Low-tension knitting method of high-count single-strand wool yarn knitted fabric and knitted goods thereof

A technology for knitted fabrics and high-count wool yarns, which is applied to knitting, circular machines for weft knitting with individual moving needles, and weft knitting. It can solve problems such as large process resistance, high contact pressure, and rising tension. Achieve the effects of improving weaving efficiency, high twist unevenness, and reducing yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A low-tension high-count single-ply wool yarn knitted fabric weaving method, the raw material in this embodiment is single-ply high-count wool 72N / 1, and the high-gauge circular knitting machine is single-sided high-gauge (28 gauge and above) knitting Circular machine knitting. Specifically include the following steps:

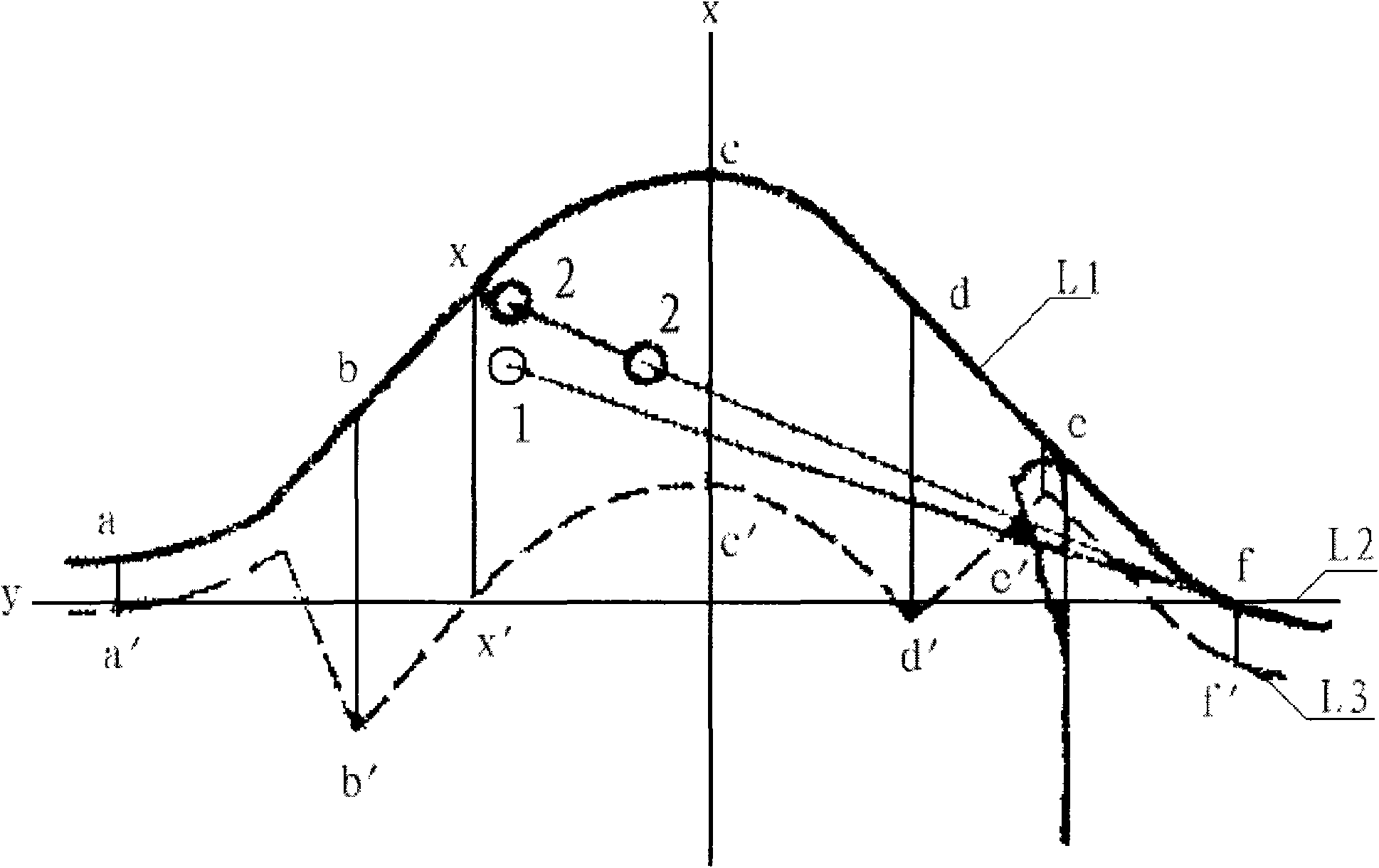

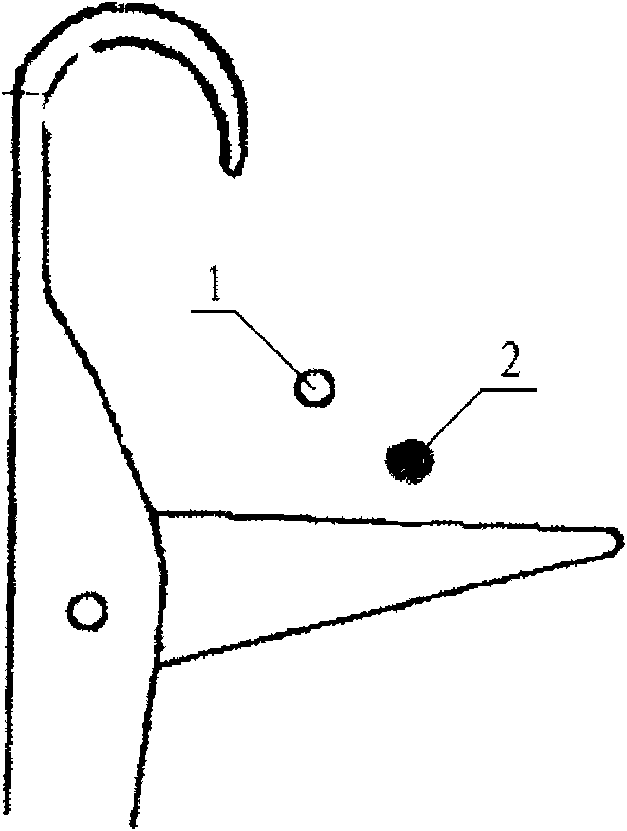

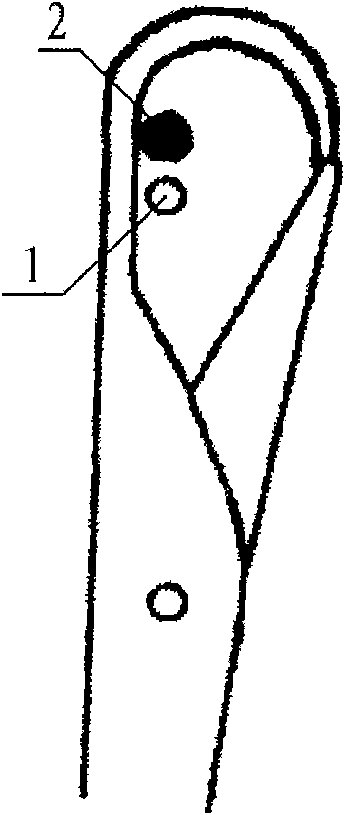

[0019] Because the wool yarn has better elasticity than ordinary fibers in the stage of looping and looping, it can withstand greater looping resistance than ordinary fibers, so the cam that drives the movement of the knitting needle is improved as follows: increase the camber in the looping, continuous looping, and looping stages Slope, to control the downward movement and stop time of knitting needles, reduce the number of yarns bent between knitting needles, and reduce the rise of yarn tension (compared with the conventional 3-4G tension, it is about 20% lower); at the same time Shorten the flat width of the bottom of the pressing triangle (by 0.2 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flat width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com