Production technique for synthesizing Manidipine Hydrochloride through separation with non-column chromatography

A technology of hydrochloric acid and dipine base, applied in the fields of drug combination, cardiovascular system diseases, organic chemistry, etc., can solve the problems of endangering the physical and mental health of operators, difficult to remove impurities, etc., to reduce production costs, improve product quality and yield, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

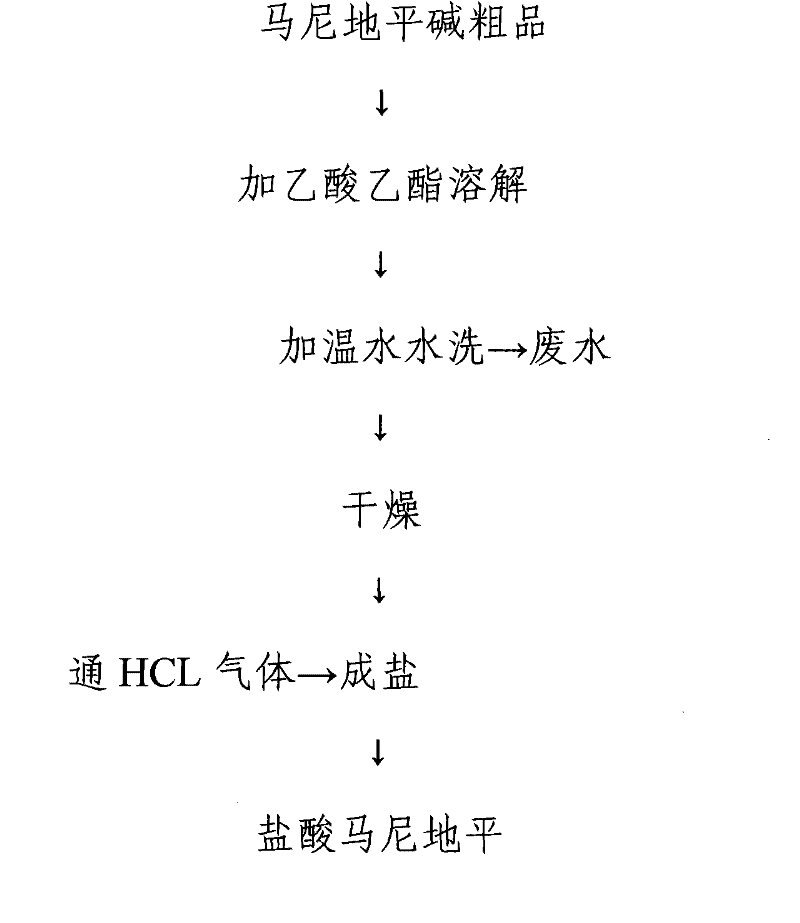

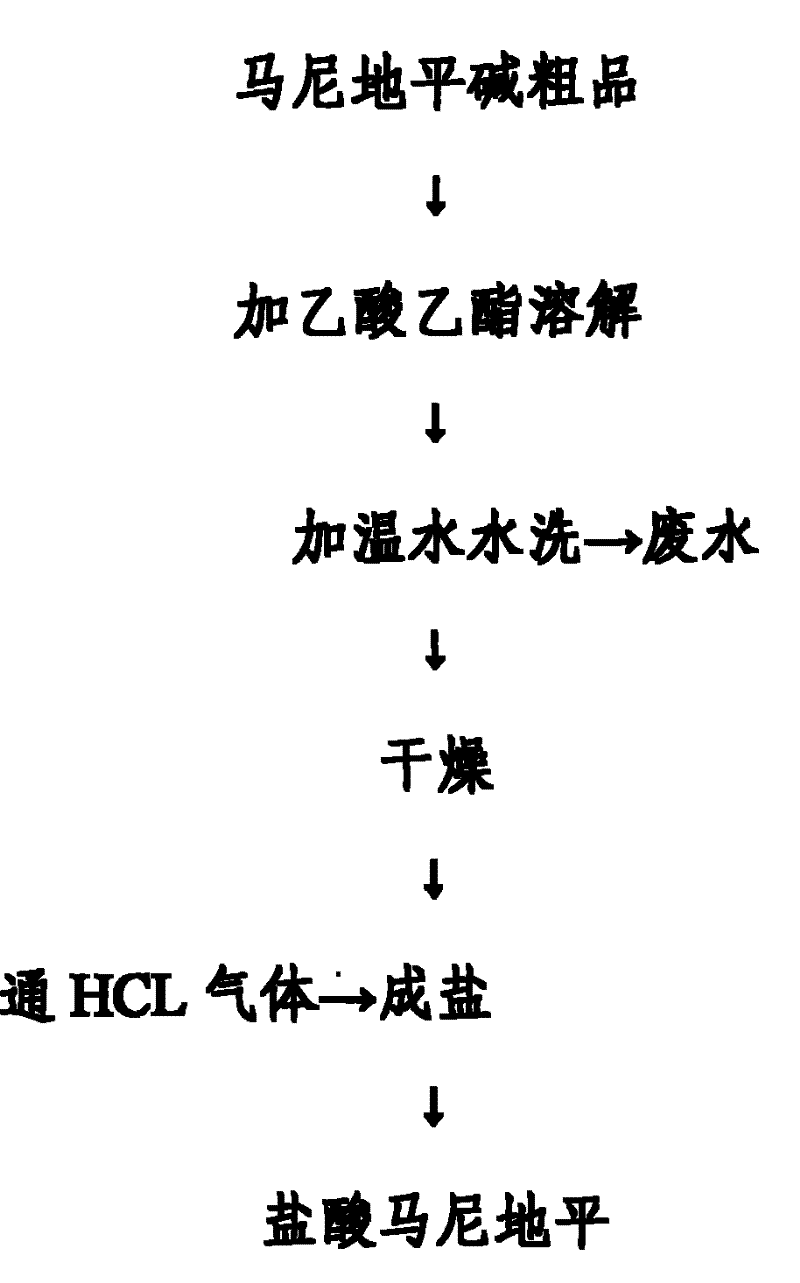

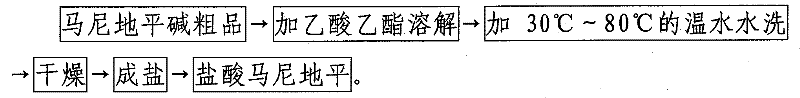

Method used

Image

Examples

Embodiment 1

[0018] Take 10 kg of manidipine base crude product and 70 kg of ethyl acetate, stir to dissolve the manidipine base crude product, wash with water three times to remove impurities with 25 kg of water at a temperature of 60° C. Nidipine

Embodiment 2

[0020] Take 10kg of crude manidipine base and 80kg of ethyl acetate, stir to dissolve the crude manidipine base, wash with 50 kg of water at 50°C for four times to remove impurities, dry after removing impurities, and feed HCL gas to make hydrochloric acid manidipine

[0021] With the method of the present invention for impurity removal, the purity of manidipine hydrochloride can be improved to 92.2% from 75.8% of the traditional method for impurity removal and purification; pollution of the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com