Method for producing STI lining oxide layer

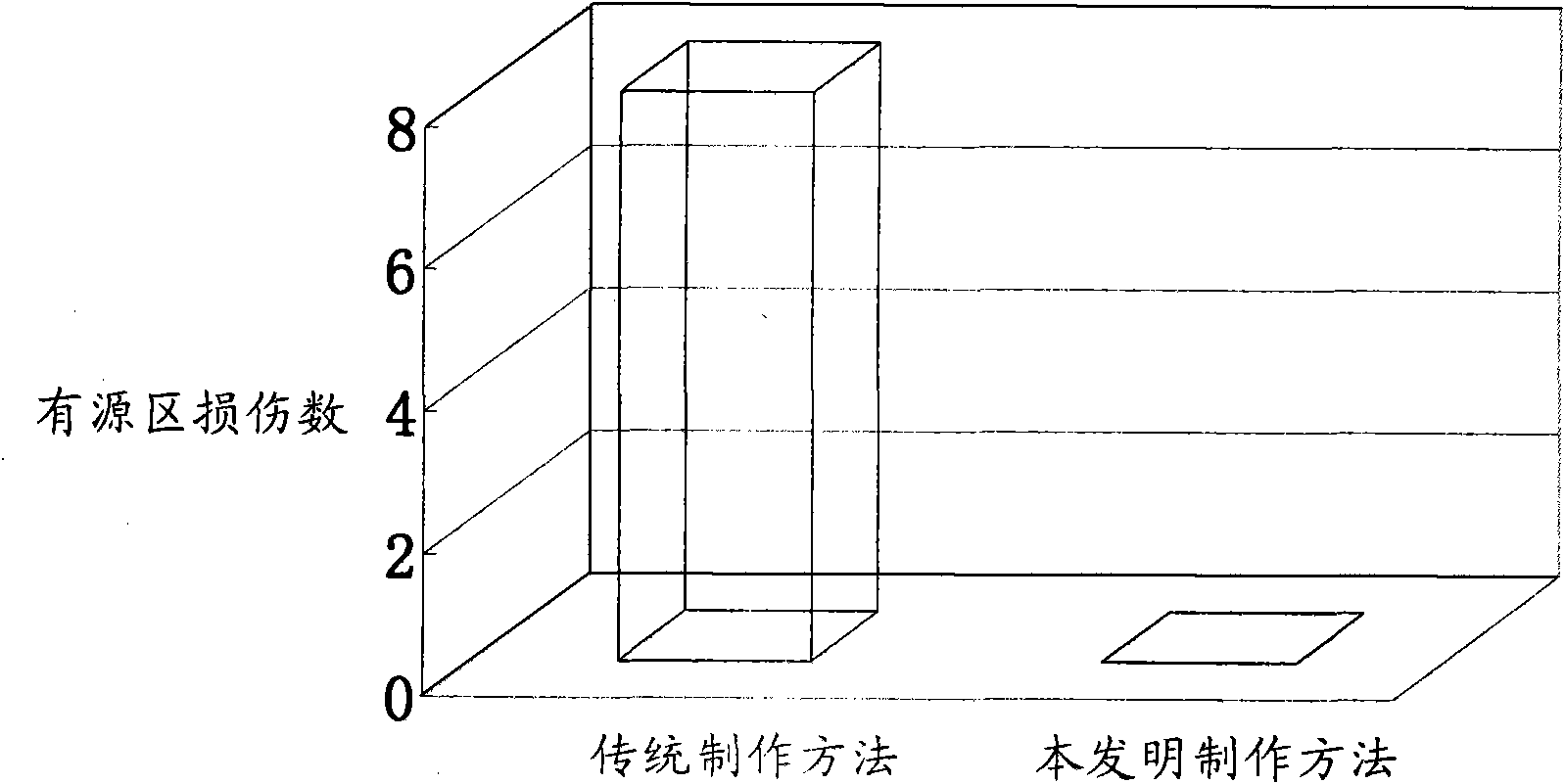

A technology of lining oxide layer and oxidizing gas, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as active area damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

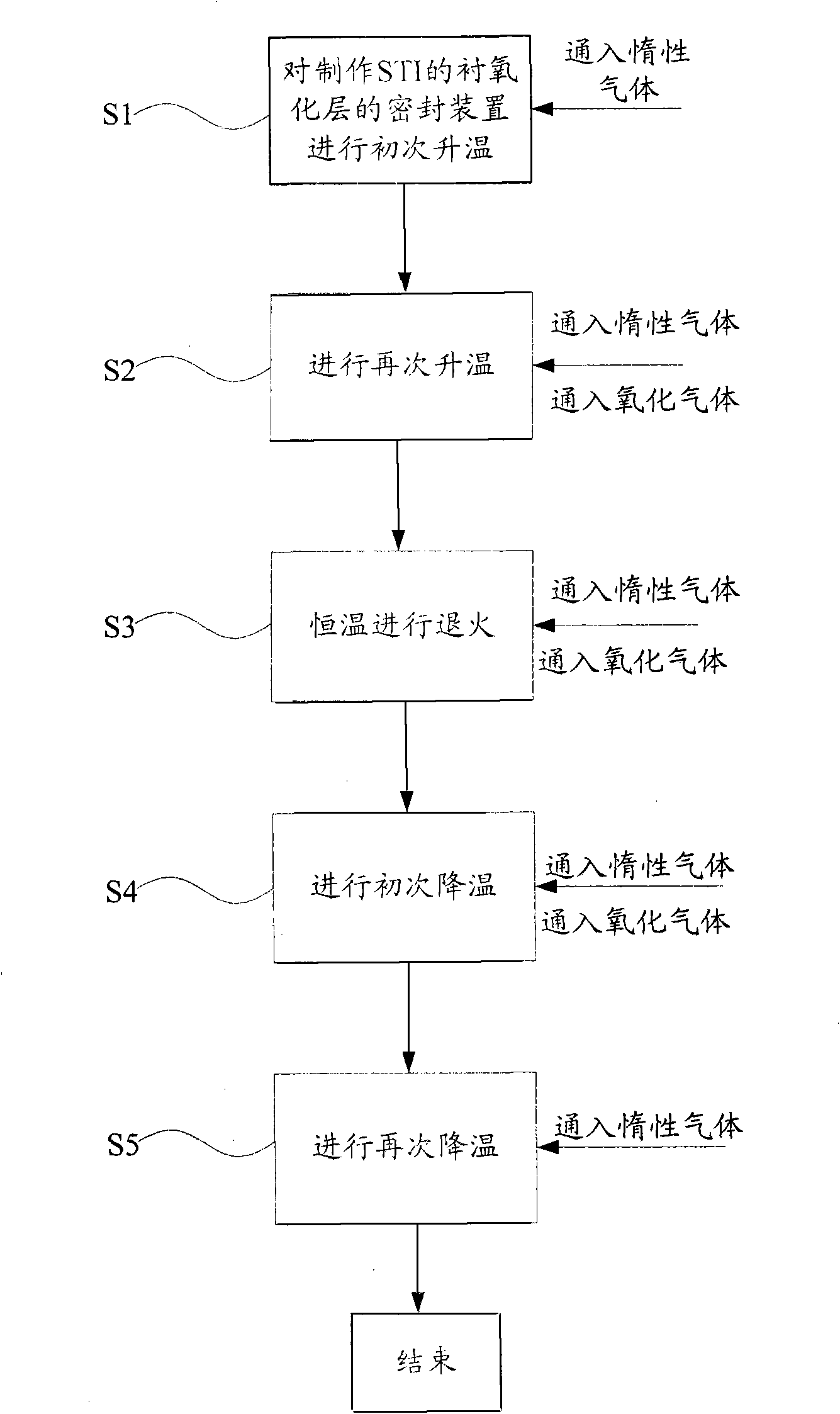

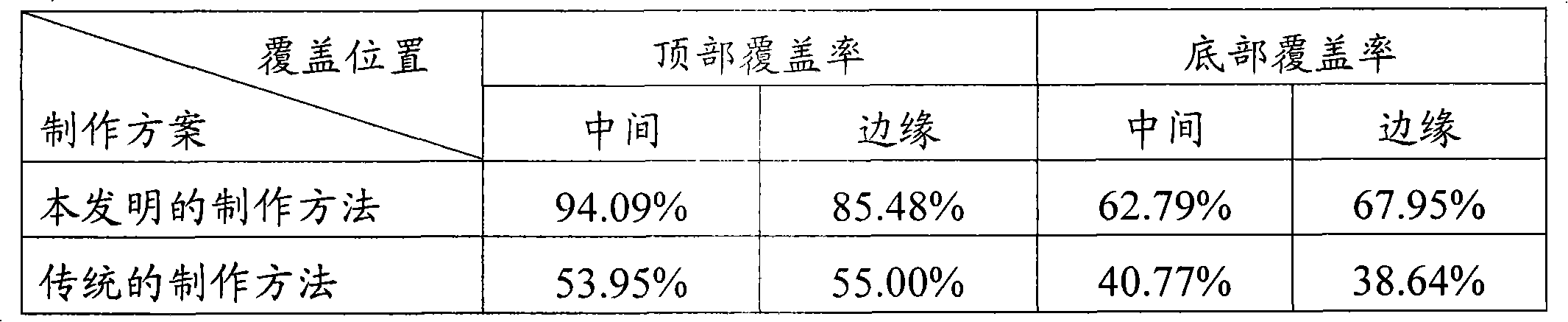

[0009] The lining oxide layer of STI is made by direct oxidation on the etched silicon substrate in the sealing device. The method for making the lining oxide layer of STI of the present invention comprises the following steps: Step 1: Pass the inert gas into the sealing device while heating up for the first time. Gas; step 2: enter the sealing device and heat up again to make it reach the temperature for making the lining oxide layer of STI, and at the same time pass inert gas and oxidizing gas into the sealing device to grow the lining oxide layer of STI. The temperature for making the lining oxide layer of STI is 950-1150 degrees Celsius. In order to better control the temperature of the sealing device, the initial temperature increase in step 1 is greater than the second temperature increase in step 2. In step 1, when the temperature of the sealing device is greatly increased to be close to the fabrication temperature of the STI liner oxide layer, a small increase in temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com