Wave type headshaking mechanism as well as electric fan and heater using same

A wave-type, crank-link mechanism technology, which is applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as complex installation structures, complex circuits, and fatigue fractures of shrapnel, and achieve The effect of expanding the wind receiving area, high transmission efficiency and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

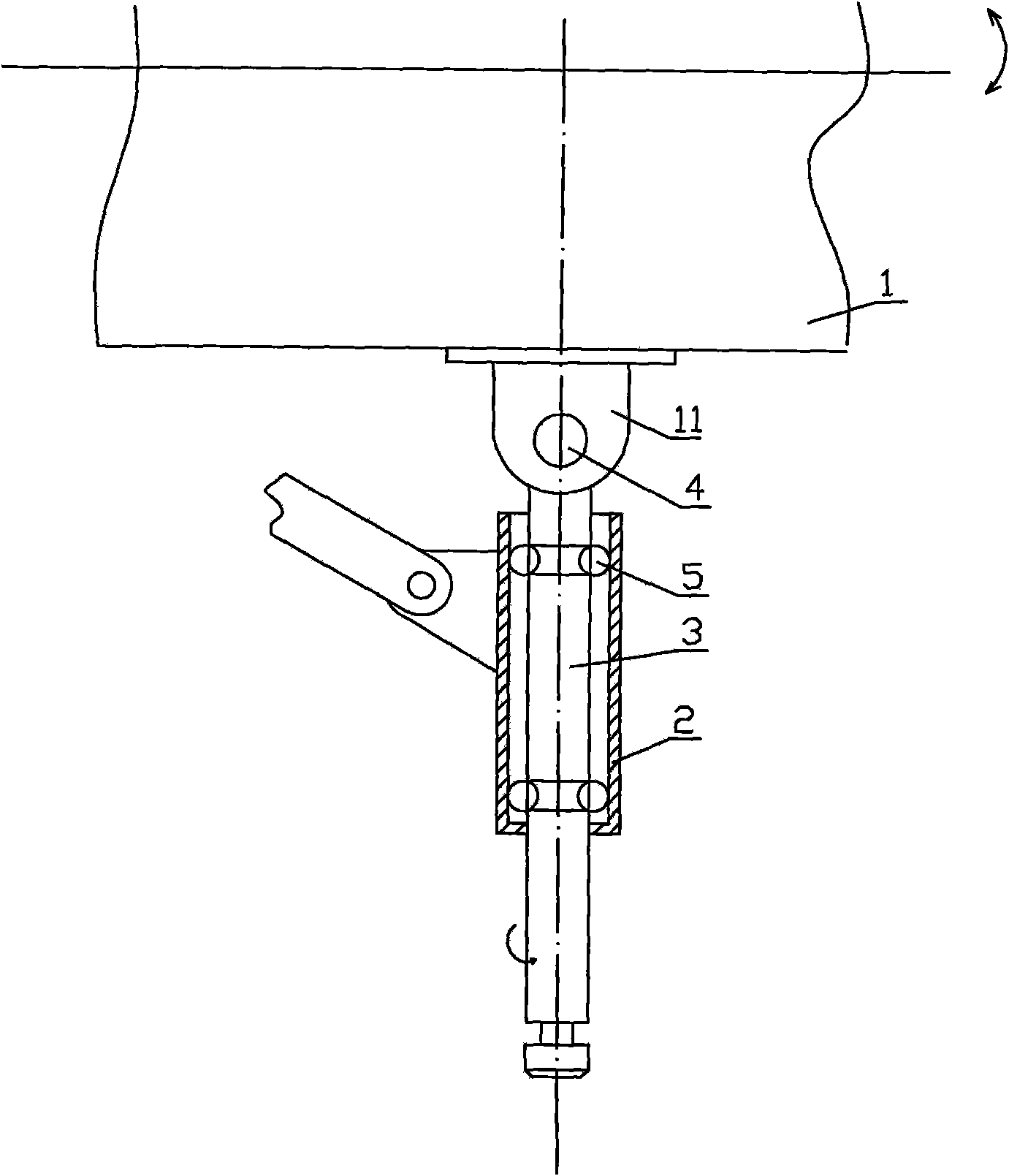

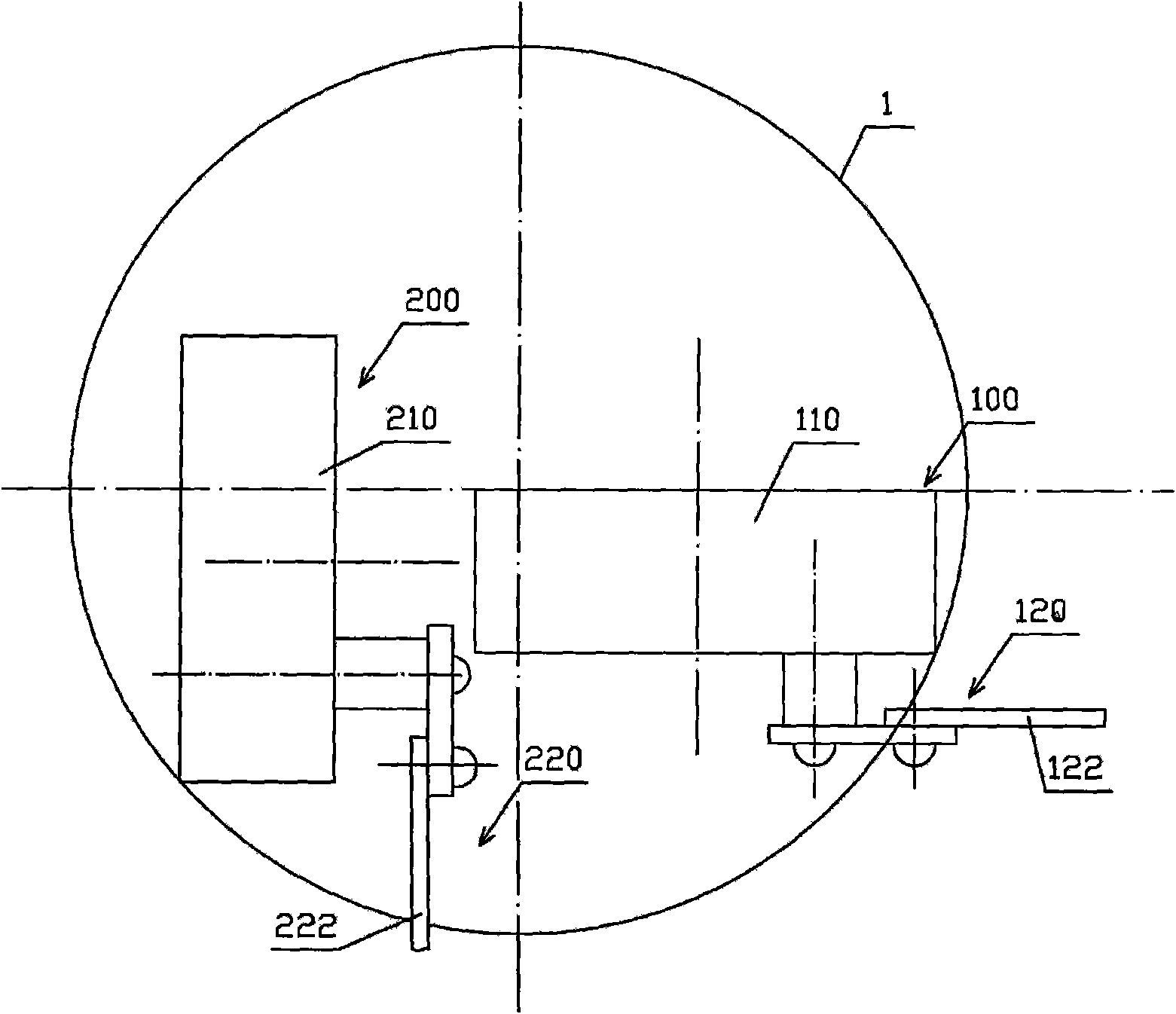

[0052] see figure 2 , figure 2 The first oscillating mechanism 100 and the second oscillating mechanism 200 are all motor type. The first oscillating mechanism 100 is composed of a geared motor 110 installed in the machine head 1 and a crank linkage mechanism 120 installed on the output shaft of the geared motor 110. The other end of the connecting rod 122 of the crank linkage mechanism 120 stretches out of the machine head 1 Outer hinges with 2 bases. The first oscillating mechanism 100 can realize the left and right oscillating head of the machine head 1 .

[0053] The second oscillating mechanism 200 is composed of a gear motor 210 installed in the machine head 1 and a crank linkage mechanism 220 installed on the output shaft of the gear motor 210. The other end of the connecting rod 222 of the crank linkage mechanism 220 stretches out of the machine head 1 Outer hinges with 2 bases. The second oscillating mechanism 200 can realize the up and down oscillating of the m...

Embodiment 3

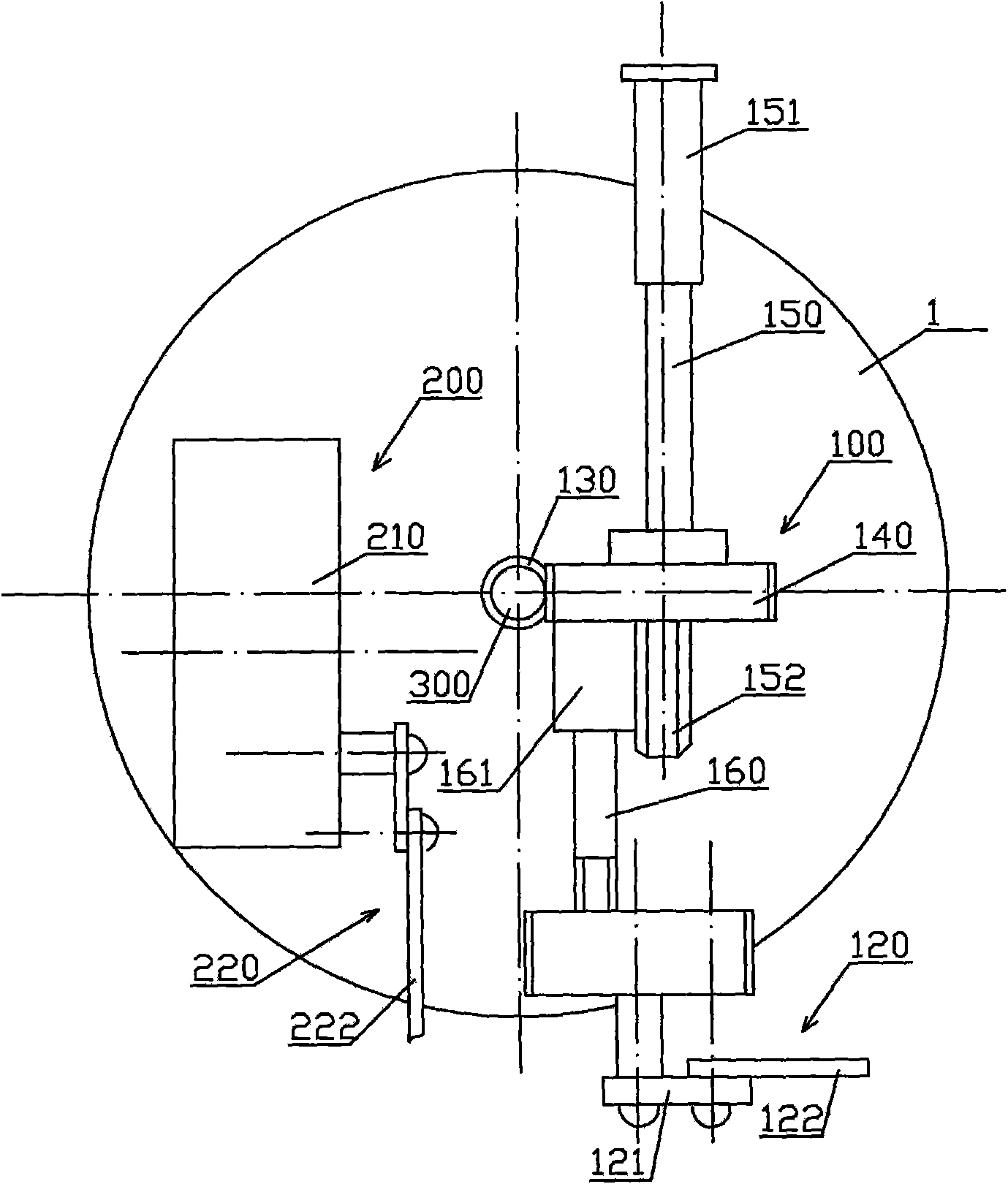

[0056] see image 3 , image 3 The first oscillating mechanism 100 is mechanical, and the second oscillating mechanism 200 is electromechanical. A main motor (not shown in the figure) that drives the fan to rotate is arranged in the machine head 1 .

[0057] The first shaking head mechanism 100 comprises a worm screw 130, a worm wheel 140, a clutch puller 150, a gear shaft 160, and a crank linkage mechanism 120; In the machine head 1, the worm gear 140 is sleeved on the middle part of the clutch puller 150 and meshed with the worm screw 130, so that when the power output shaft 300 of the main motor rotates, the worm gear 140 is driven to rotate by the worm screw 130.

[0058] The middle part of the clutch lever 150 is also provided with clutch external teeth, and one end of the clutch lever 150 protrudes out of the machine head 1 and is provided with a toggle handle 151, and the other end of the clutch lever 151 is provided with a driving gear 152, inside the worm wheel 140 ...

Embodiment 4

[0072] see Figure 5 , Figure 5 The second oscillating mechanism 200 in is all motor type. The second oscillating mechanism 200 is composed of a gear motor 210 installed in the machine head 1 and a crank linkage mechanism 220 installed on the output shaft of the gear motor 210. The other end of the connecting rod 222 of the crank linkage mechanism 220 stretches out of the machine head 1 Outer hinges with 2 bases. The second oscillating mechanism 200 can realize the independent up and down oscillating of the machine head 1 .

[0073] The decelerating motor 220 in the second shaking head mechanism 200 can be controlled by an independent switch (not shown in the figure) arranged on the machine base 2, so as to realize shaking the head up and down,

[0074] The wave-type shaking head mechanism of the above-mentioned embodiment can be used to make a wave-type shaking head electric fan. The fan cover of the existing electric fan is installed on the machine head 1, and the fan le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com