Measurement method of concrete resistivity and device thereof

A measurement method and technology of a measurement device, which is applied in the direction of measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as poor accuracy, poor measurement accuracy, and inability to test concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

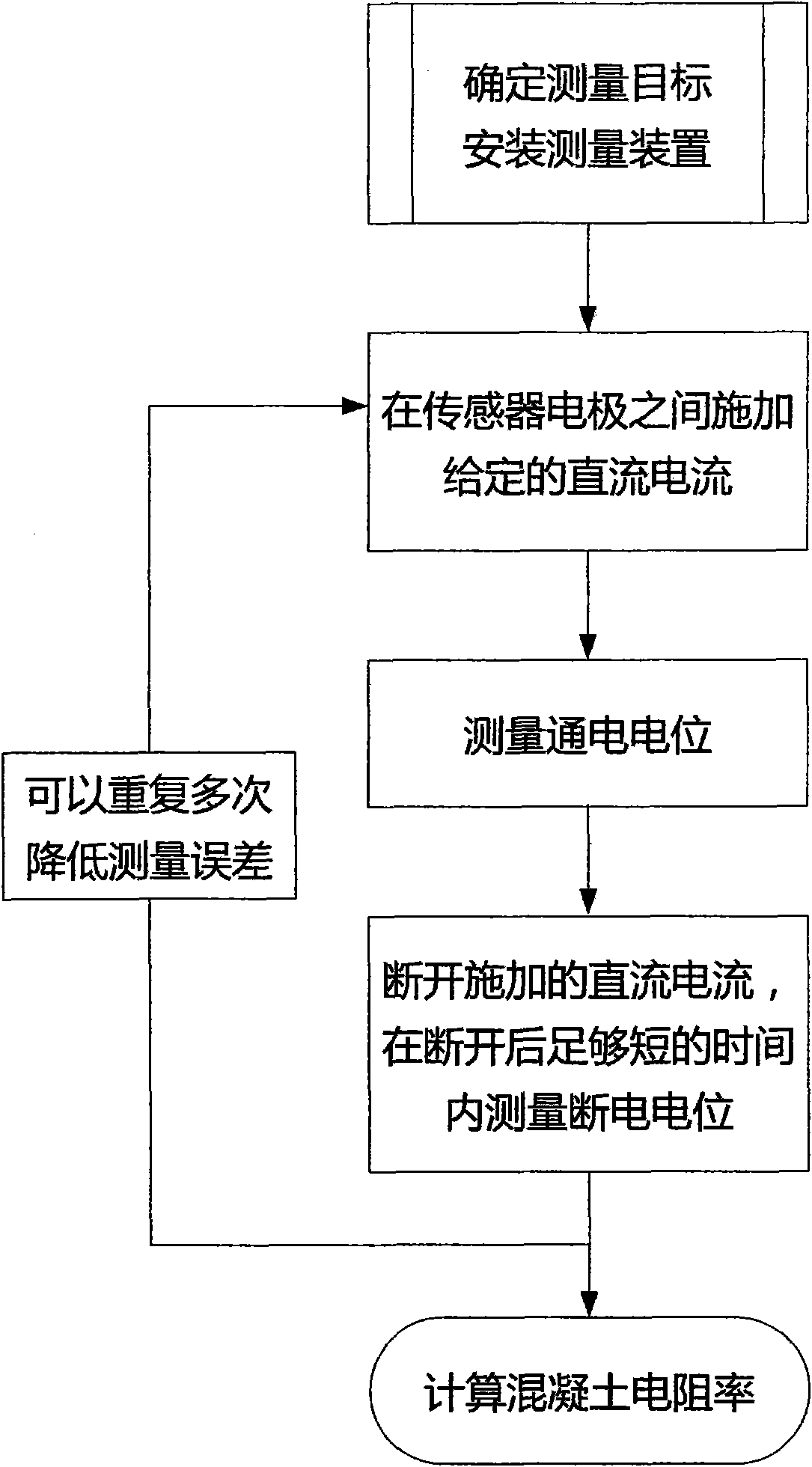

[0059] like figure 1 Shown is the flow chart of the concrete resistivity measurement method described in the embodiment of the present invention. The measurement method includes the following steps:

[0060] a. Set an electrode at each end of the concrete to be tested;

[0061] B. apply direct current between above-mentioned two electrodes, measure the potential between described electrodes, be recorded as energization potential;

[0062] c. Disconnect the direct current applied to the electrodes, and measure the potential between the electrodes in a short enough time, which is recorded as the power-off potential;

[0063] d. Step b and step c can be repeated multiple times, for example, 1 to 50 times; step e can also be performed directly;

[0064] e. Calculate the concrete resistivity according to the energized potential and the de-energized potential measured in the preceding steps.

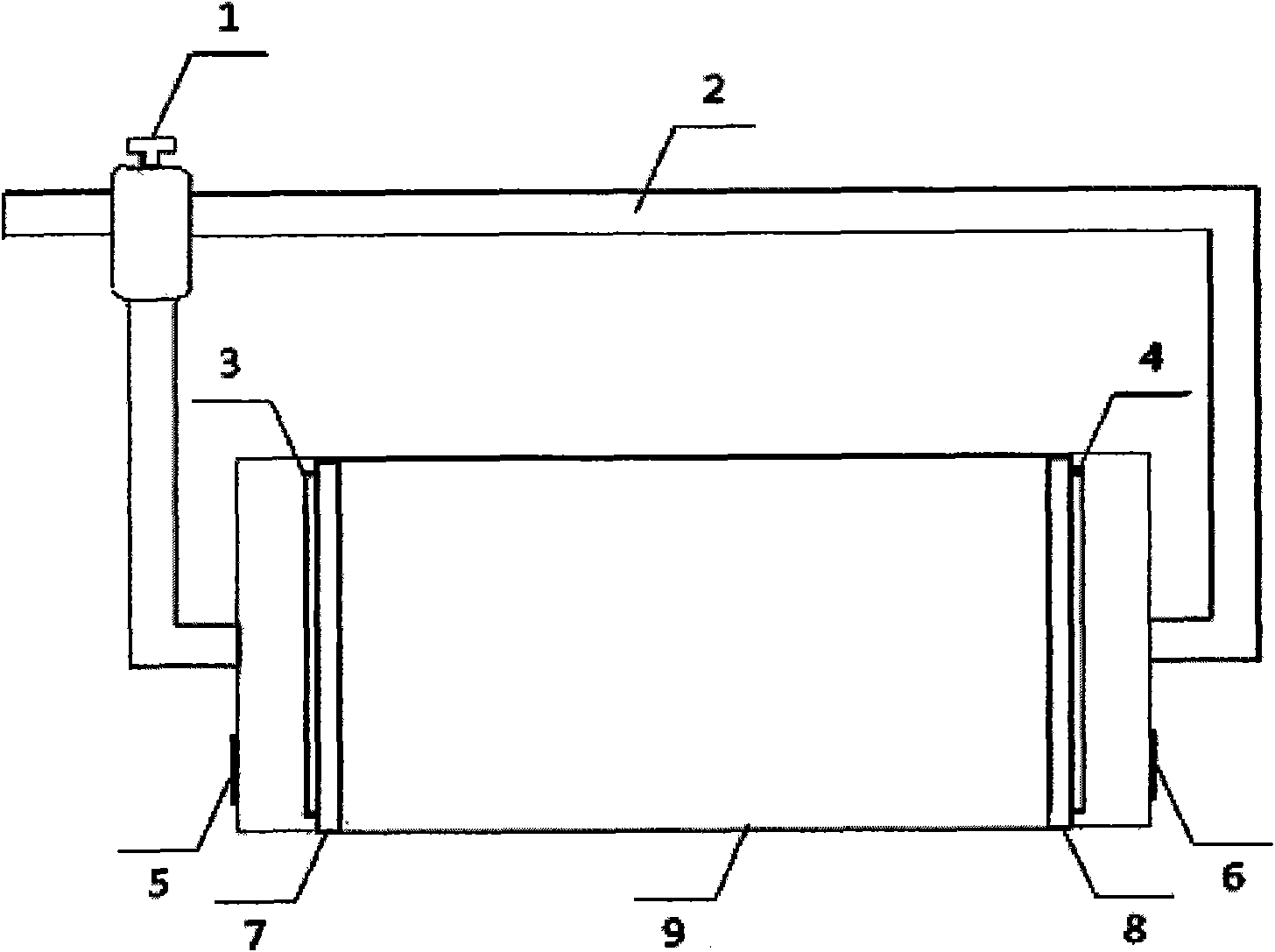

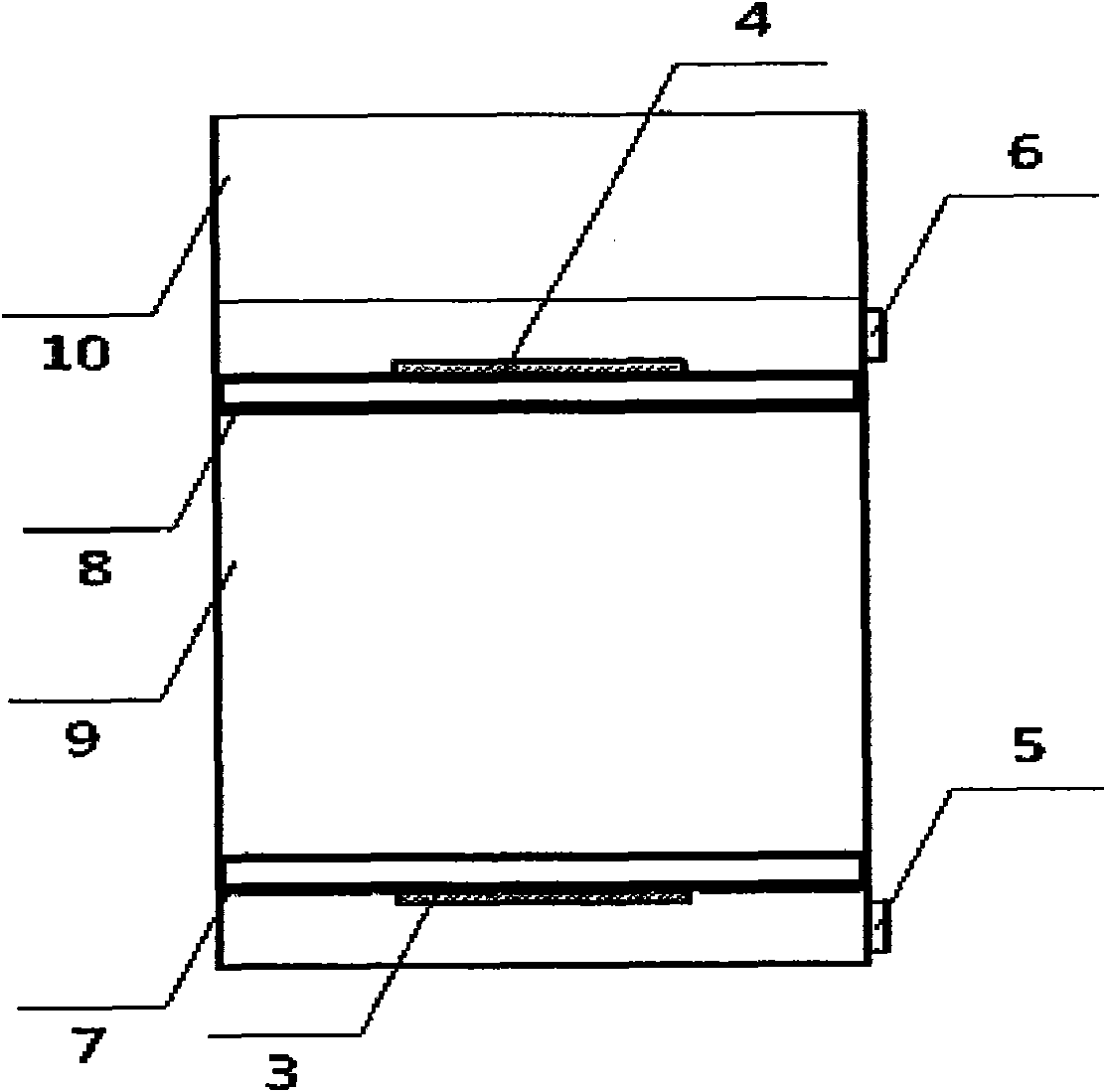

[0065] In the step a, the electrode can be provided with a fixed contact surface, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com