PAR type heating bulb and production method

A light bulb and lamp cup technology is applied in the structural field of PAR type heating bulbs to achieve the effects of stable product quality, simplified production process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and attached figure 1 , 2 and image 3 The present invention is described further:

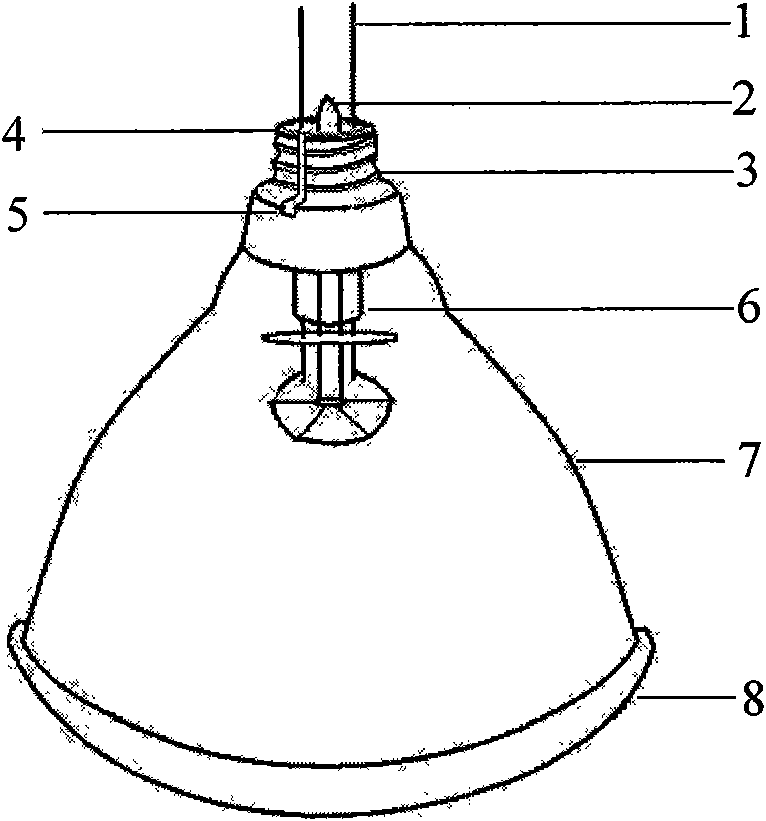

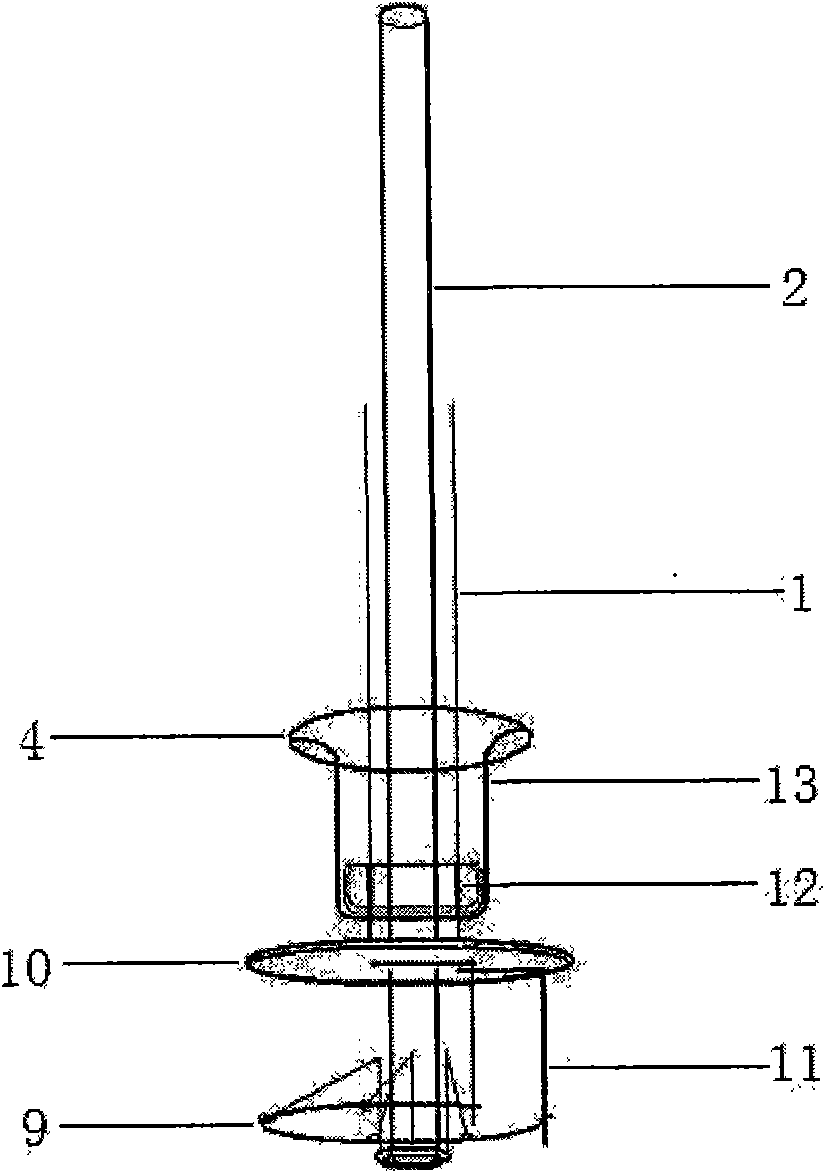

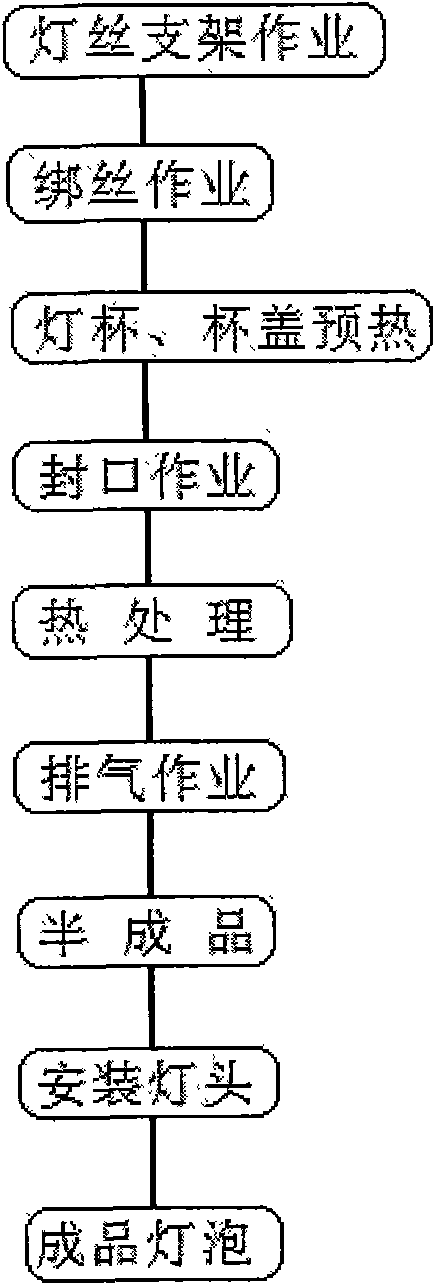

[0014] A 230V175W PAR type heating bulb structure for hospital treatment, which consists of a guide wire 1, an exhaust pipe 2, a thread for fixing the lamp cap 3, a wick glass horn tube and a sealing part 4 at the tail of the lamp cup, and a lamp cap fixing slot 5. Composition of wick 6, lamp cup 7 and cup cover 8 (see attached figure 1 ), the wick 6 is an assembly, including the filament 9 of the tungsten wire, the diameter 32mm ceramic disc 10, diameter 1.5mm nickel wire 11. Diameter 0.8mm tungsten rod 12 and glass trumpet tube 13 (see attached figure 2 ), these components are figure 1 and figure 2 structure installation. Wherein: the head of the glass lamp cup 7 and the glass cup cover 8 are sealed with fire, and the glass horn tube 13 of the wick and the glass bulb at the end of the lamp cup 7 are directly sealed into the sealing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com