Noble metal doped SnO2 composite material and preparation method thereof

A technology of composite materials and precious metals, applied in the direction of material resistance, etc., can solve the problems of unsatisfactory appearance shape and particle size, and greater influence on the gas-sensing characteristics of components, etc., to achieve excellent selectivity, improve sensitivity and response time, and work temperature range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

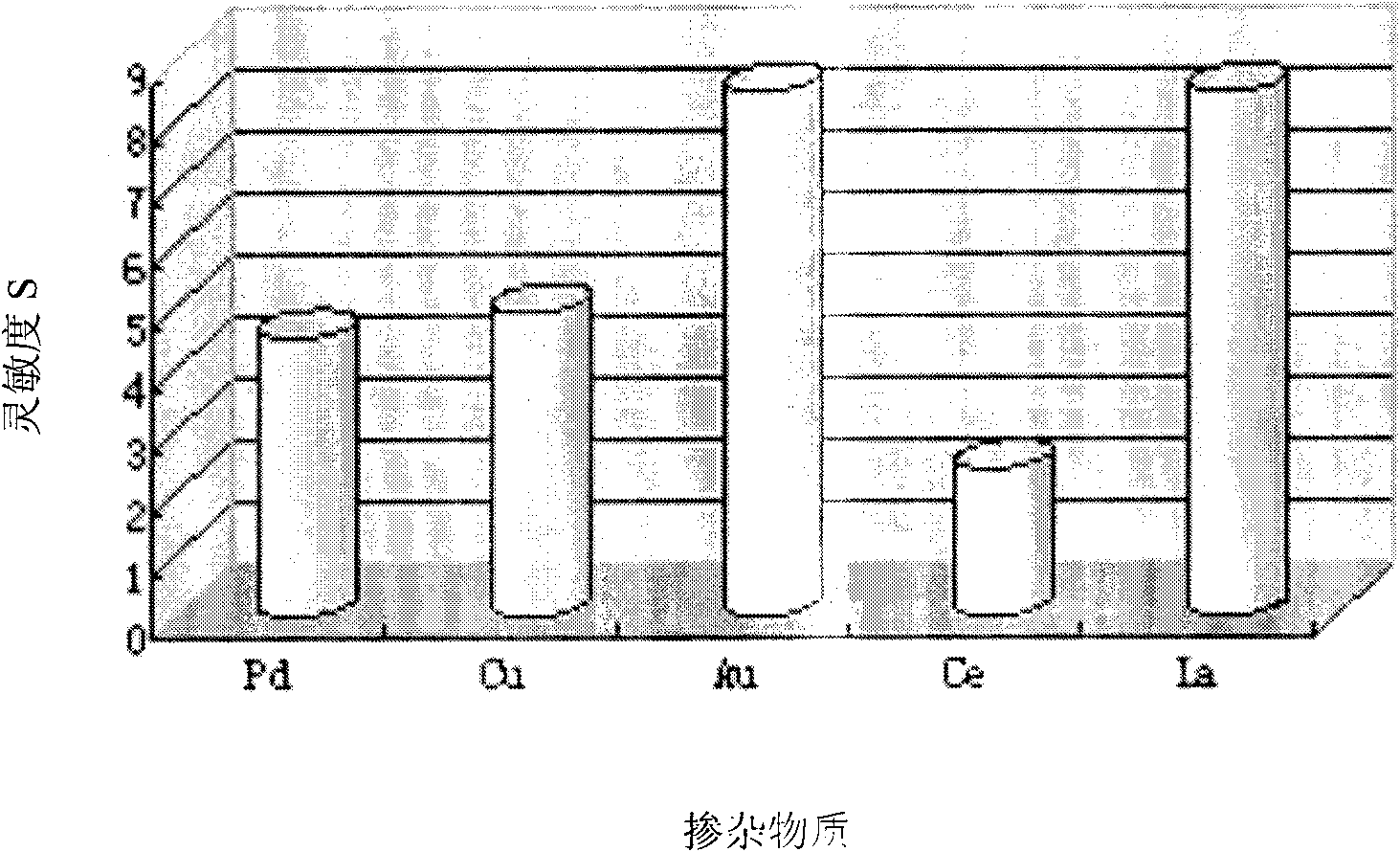

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the mass fraction of 0.3 parts of Pd and 99.7 parts of SnO 2 Powder mixing; add deionized water with a mass fraction of 20-40%, and stir to form a slurry; evenly coat the slurry on the ceramic substrate and dry it in an oven; put the ceramic substrate in a muffle furnace, Sinter at high temperature for 1 hour, and cool to room temperature with the furnace to obtain SnO doped with noble metal Pd 2 composite material.

specific Embodiment approach 2

[0015] Specific embodiment two: the mass parts of 0.05 parts of Au and 99.95 parts of SnO 2 Powder mixing; add deionized water with a mass fraction of 20-40%, and stir to form a slurry; evenly coat the slurry on the ceramic substrate and dry it in an oven; put the ceramic substrate in a muffle furnace, Sintering at high temperature for 1 hour, and cooling to room temperature with the furnace to obtain SnO doped with noble metal Au 2 composite material.

specific Embodiment approach 3

[0016] Specific embodiment three: the mass parts of 0.13 parts of Cu, 0.42 parts of Sb and 99.45 parts of SnO 2 Powder mixing; add deionized water with a mass fraction of 20-40%, and stir to form a slurry; evenly coat the slurry on the ceramic substrate and dry it in an oven; put the ceramic substrate in a muffle furnace, Sintering at high temperature for 1 hour, and cooling to room temperature with the furnace to obtain SnO doped with noble metals Cu and Sb 2 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com