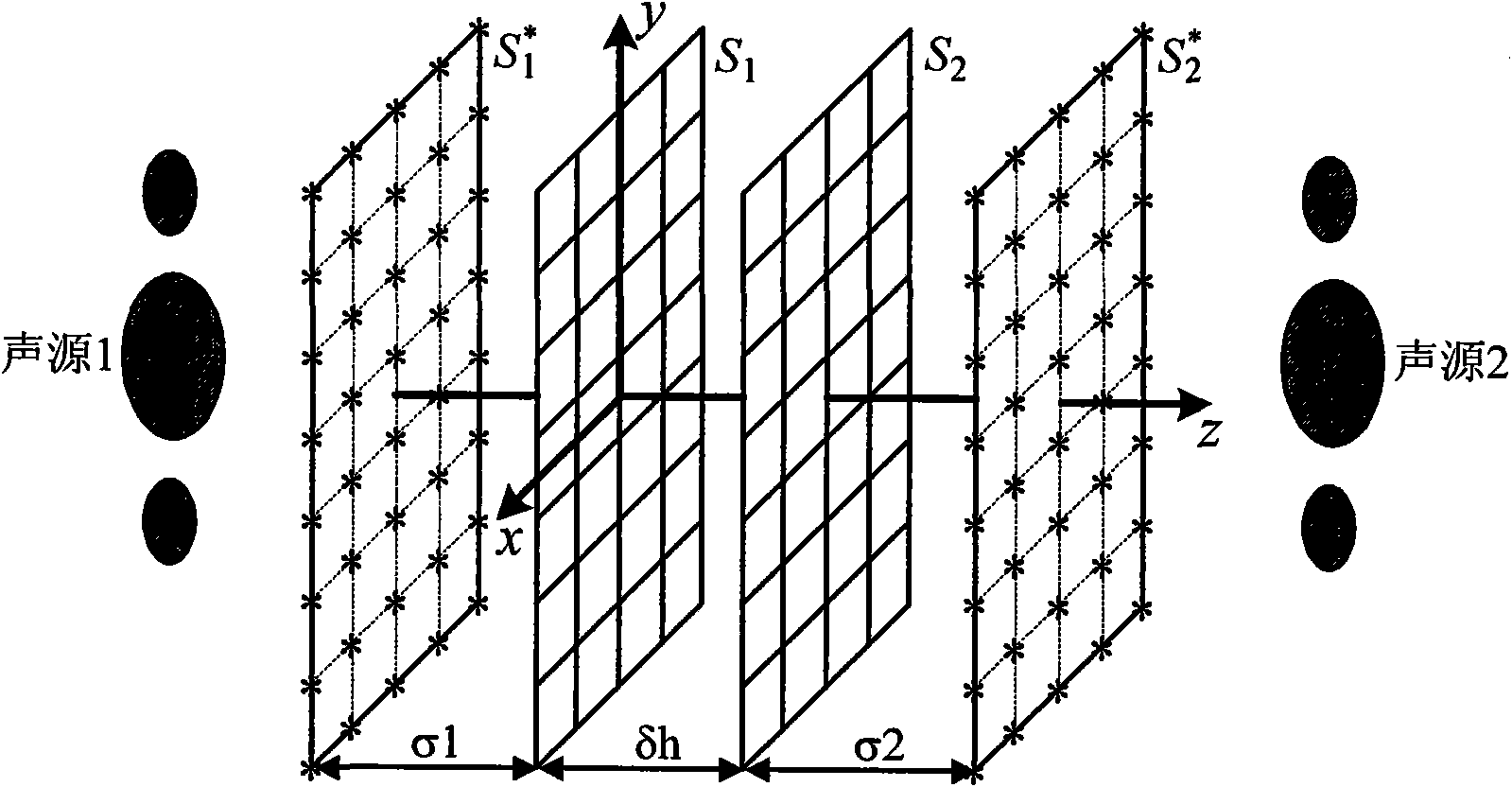

[0116] see figure 2 , in this embodiment, sound sources are distributed on both sides of the measurement surface, wherein sound source 1 is the main sound source, and sound source 2 is a noise source or a reflection or scattering source. In the measured sound field composed of sound source 1 and sound source 2 , there is a measurement surface S between sound source 1 and sound source 2 1 , on the measurement surface S 1 Set between the sound source 2 and the measurement surface S 1 Auxiliary measuring surface S parallel and separated by a distance of δh 2 ; Measuring grid points are respectively distributed on the two measuring surfaces, and the distance between adjacent grid points is less than half a wavelength; δh value is not zero, and is not greater than the minimum interval of measuring grid points.

[0117] The specific implementation steps are:

[0118] a. Use single or multiple particle velocity sensors to scan on the two measuring surfaces respectively, use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com