Reverse heating method of intermittent temperature zone at normal pressure and device thereof

A heating device and heating method technology, applied in the direction of heating methods, steam generation methods using heat carriers, water heaters, etc., can solve problems such as non-compliance, smoke pollution, loss of valuable energy, etc., and achieve lower manufacturing levels , reduce investment, reduce the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

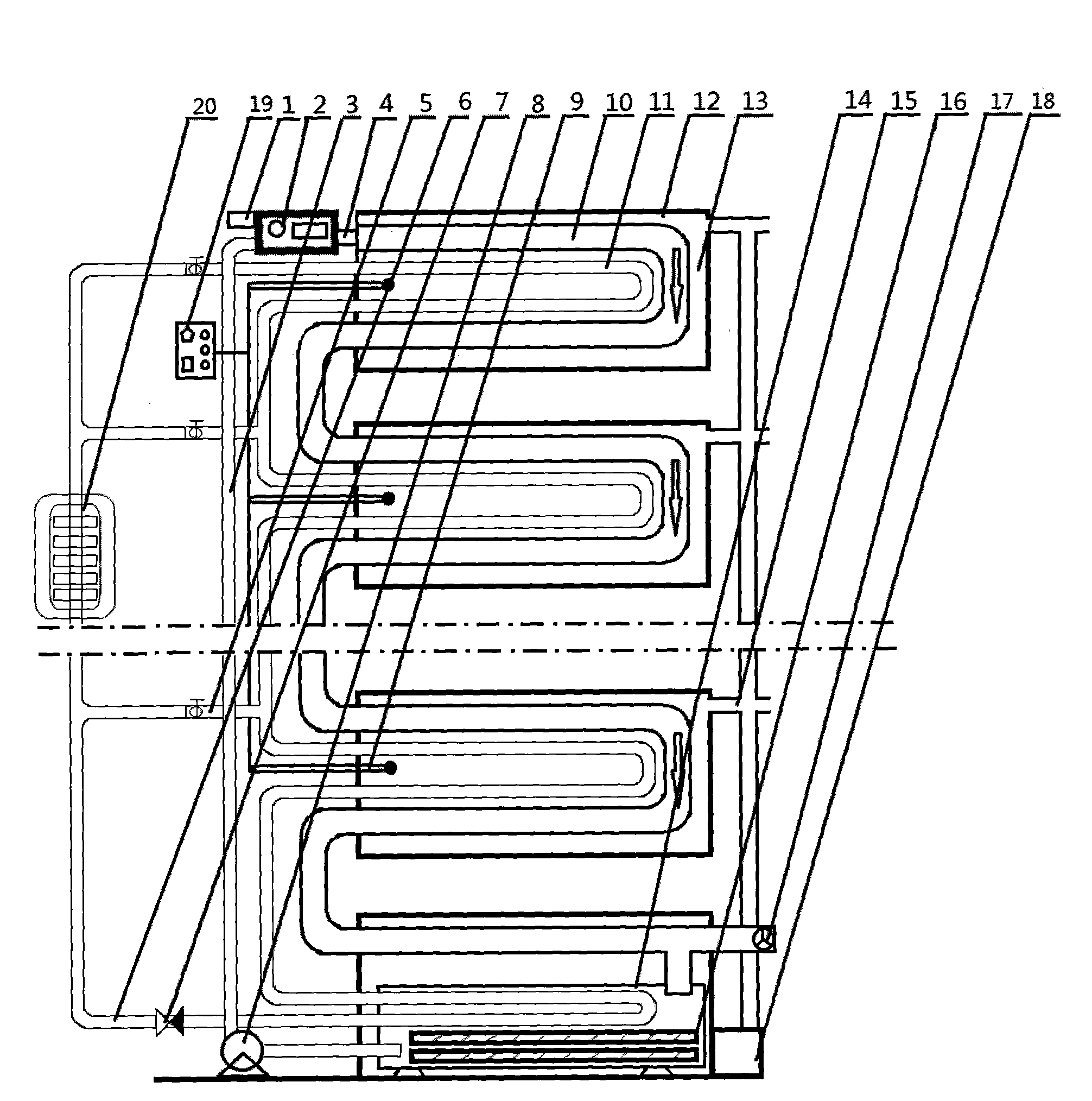

[0030] The present invention is described in detail below in conjunction with accompanying drawing.

[0031] As shown in the figure, the present invention provides a method of reverse heating in an intermittent temperature zone at atmospheric pressure, which is characterized in that it includes the following steps:

[0032] ① Input the hot liquid (or steam) into the heating coil (11) in the intermittent temperature zone of the heating device box (12) through the pipeline (6);

[0033] ② Pass the high-temperature flue gas after combustion through the flue (4), and reversely input it into the heat radiation coil (10) in the box (12) of the heating device;

[0034] ③Under normal pressure, the flue gas mixes with the heat transfer medium (13) in the heating device box (12) to heat the hot liquid (or steam).

[0035] The discontinuous temperature zone refers to that the heating device is connected in series by multiple casings (12), and the adjacent two-stage heating device casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com