Method for controlling temperature of crude oil for emulsion of rolling mill and control device

A temperature control method and emulsion technology, applied in the direction of transportation of passenger cars, tank cars, railway car body parts, etc., can solve the problems of inconvenient maintenance and repair of equipment, uneven heating of crude oil tanks, and affecting the quality of crude oil, etc., to achieve easy maintenance, Good heating effect and strong temperature control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

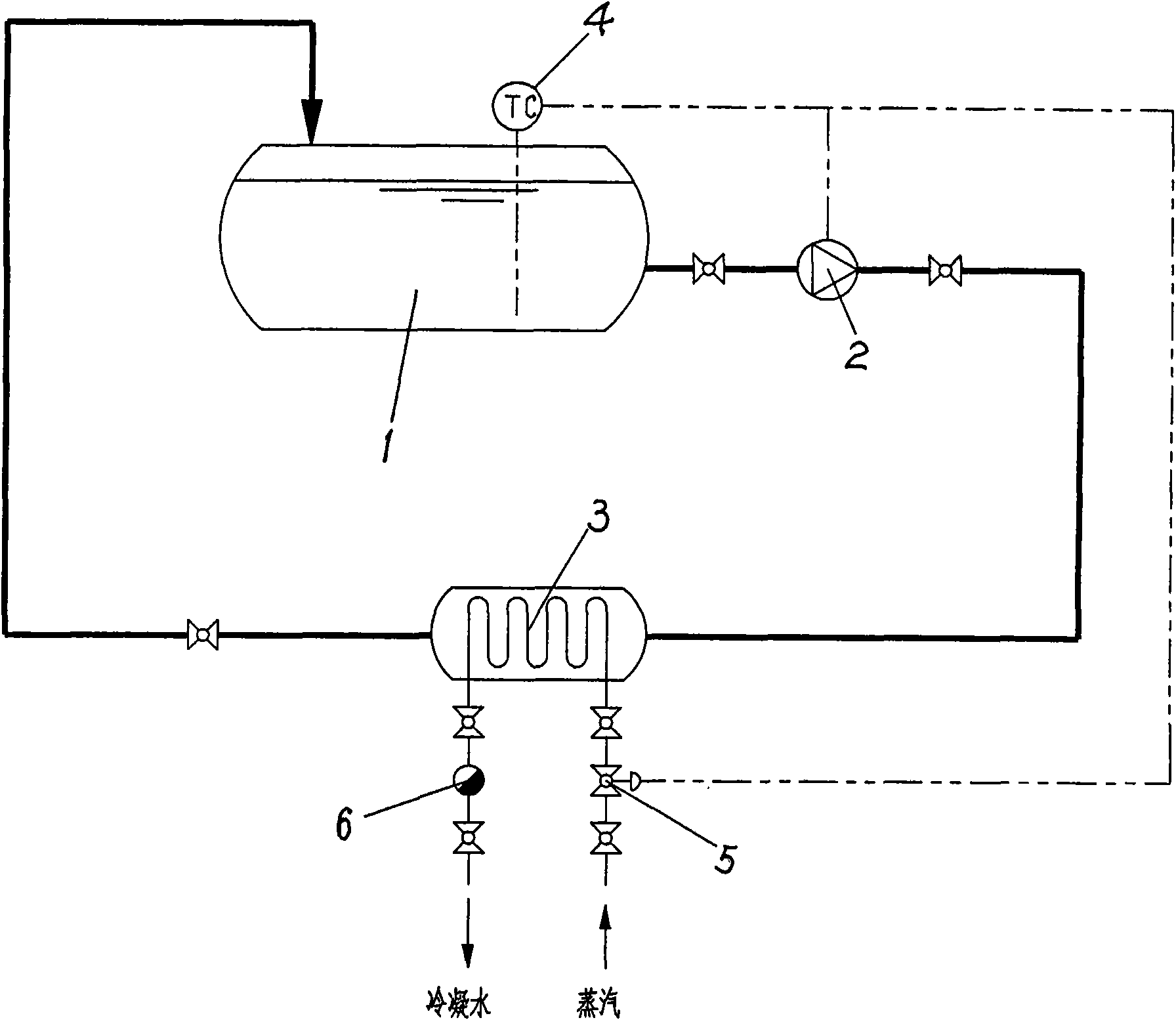

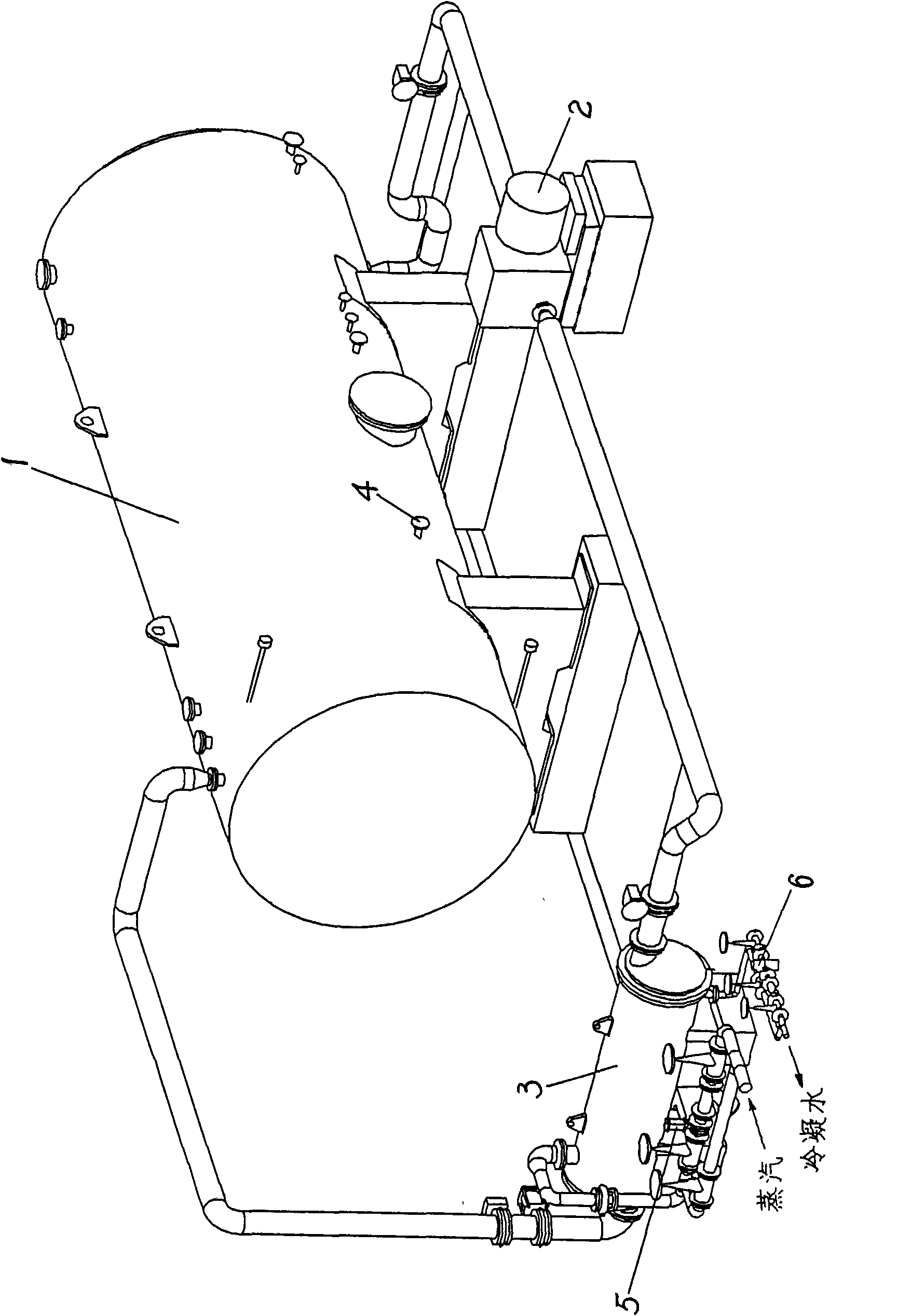

[0039] The preferred embodiments of the method and device for controlling the temperature of the emulsion crude oil in a rolling mill according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] The manufacturer transports the crude oil to the site with a tank truck, and uses an unloading pump to suck the crude oil on the tank truck into the crude oil tank through the hose. The crude oil tank plays the role of storage and transfer, and generally stores the amount for one month. Crude oil has a pH value of 4.0-7.0 and a density of ρ=0.95kg / L. If the temperature of crude oil is too low, it is generally below 30°C and is easy to solidify. If the temperature of crude oil is too high, generally above 45°C, it will cause the crude oil to breed bacteria and deteriorate. Therefore, it is necessary to Control the crude oil within a certain temperature range.

[0041] see figure 1 , according to the rolling mill emulsion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com