Non-contact method for dehumidifying liquid and dehumidifier

A liquid dehumidification, non-contact technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as living room, furniture corrosion, and adverse effects on human health, to strengthen the dehumidification process and regeneration process, improve The effect of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

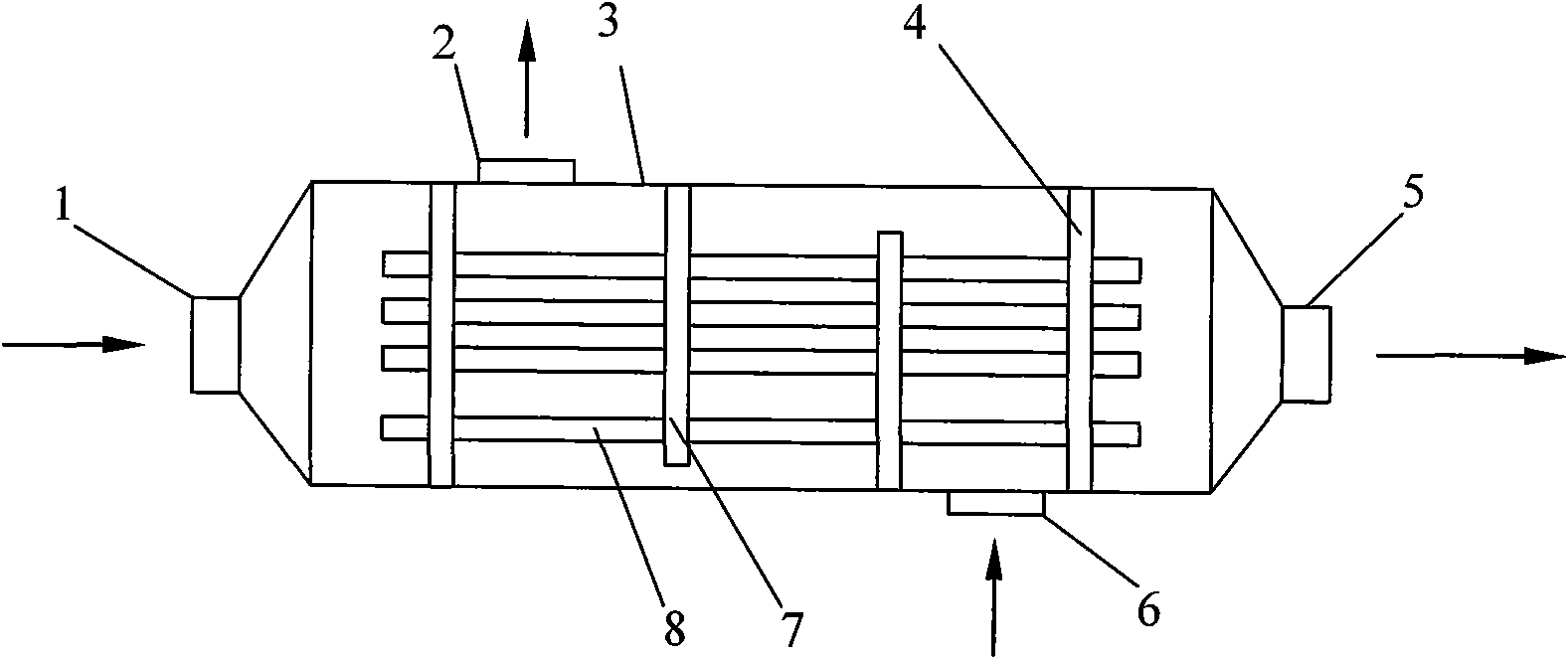

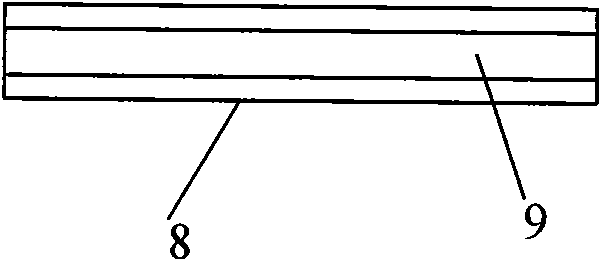

[0025] Hollow fiber or tubular membrane dehumidifier structure such as figure 1 shown by figure 1 It can be seen that the dehumidification salt solution (such as lithium chloride solution, lithium bromide solution, etc.) inlet flow channel 1 of the membrane dehumidifier is connected with the left end of the shell 3, the outlet flow channel 5 of the dehumidification salt solution is connected with the right end of the shell 3, and the dehumidification air inlet flow channel 6 is connected to the opening on the lower right side of the housing 3 , and the dehumidified air outlet channel 2 is connected to the opening on the upper left side of the housing 3 . The head 4 is placed at both ends of the shell, and the left and right ends of the shell are blocked. There are many holes on it, and a plurality of hollow fibers or tubular membranes 8 pass through the head 4 through these holes and are fixed inside the shell. . The fluid inside the tube is called the tube side, and the flu...

Embodiment 2

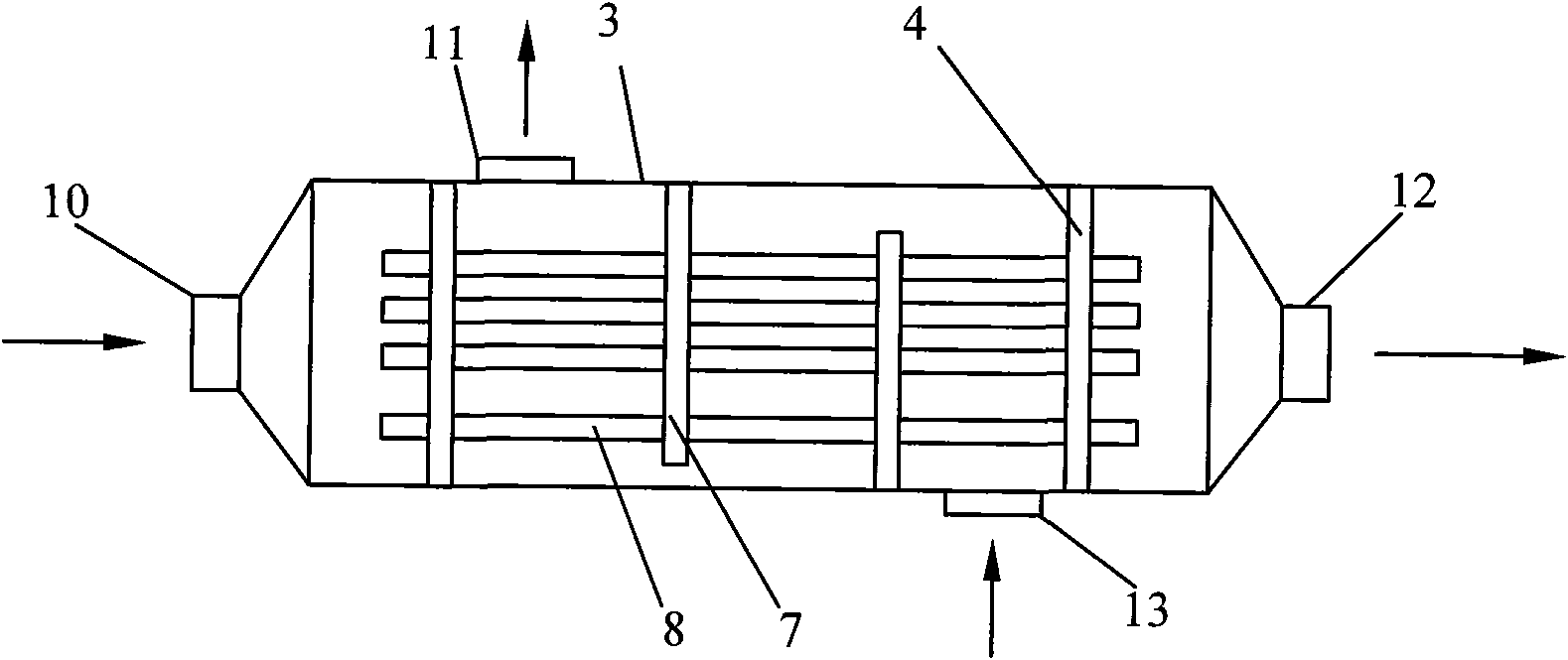

[0030] The hollow fiber or tubular membrane dehumidifiers of the present invention can also be used as regenerators. structured as image 3 shown by image 3 It can be seen that when used as a regenerator, the inlet channel 13 of the regenerated salt solution (such as lithium chloride solution, lithium bromide solution, etc.) is connected to the lower right end of the housing 3, and the outlet channel 11 of the regenerated salt solution is connected to the upper left end of the housing 3. The air inlet channel 10 is connected to the left side of the housing 3 , and the regeneration air outlet channel 12 is connected to the right side of the housing 3 . The head 4 is placed at both ends of the housing to seal the two sides of the housing. There are multiple holes on it, and the hollow fiber or tubular membrane 8 passes through the openings of the head 4 and is fixed inside the housing. The fluid inside the tube is called the tube side, and the fluid outside the tube is called...

Embodiment 3

[0034] The structure of flat membrane dehumidifier of the present invention is as Figure 4 shown by Figure 4 It can be seen that the flat membrane dehumidifier and regenerator of the present invention are connected to the left side of the housing 3 by the inlet channel 14 of the salt solution (such as lithium chloride solution, lithium bromide solution, etc.), and the outlet channel 16 of the salt solution is connected to the right side of the housing 3. The air inlet channel 15 is connected to the upper end of the housing 3 , and the air outlet channel 18 is connected to the lower end of the housing 3 . A core body 17 made of parallel plate film is placed in the casing 3 . The structure of the core is as Figure 5 As shown, the core body is formed by stacking multi-layer flat membranes, and each layer of flat membranes is separated by a partition to form a hollow layer. The opposite sides of the hollow layer are blocked by sealing plates 20 to prevent fluid leakage, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com