Five-face drilling-tapping central machine structure

A technology of center machine and shaft structure, which is applied to metal processing machinery parts, other manufacturing equipment/tools, driving devices, etc., can solve the problems such as the inability to add hydraulic clamps, inconvenience, slow moving speed, etc. The calibration process is convenient and safe, the cleaning of falling chips is convenient, and the processing speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

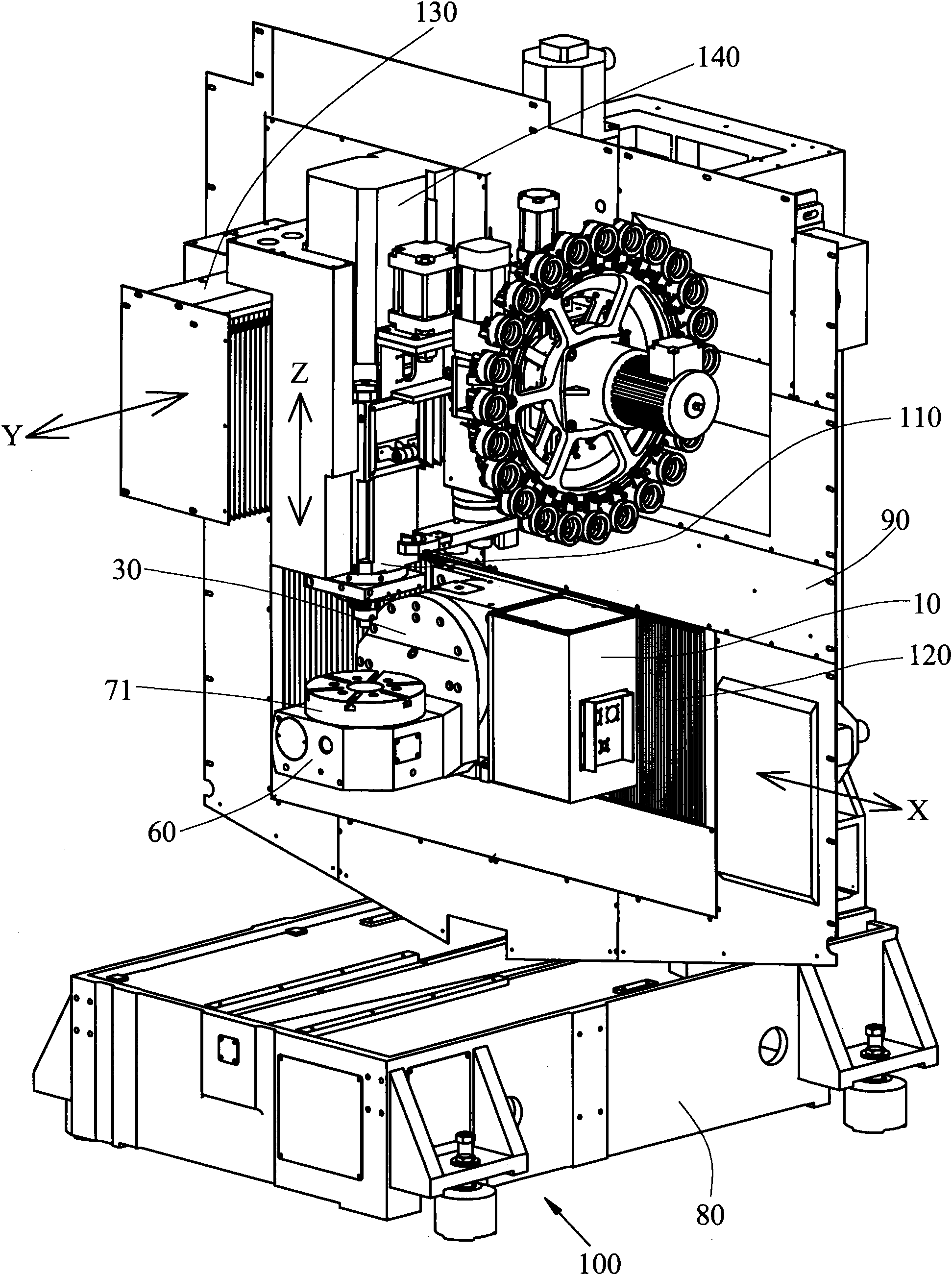

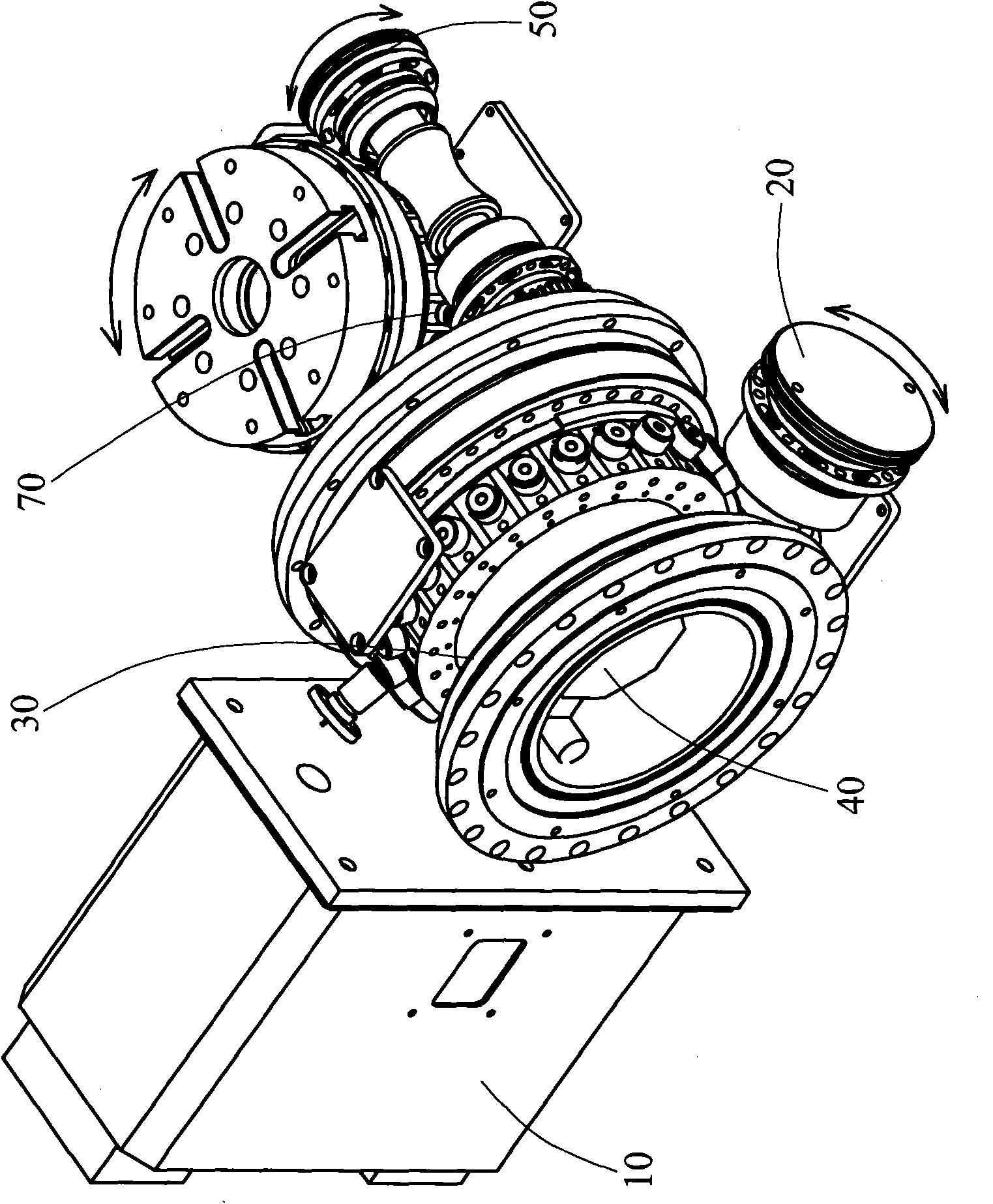

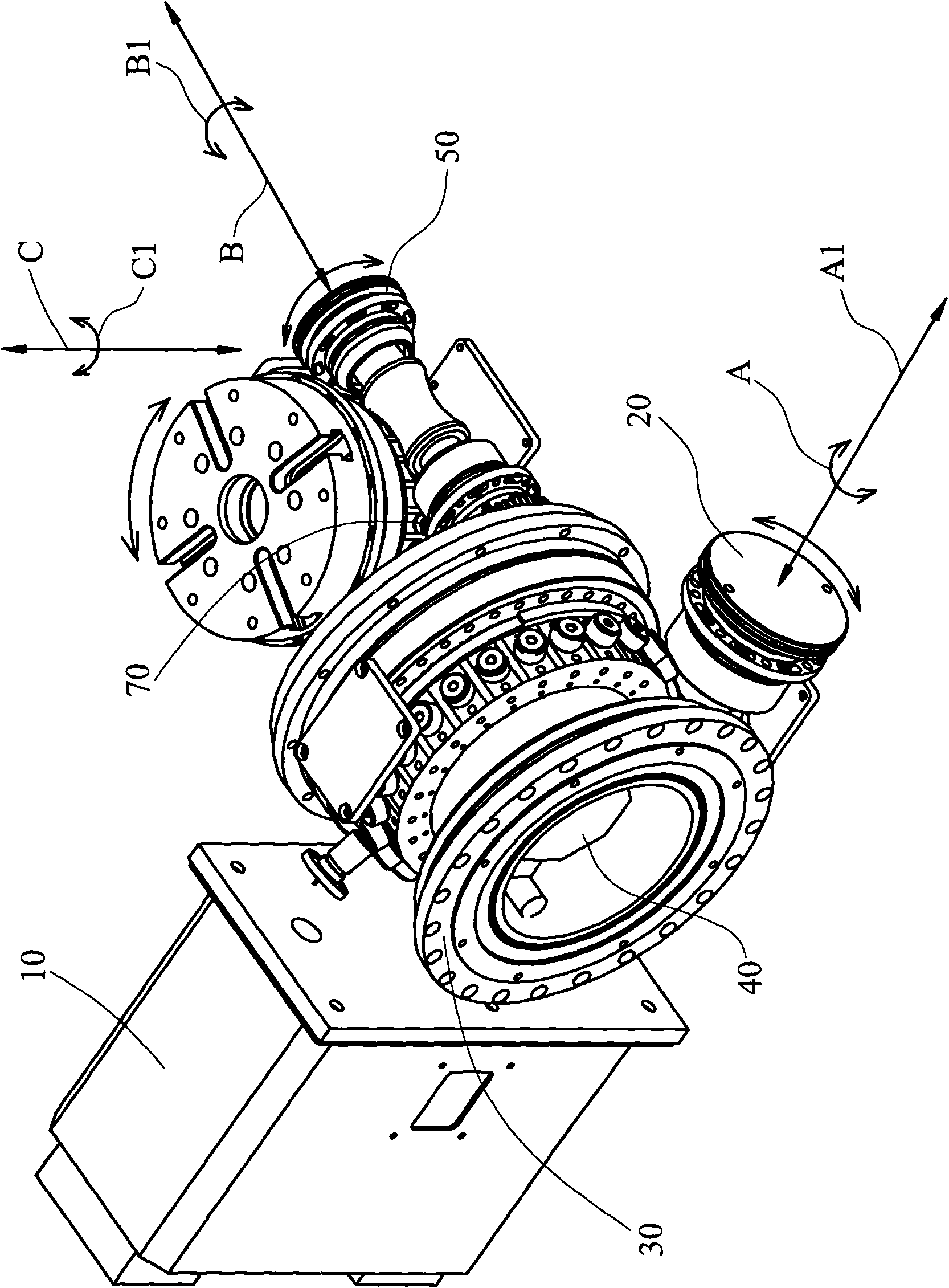

[0037] see Figure 1 ~ Figure 3 As shown, the present invention provides a five-sided drilling and tapping center machine structure, the fourth axis and the fifth axis structure are arranged on a machine platform 100, and the described machine platform 100 includes a base 80 and A column 90, the structure of the fourth shaft and the fifth shaft includes: a first servo motor 10, a first input shaft 20, a first output shaft roller 30, a second servo motor 40, a second The input shaft 50 , a supporting body 60 and a second output shaft roller 70 .

[0038]Wherein, the first servo motor 10 is electrically connected to a first power supply; the first output shaft roller 30 is a cam roller, and the first input shaft 20 corresponds to the first output shaft on the peripheral surface The roller 30 is provided with a tapered support rib not shown in the figure, the second output shaft roller 70 is a cam roller, and the second input shaft 50 is provided with a taper on the peripheral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com