Oil-gas mixing regulating distributor

A technology of oil and gas mixing and distributor, applied in the direction of fluid mixer, mixer, mixing method, etc., can solve the problems of limited lubrication effect and insufficient penetration of cutting fluid, so as to improve the service life, reduce equipment maintenance costs, reduce effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

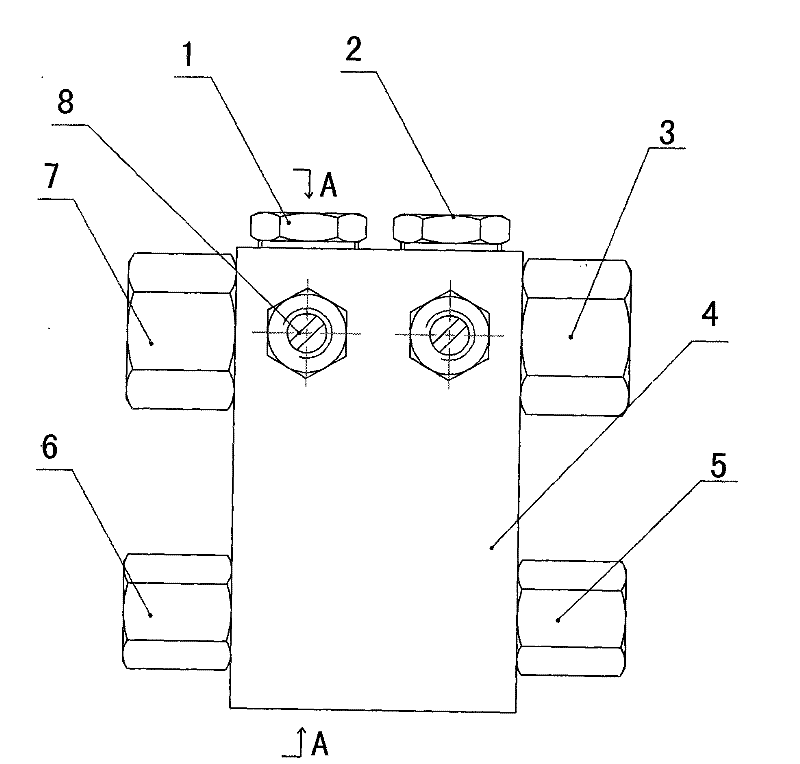

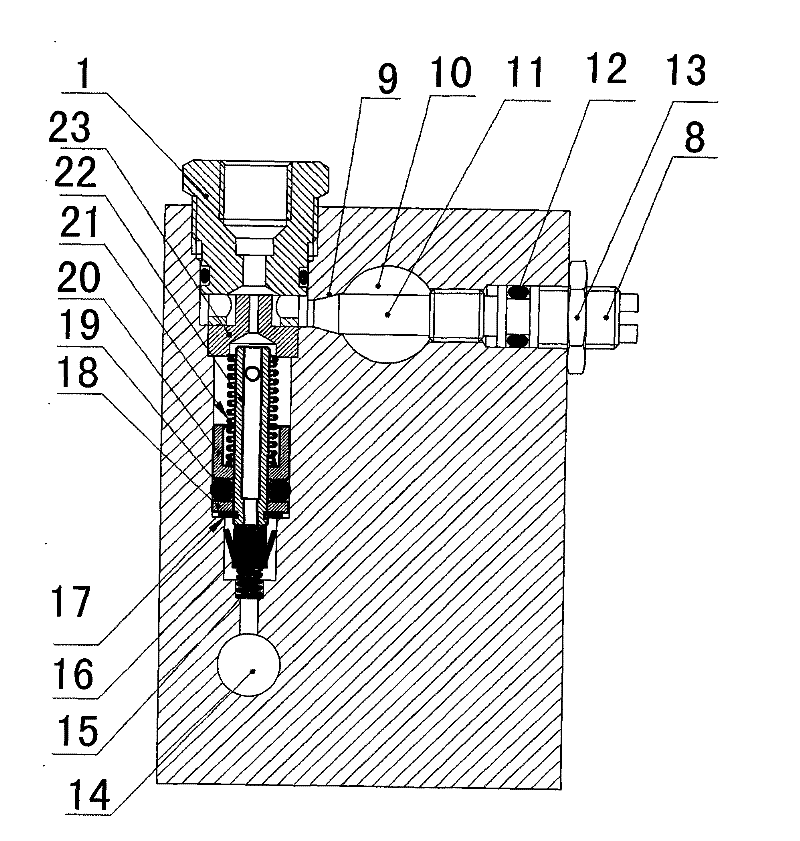

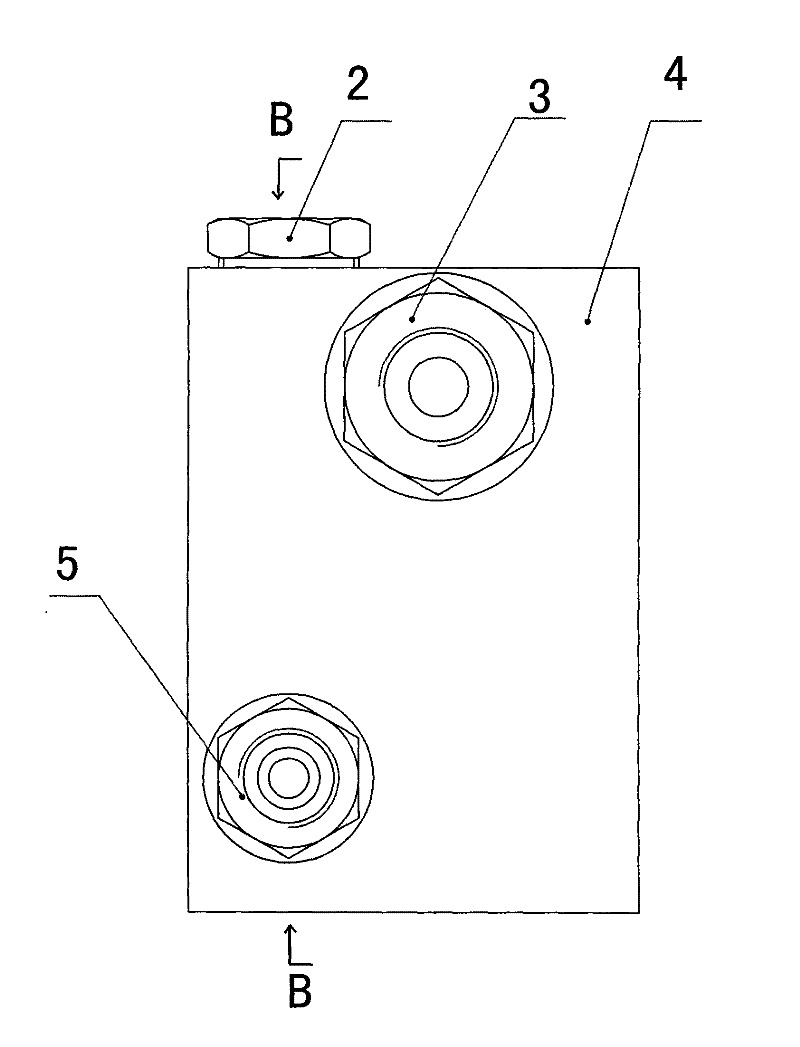

[0014] As shown in the figure, the present invention includes a body 4 and a passage provided in the body. Two sets of oil supply devices are arranged in the body 4 . The body is provided with an oil inlet joint 5, an oil inlet joint 6, an oil outlet joint 1, an oil outlet joint 2, an air intake joint 3, an air intake joint 7 and a gas regulating device. The channels include an air channel 10 and an oil channel 14 . The top end of the gas regulating device is an adjusting taper rod 11 . The output ends of the two sets of oil supply devices communicate with the oil outlet joint 1 and the oil outlet joint 2 respectively. The oil inlet end of the oil supply device communicates with the oil passage 14 . The oil inlet connector 5 and the oil inlet connector 6 are connected to the oil passage 14 . The intake joint 3 and the intake joint 7 are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com