Disposable nose breathing filtering paste and manufacturing method thereof

A disposable, filter sticker technology, applied in breathing filters, respiratory protection containers, life-saving equipment, etc., can solve the problems of difficulty in mass production and cost control, disjointed production technology, and large volume, so as to reduce the impact on the body. The effect of harm, obvious practical benefit, long-term social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

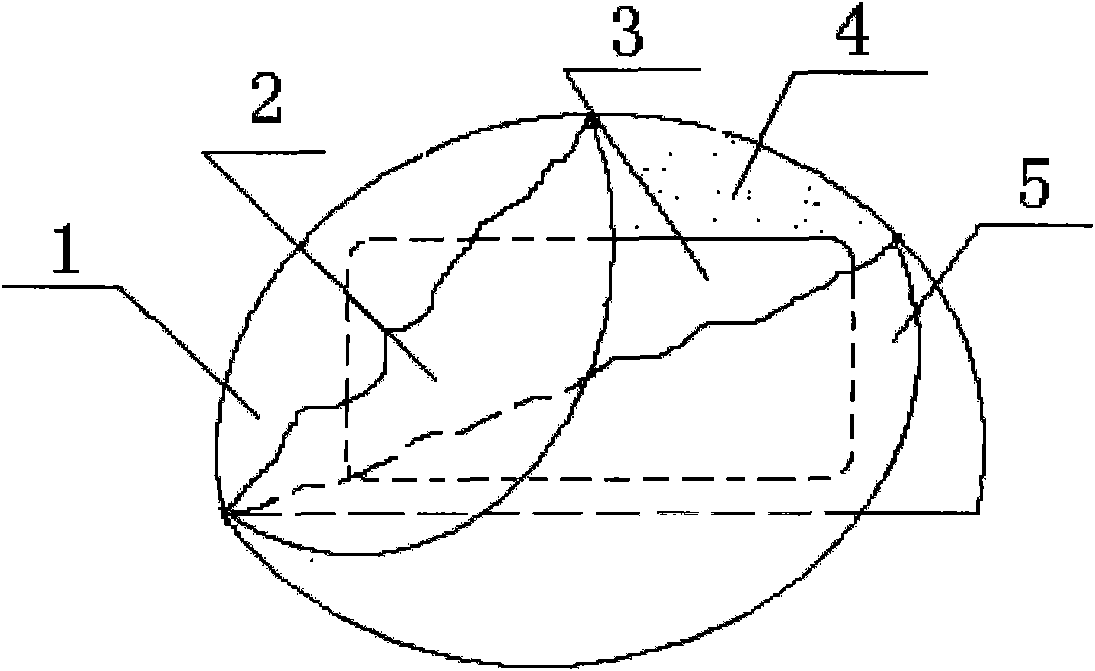

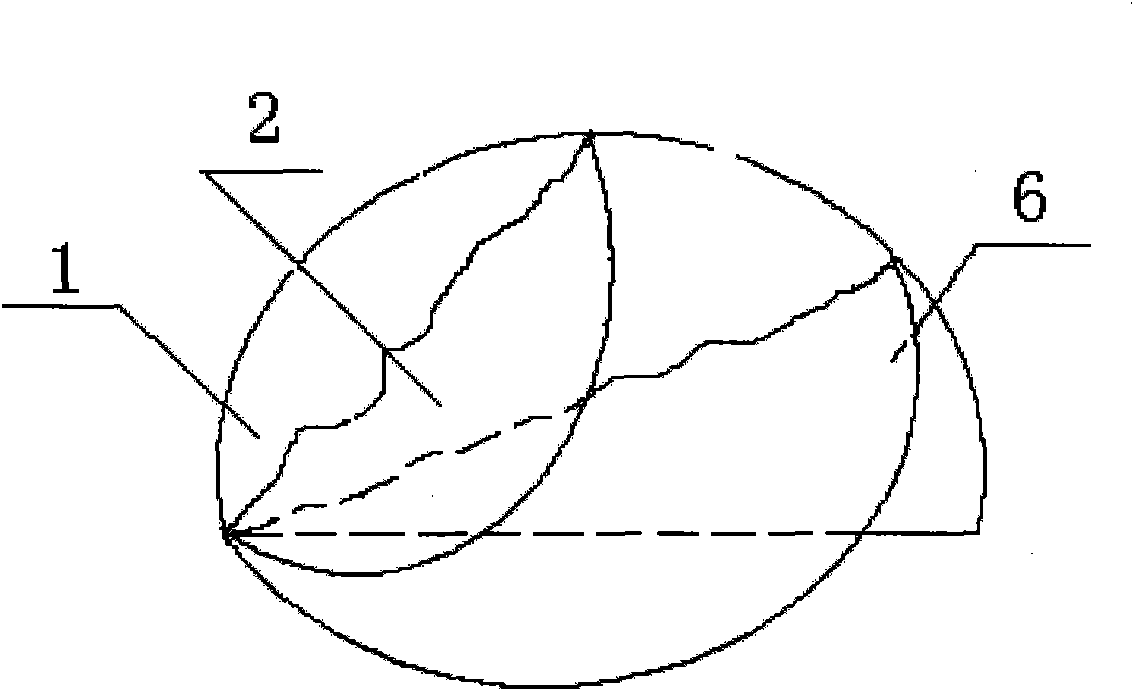

[0029] see figure 1 As shown, the disposable nasal cavity filter patch includes a non-woven layer 1, an activated carbon fiber layer 2, an adhesive tape layer 3, a self-adhesive layer 4 and a release paper layer 5, wherein the non-woven layer, activated carbon The areas of the fiber layer and the release paper layer are all the same; the activated carbon fiber layer 2 is covered and arranged on the non-woven fabric layer 1 of the same area, and forms a heat-compressed composite layer jointly by hot pressing, and the described release paper Layer 5 is pasted and covered on the activated carbon fiber layer in the heat-pressed composite layer of the same area through the self-adhesive layer 4 .

[0030] Wherein, the outer contour shape of the disposable nasal cavity breathing filter patch is semicircular, and matches the outer shape and size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com