Patents

Literature

32results about How to "Depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

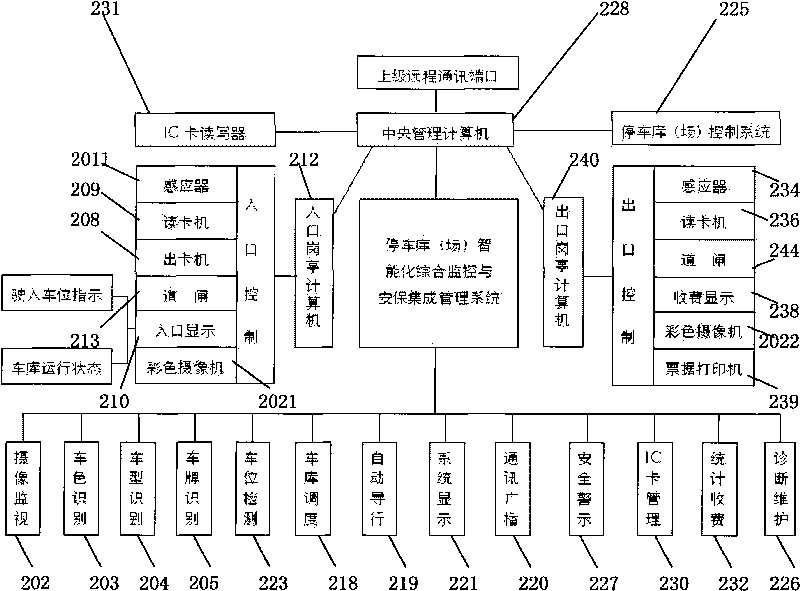

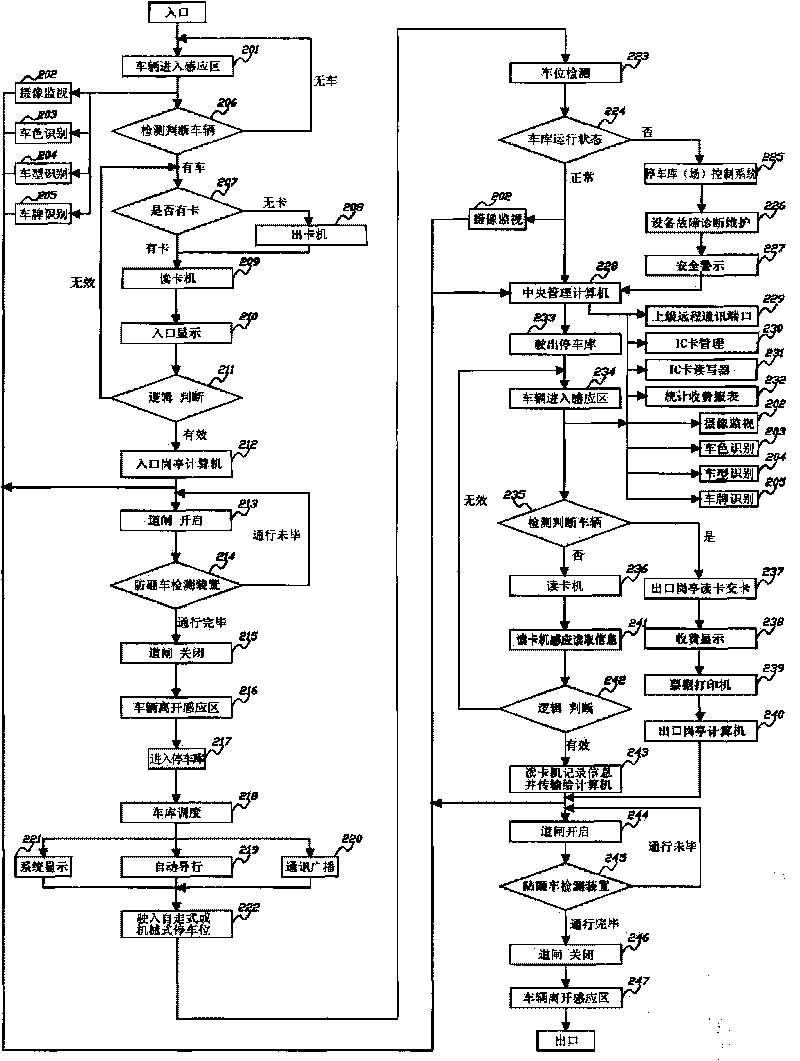

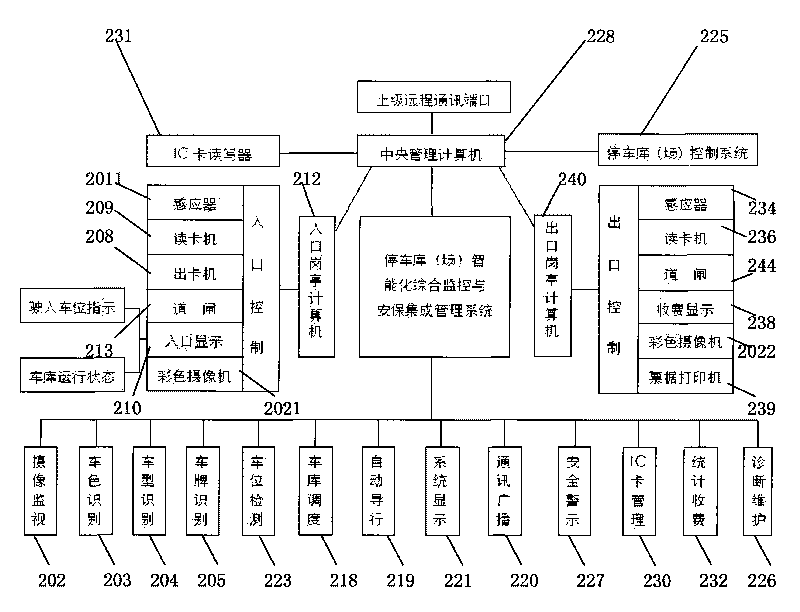

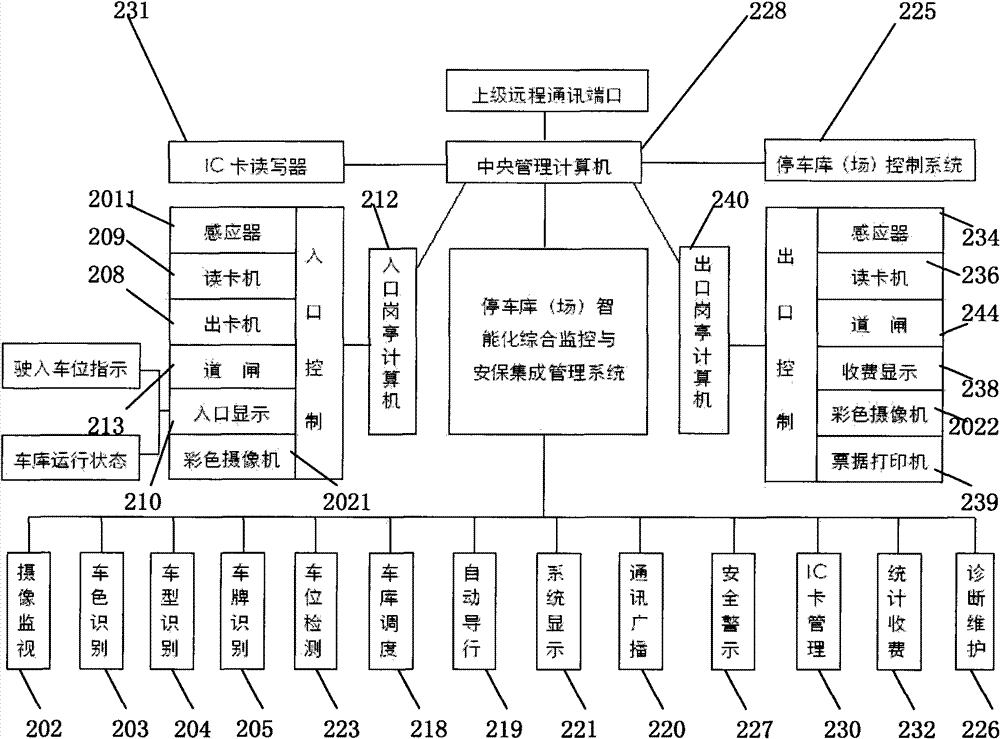

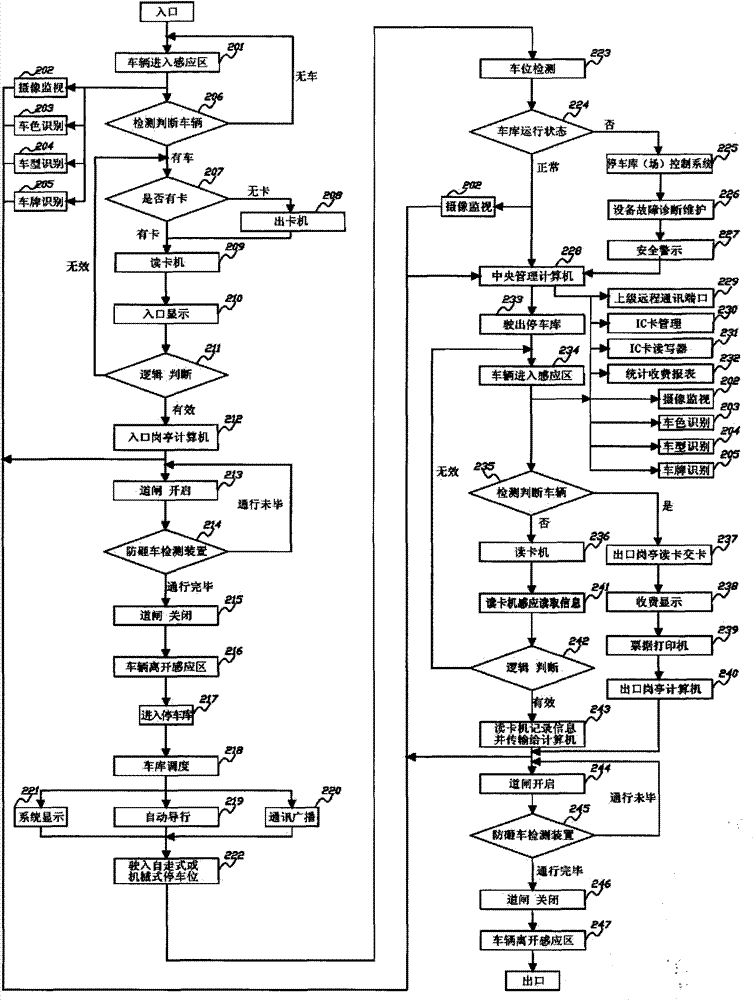

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841AComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

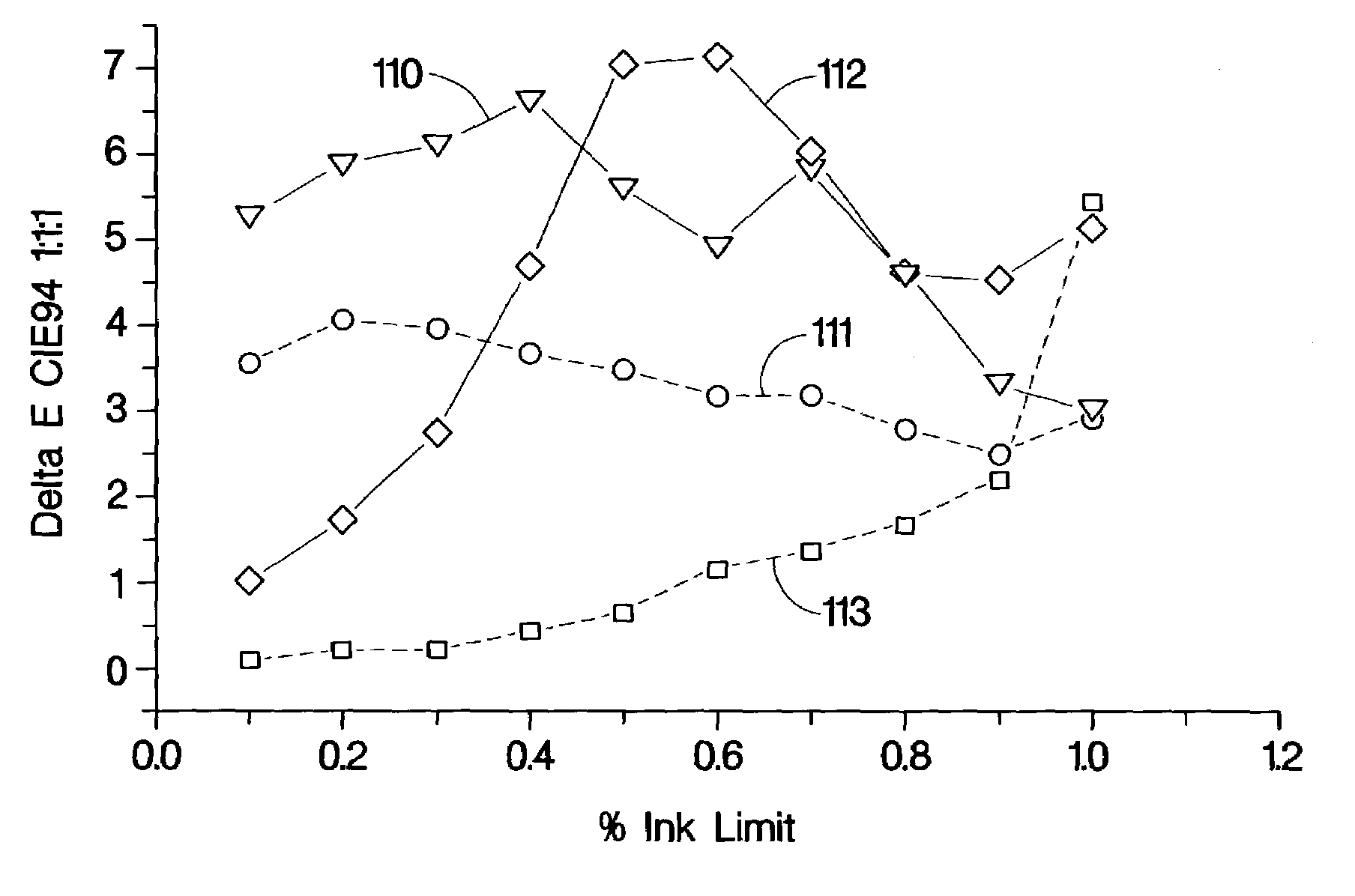

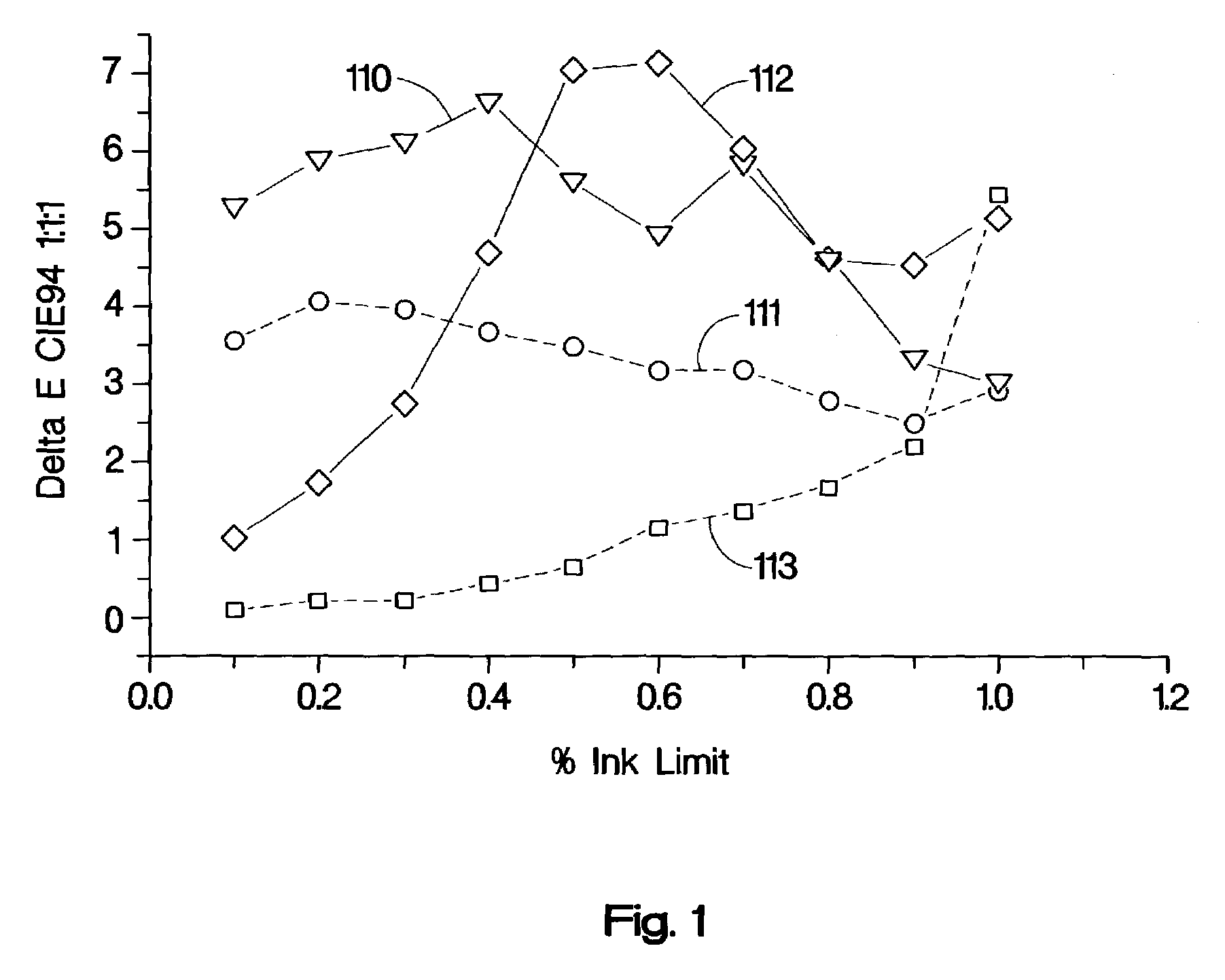

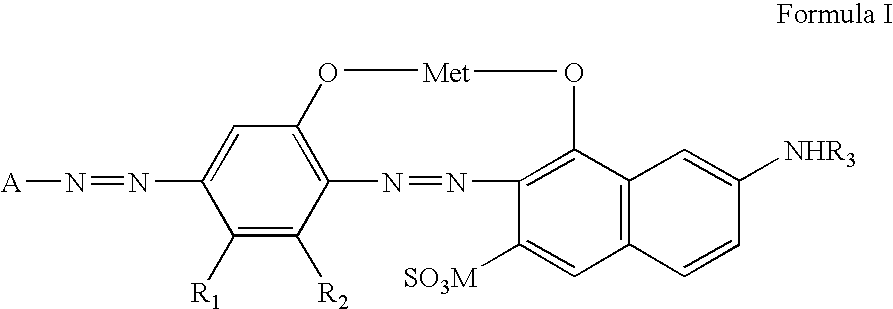

Gray inks for ink-jet printing

ActiveUS7033423B2Increase grayscaleEnhance the imageMeasurement apparatus componentsInksYELLOW DYEMagenta

A gray ink for ink-jet printing, comprising an ink vehicle; and at least one black dye selected from the group consisting of pacified Reactive Black 31, Formula I, and Direct Blue 199 TMA; and at least one yellow dye selected from the group consisting of AY23, Y104 and Y1189. Magenta and cyan dyes can also be used with the black and yellow dyes in the gray ink.

Owner:HEWLETT PACKARD DEV CO LP

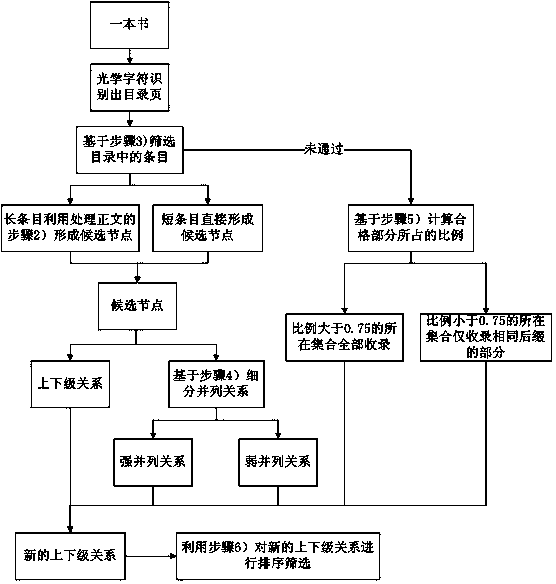

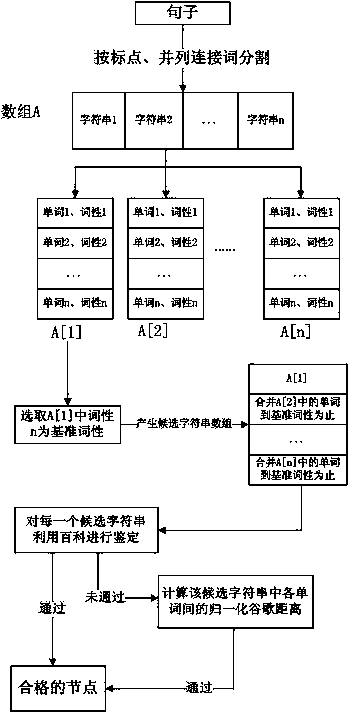

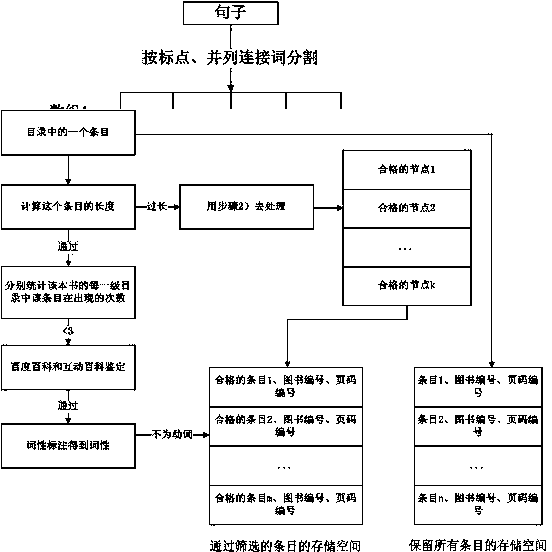

Method for establishing mapping knowledge domain based on book catalogue

ActiveCN103729402AImprove scalabilityRelationship richSpecial data processing applicationsNODALArray data structure

The invention discloses a method for establishing a mapping knowledge domain based on a book catalogue. The method comprises the steps that a catalogue page in a digitized book is extracted, the lengths of items in the catalogue are differentiated, and part-of-speech tagging is conducted on the long items through a natural language processing tool, so that part-of-speech arrays are obtained, and candidate nodes are extracted according to rules of conjunctions, punctuations and parts of speech; the long items and the short items are authenticated in the Baidu encyclopedia and the Hudong encyclopedia, a leader-member relation and parallel relations are formed through a catalogue structure and serve as a framework of the mapping knowledge domain, the strong and weak parallel relations are differentiated and serve as increments respectively, and the leader-member relation is supplemented with the strong and weak parallel relations; according to a noisy data excavating algorithm with suffixes serving as a base, nodes are selected from the items which do not pass the authentication of the encyclopedias and the mapping knowledge domain is supplemented with the selected nodes; finally, the weights of relations in the supplemented mapping knowledge domain are calculated and ranked, so that noise is removed through screening. Compared with an existing mapping knowledge domain, the mapping knowledge domain established through the method is richer in node, better in expandability and higher in accuracy.

Owner:ZHEJIANG UNIV

Method for preparing carved wood grain-simulated PVC decorative film

ActiveCN101531081AWith flame retardant functionSolve the disadvantage of being easy to burnFlexible coversWrappersColor printingSlurry

The invention relates to a method for preparing a carved wood grain-simulated PVC decorative film. The method comprises the following technological steps: preparing a PVC face film; preparing a PVC substrate; carrying out two to six sets of color printing on the surface of the PVC face film according to the pattern demands; adopting each set of color slurry, and entering the next set of color printing after printing each set of colors and drying the PVC face film at a temperature of 140 to 160 DEG C; preparing the colorful PVC face film; coiling the printed colorful PVC face film into a large coil; heating, pressing and jointing the printed colorful PVC face film and the PVC substrate on a dual-roller jointing embossing machine, making pressing rollers used for pressing the colorful PVC face film surface be wood thorn embossing rubber rollers, and adjusting the temperature of both rollers to between 100 and 200 DEG C; directly loading the jointed and embossed PVC decorative film into a drying box to carry out secondary heating to 200 to 220 DEG C, and foaming the PVC face film; and cooling the PVC face film. The carved wood grain-simulated PVC decorative film prepared by the method has the advantages of flame retardant function, lifelike sculpture, hollow three-dimensional view and flash discoloration functions.

Owner:ECONESS ENERGY

Preparing method for carving simulating UV scratch resisting wood grain decoration film

InactiveCN107877892ANot easily stainedImprove scratch resistanceFlat articlesWood splinterEngineering

The invention relates to a preparing method for a carving simulating UV scratch resisting wood grain decoration film. The preparing method comprises the technology steps that a PVC face film is prepared; a PVC base material is prepared; two to six polychrome printing is conducted on the surface of the PVC face film according to pattern requirements; color pulp of one color in each set is adopted,a colorful PVC face film is prepared, and finally the printed colorful PVC face film is rolled into a big roll; the printed colorful PVC face film and the PVC base material are heated, pressurized andattached on a double-roller attaching embossing machine, press rollers pressing and attaching the face of the PVC face film are wood splinter embossing rubber rollers, and the temperature of the tworollers can be adjusted to range from 100 DEG C to 200 DEG C; and the attached and embossed PVC decoration film is fed to a printing machine and coated with UV to be conveyed into an oven, secondary temperature increasing is conducted to range from 200 DEG C to 220 DEG C, and PVC face film foaming and cooling are conducted. The carving simulating UV scratch resisting wood grain decoration film prepared through the method has the functions of being capable of achieving the three-dimensional hand feeling, scratch resistance, inflaming retarding, rich colors, carving hollow-out three-dimension and flickering color changing.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

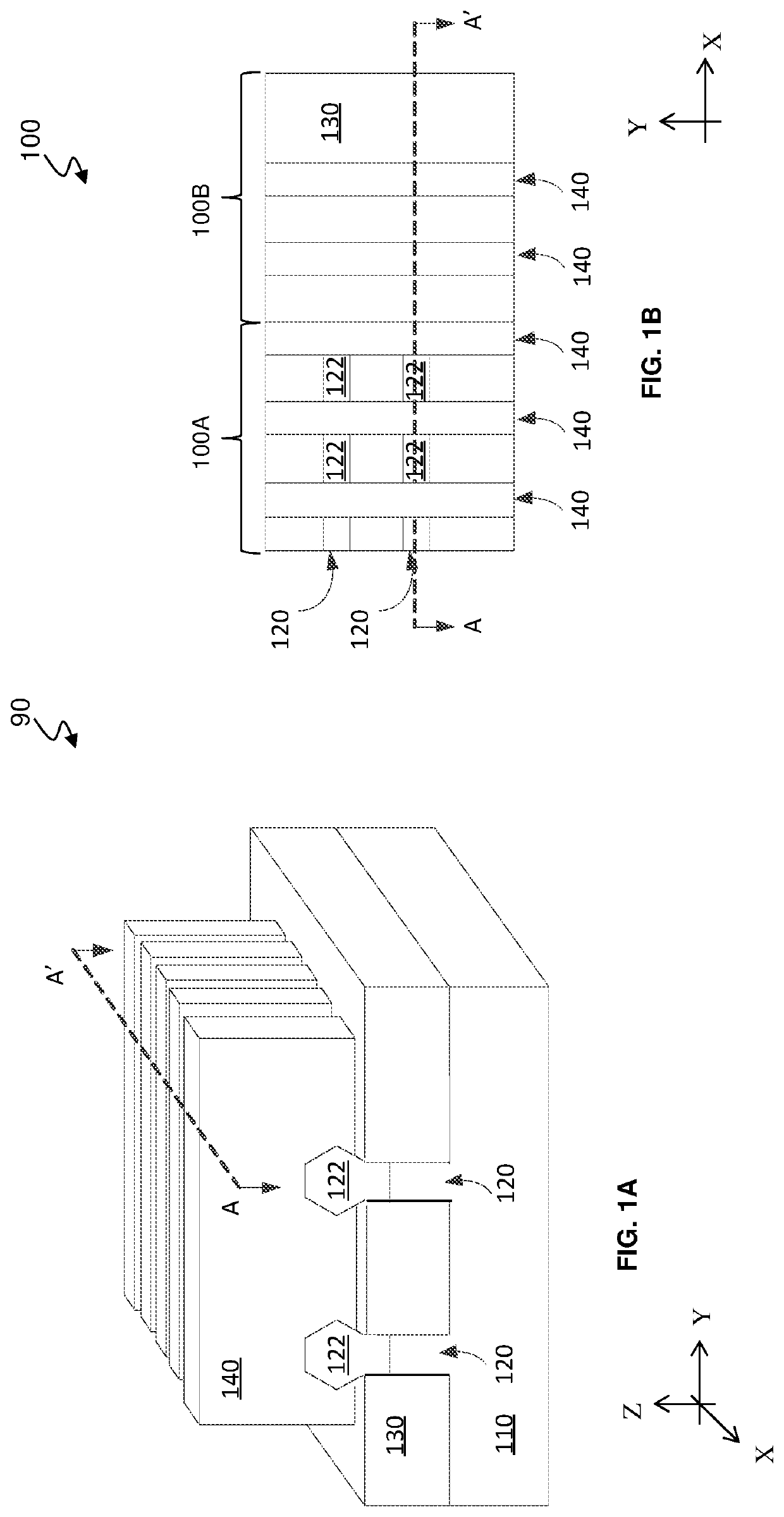

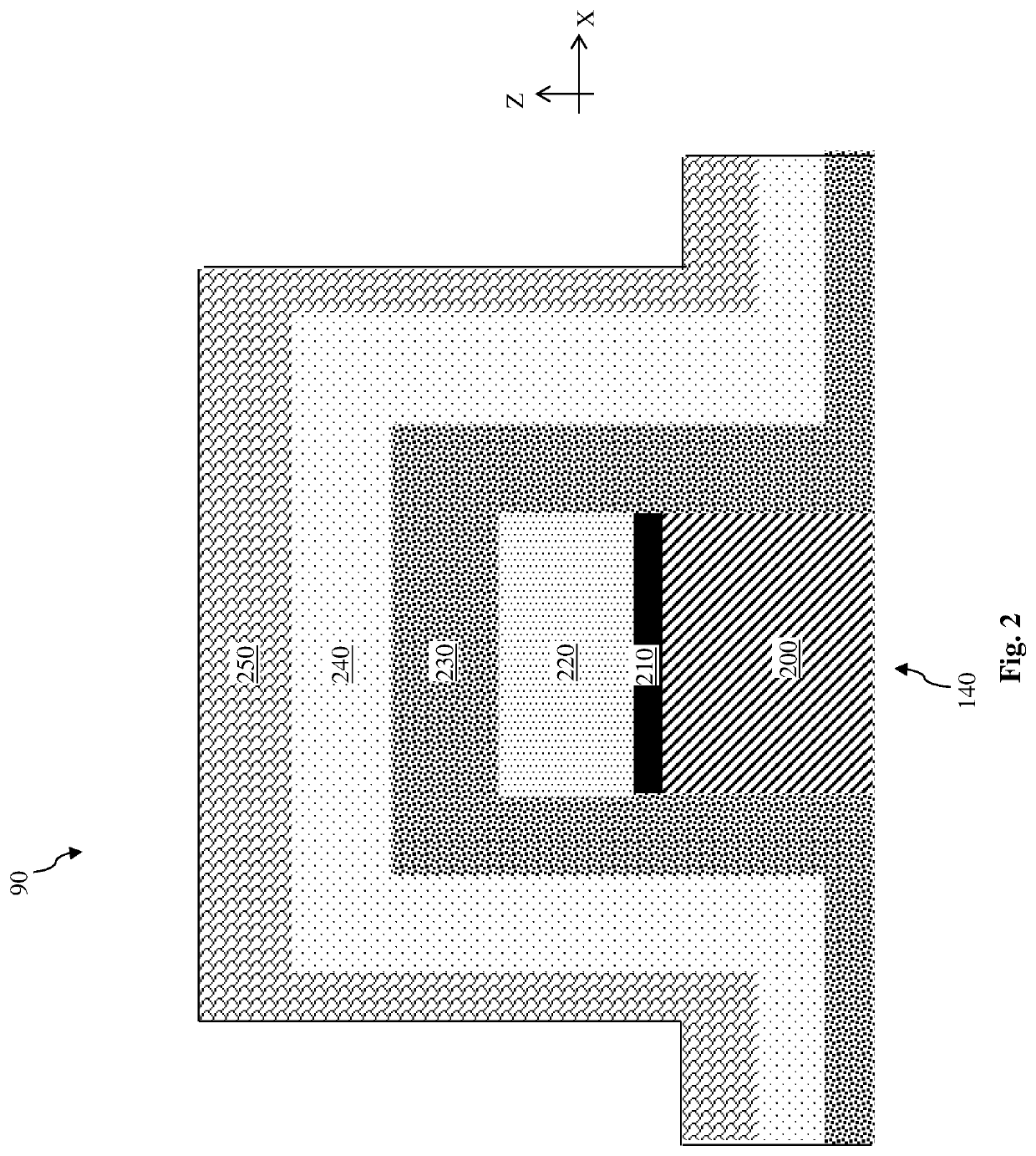

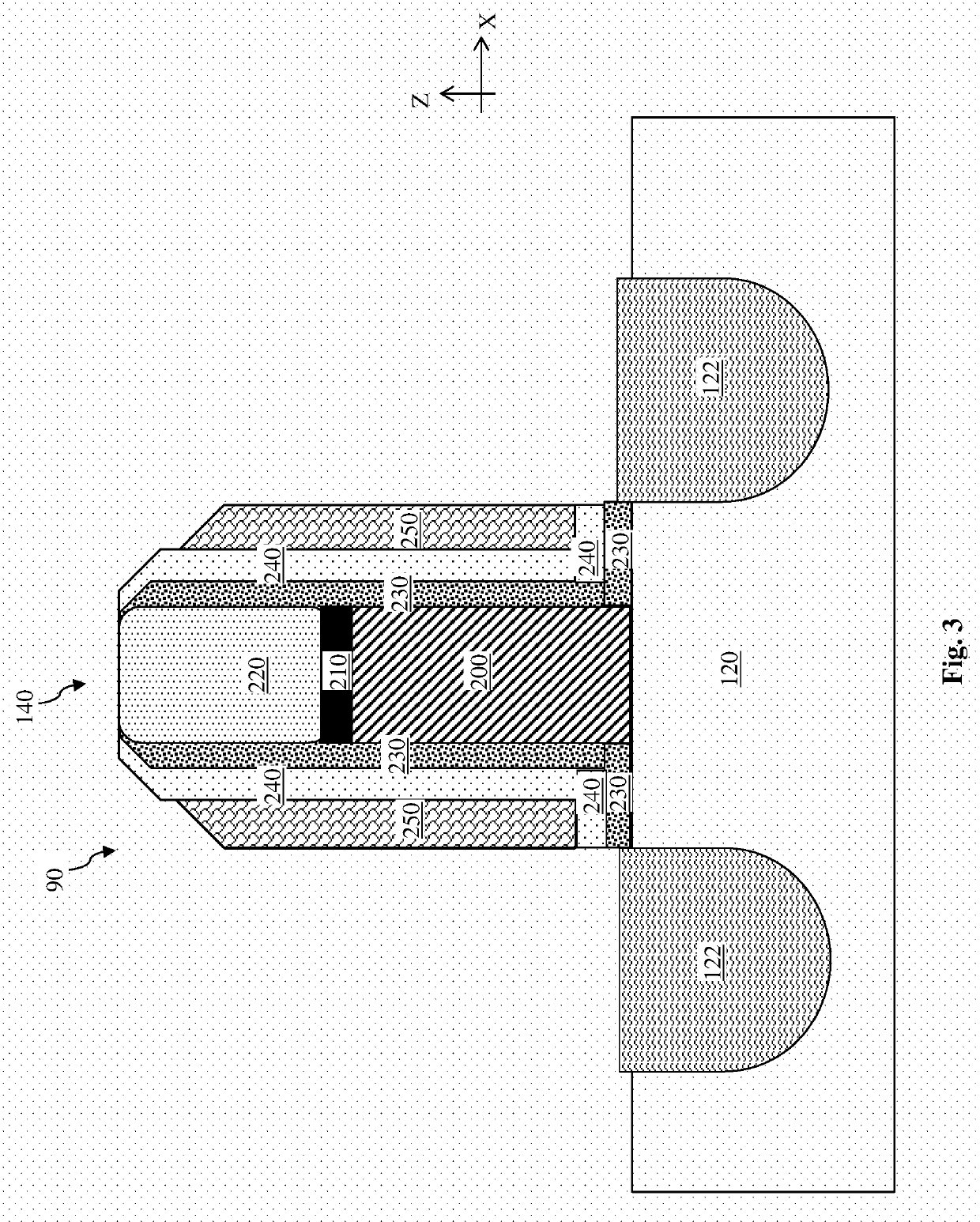

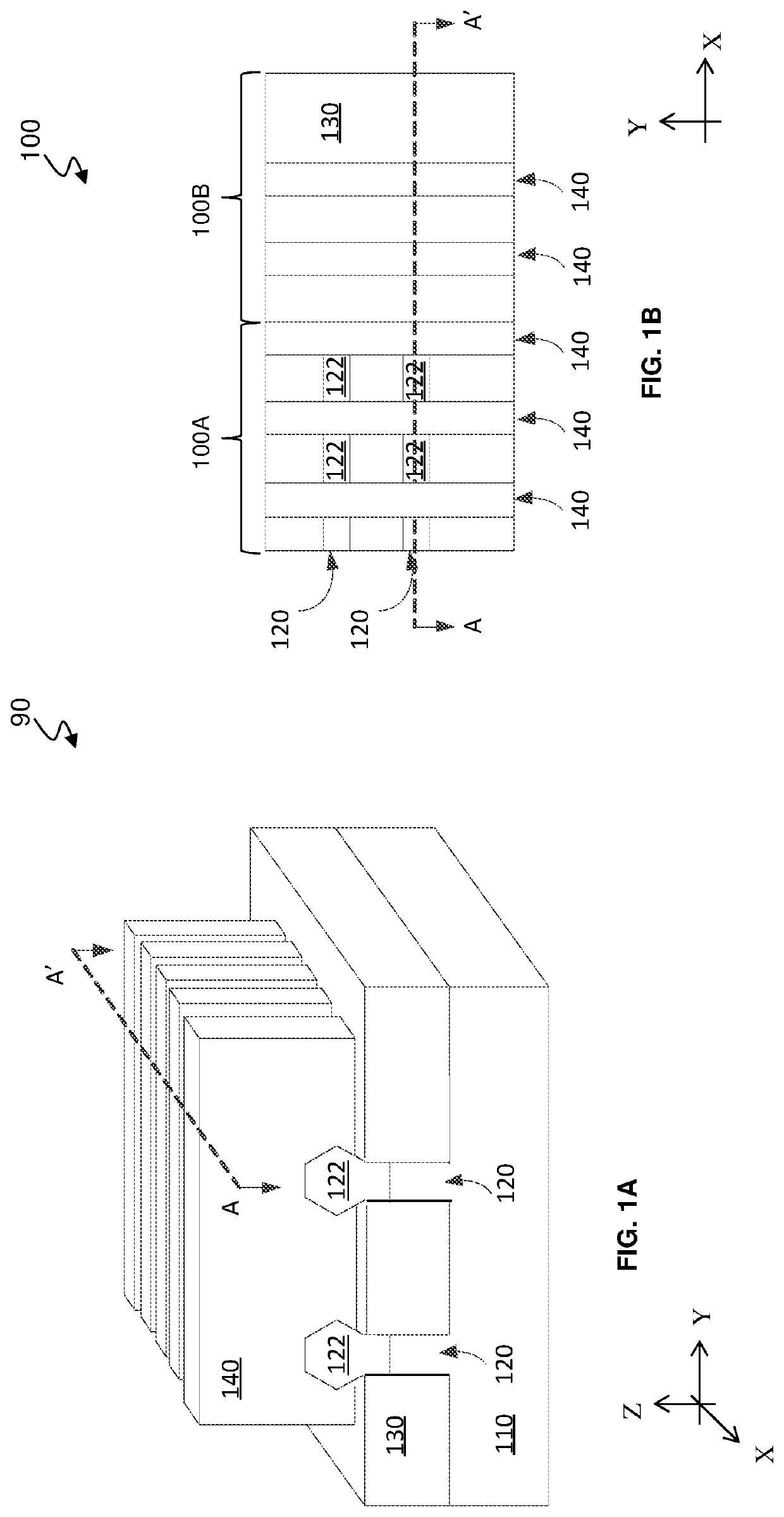

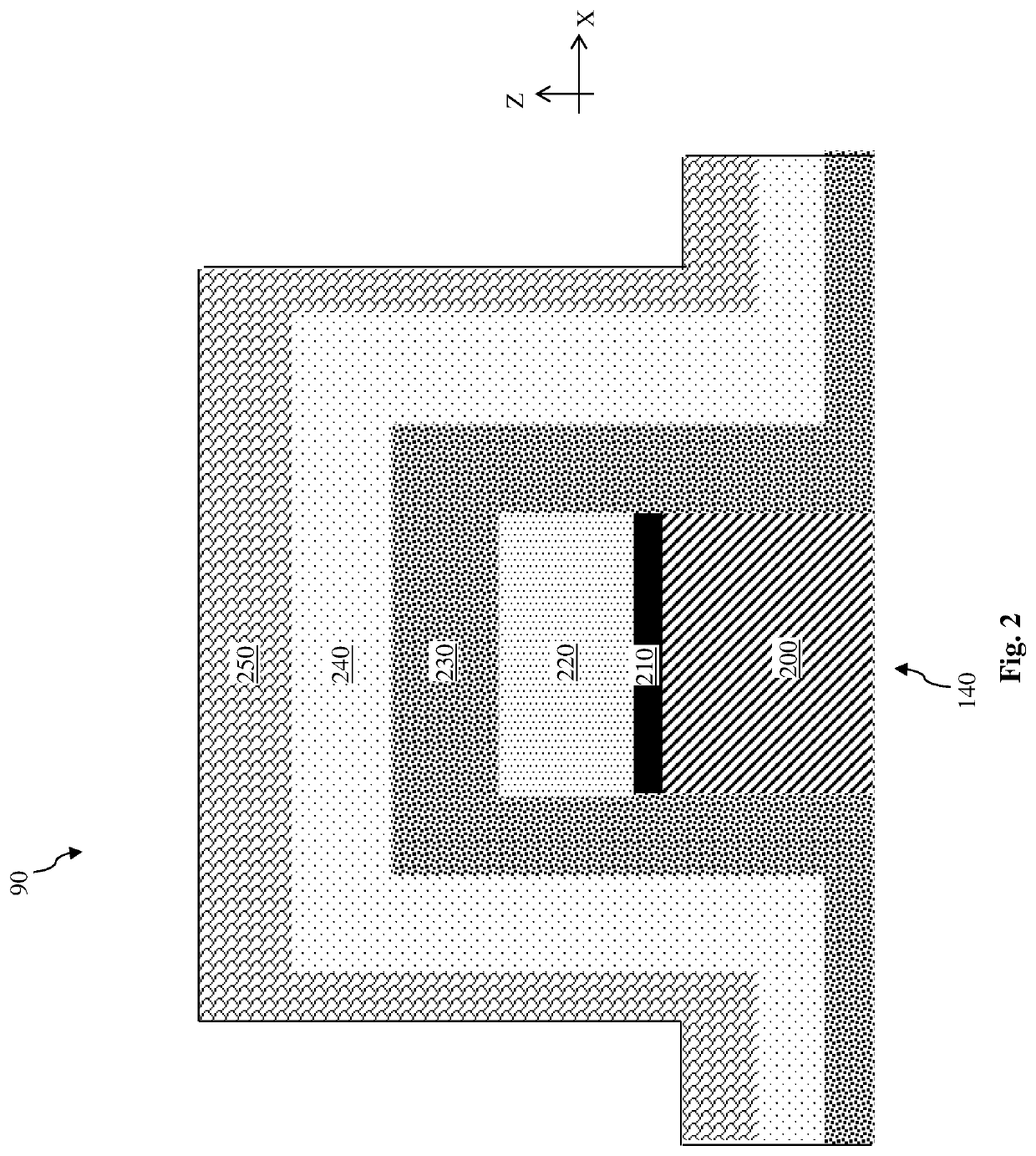

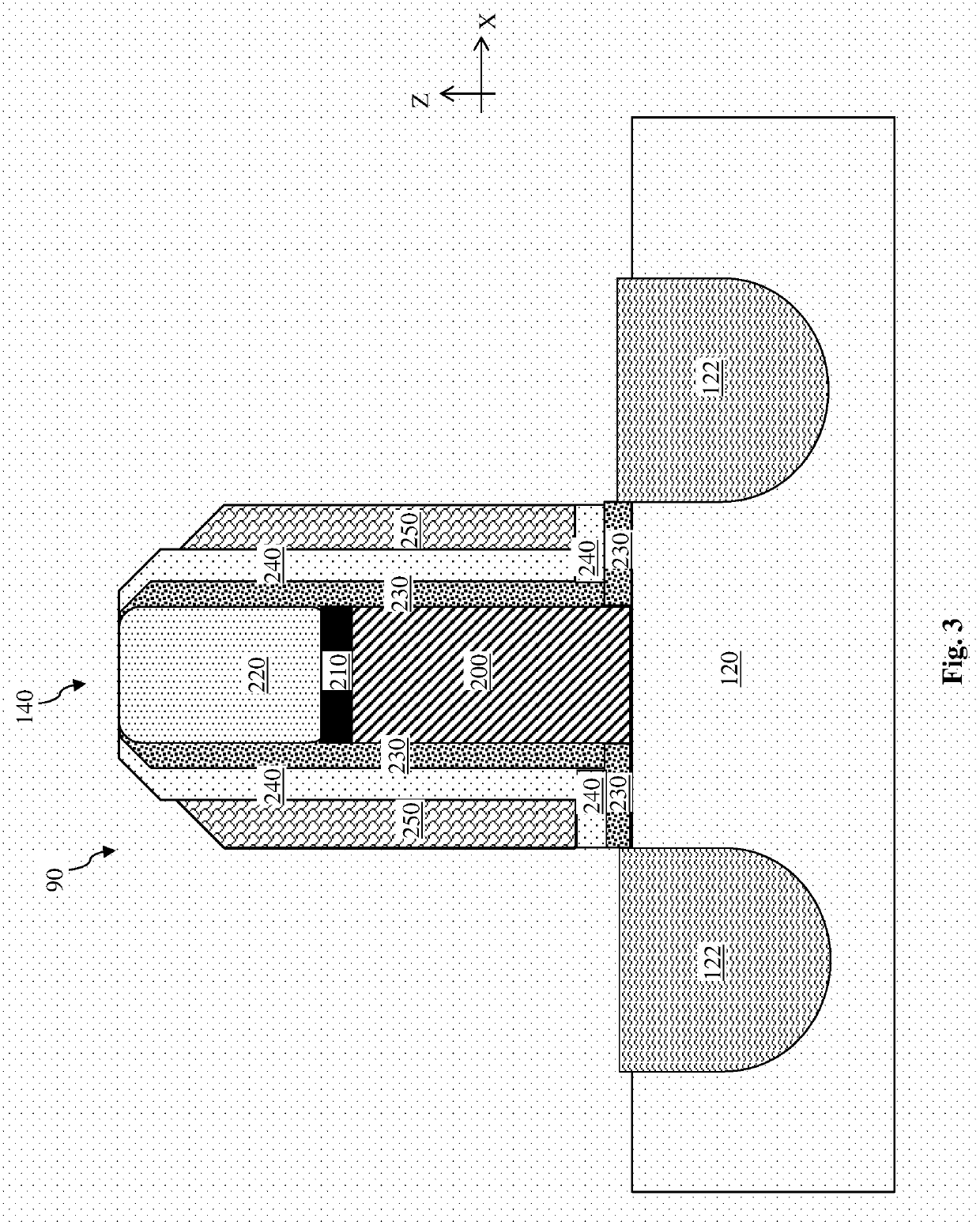

Air spacer for a gate structure of a transistor

ActiveUS20200098886A1DepthReduce riskTransistorSolid-state devicesSemiconductor structureEngineering

A semiconductor structure includes a first device and a second device. The first device includes: a first gate structure formed over an active region and a first air spacer disposed adjacent to the first gate structure. The second device includes: a second gate structure formed over an isolation structure and a second air spacer disposed adjacent to the second gate structure. The first air spacer and the second air spacer have different sizes.

Owner:TAIWAN SEMICON MFG CO LTD

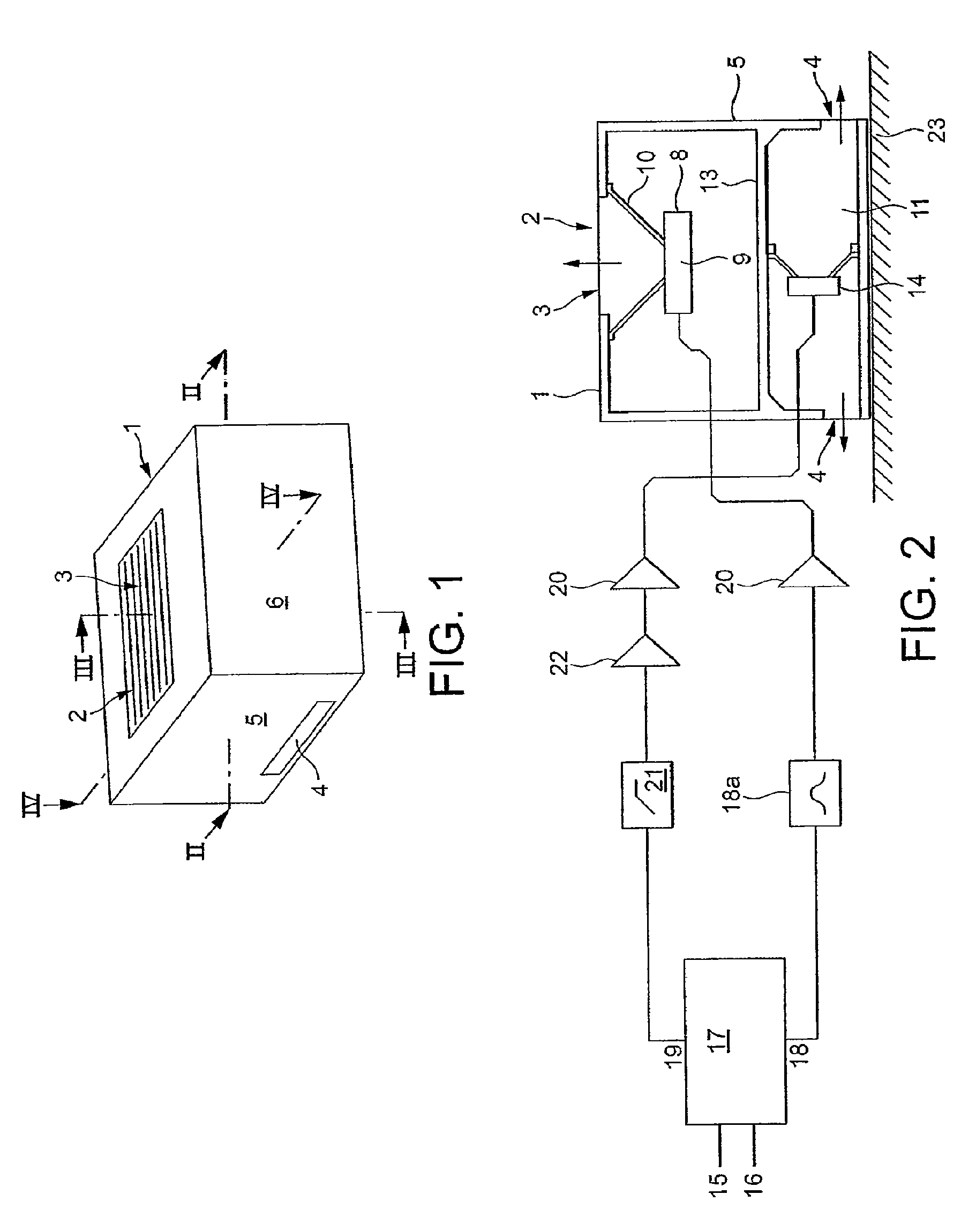

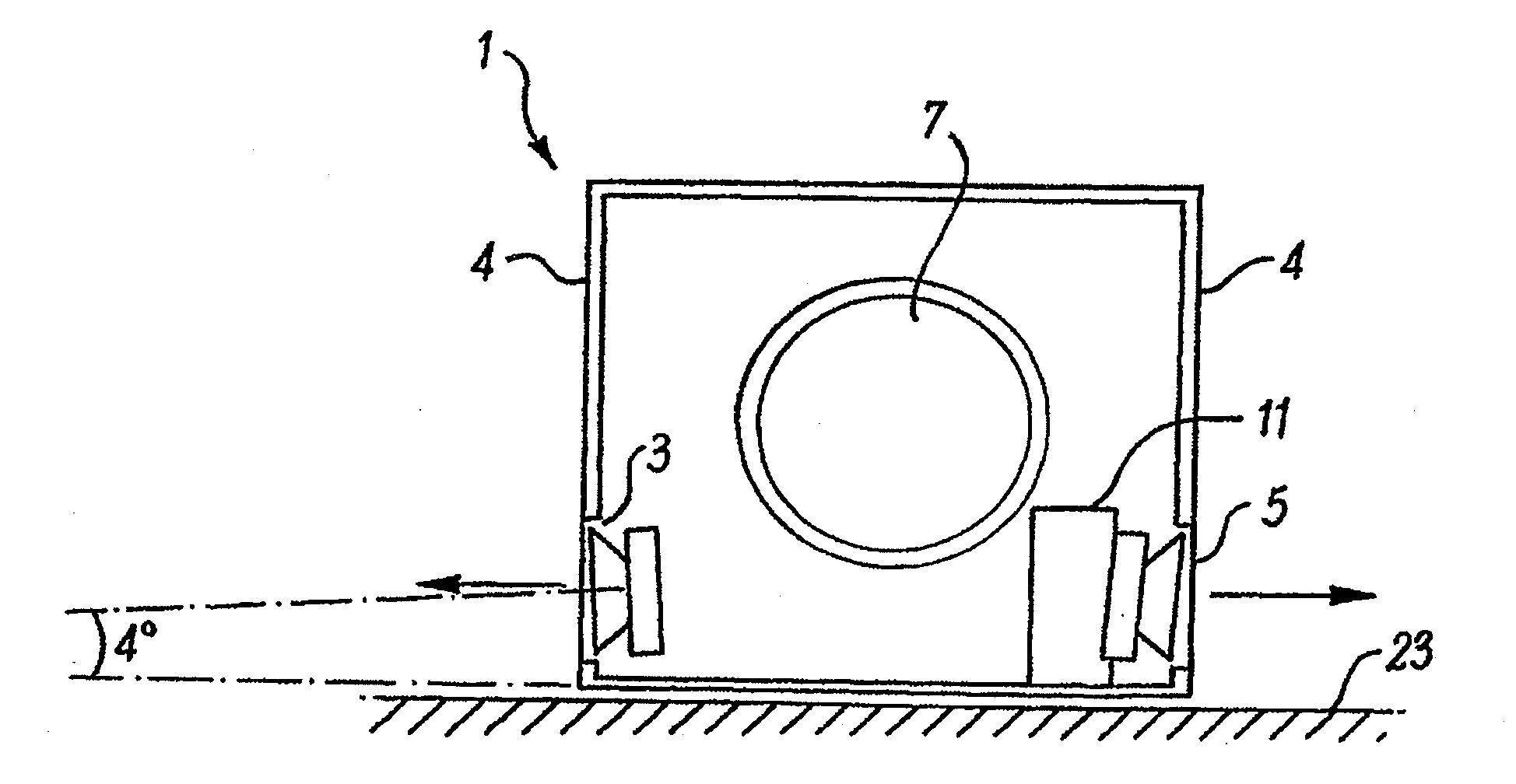

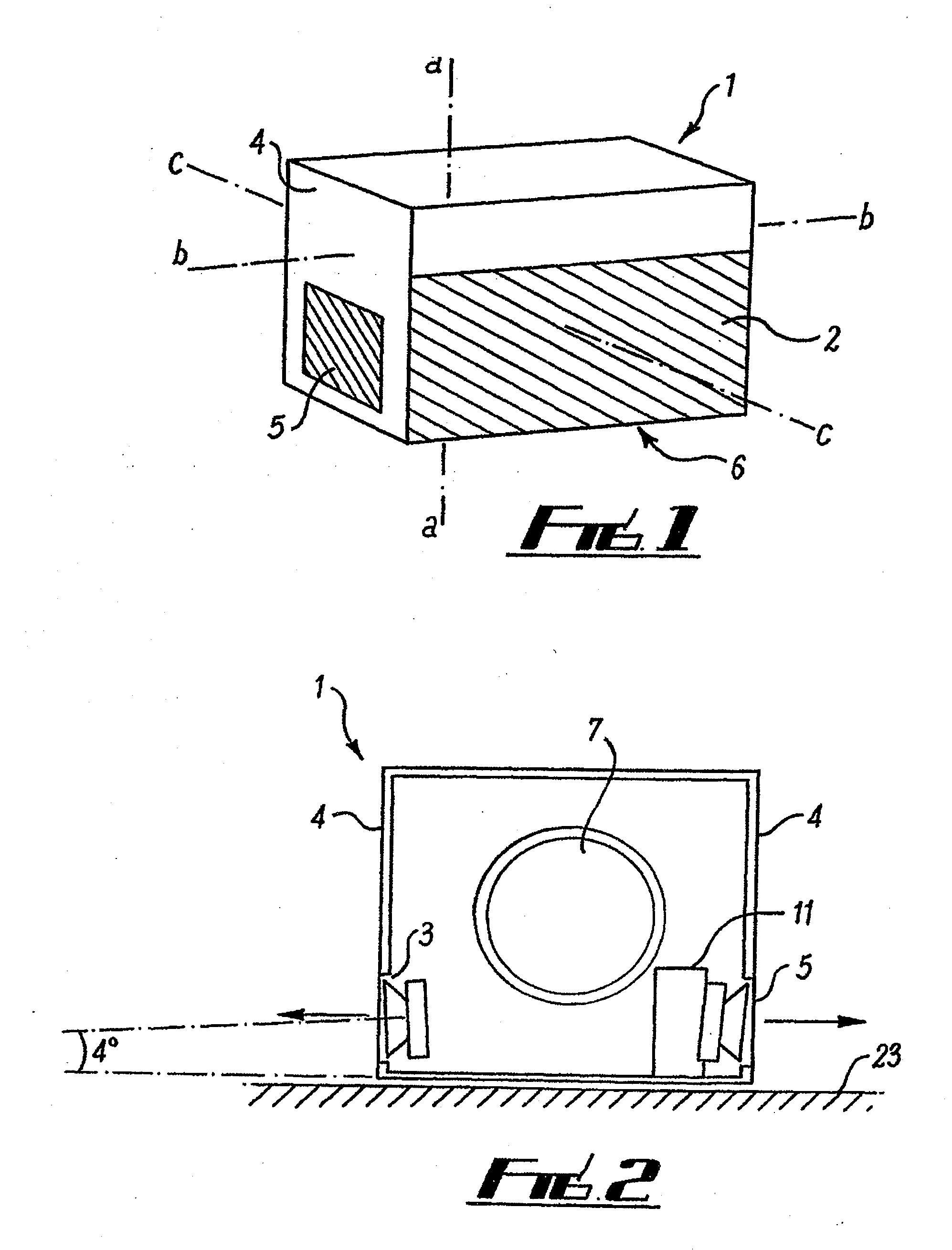

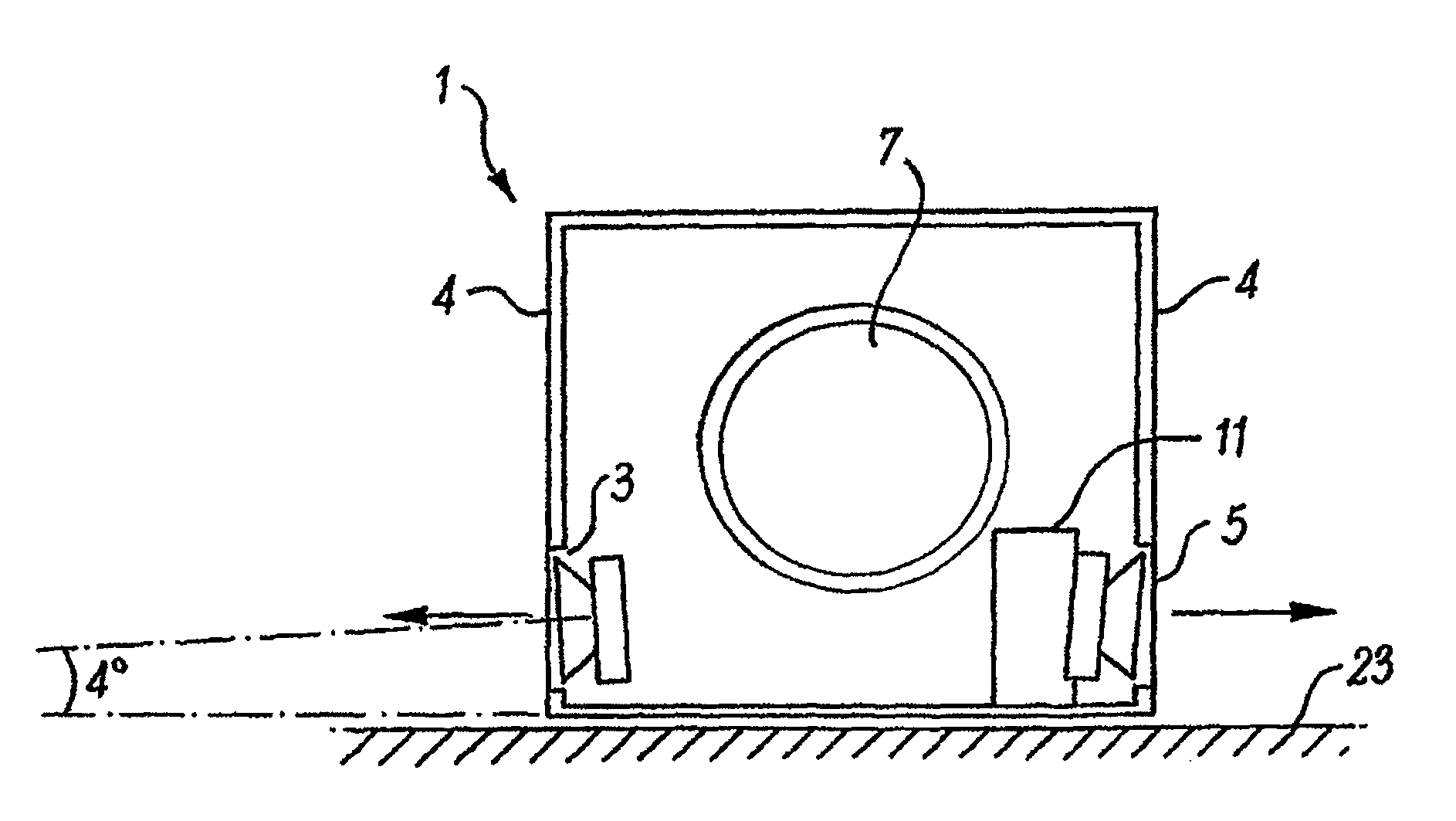

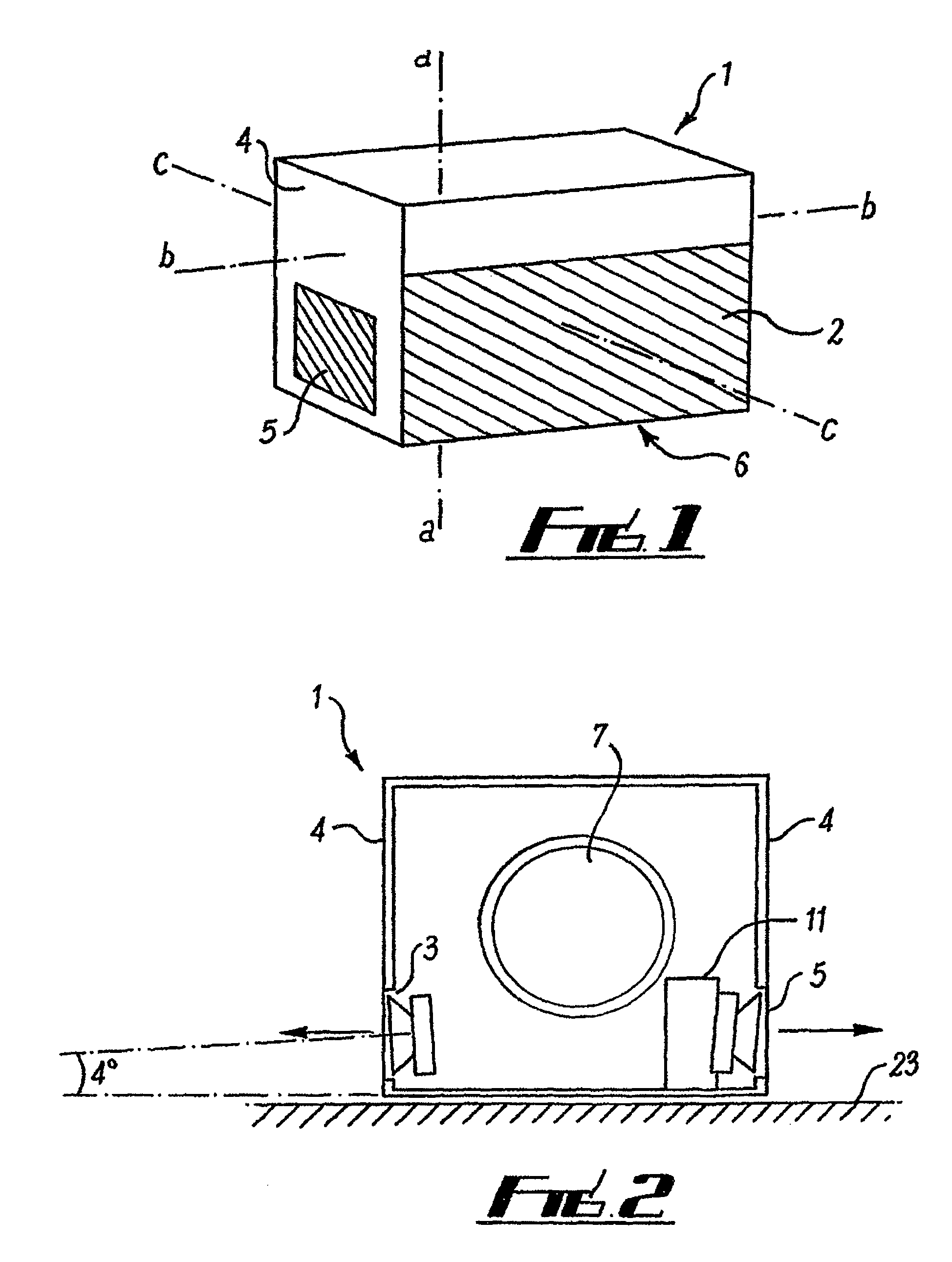

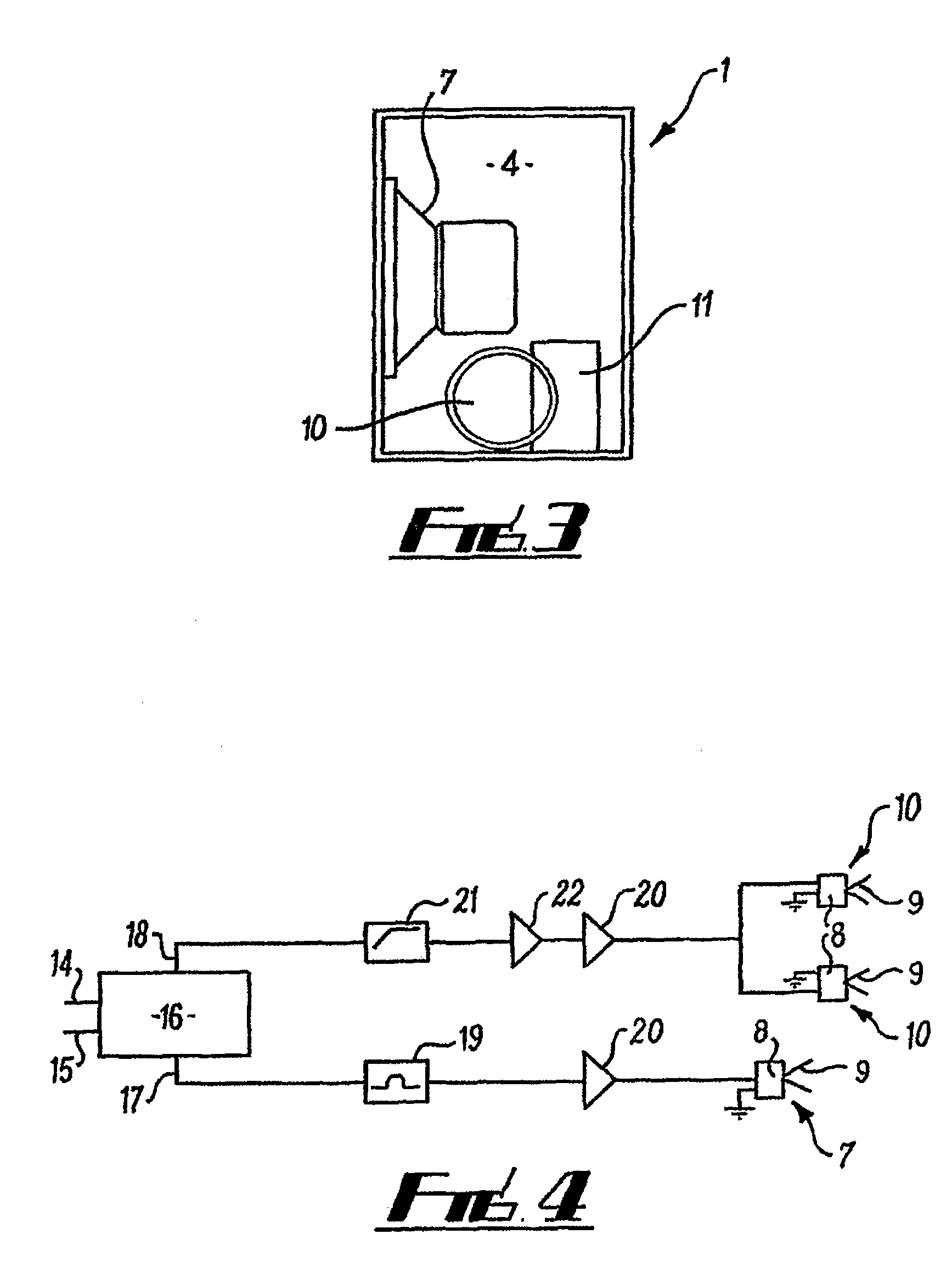

Apparatus and method for reproduction of stereo sound

InactiveUS20090067635A1Depth and widthTrend downTransducer detailsLoudspeaker spatial/constructional arrangementsStereophonic soundOut of phase

An apparatus and method for reproducing stereo sound. A transducer (14) is provided for reproducing two audio signals which are substantially out of phase with each other. Means, such as duct (11), are associated with the transducer to conduct at least one of the audio signals to a location such that the two substantially out of phase signals are transmitted from respective spaced apart locations. The duct (11) may lead to ports (4). These may be elongate and arranged to transmit sound across a flat surface. A second transducer (8) may be provided for transmitting a second audio signal. A conventional two channel stereo audio signal may be reproduced by the sum and difference system.

Owner:AIRSOUND LLP

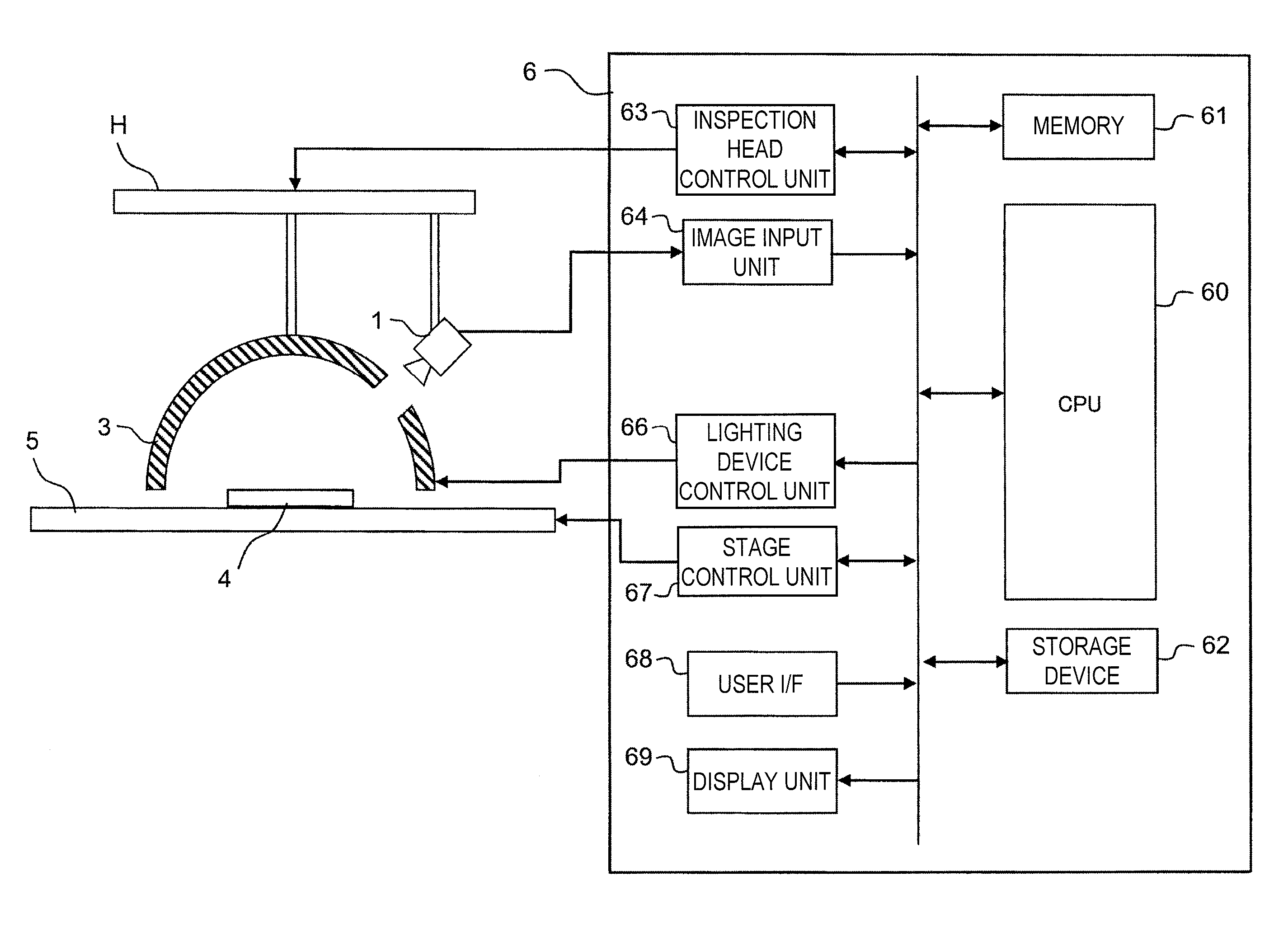

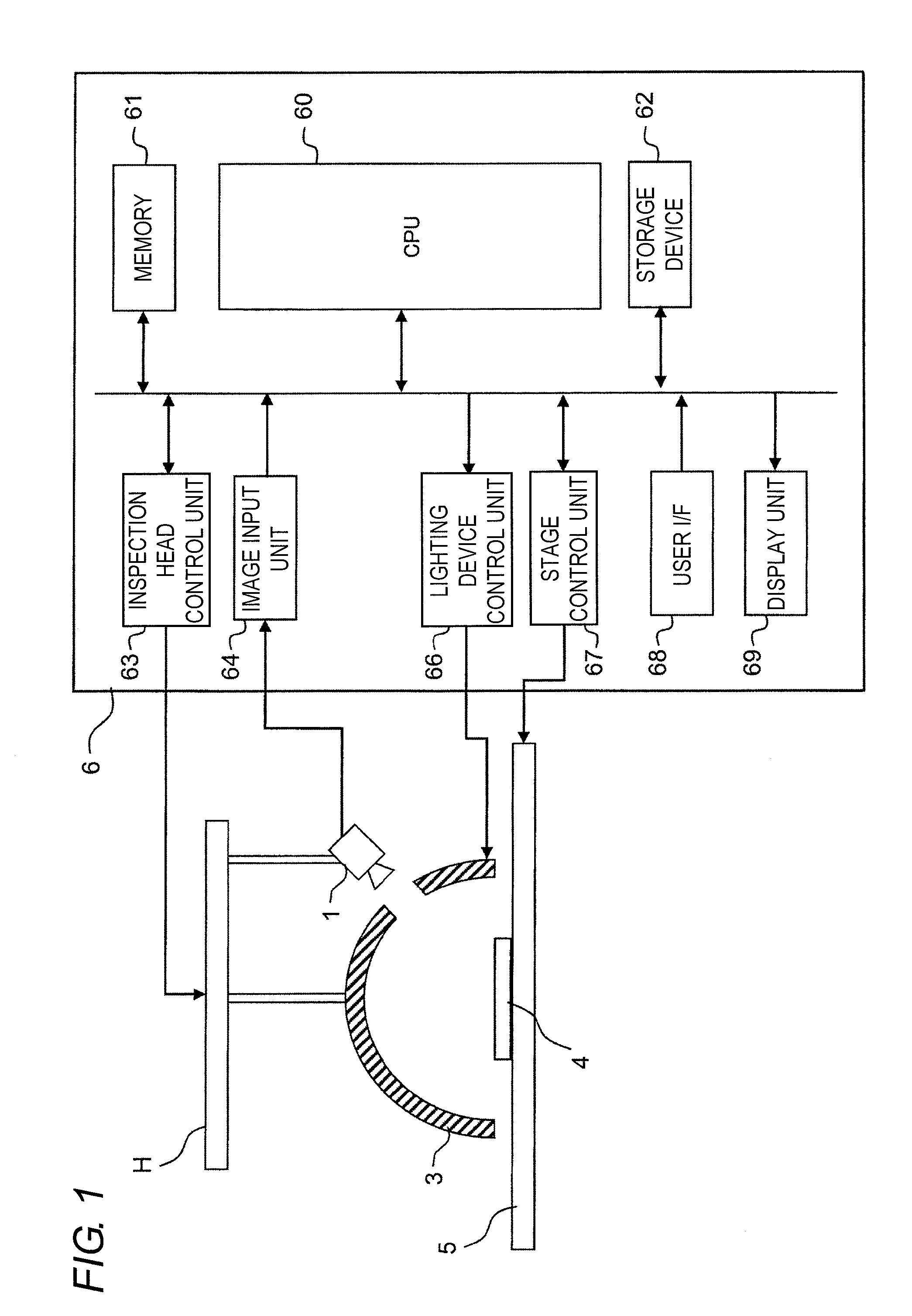

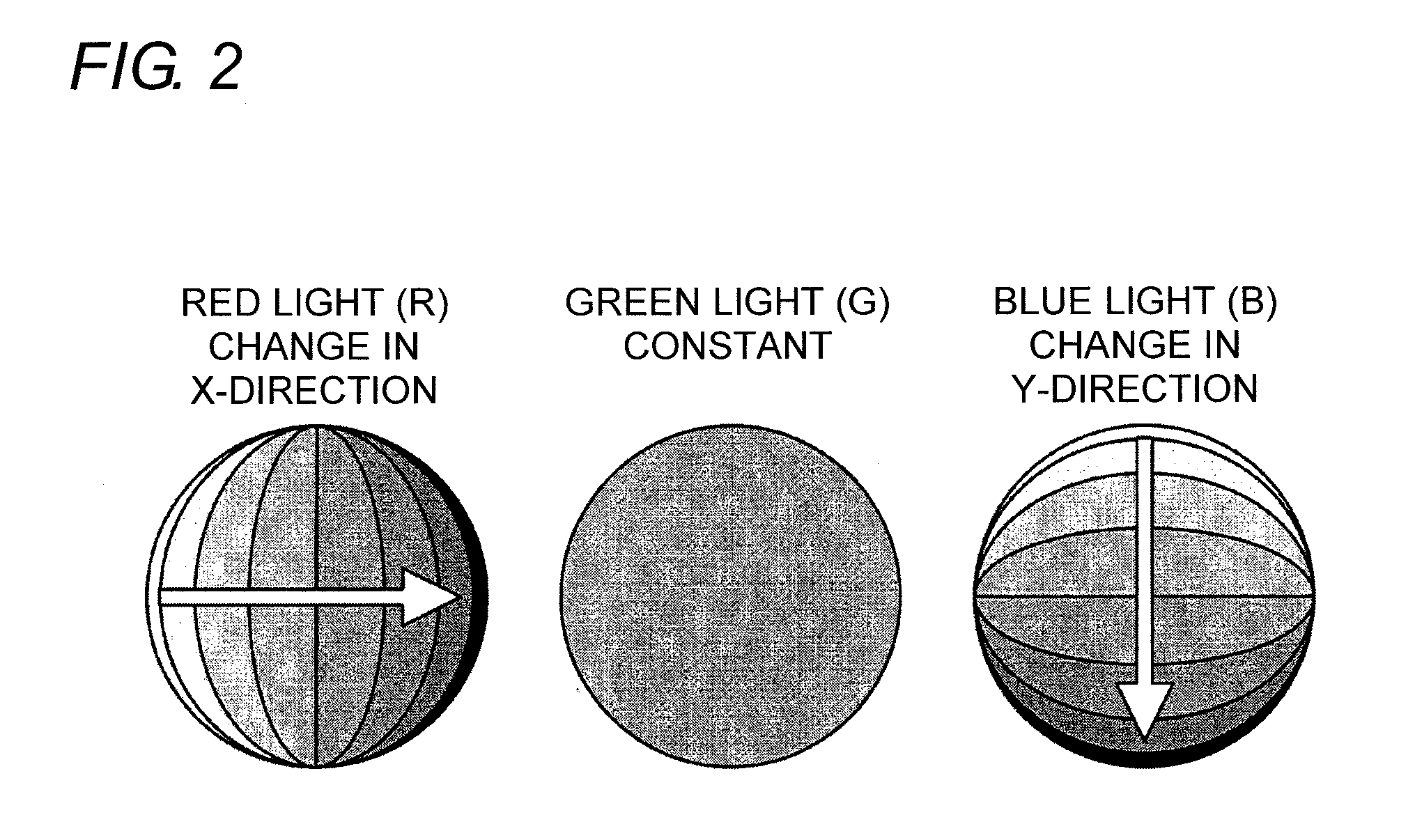

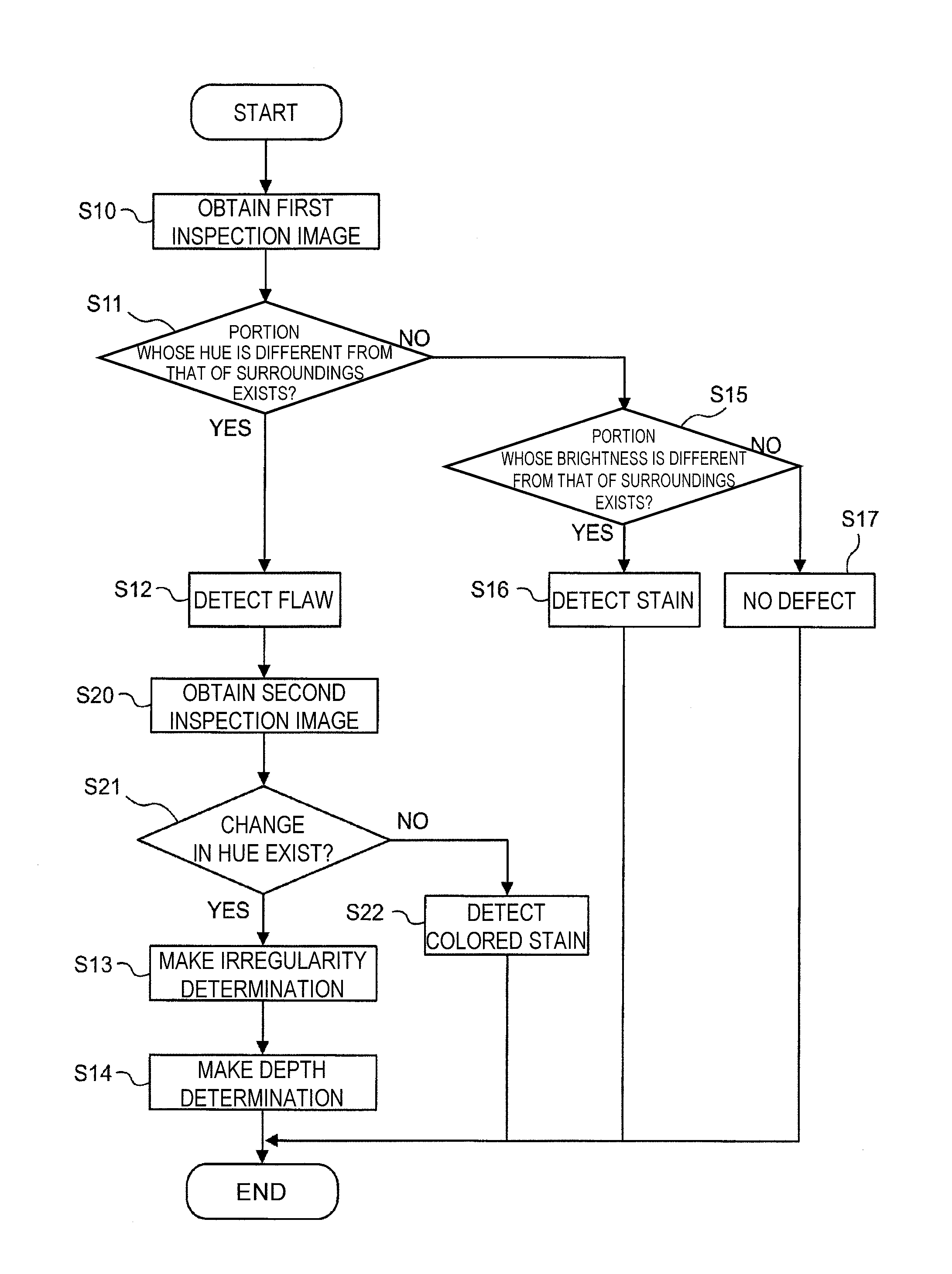

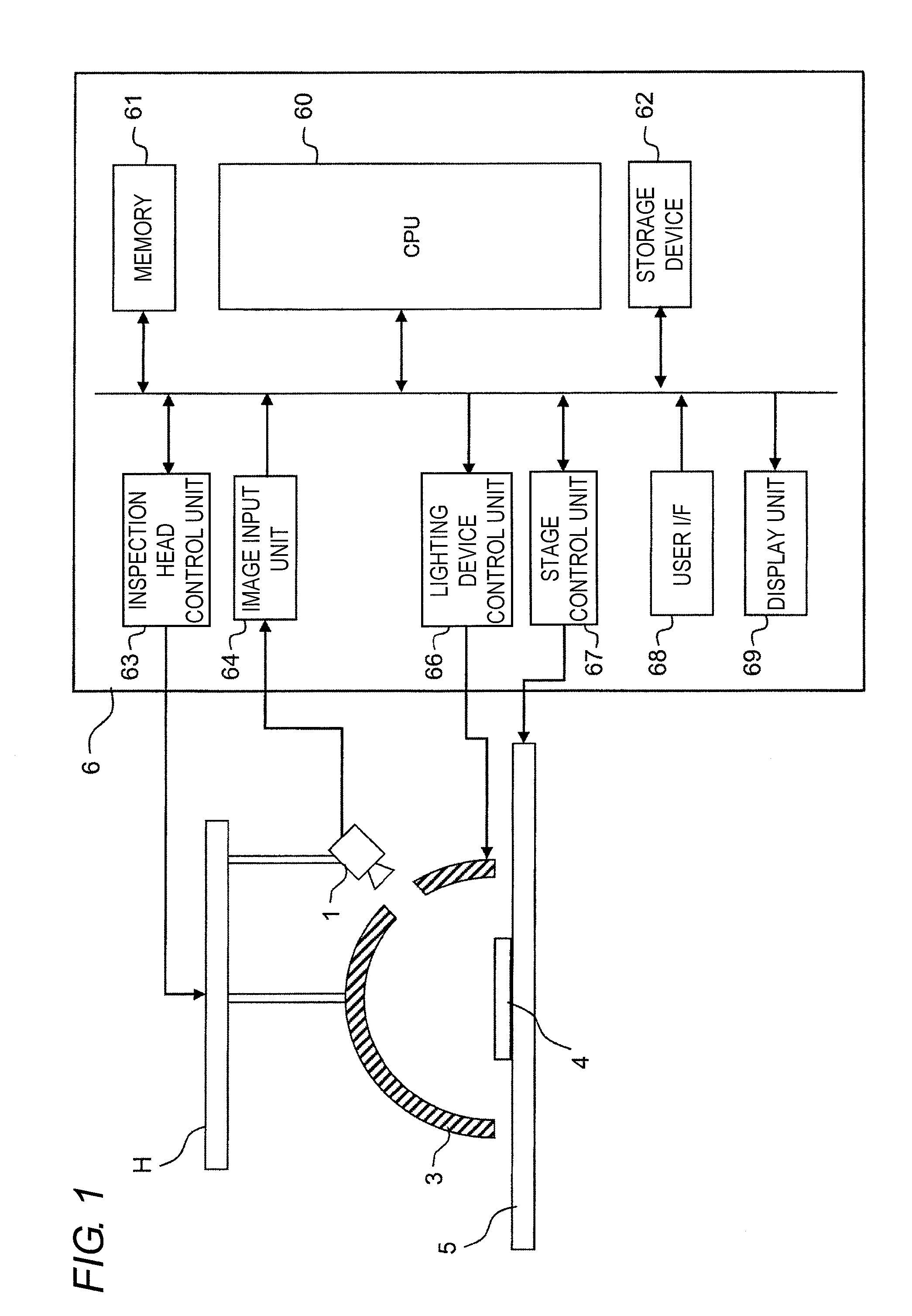

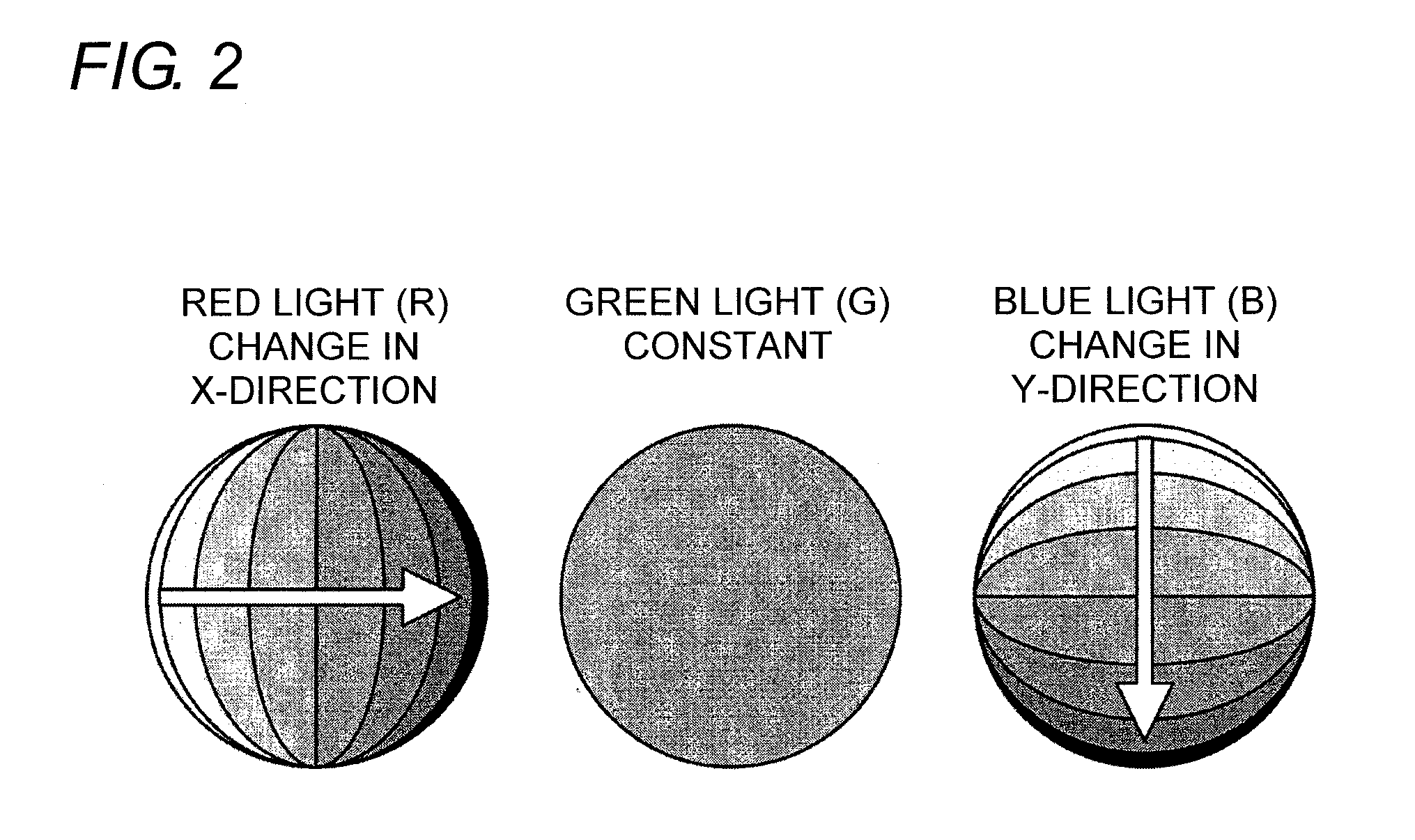

Apparatus and method for inspecting surface state

ActiveUS20120087566A1Accurate identificationSimple processImage enhancementImage analysisTarget surfaceHue

A surface state inspection apparatus has a lighting device that irradiates an inspection target placed on a stage with light, an imaging device that images the inspection target, and a detection device that detects a surface defect of the inspection target by analyzing a first inspection image obtained by the imaging device. The lighting device is a surface light source that includes a light emission region having a predetermined size and, in the lighting device, portions of light emitted from positions in the light emission region differ from each other in a spectral distribution. The detection device detects a portion in which a hue is different from that of its surrounding portion in the inspection target surface as a flaw. The detection device detects a portion in which the hue is substantially equal to that of its surrounding portion while brightness is different from that of its surrounding portion as a stain.

Owner:ORMON CORP

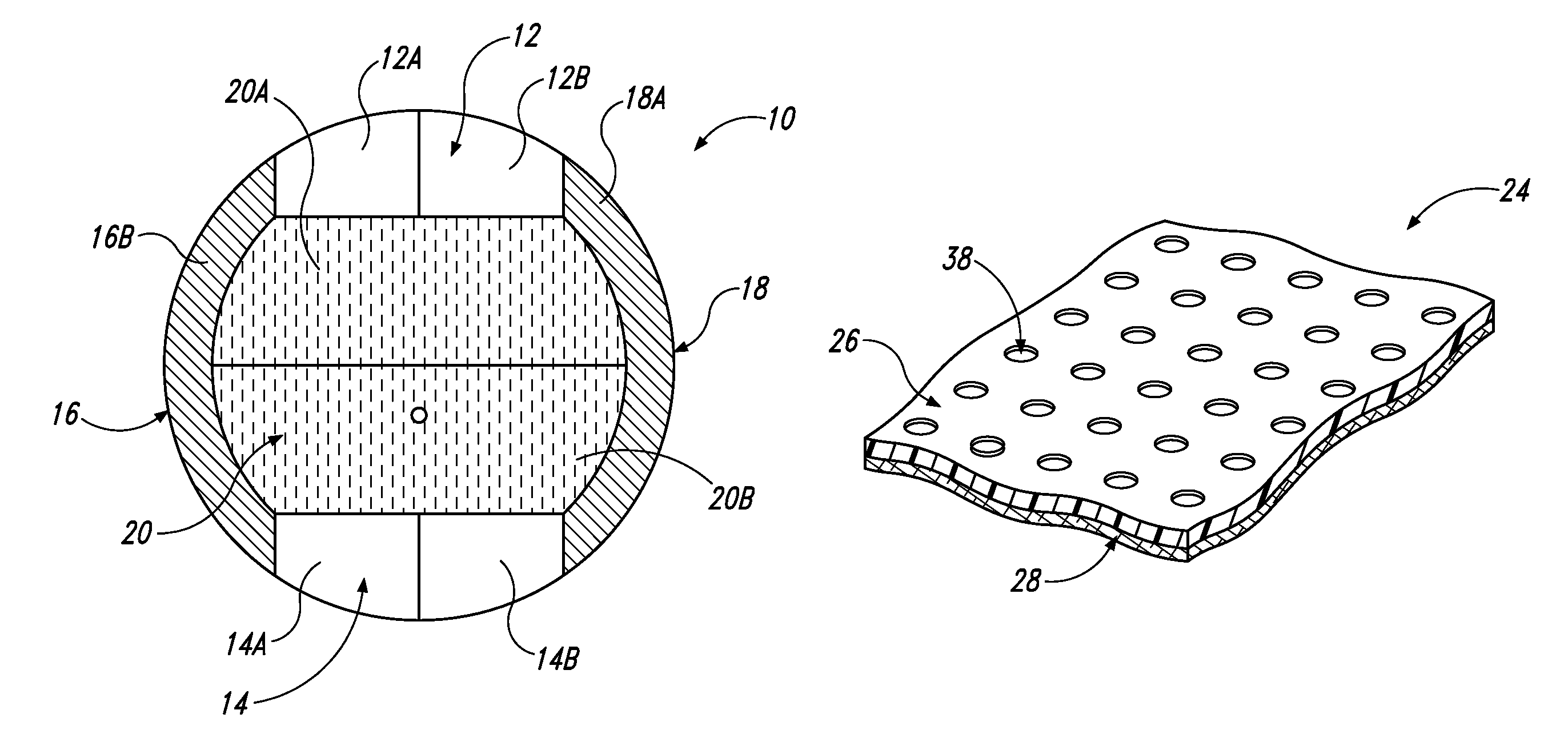

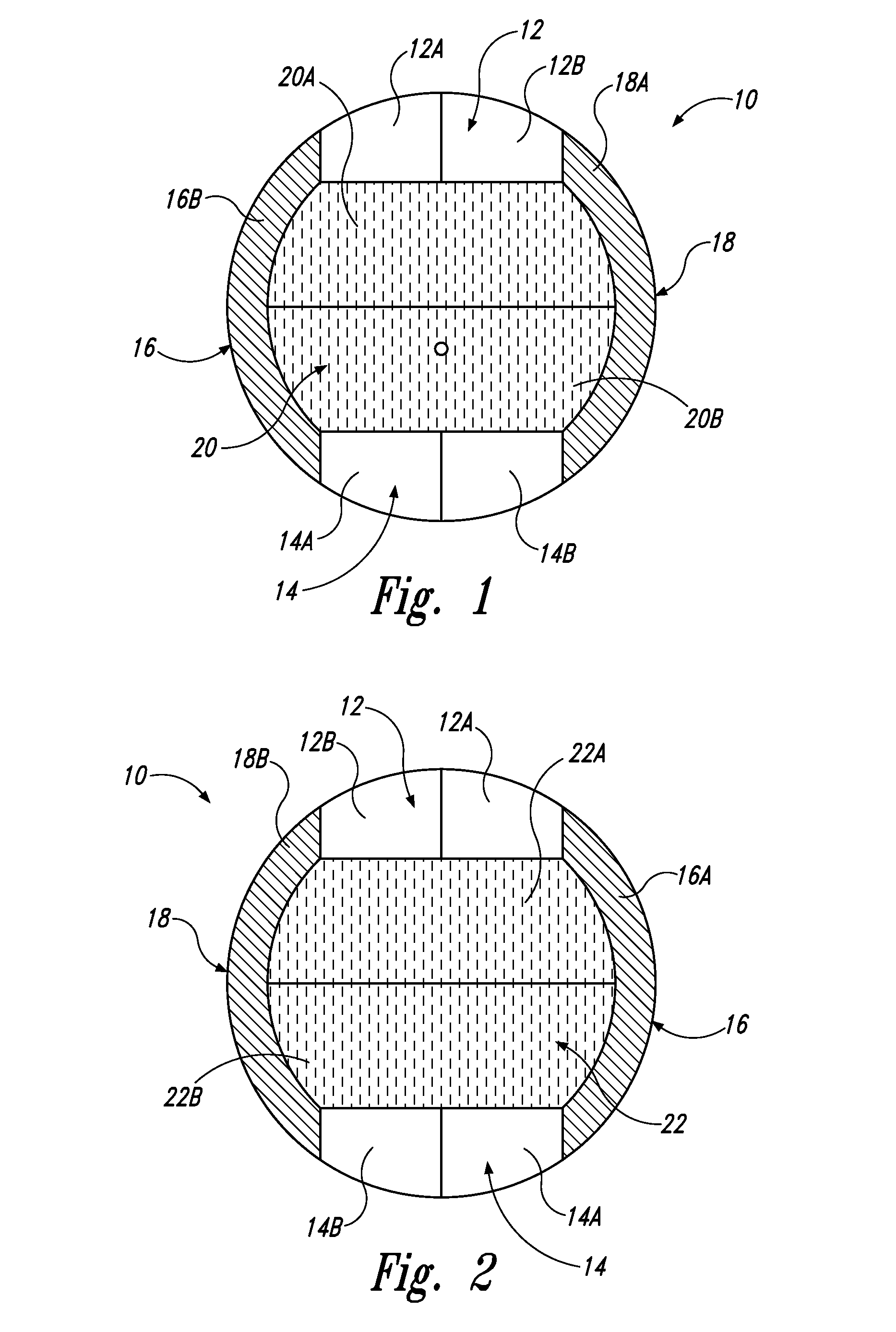

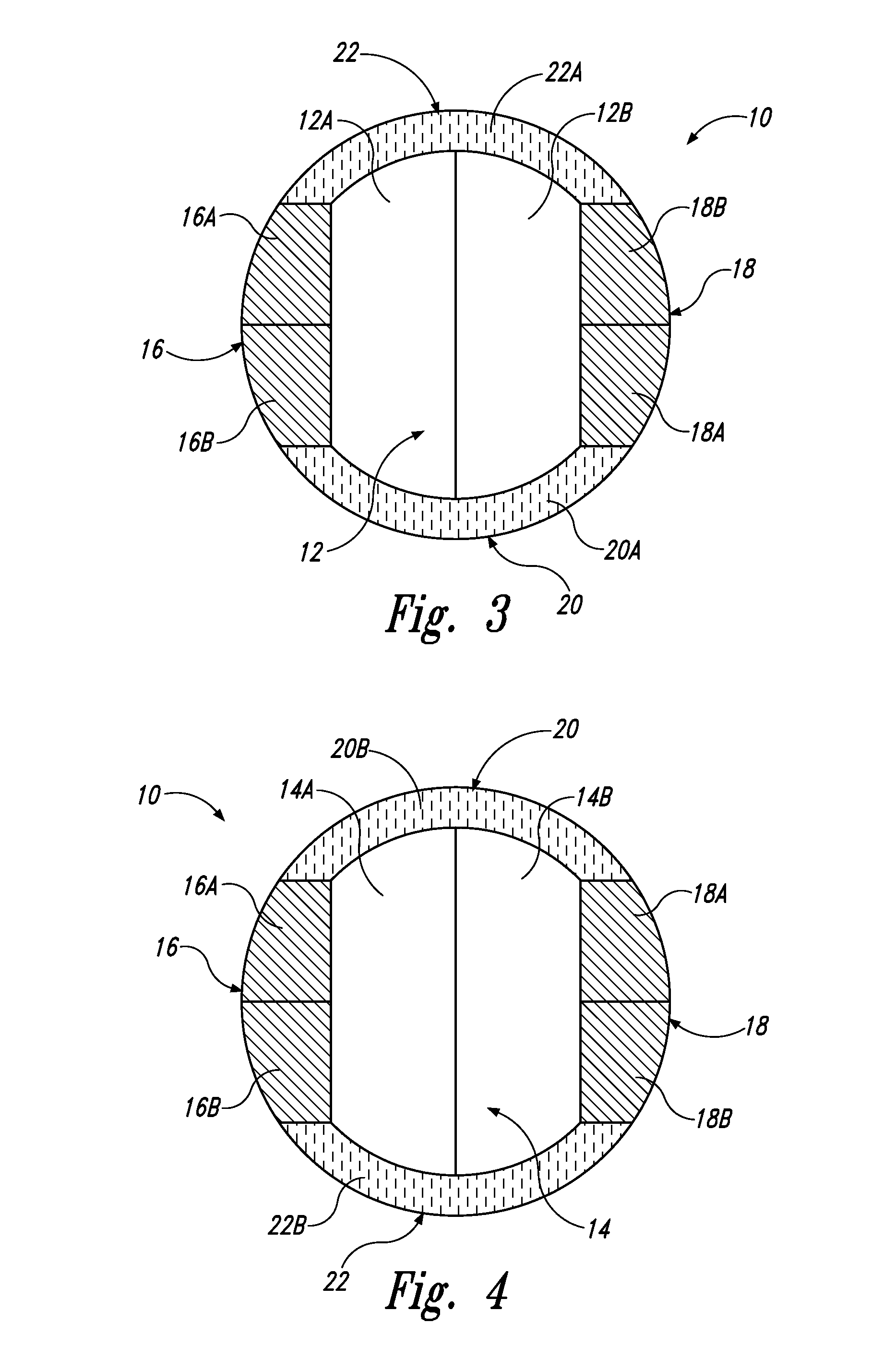

Volleyball cover

Owner:BADEN SPORTS

Apparatus and method for inspecting surface state

ActiveUS8615125B2Accurate identificationDepthImage enhancementImage analysisTarget surfaceEffect light

Owner:ORMON CORP

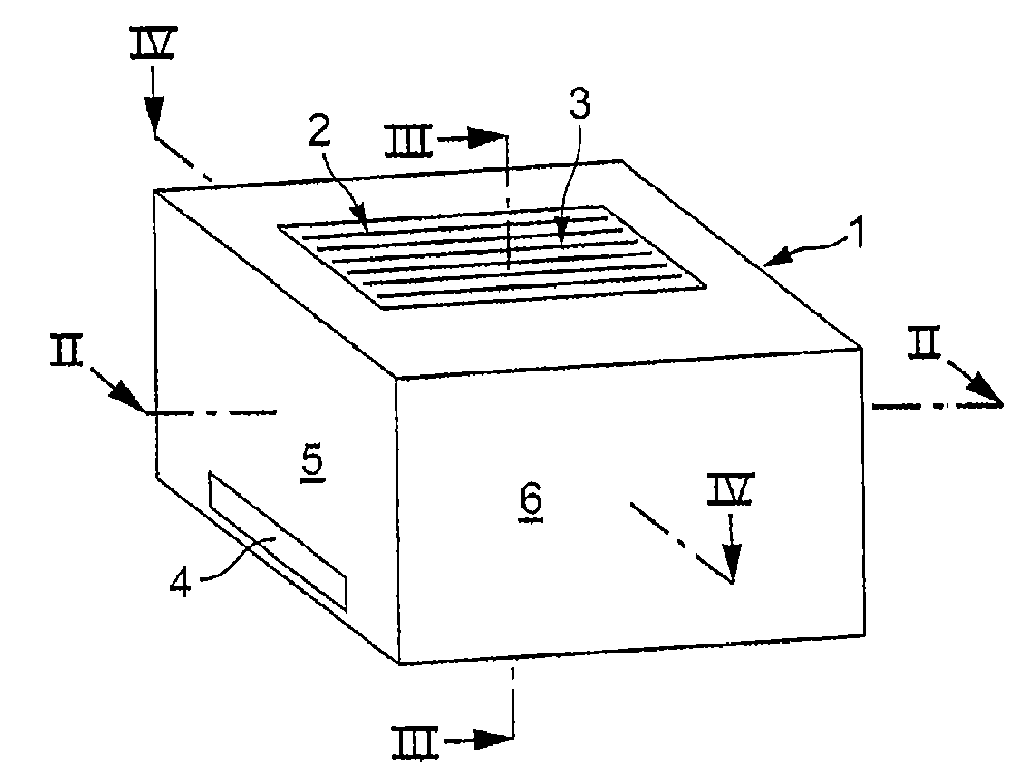

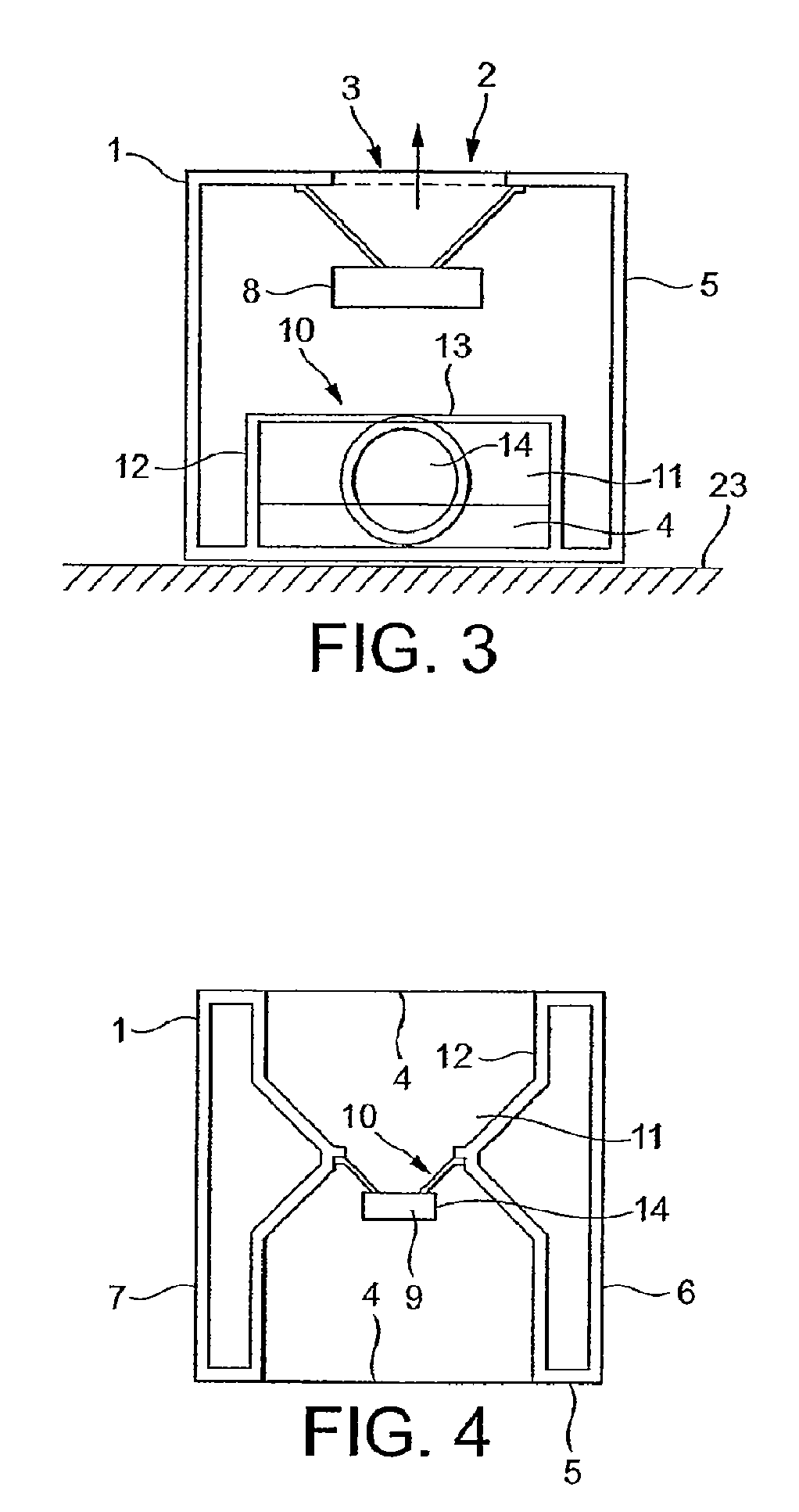

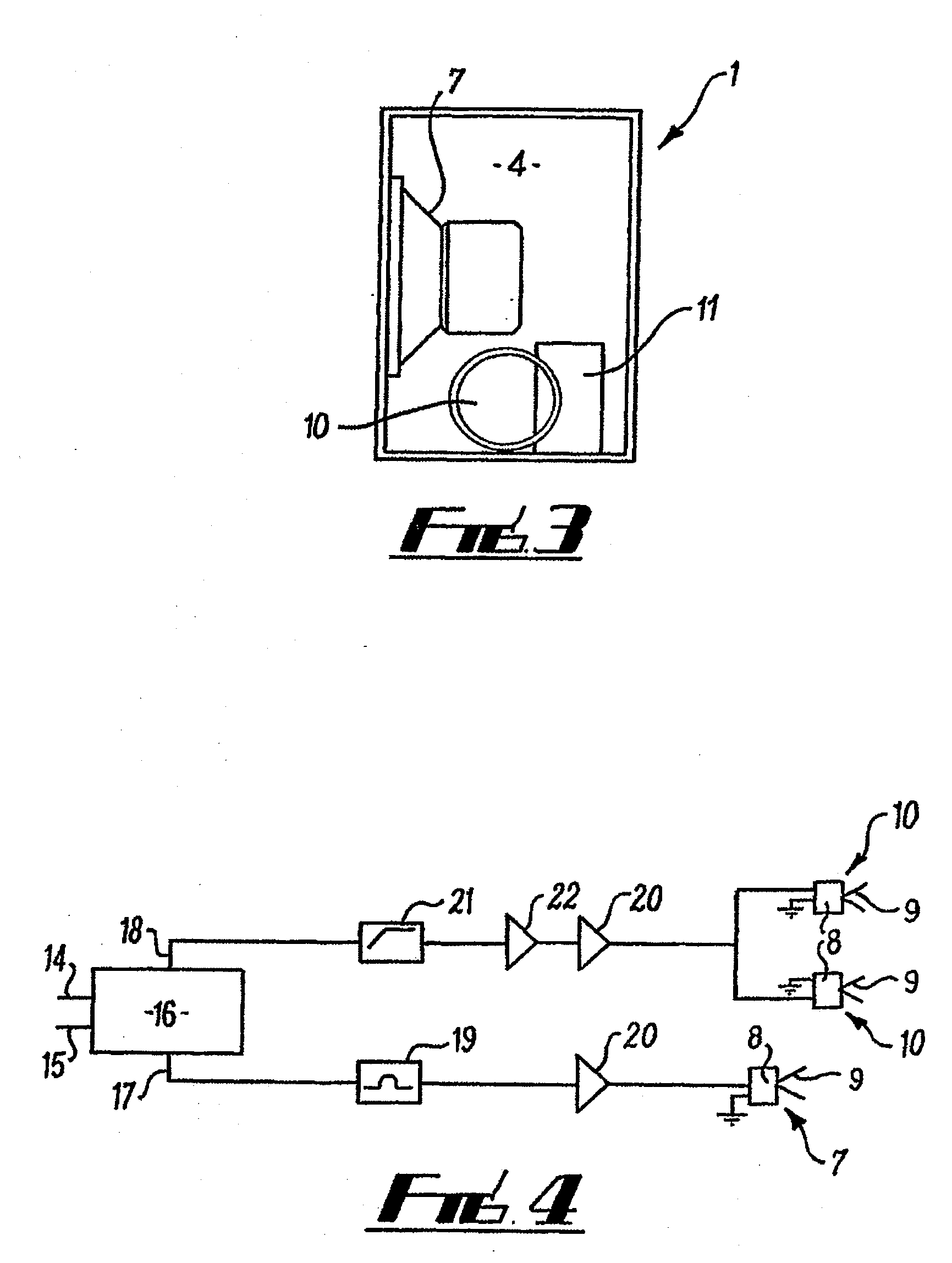

Apparatus for reproduction of stereo sound

ActiveUS20100061575A1DepthReduce the amplitudeTransducer detailsTwo-channel systemsTransducerEngineering

Apparatus for reproducing stereo sound having a housing (1, 25) defining an at least partially enclosed space. A first transducer (7) or pair of transducers (28, 29) is provided and arranged to reproduce one, both or the sum of two audio signals. A pair of transducers (10, 32) is also provided and arranged to reproduce a signal comprising the difference of the two audio signals. As the transducers communicate with the at least partially enclosed space, and the transducers arranged to reproduce the difference between the two audio signals are each arranged to direct their output primarily in a direction generally at right angles to the direction in which the first transducer or pair of transducers primarily direct their output. The apparatus may be arranged to be placed on or adjacent a generally flat surface, and the transducers arranged to reproduce the difference of the two audio signals may be arranged to direct their output towards the flat surface.

Owner:ORBITSOUND LTD

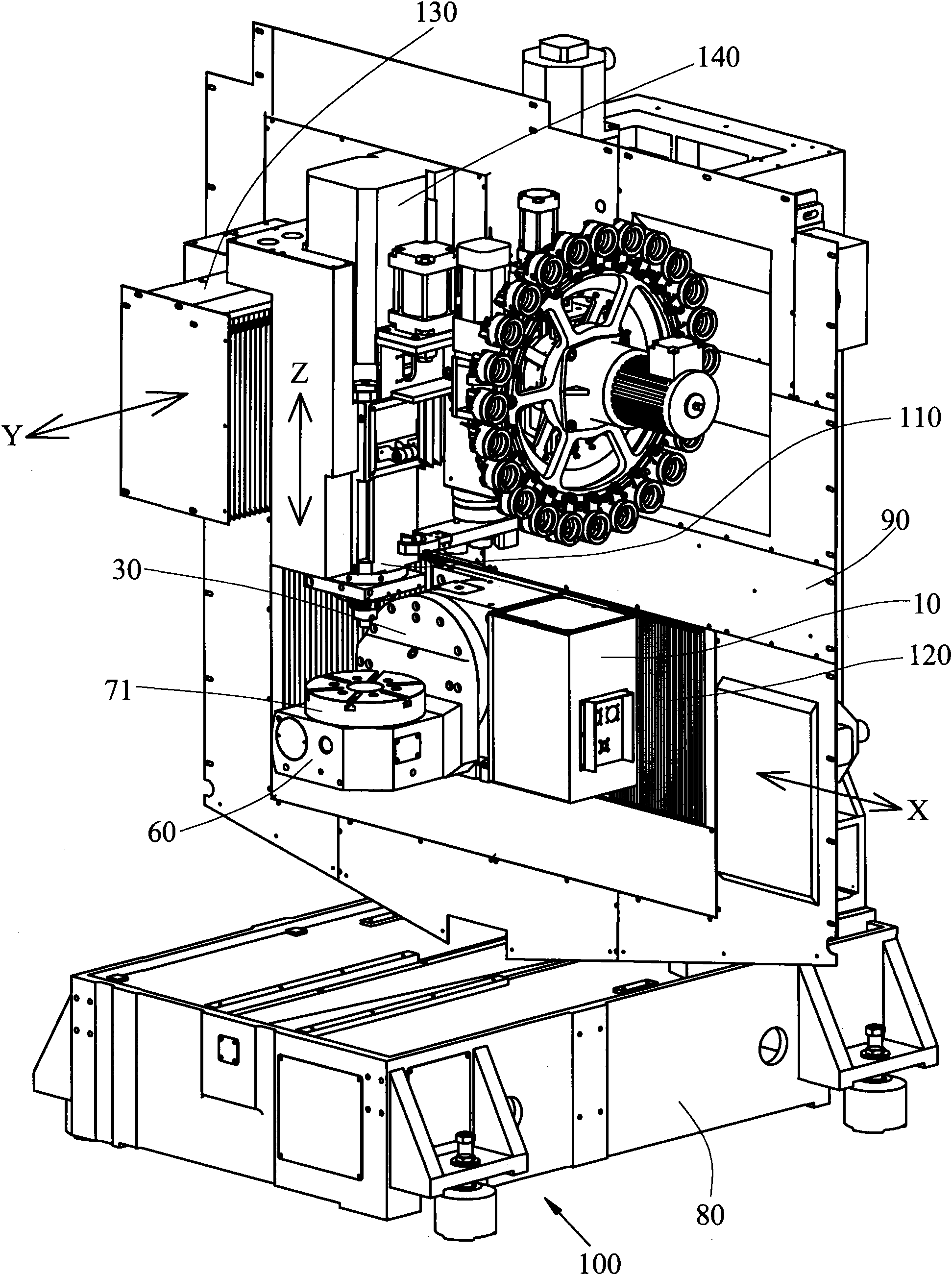

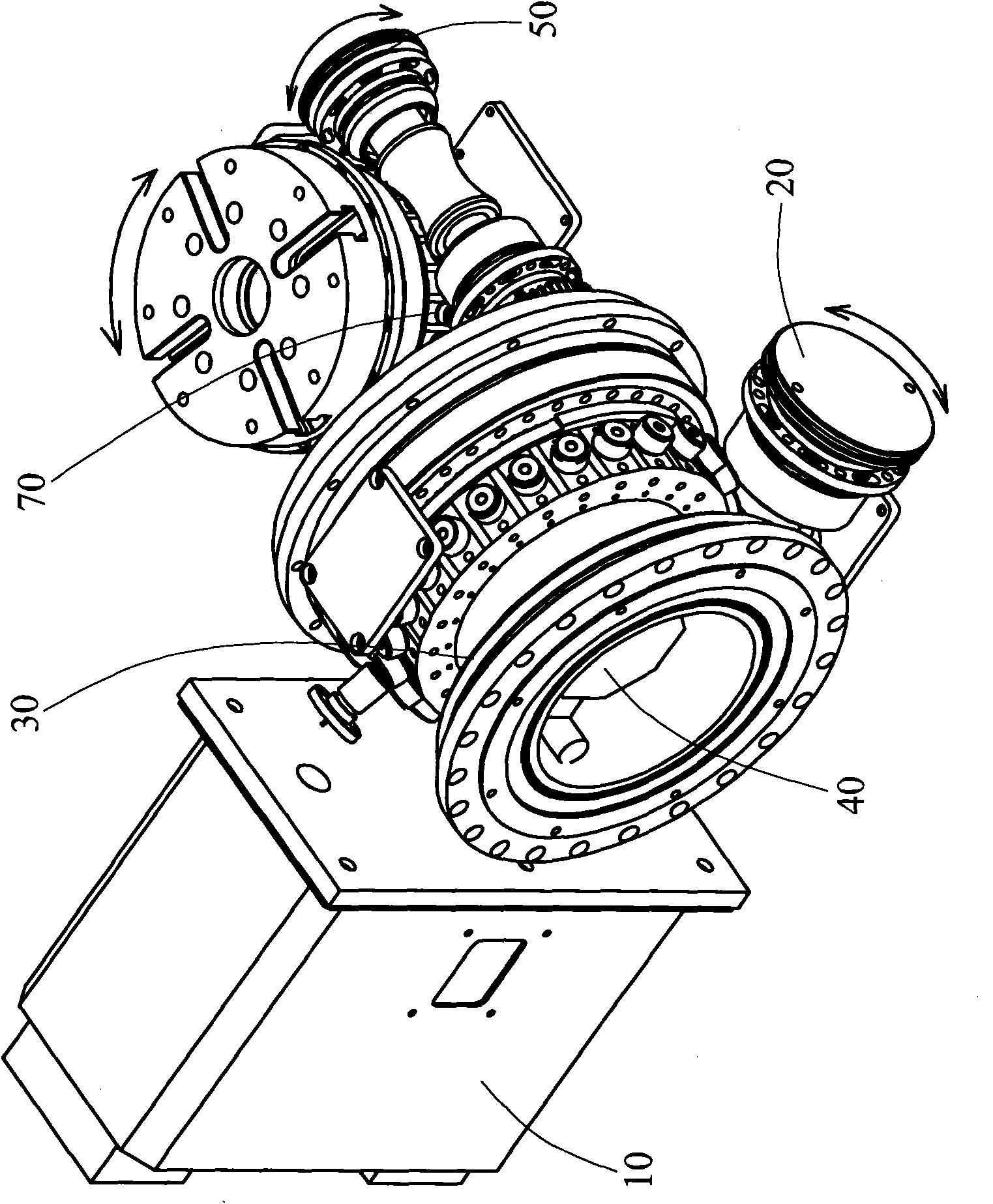

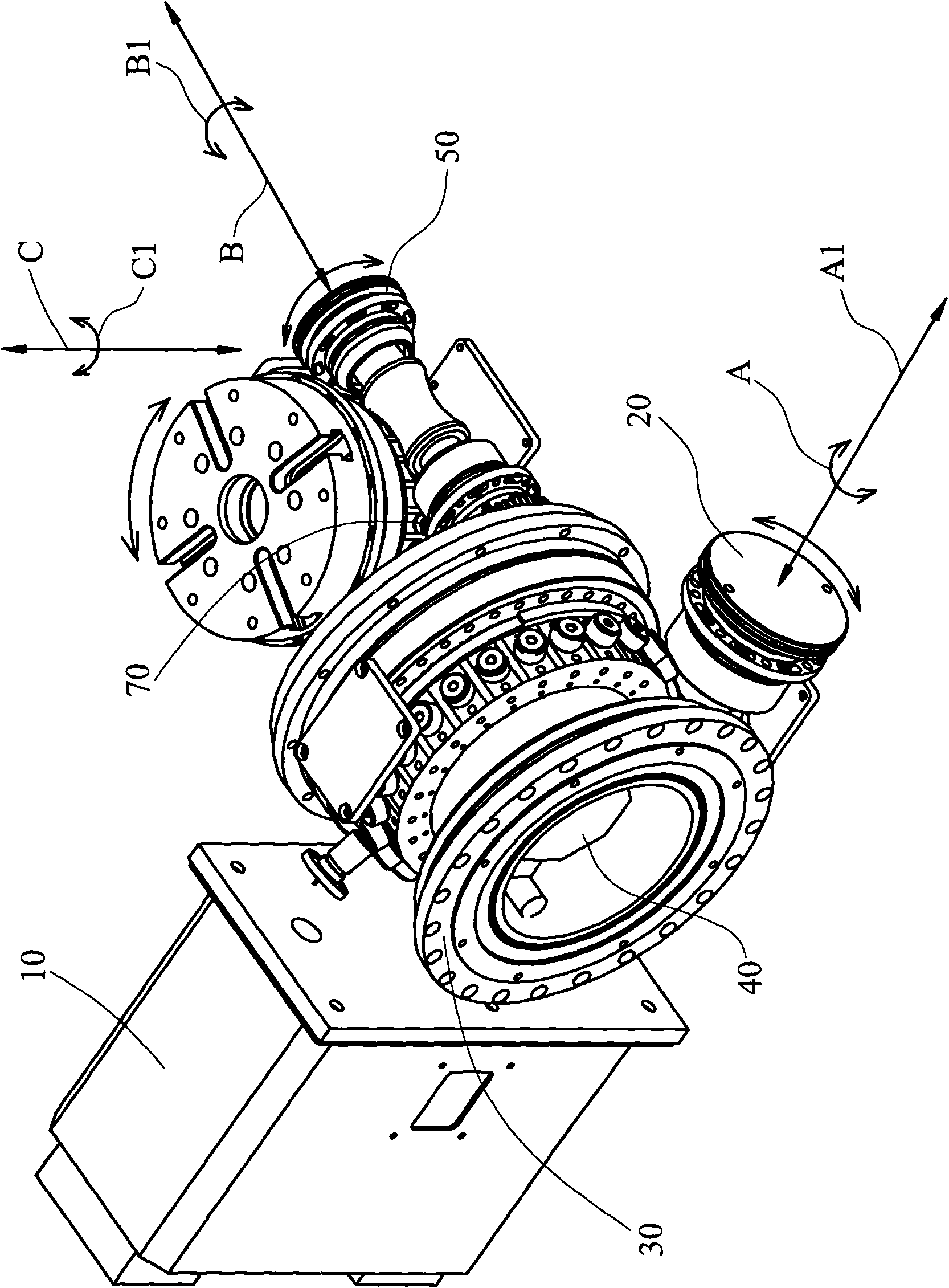

Five-face drilling-tapping central machine structure

InactiveCN101569991AStructure miniaturizationImprove processing efficiencyFeeding apparatusOther manufacturing equipments/toolsServomotor

The invention relates to a five-face drilling-tapping central machine structure, the main structure of which comprises a board, a fourth shaft structure and a fifth shaft structure. The fourth shaft structure and the fifth shaft structure comprise a first servo motor, a first input shaft, a first output shaft roller, a second servo motor, a second input shaft, a support and a second output shaft roller, wherein the first input shaft can be transmitted by the first servo motor and can link the first output shaft roller to rotate by taking the B axis as a centre, meanwhile, the second servo motor can link the second input shaft which can link the second output shaft roller to rotate by taking the C axis as a centre. The five-face drilling-tapping central machine structure is safe, and has light weight, excellent piece falling property and better efficiency of processing and correcting processes.

Owner:捷力精密机械股份有限公司

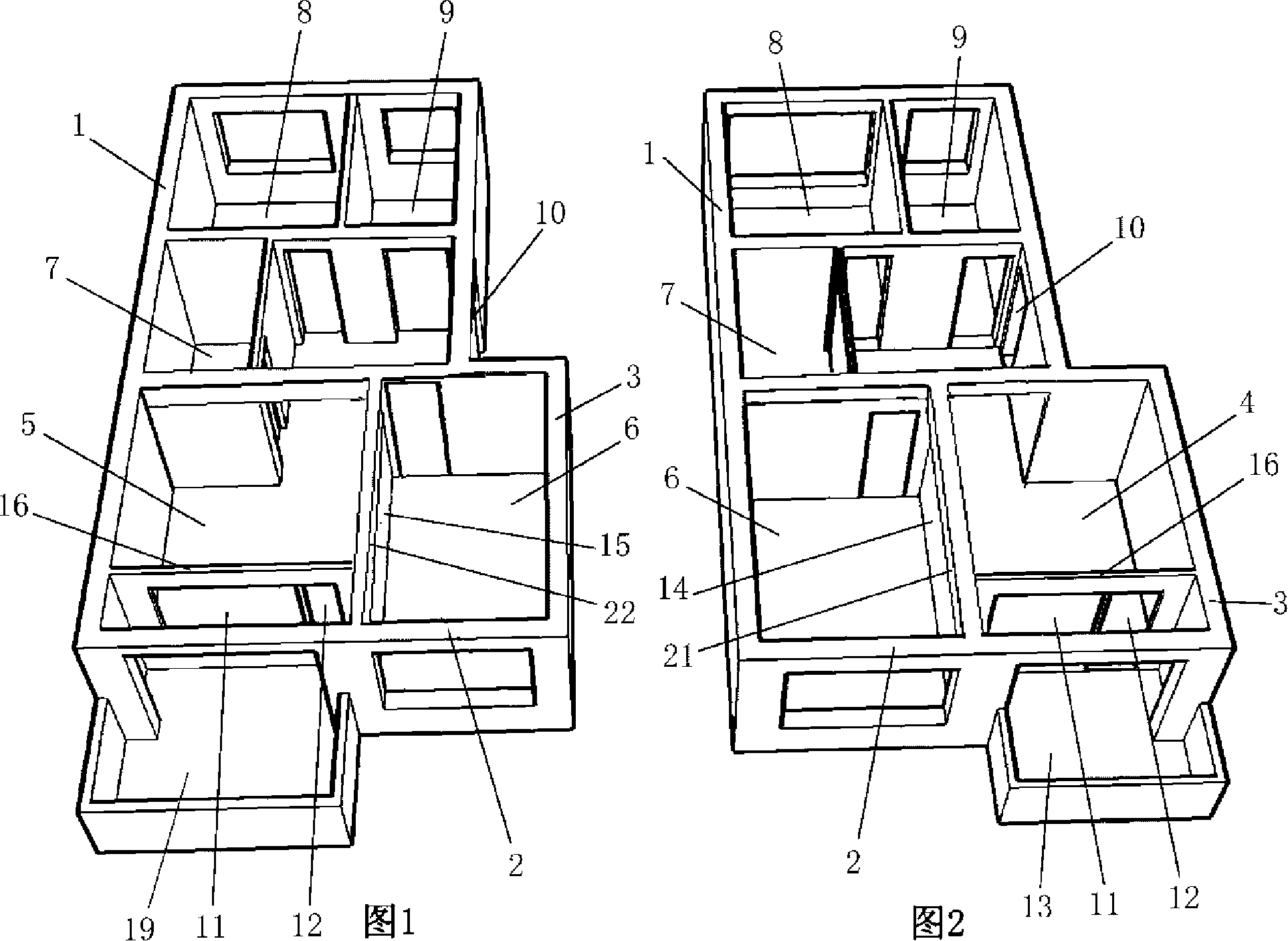

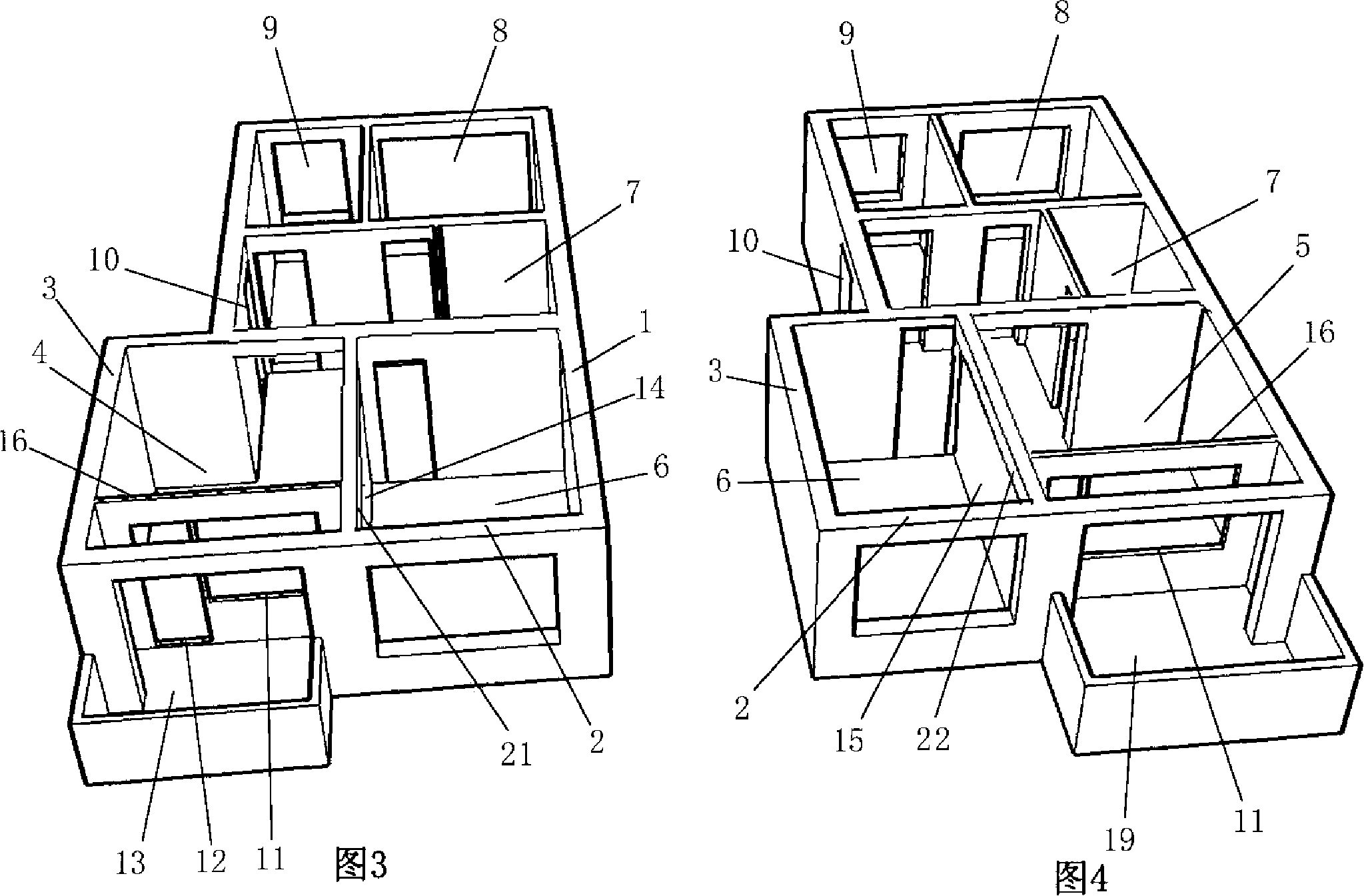

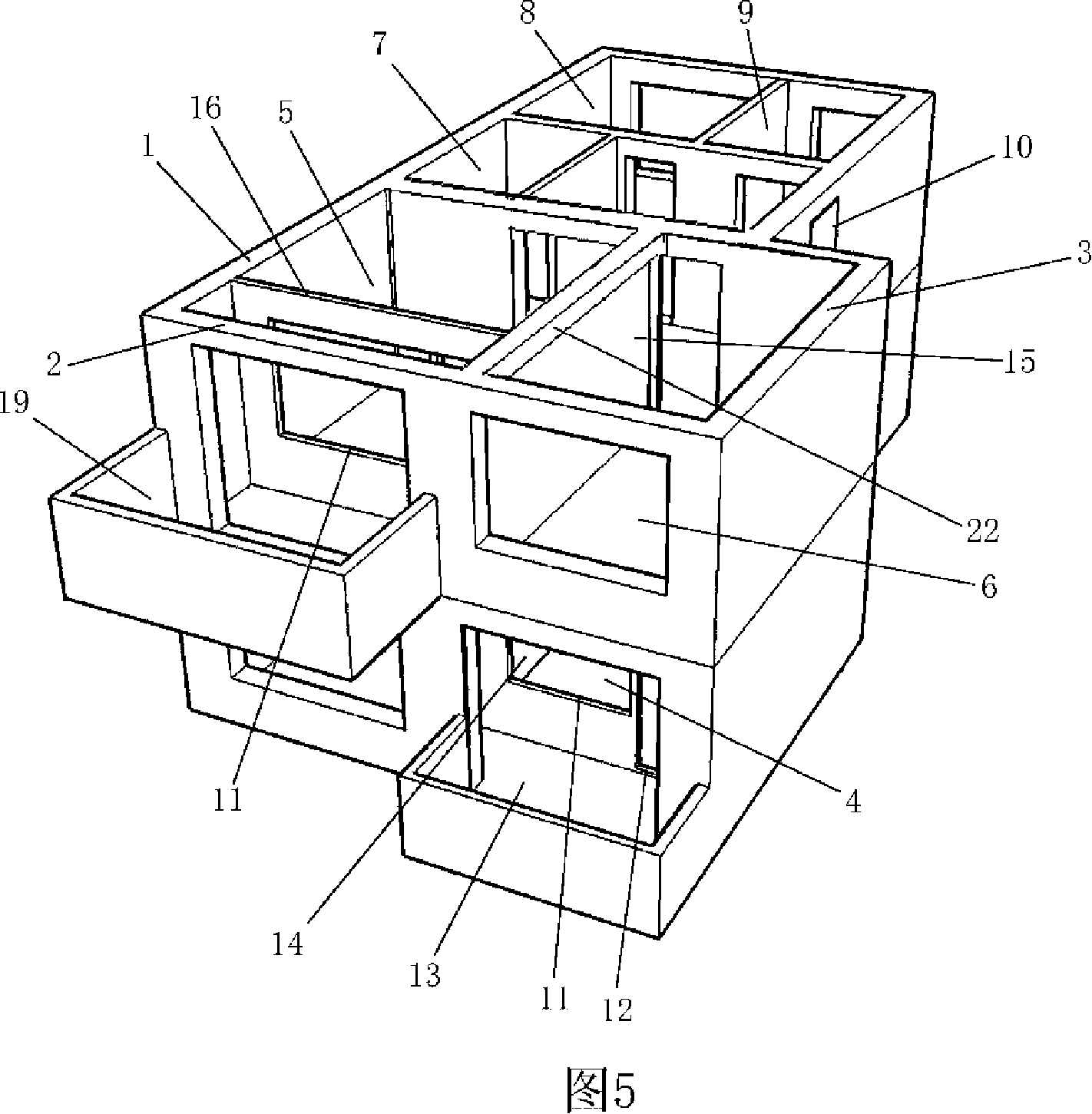

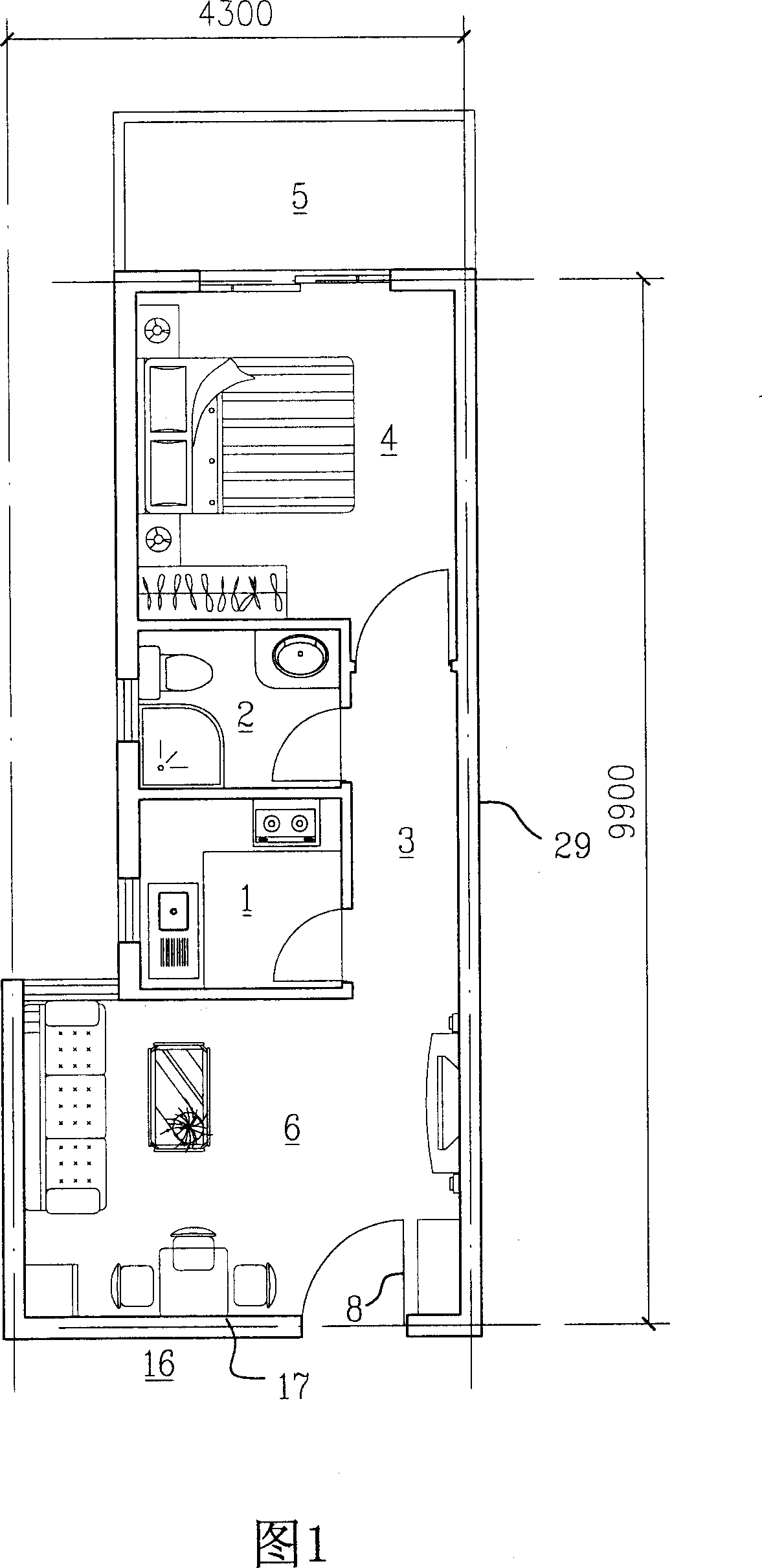

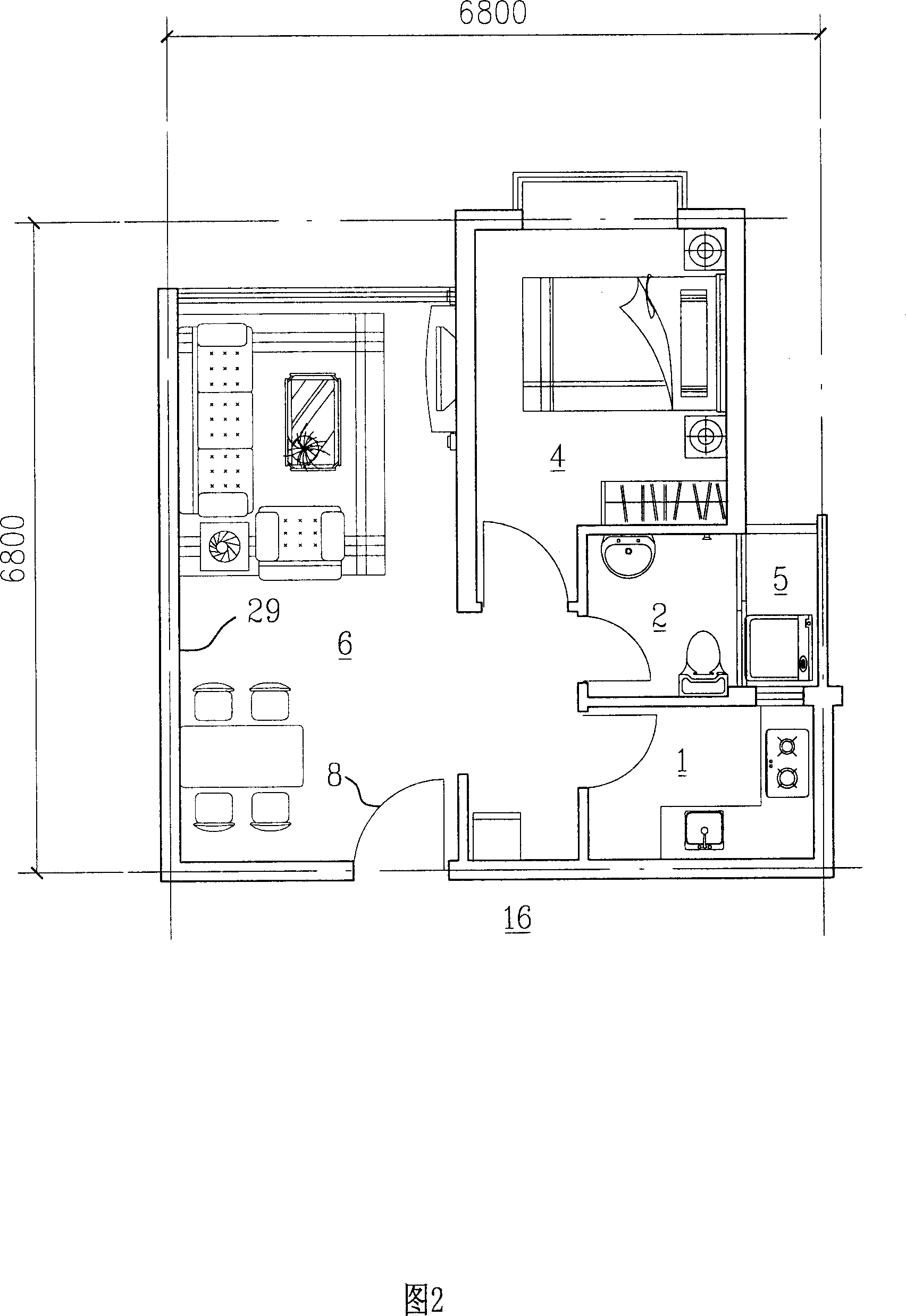

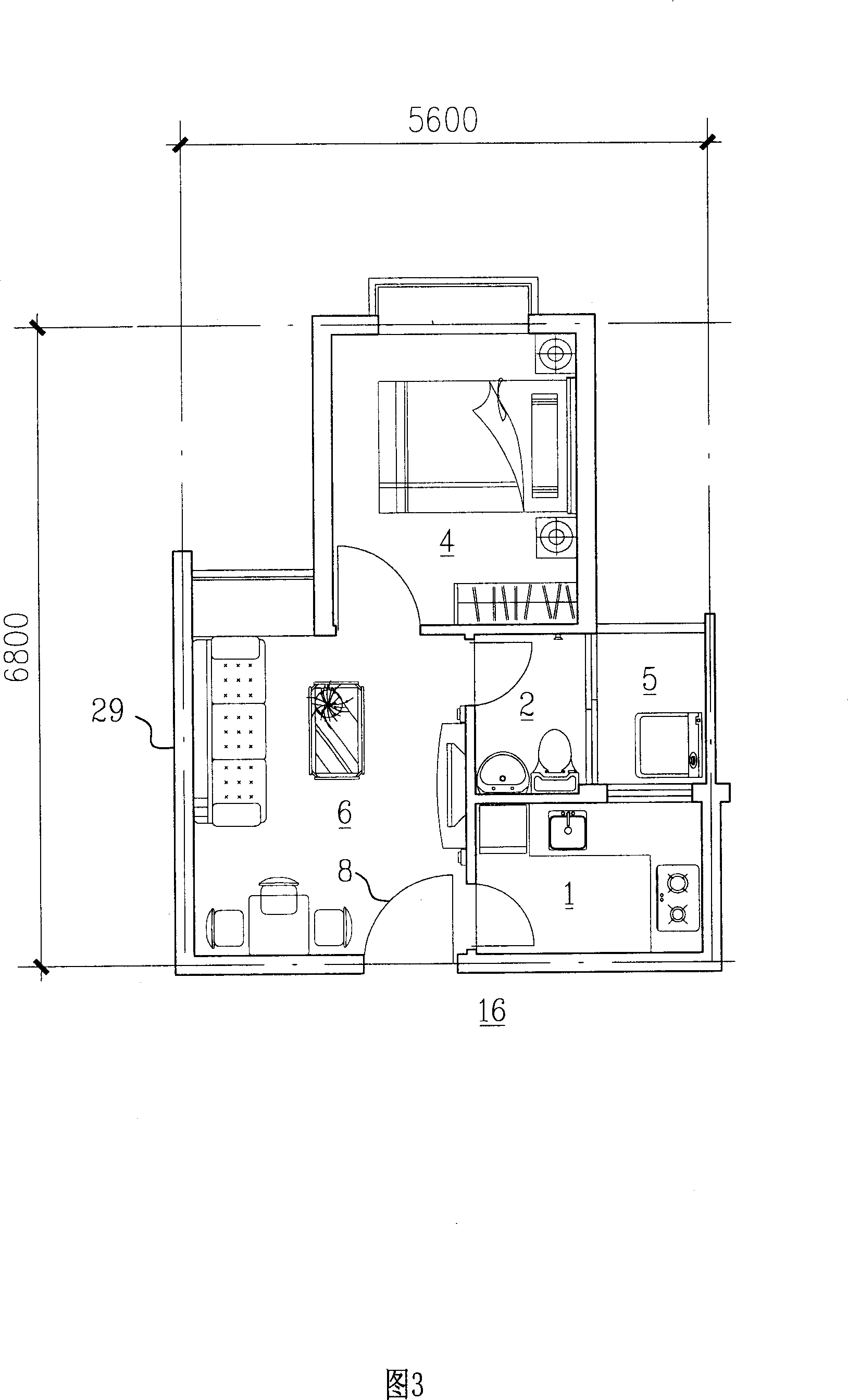

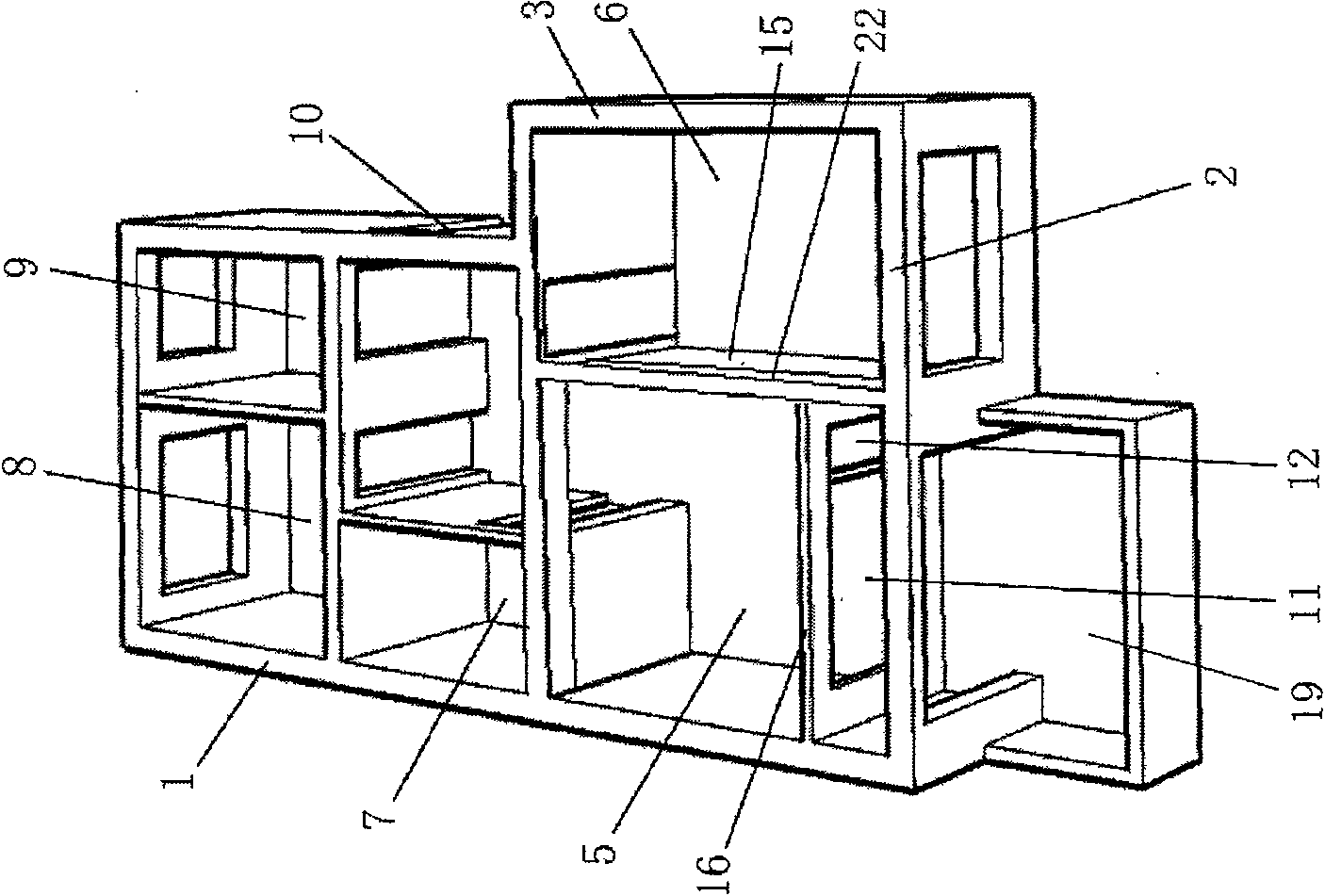

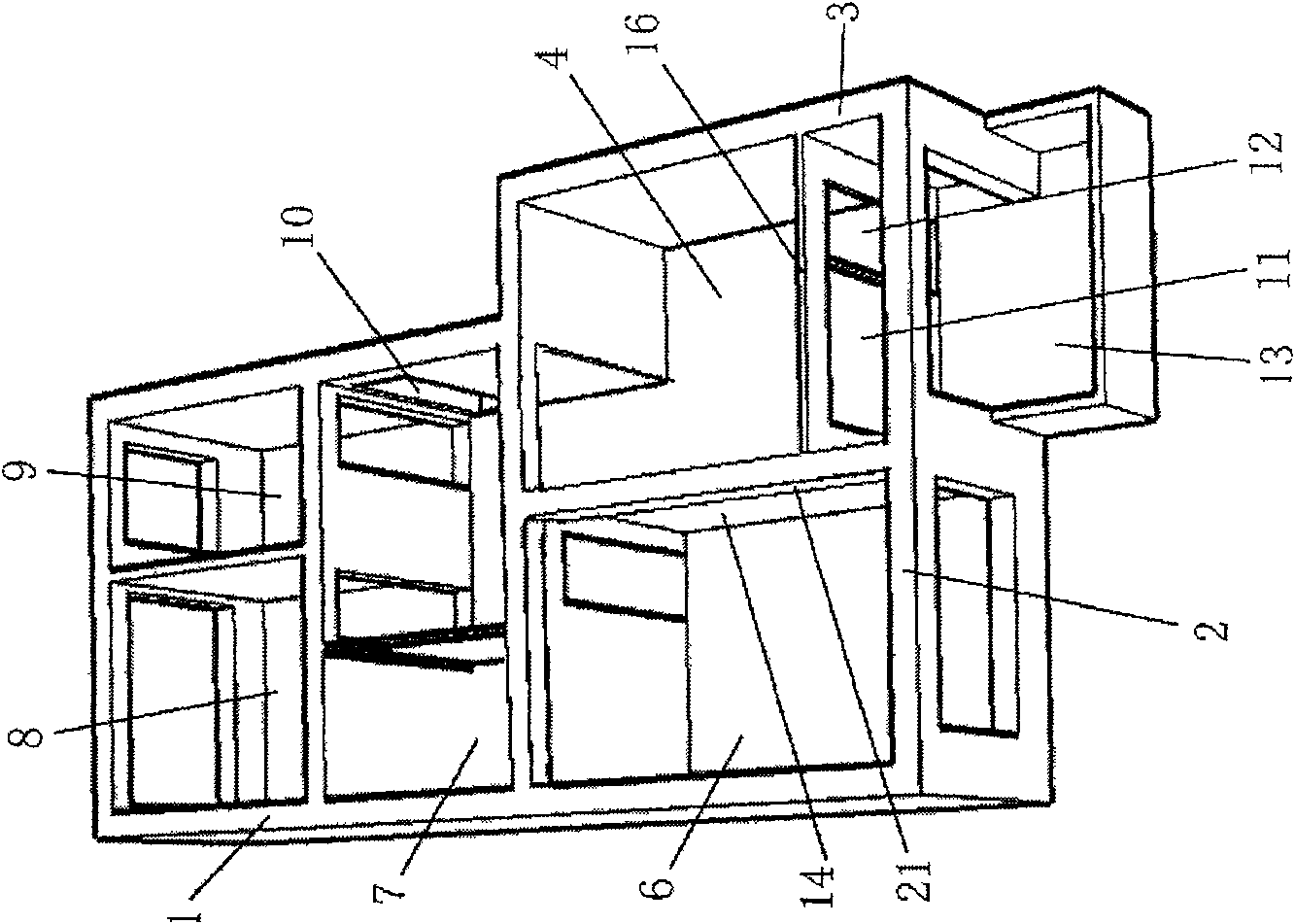

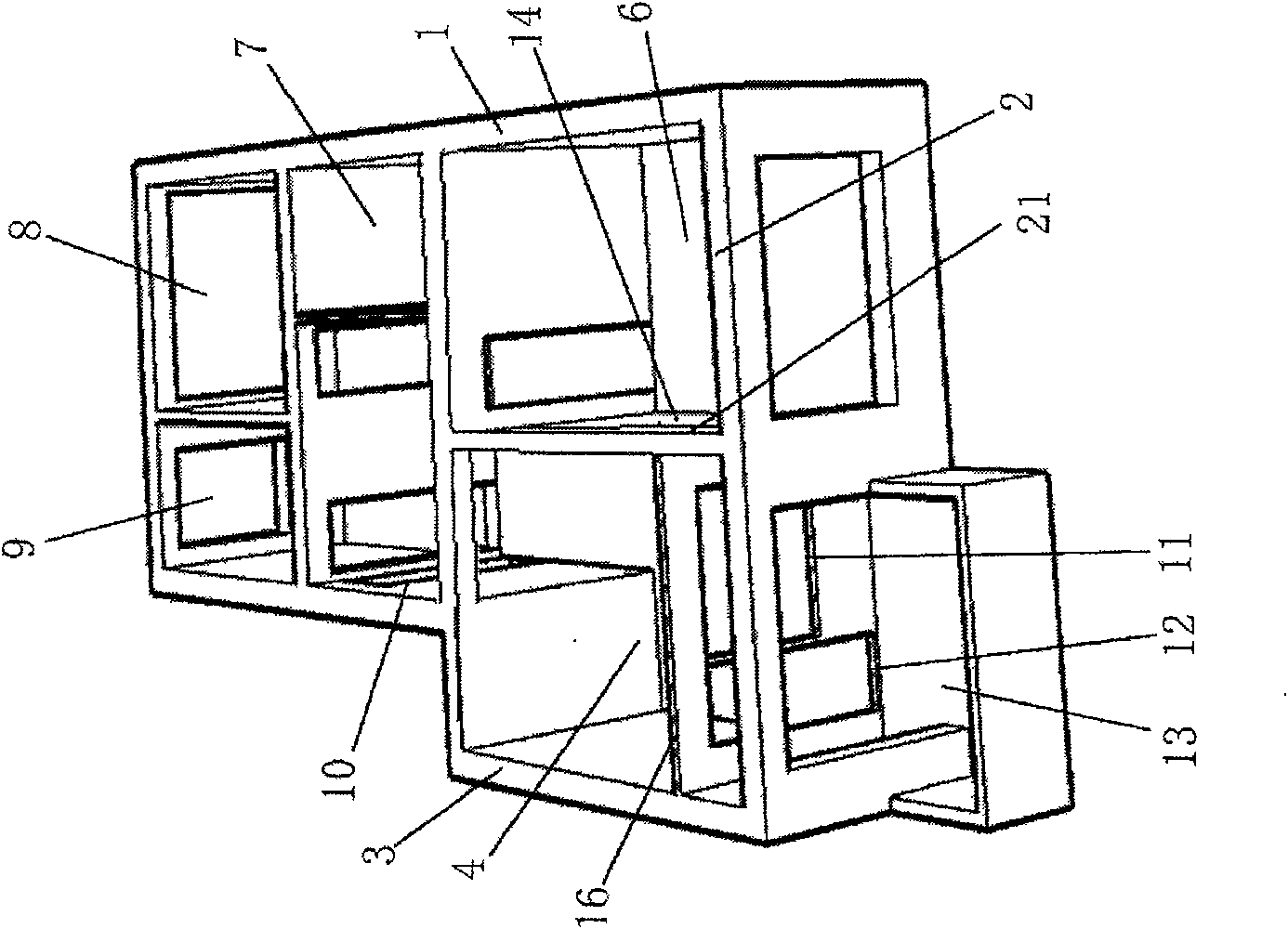

Multilayer and high-rise residential building of odd and even layer asymmetric matrix

InactiveCN101144326AImprove use valueDoes not affect privacyBuilding scaffoldsNon symmetricLiving room

A kind of odd-even-floor asymmetric matrix multi-level and high-rise residence, which is a cast-in-place concrete structure, composed of odd-numbered-story houses and vertically adjacent even-numbered-story houses stacked on top of each other and combined repeatedly. Each house includes a living room, At least one non-living room and terrace, the single house is surrounded by walls and floors, characterized in that: the living hall of the odd-numbered single-house and the living hall of the even-numbered single house are arranged alternately from left to right or right and left, and the odd-numbered floor There are terraces outside the living room of the single-family house and the living room of the even-numbered-floor single-suite house. The terrace and the living room are separated by a partition wall. The invention makes the front facade of the house form an asymmetrical matrix form, and each house not only obtains a high-quality terrace with a large depth outside the living room, but also does not block the daylighting of the living room, and obtains a high-quality garden-style living space. The living room improves the quality of the residence and can be applied to various multi-storey and high-rise buildings.

Owner:王治国

Apparatus for reproduction of stereo sound

ActiveUS8553914B2DepthReduce the amplitudeTransducer detailsTwo-channel systemsTransducerEngineering

Apparatus for reproducing stereo sound having a housing (1, 25) defining an at least partially enclosed space. A first transducer (7) or pair of transducers (28, 29) is provided and arranged to reproduce one, both or the sum of two audio signals. A pair of transducers (10, 32) is also provided and arranged to reproduce a signal comprising the difference of the two audio signals. As the transducers communicate with the at least partially enclosed space, and the transducers arranged to reproduce the difference between the two audio signals are each arranged to direct their output primarily in a direction generally at right angles to the direction in which the first transducer or pair of transducers primarily direct their output. The apparatus may be arranged to be placed on or adjacent a generally flat surface, and the transducers arranged to reproduce the difference of the two audio signals may be arranged to direct their output towards the flat surface.

Owner:ORBITSOUND LTD

Agglomerated residence

The present invention relates to one kind of agglomerated residence. The toilet in each apartment has one linear outer wall with window or door and the toilet outer wall, the house outer wall and the hall outer wall constitute the U-outer wall combination of balcony. The balcony has one outside opened to outside and with end connected to the house outer wall and one inside opened to the patio and with end connected to the hall outer wall. The wall of the balcony opposite to the toilet outer wall is the apartment separating straight wall. The agglomerated residence has apartments with small width, great depth, all bright rooms, high land utilization and low power consumption.

Owner:郭建军

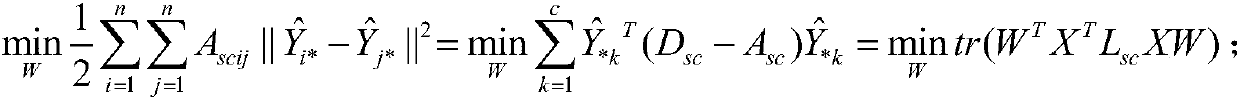

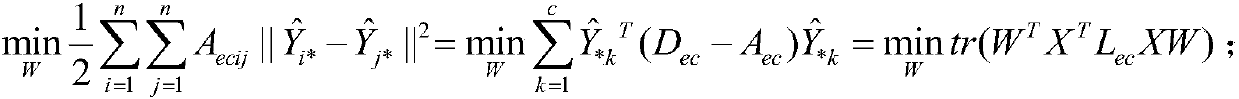

Microblog emotion analysis method combining microblog weak relationship

InactiveCN108595515AIn line with the actual situationRelationship richData processing applicationsSpecial data processing applicationsPattern recognitionMicroblogging

The invention discloses a microblog emotion analysis method combining microblog weak relationship, and belongs to the technical field of text classification. The method comprises the following steps:step (1): calculating an emotion consistency relationship matrix between microblogs, and establishing a microblog emotion analysis model based on the emotion consistency; step (2): calculating a microblog emotional infectivity matrix, and establish a microblog emotion analysis model based on the emotional infectivity; step (3): using a community partitioning algorithm to calculate the microblog weak relationship matrix, and establishing a microblog emotion analysis model based on the microblog weak relationship; step (4): combining the steps (1), (2) and (3) to obtain a comprehensive model, and then adding the emotion analysis model based on the microblog text content and performing regularization to obtain a final model; step (5): optimizing the final model and solving a microblog emotionanalyzer. The microblog emotion analysis method combining microblog weak relationship in the invention not only utilizes the microblog matrix, but also considers the text content of the microblog, which is more accurate and credible.

Owner:HARBIN ENG UNIV

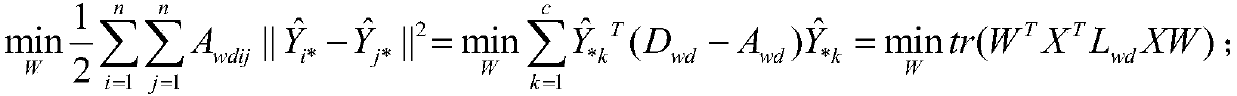

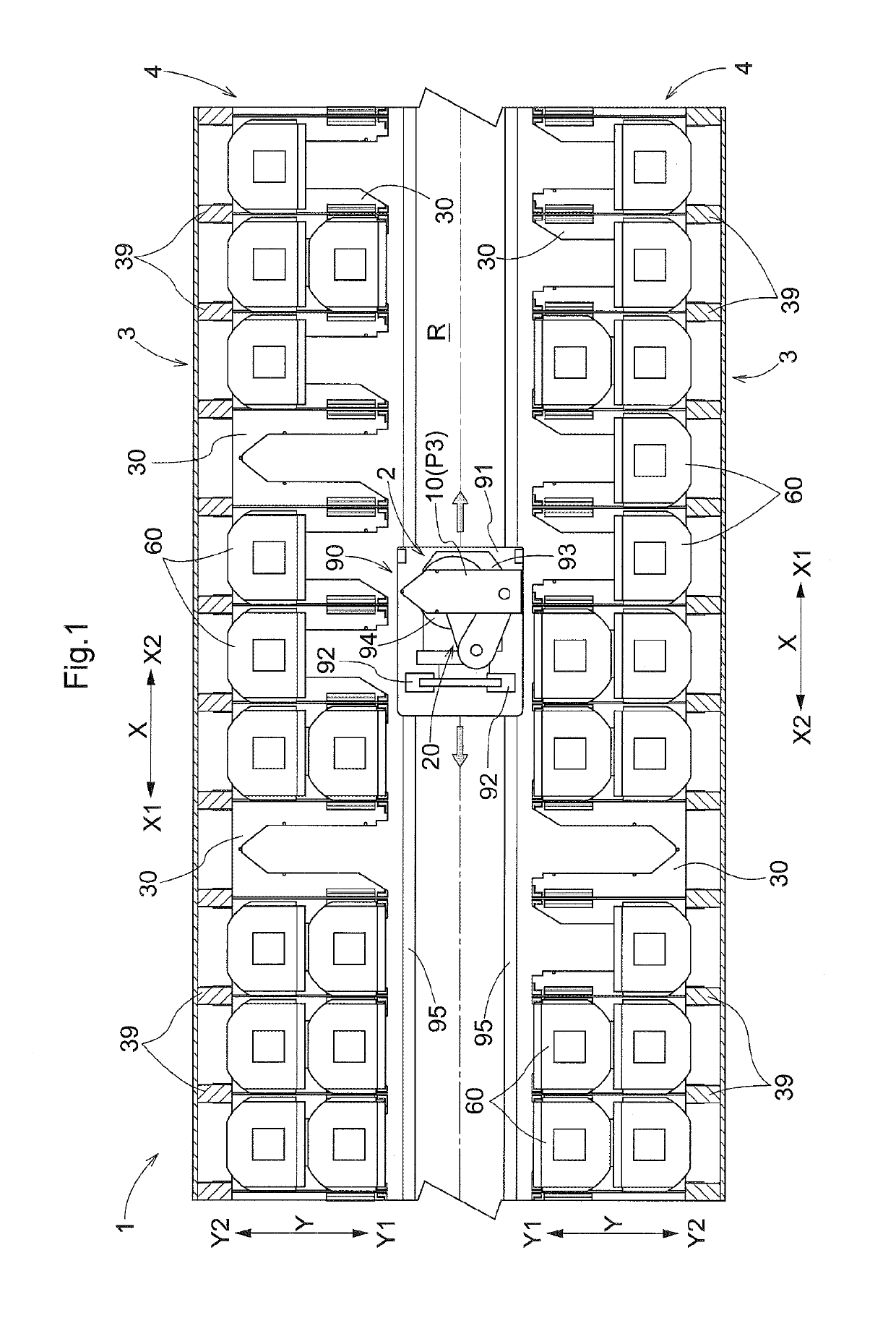

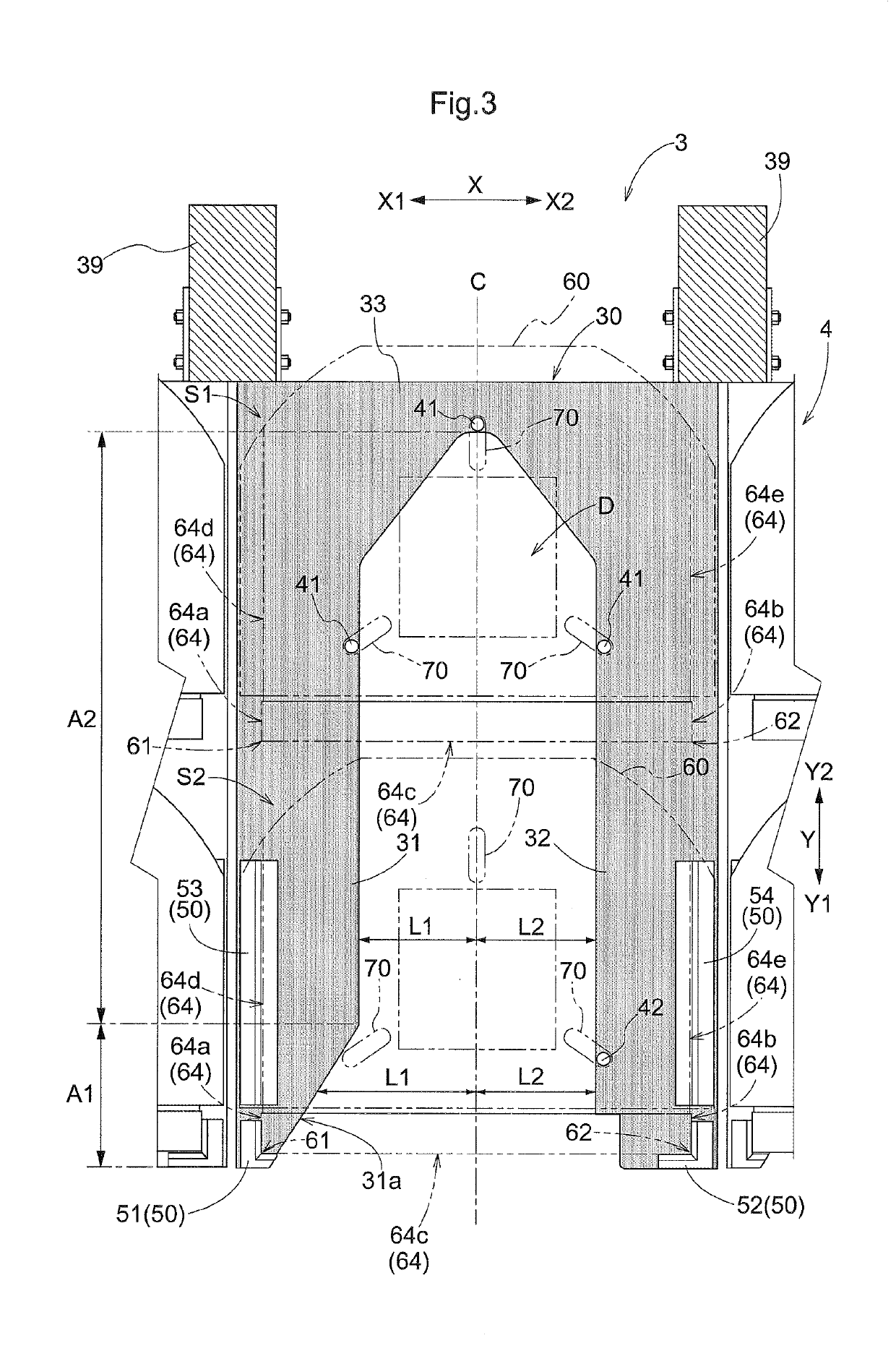

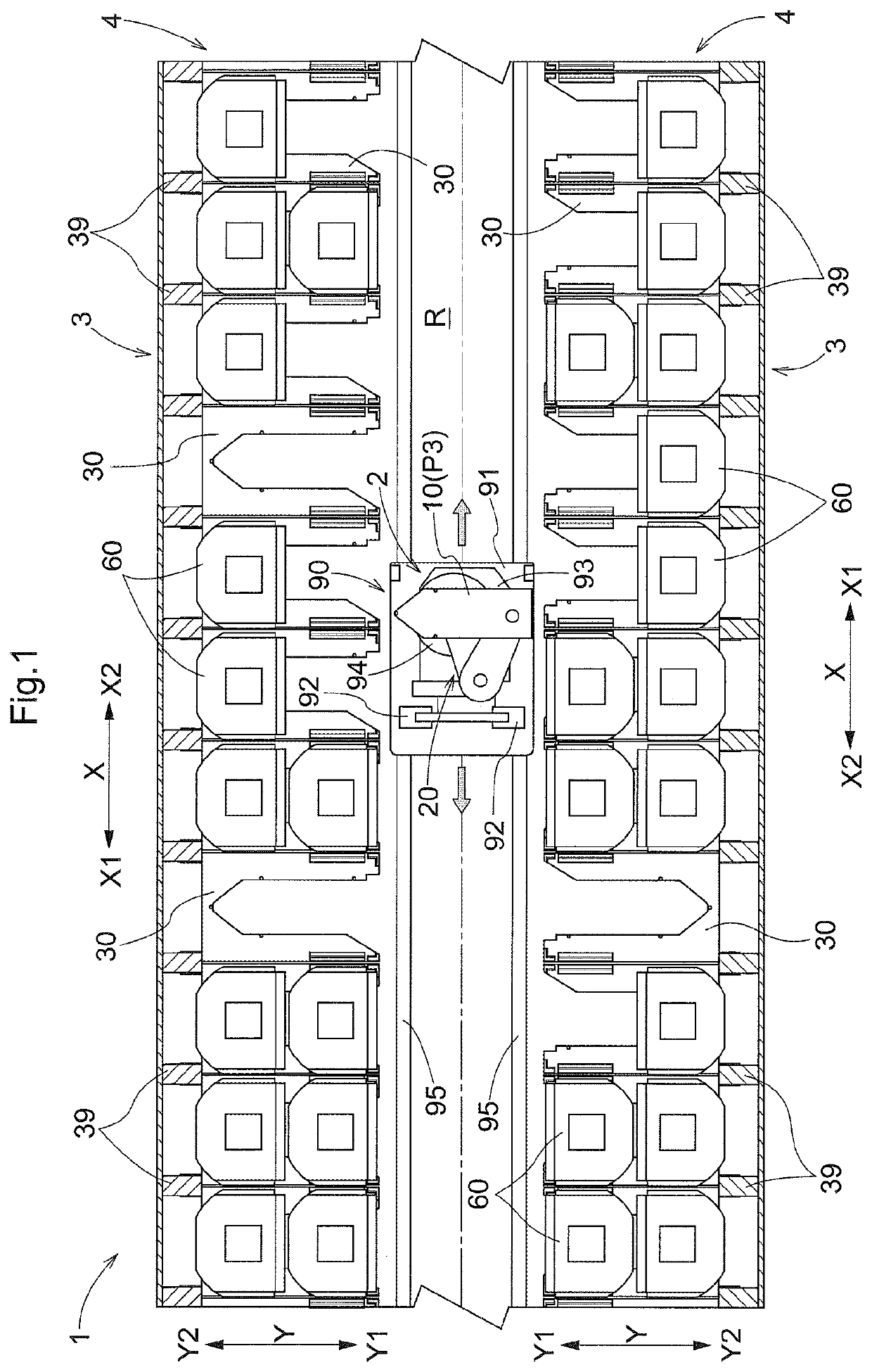

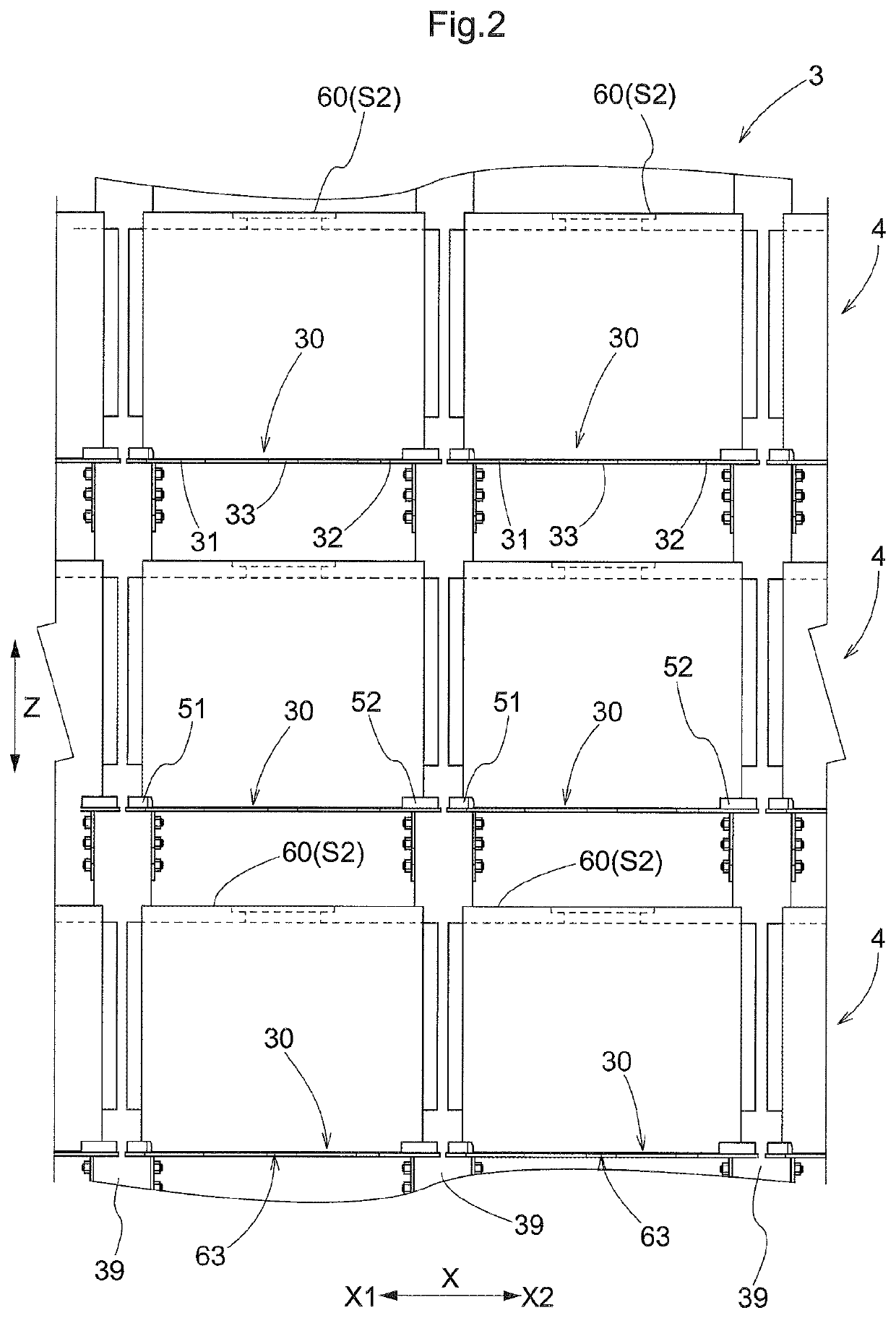

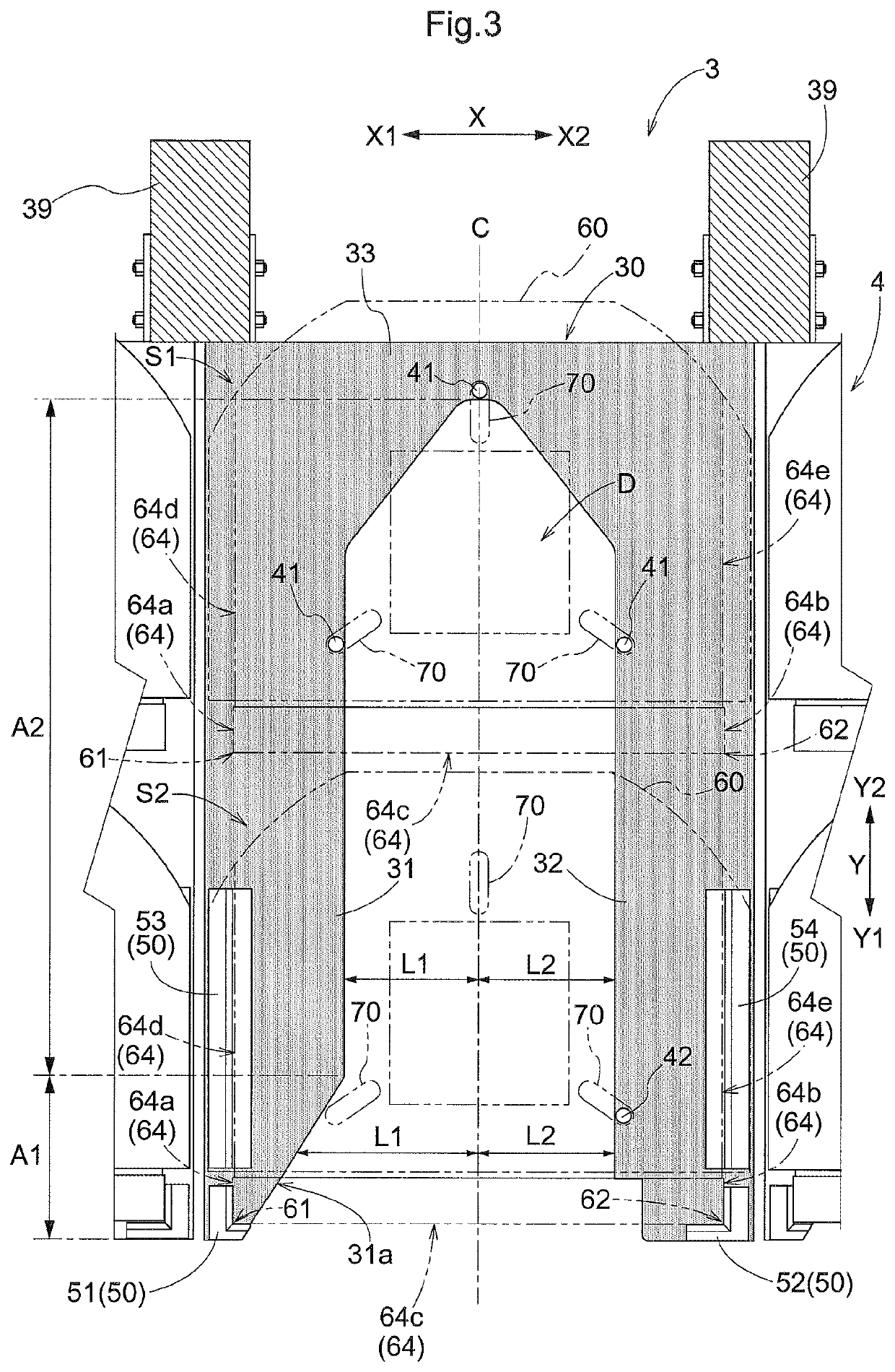

Article Storage Facility

ActiveUS20190198370A1Increase separation spaceConvenient ArrangementSemiconductor/solid-state device manufacturingStorage devicesCouplingEngineering

An advancing / retracting mechanism includes a first arm, a second arm, a first coupling part that couples the first arm and the second arm, and a second coupling part that couples a supporting body and the first arm. A transfer device is configured to move the supporting body back and forth with the first coupling part located on a first side relative to the second coupling part, by rotating the first arm and the second arm. In a first region, which is a region in the depth direction and includes an end on the front side of the rack body, a distance from the width directional center to the first supporting portion is longer than a distance from the width directional center to the second supporting portion.

Owner:DAIFUKU CO LTD

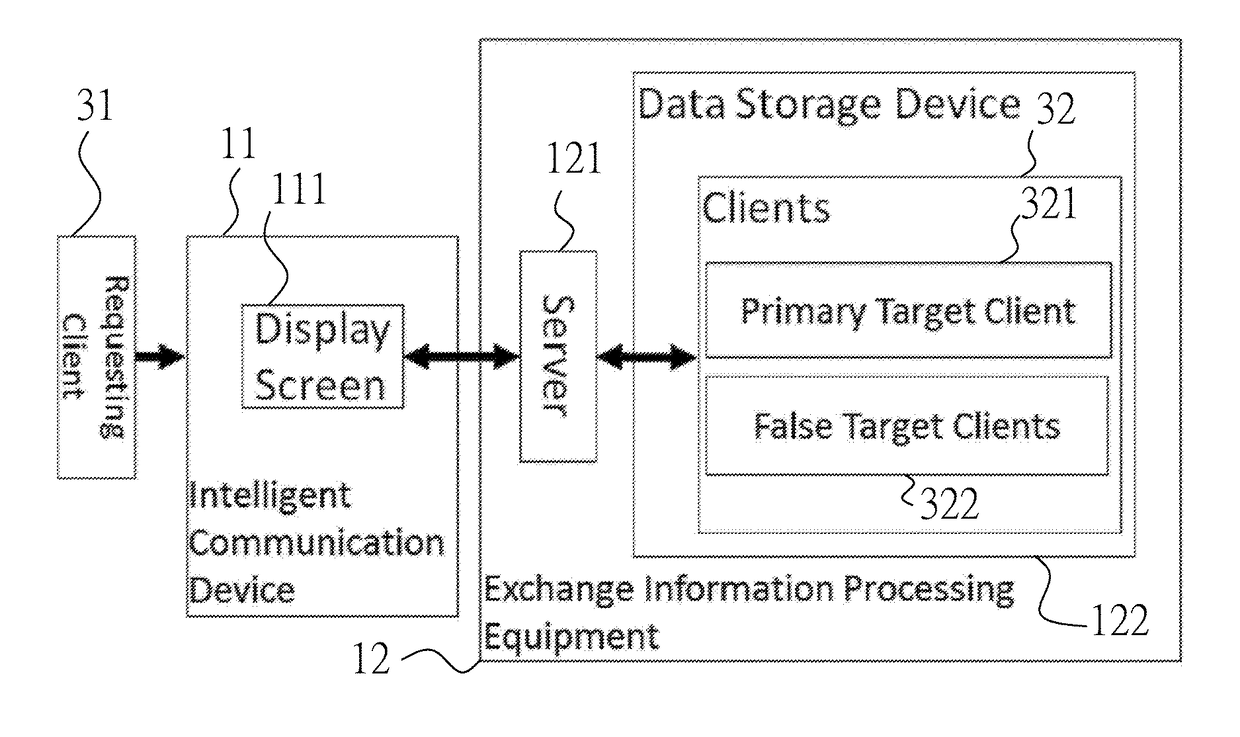

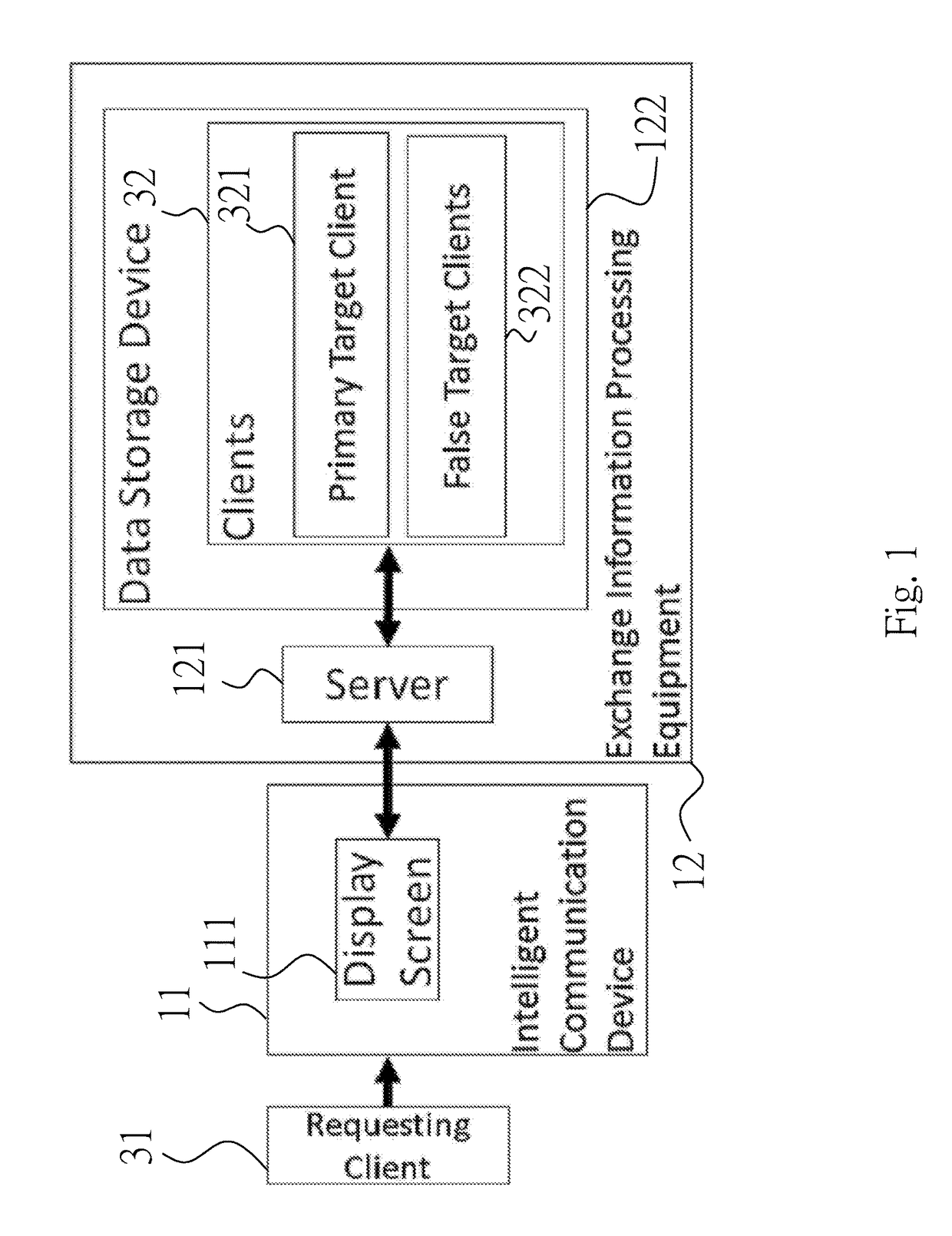

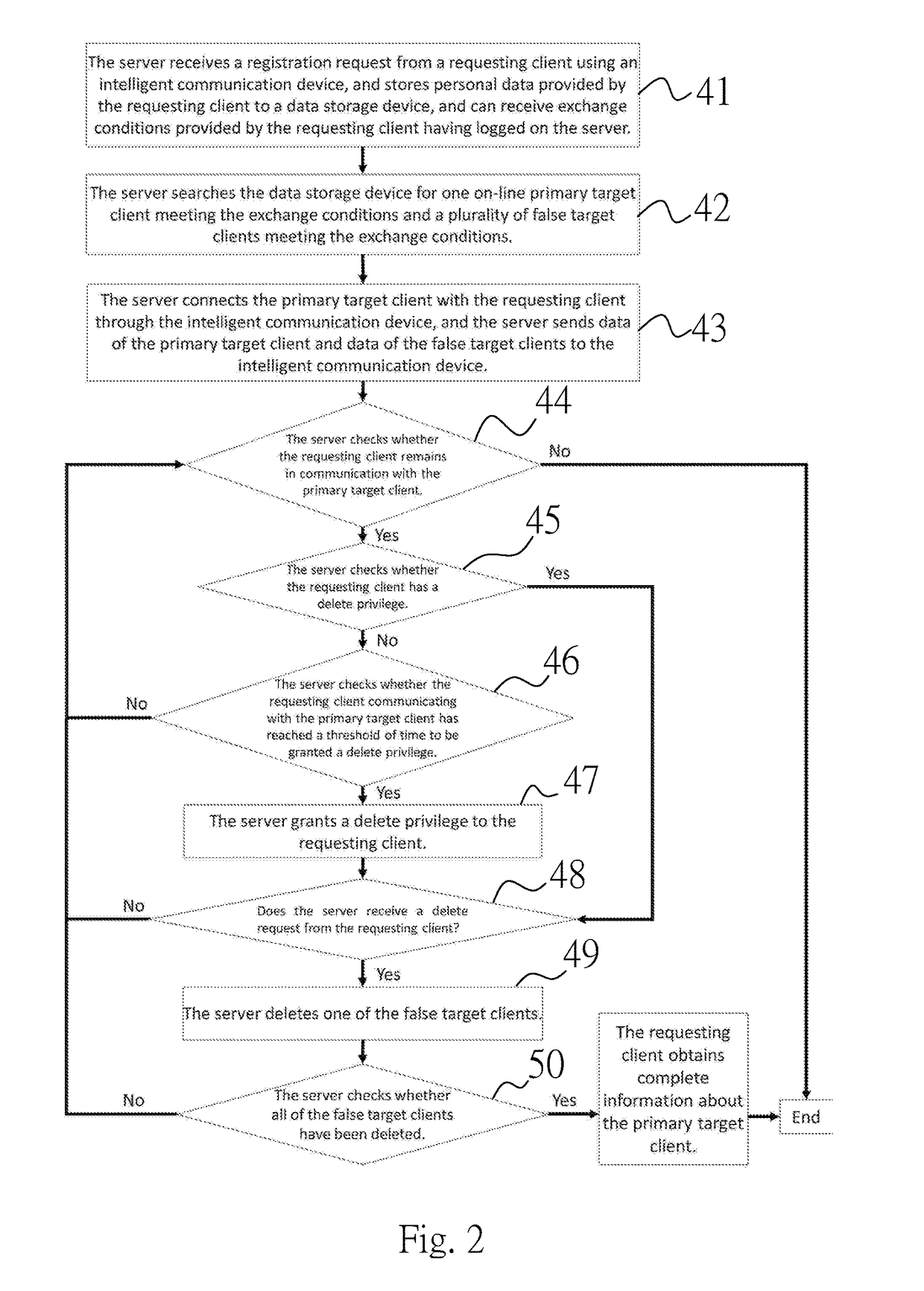

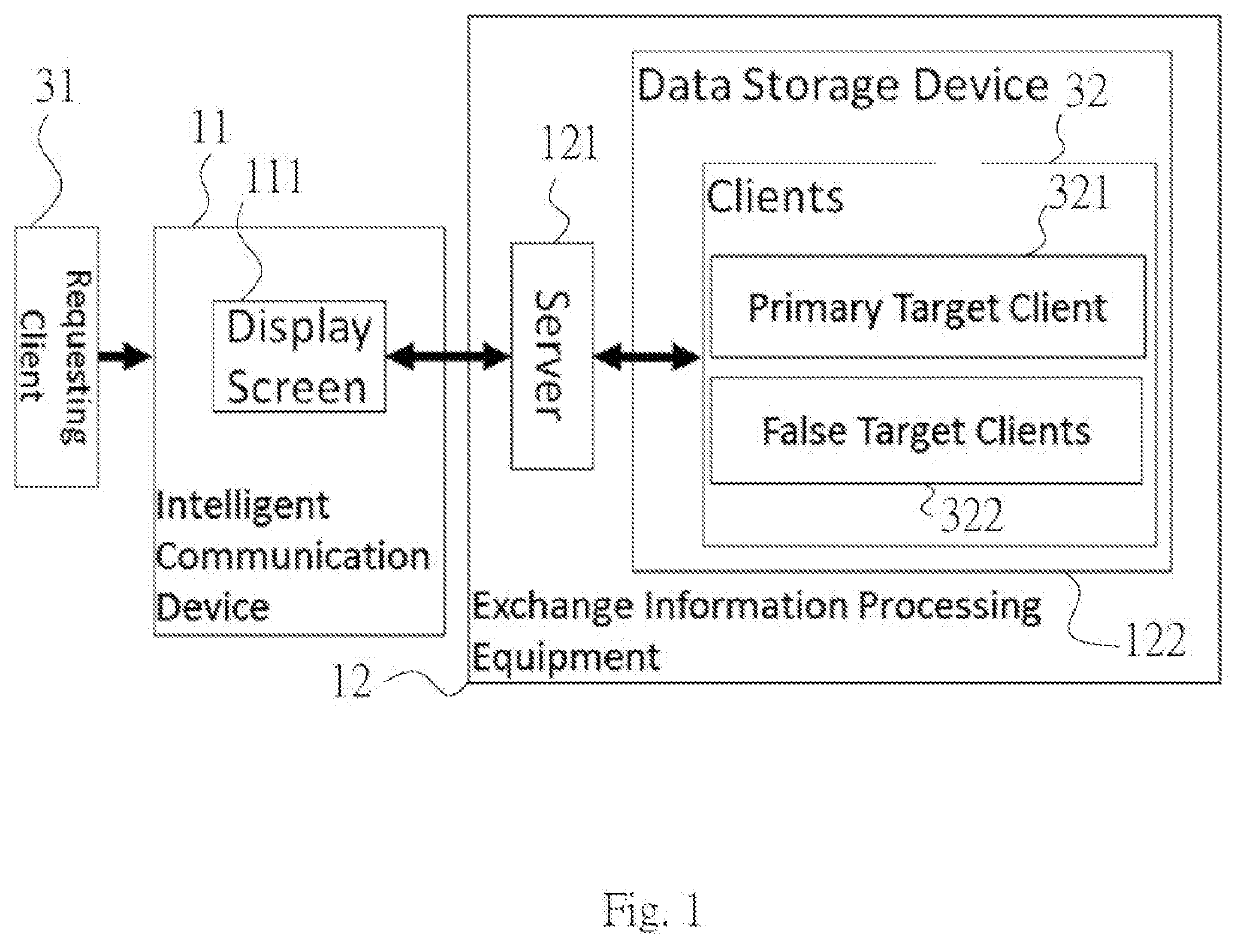

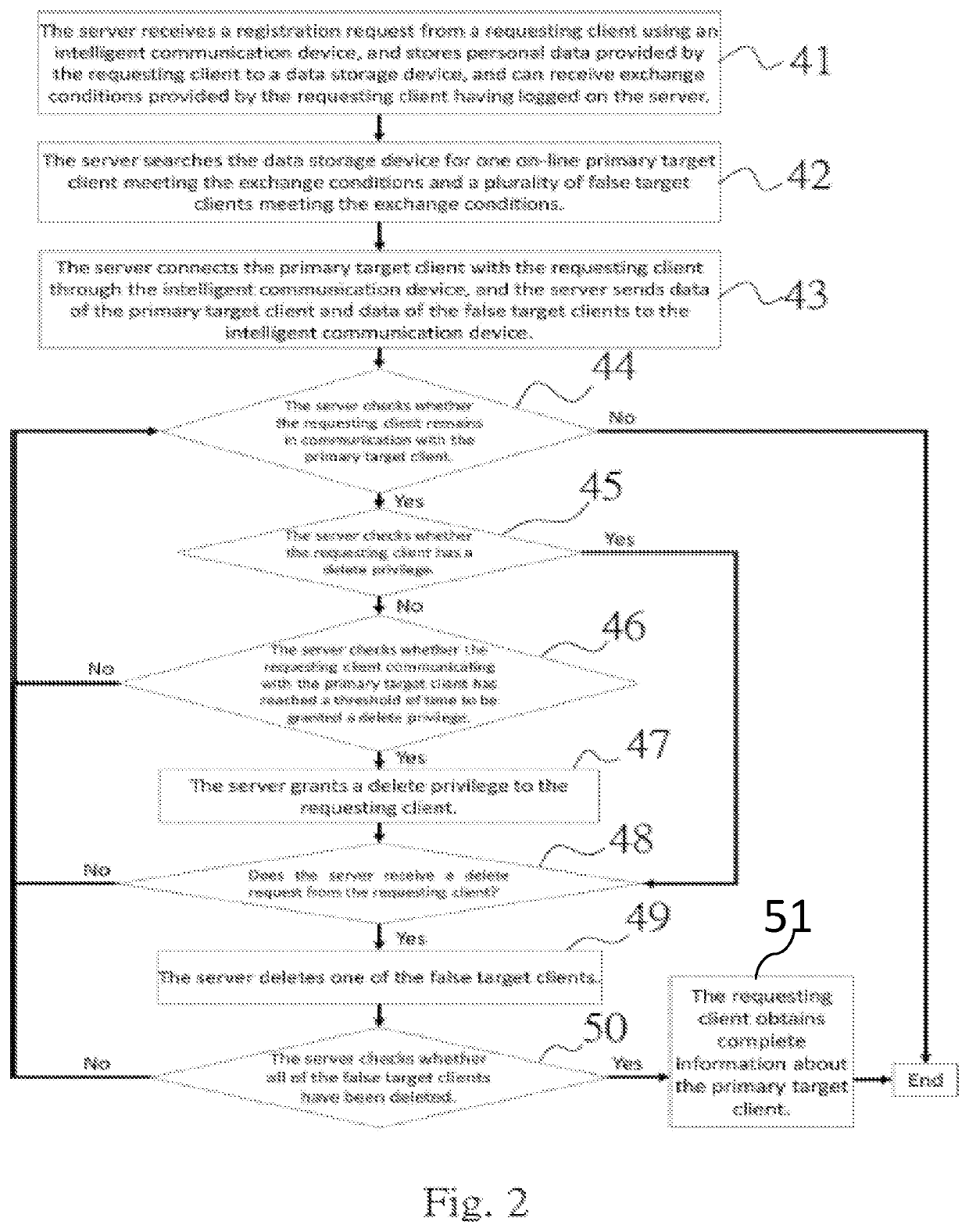

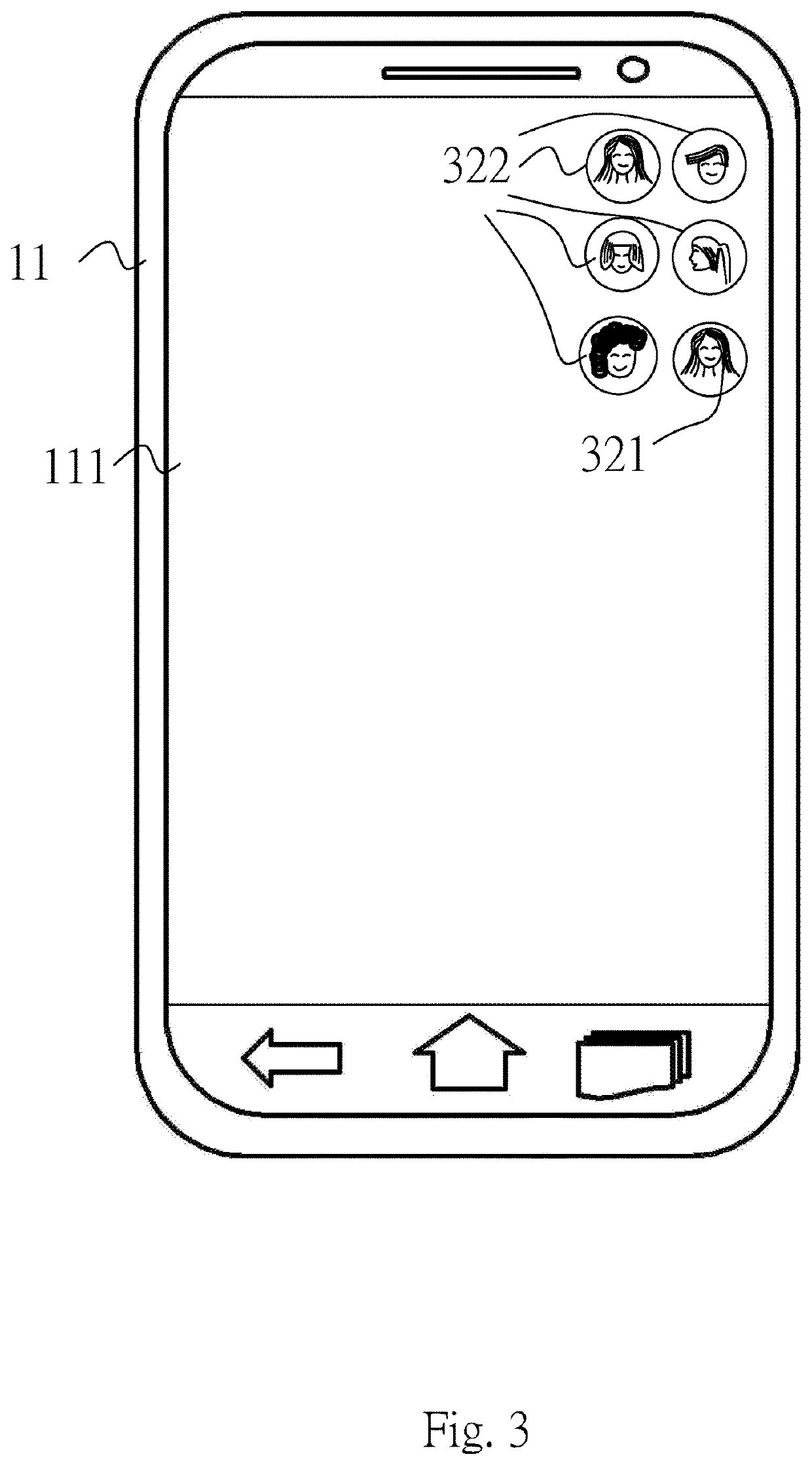

Method of Two-Way Information Exchange for Intelligent Communication Devices and System using the Method

ActiveUS20180020079A1Extension of timeTrue interpersonal relationshipTransmissionClient-sideCommunication device

A method of two-way information exchange for intelligent communication devices is provided on a system for creating an information exchange channel between at least one requesting client and at least one target client. The method comprises: (a) the requesting client logs on a server of the system through an intelligent communication device; (b) the server receiving exchange conditions provided by the requesting client; (c) the server searching a data storage device of the system for a primary target client and a plurality of false target clients; (d) the requesting client communicating with the primary target client through the intelligent communication device; (e) the server granting the requesting client a delete privilege when the requesting client communicating with the primary target client reaches a threshold of time; (f) the server deleting at least one of the false target clients when receiving a delete request from the requesting client.

Owner:WANG YI CHEN

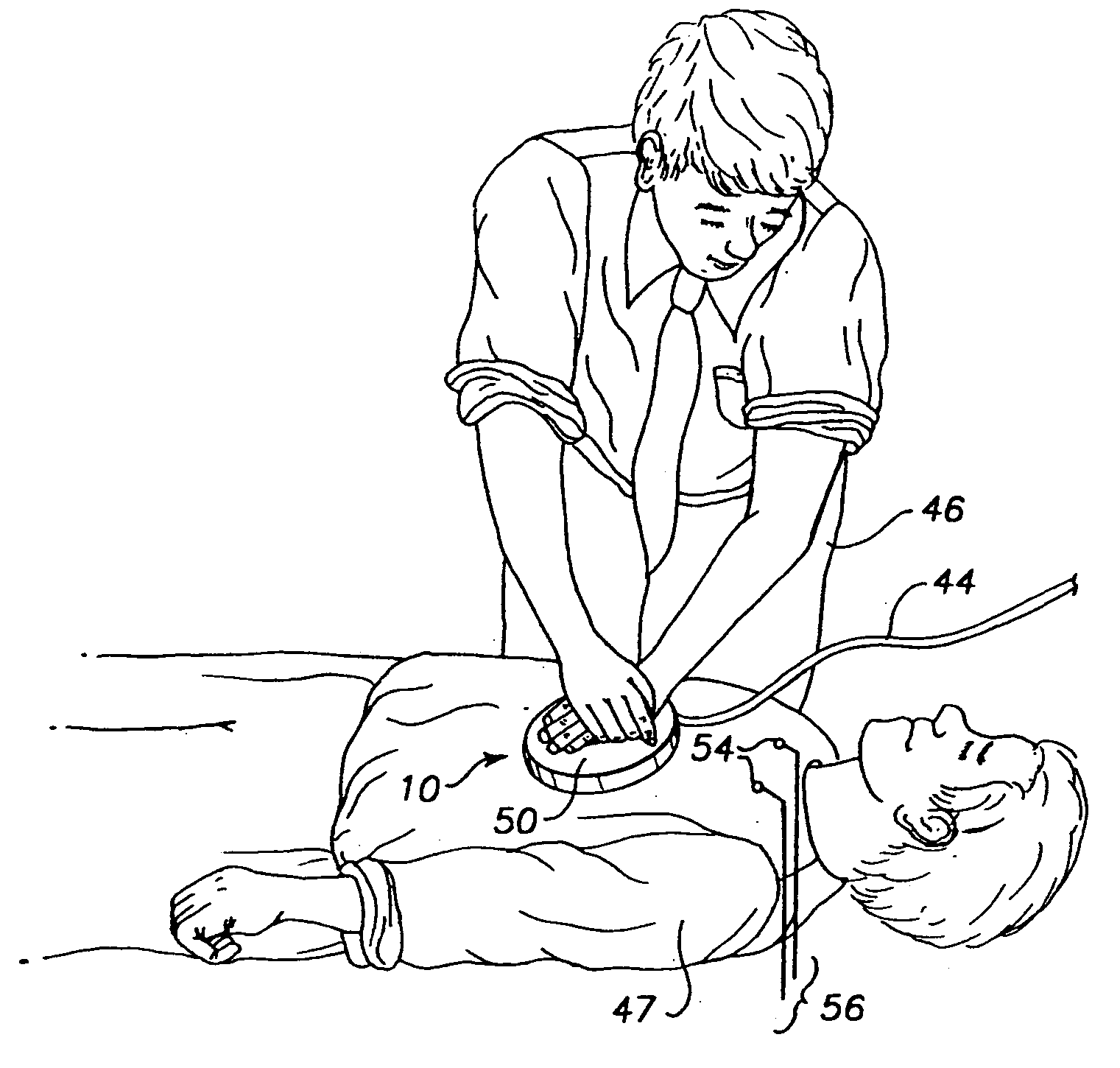

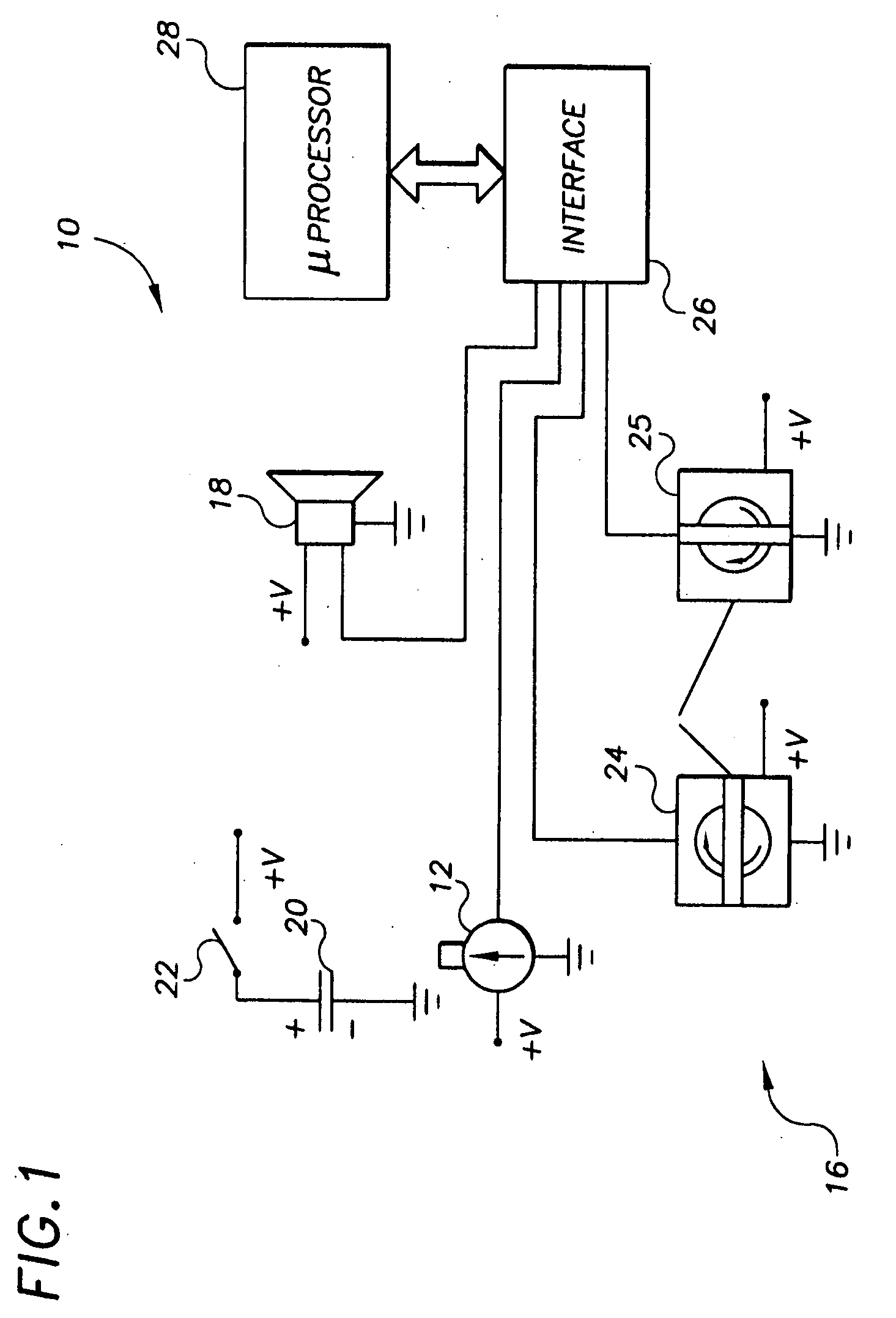

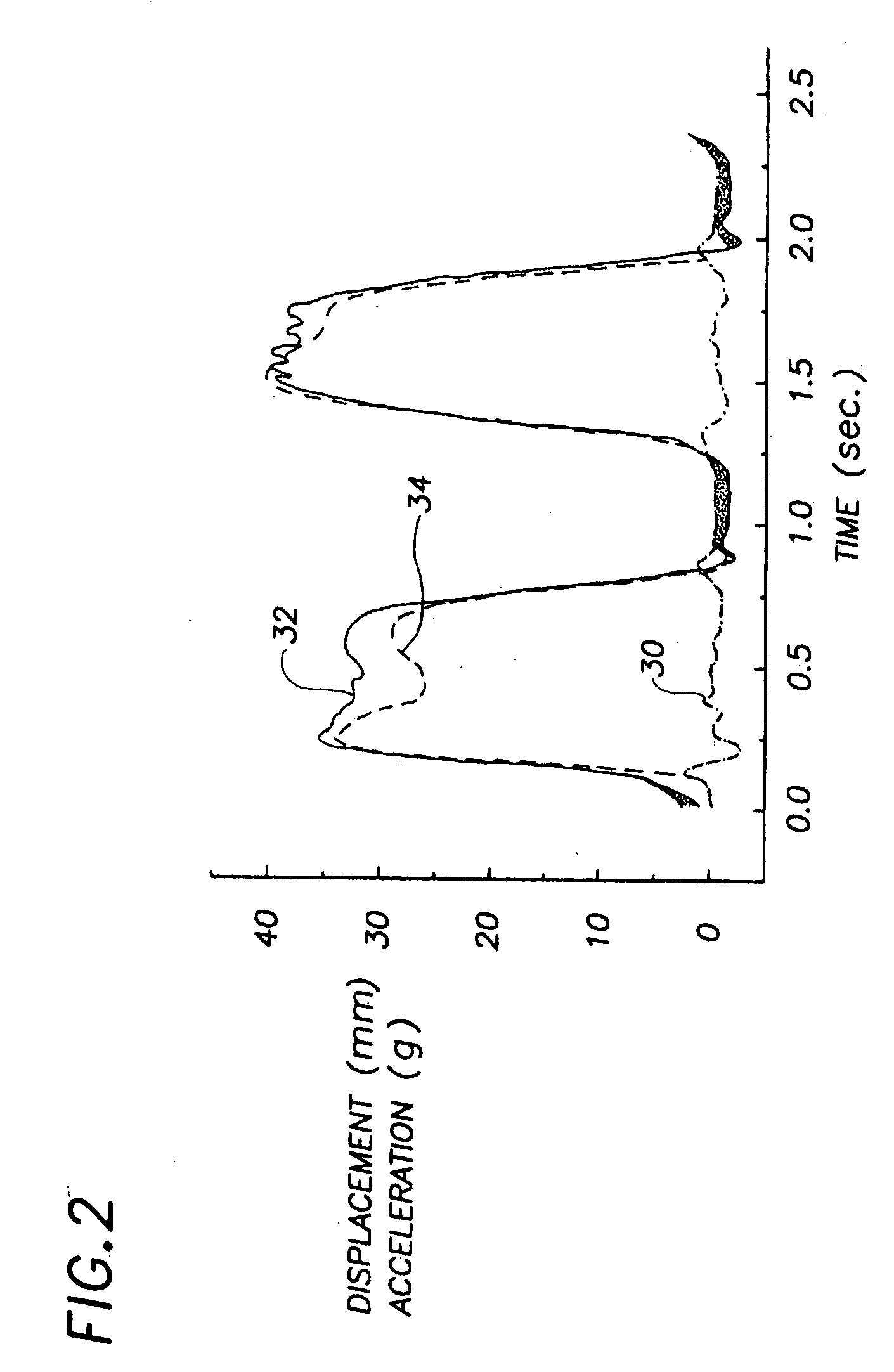

ECG signal processor and method

InactiveUS20050004484A1Improve survival rateEasy to manage effectivelyRespiratorsElectrocardiographyEcg signalEmergency medicine

Chest compressions are measured and prompted to facilitate the effective administration of CPR. A displacement detector determines a displacement indicative signal indicative of the displacement of the CPR recipient's chest toward the recipient's spine. A signaling mechanism provides chest compression indication signals directing a chest compression force being applied to the chest and a frequency of such compressions. An automated controller and an automated constricting device may be provided for applying CPR to the recipient in an automated fashion. The automated controller receives the chest compression indication signals from the signaling mechanism, and, in accordance with the chest compression indication signals, controls the force and frequency of constrictions. The system may be provided with a tilt compensator comprising a tilt sensor mechanism outputting a tilt compensation signal indicative of the extent of tilt of the device, and may be further provided with an adjuster for adjusting the distance value in accordance with the tilt compensation signal. An ECG signal processor may be provided which removes the CPR-induced artifact from a measured ECG signal_obtained during the administration of CPR.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

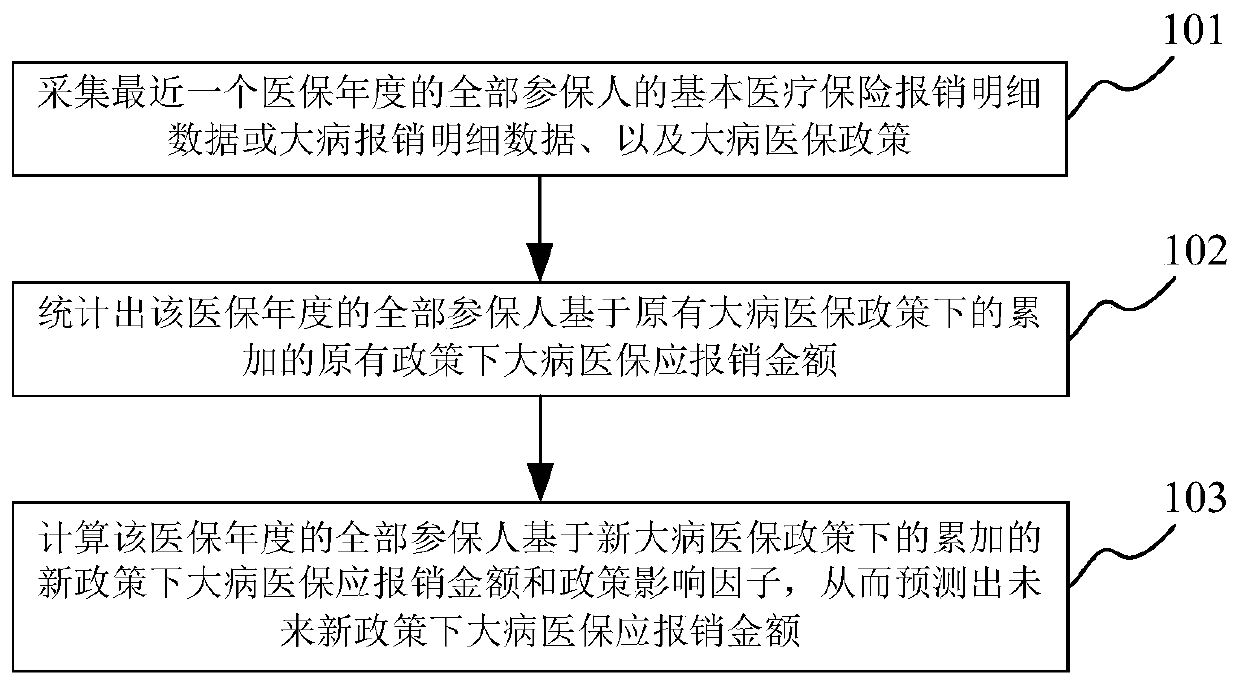

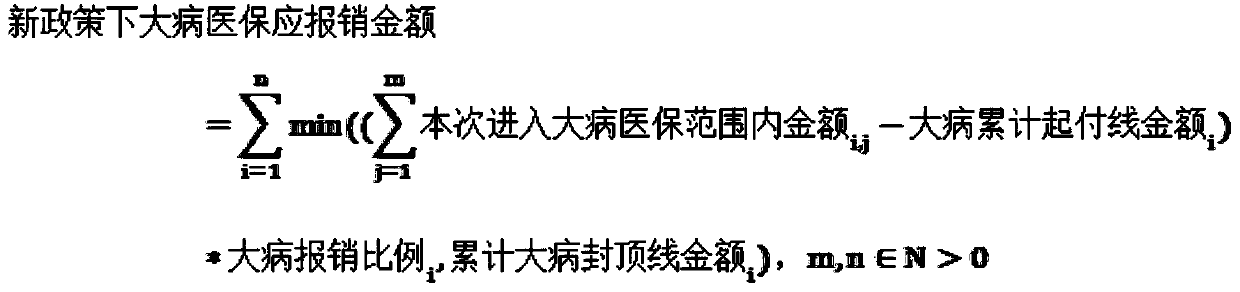

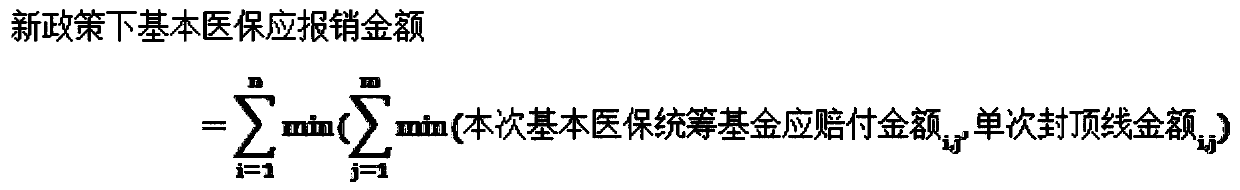

Method and system for quantifying influence of big disease medical insurance policy adjustment on fund expenditure

The invention discloses a method and a system for quantifying the influence of big disease medical insurance policy adjustment on fund expenditure. The method comprises the following steps of collecting samples: collecting Basic medical insurance reimbursement detail data or serious illness reimbursement detail data of all insured persons in the recent medical insurance year and a serious illnessmedical insurance policy wherein the serious illness medical insurance policy comprises an original serious illness medical insurance policy and a new serious illness medical insurance policy corresponding to the medical insurance year; counting data: counting the accumulated large-disease medical insurance reimbursement amount of all insured people in the medical insurance year based on the original large-disease medical insurance policy; and carrying out modeling prediction: calculating the accumulated amount and the policy influence factor of the serious medical insurance to be reimbursed of all insured people of the medical insurance year based on the new policy under the new serious medical insurance policy so as to predict the amount of the serious medical insurance to be reimbursedof the future new policy.

Owner:PACIFIC MEDICAL HEALTH MANAGEMENT CO LTD

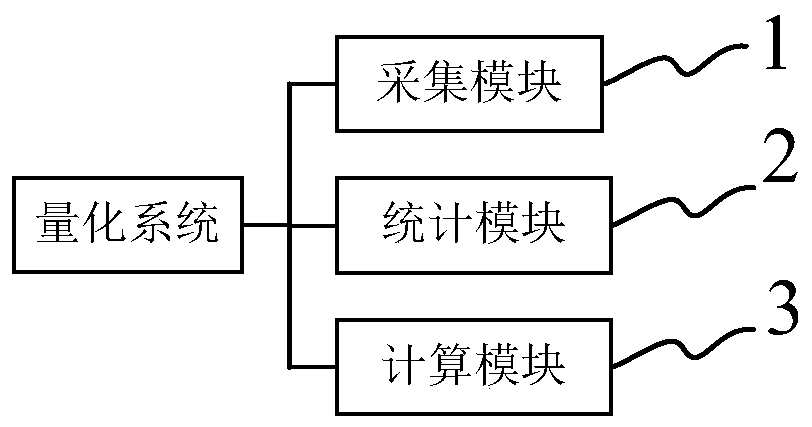

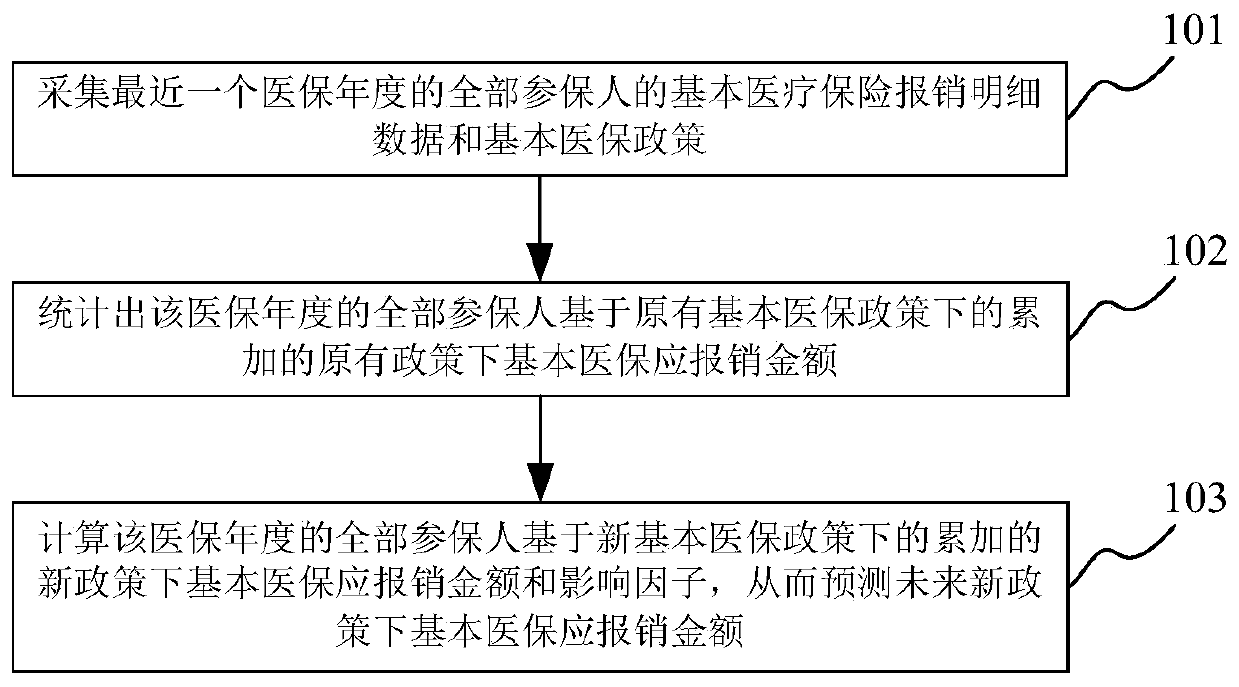

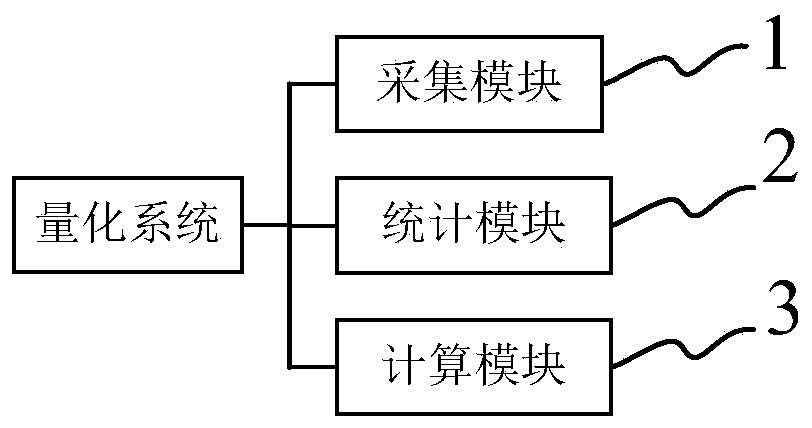

Method and system for quantifying influence of basic medical insurance policy adjustment on fund expenditure

PendingCN110210985AAdjustment sensitivity is highRich dimensionFinanceModel predictionMonetary Amount

The invention discloses a method and a system for quantifying the influence of basic medical insurance policy adjustment on fund expenditure. The method comprises the following steps of collecting samples: collecting basic medical insurance reimbursement detail data and basic medical insurance policies of all insured persons in the recent medical insurance year wherein the basic medical insurancepolicies comprise the original basic medical insurance policies and the new basic medical insurance policies corresponding to the medical insurance year; counting data: counting the accumulated basicmedical insurance reimbursement amount of all insured people in the medical insurance year based on the original basic medical insurance policy; and carrying out modeling prediction: calculating the basic medical insurance reimbursement amount and the policy influence factor of all insured people of the medical insurance year based on the accumulated new policy under the new basic medical insurance policy so as to predict the basic medical insurance reimbursement amount under the new policy in the future.

Owner:PACIFIC MEDICAL HEALTH MANAGEMENT CO LTD

Article storage facility

ActiveUS10957570B2Shorten the timeAvoid interferenceSemiconductor/solid-state device manufacturingStorage devicesCouplingSoftware engineering

An advancing / retracting mechanism includes a first arm, a second arm, a first coupling part that couples the first arm and the second arm, and a second coupling part that couples a supporting body and the first arm. A transfer device is configured to move the supporting body back and forth with the first coupling part located on a first side relative to the second coupling part, by rotating the first arm and the second arm. In a first region, which is a region in the depth direction and includes an end on the front side of the rack body, a distance from the width directional center to the first supporting portion is longer than a distance from the width directional center to the second supporting portion.

Owner:DAIFUKU CO LTD

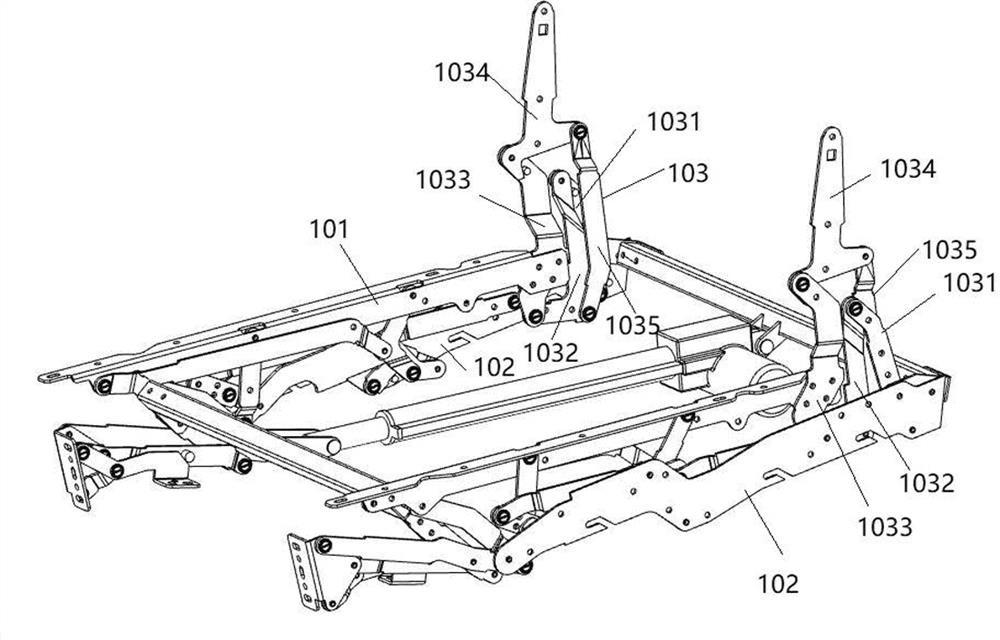

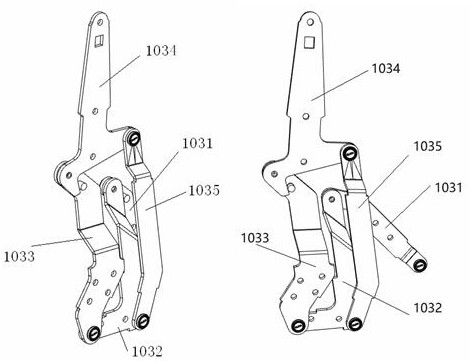

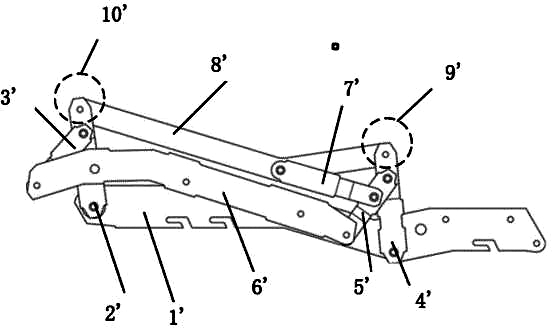

Back linkage mechanism for sofa

PendingCN113040556AIncrease the areaImprove use comfort performanceSofasCouchesPhysicsSitting Positions

The invention relates to a back linkage mechanism for a sofa. The mechanism is characterized in that a connecting rod assembly forming the back linkage mechanism comprises a plurality of rod bodies and a backrest mounting seat, the rod bodies are rotationally connected end to end, and the backrest mounting seat is arranged on one rod body and rotationally connected with the other connecting rod through the other auxiliary connecting rod, so that the backrest mounting seat is fixed above the rod bodies; the rod bodies which are rotationally connected end to end are in a folded state of being sequentially stacked when the sofa is in a sitting posture; and when the sofa is in a TV posture or a lying posture, the rod bodies are in a half-stretching state or a full-stretching state respectively. The mechanism has the advantages that the back mechanism is designed into a transverse stacking structure and a movement track, so that the space is saved, and a user is prevented from feeling squeezed in the posture changing process of the sofa; and the use comfort of a user is improved.

Owner:KUKA HOME

Method for preparing carved wood grain-simulated PVC decorative film

ActiveCN101531081BWith flame retardant functionSolve the disadvantage of being easy to burnFlexible coversWrappersColor printingEngineering

The invention relates to a method for preparing a carved wood grain-simulated PVC decorative film. The method comprises the following technological steps: preparing a PVC face film; preparing a PVC substrate; carrying out two to six sets of color printing on the surface of the PVC face film according to the pattern demands; adopting each set of color slurry, and entering the next set of color printing after printing each set of colors and drying the PVC face film at a temperature of 140 to 160 DEG C; preparing the colorful PVC face film; coiling the printed colorful PVC face film into a largecoil; heating, pressing and jointing the printed colorful PVC face film and the PVC substrate on a dual-roller jointing embossing machine, making pressing rollers used for pressing the colorful PVC face film surface be wood thorn embossing rubber rollers, and adjusting the temperature of both rollers to between 100 and 200 DEG C; directly loading the jointed and embossed PVC decorative film into a drying box to carry out secondary heating to 200 to 220 DEG C, and foaming the PVC face film; and cooling the PVC face film. The carved wood grain-simulated PVC decorative film prepared by the method has the advantages of flame retardant function, lifelike sculpture, hollow three-dimensional view and flash discoloration functions.

Owner:ECONESS ENERGY

Method of two-way information exchange for a system for making friends which display a primary target client and a plurality of false target clients and grants a requesting client the ability to delete at least one of a plurality of false target clients based on a threshold of time

A method of two-way information exchange for a system for making friends is disclosed. With the method, a system can provide a primary target client blended with a plurality of false target clients for a requesting client who seeks making friends. The requesting client is entitled to request the system to delete one of the target clients when communication between both parties reaches a threshold of time. The requesting client does not know which one of the target clients is the real client until all of the false target clients have been deleted, thus reducing preconceptions due to a person's appearance. As such, after a period of communication, both parties may achieve a certain degree of mutual understanding to facilitate a decision on making friends.

Owner:WANG YI CHEN

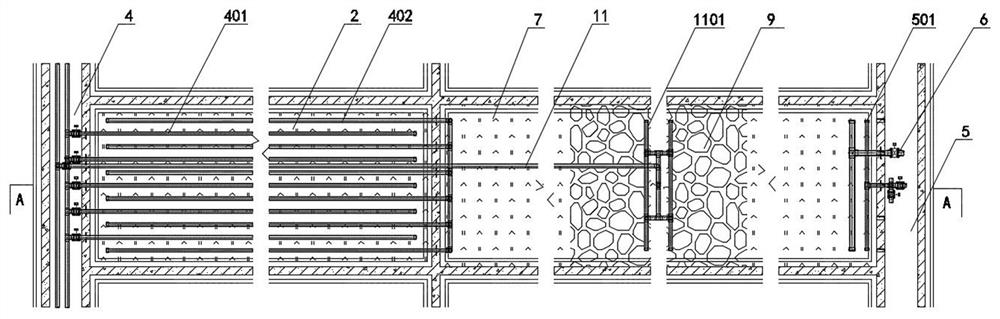

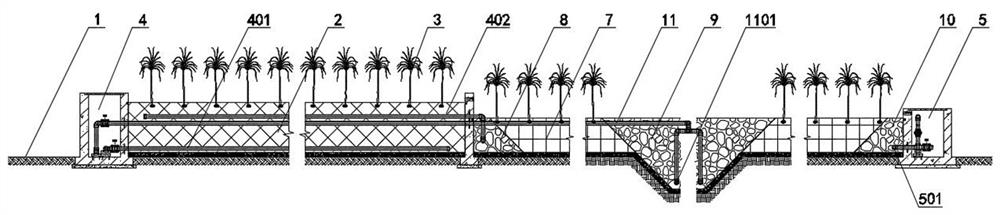

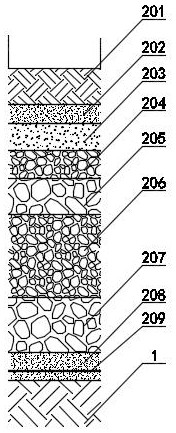

Improved constructed wetland sewage treatment system

PendingCN114772736AGood removal effectImprove water qualityWater contaminantsWater aerationConstructed wetlandAmmoniacal nitrogen

An improved constructed wetland sewage treatment system comprises a water distribution channel and a water collection channel, a first functional filler area which is connected with the water distribution channel and used for allowing sewage to longitudinally penetrate through so as to purify the sewage, and a second functional filler area which is communicated with the first functional filler area and used for allowing purified water of the first functional filler area to horizontally penetrate through, the water collecting channel is connected with the second functional filler area so as to collect purified effluent of the second functional filler area. According to the invention, sewage firstly flows through the filler in the longitudinal direction to form a vertical flow with better nitration capacity, and then the sewage horizontally flows through the filler to form a horizontal underflow, so that the combined type can improve the removal effect on indexes of pollutants such as total nitrogen, ammonia nitrogen, five-day biochemical oxygen demand, chemical oxygen demand, suspended solids, heavy metals and the like in the sewage; and the effluent quality of the wetland is optimized.

Owner:河南省宗祥环保工程有限公司

Multilayer and high-rise residential building of odd and even layer asymmetric matrix

The invention relates to a multi-storied residence and a high rise residence of an odd even story asymmetrical type matrix, and is a cast-in-situ concrete structure, the present invention is formed by being mutually overlapped and combined repeatedly and circularly by an odd storied residence and a vertical adjacent even storied residence, each residence comprises a living room, at least one non-living room and a terrace, a single residence is surrounded by a wall body and a floor slab. The invention is characterized in that the living room of the odd storied single residence and the living room of an even storied single residence are arranged in a left right or right left staggering way, the terrace is arranged in the living room of the odd storied single residence and the living room of the even storied single residence, a separated outer wall is separated between the terrace and the living room, the terrace is arranged along with the living room in a left right staggering and a right left staggering way. The invention enables the front vertical plane of the terrace to form the shape of the asymmetrical type matrix, each residence obtains a larger space from the outside the living room, simultaneously, the high-quality terrace of the living room for lighting is also covered, the high-quality garden type living room is also obtained, the residence quality is improved, the invention can be applied to various multi-storied building bodies as well as high rise building bodies.

Owner:王治国

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841BComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

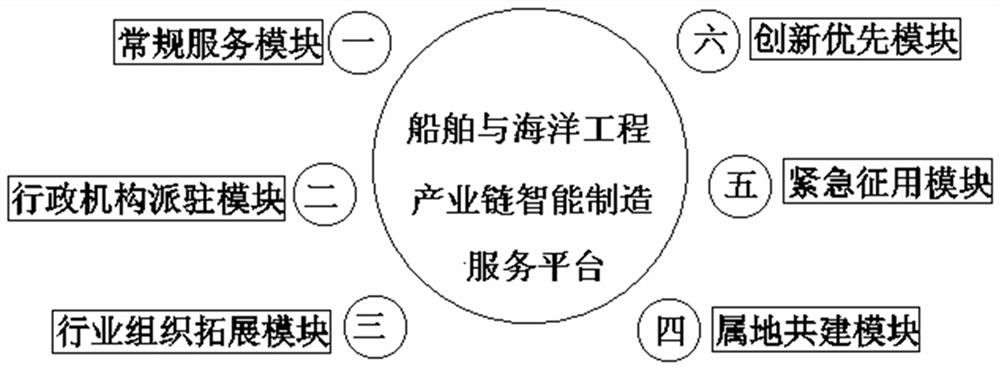

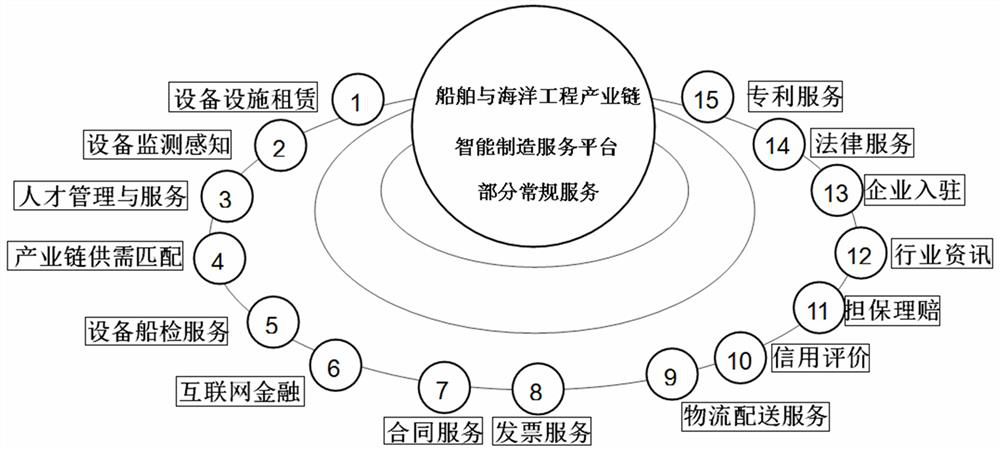

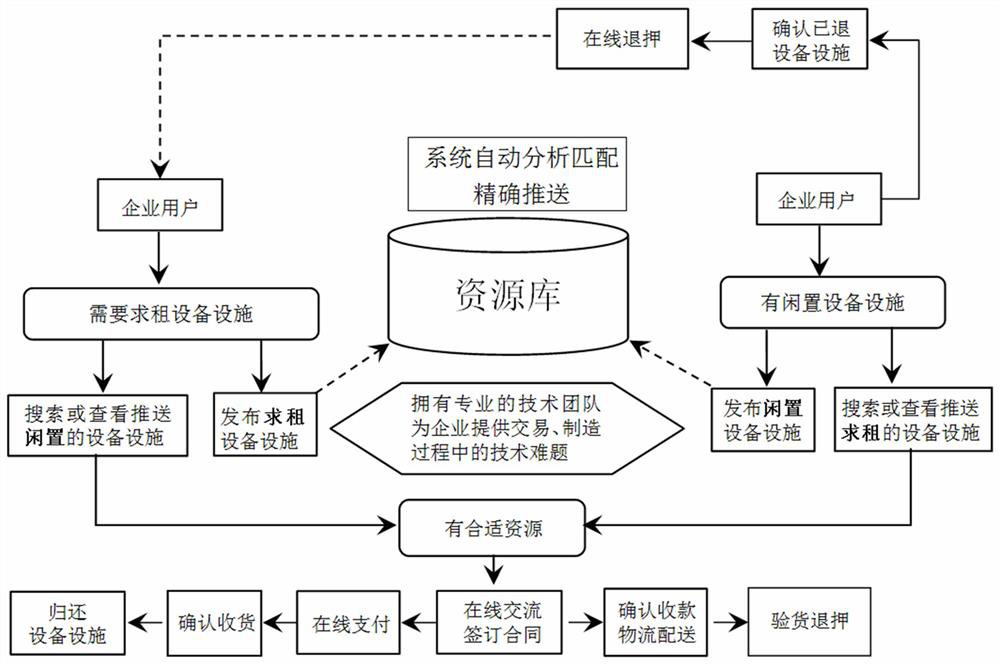

Intelligent manufacturing service platform for ship and ocean engineering industry chain

InactiveCN114757794AReduce purchasesReduce procurement costsFinanceBuying/selling/leasing transactionsConstruction engineeringThe Internet

The invention discloses a ship and ocean engineering industry chain intelligent manufacturing service platform which is provided with one or more of conventional service modules such as an industry chain supply and demand matching module of the maritime work or ship industry. The system further comprises one or more of the following characteristic service modules of the maritime work or ship industry: an administrative organization parking module, an industry organization expansion module, a home co-construction module, an emergency expropriation module and an innovation priority module. And a computer end platform based on browser access or a use mode of a mobile phone end APP or an applet is provided for a user of the platform. The Internet service level of the maritime work ship industry can be improved, the industry administrative affair handling efficiency is improved, industry information is conveyed in time, local industry and enterprise development is more orderly, the problem that emergency affairs are handled in China or in places is solved, and scientific and technological progress of the ship maritime work industry is facilitated.

Owner:南通碧兰宇环保科技有限公司

Air spacer for a gate structure of a transistor

A semiconductor structure includes a first device and a second device. The first device includes: a first gate structure formed over an active region and a first air spacer disposed adjacent to the first gate structure. The second device includes: a second gate structure formed over an isolation structure and a second air spacer disposed adjacent to the second gate structure. The first air spacer and the second air spacer have different sizes.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com