Novel fully-automatic scissor type winder for capacitor

A capacitor, fully automatic technology, applied in the direction of winding capacitor machines, etc., can solve the problems of lower product qualification rate, lower aluminum foil insulation level, quality hidden dangers, etc., to improve product quality and service life, improve insulation level, and improve yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

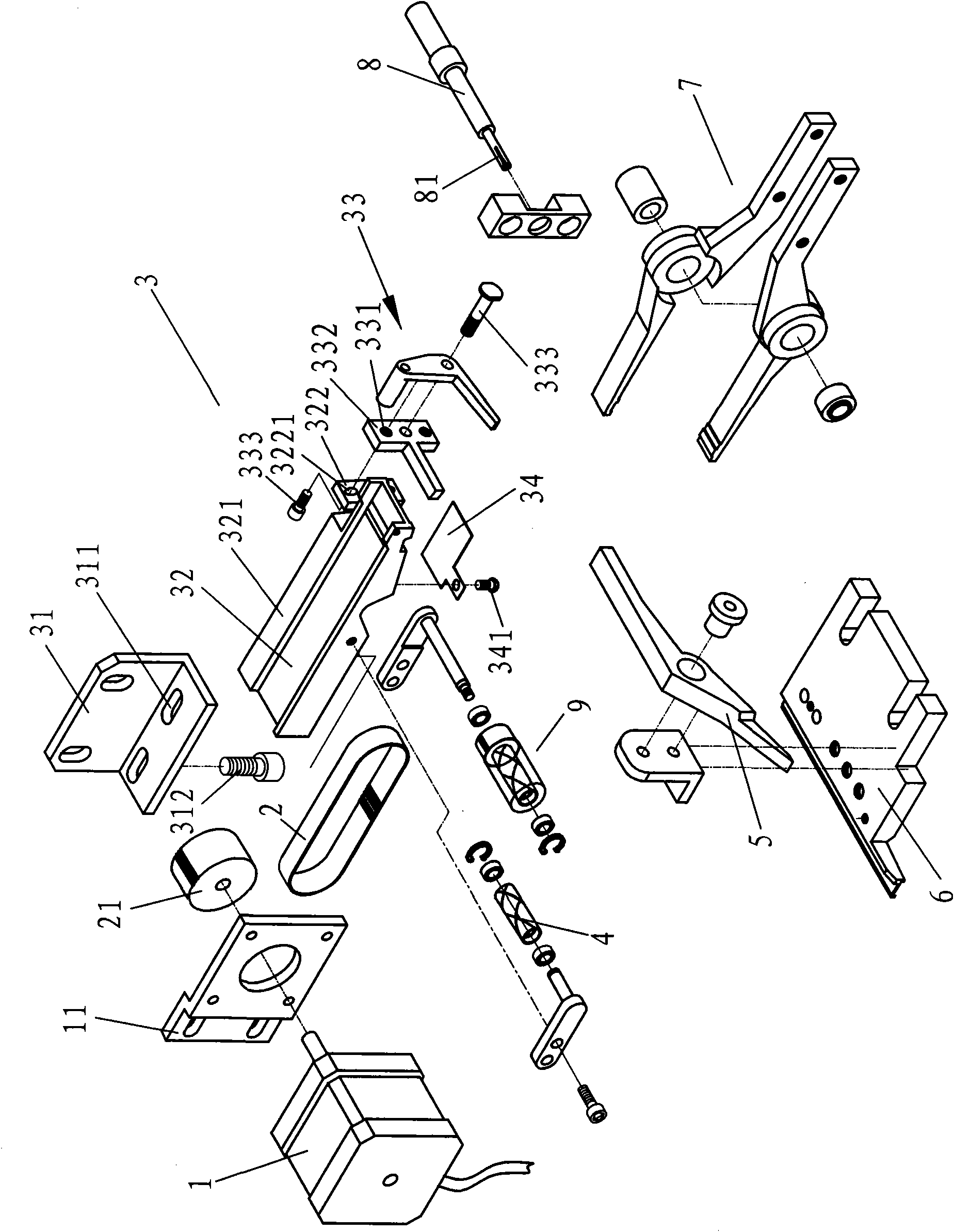

[0019] A new paper backing device for fully automatic scissor-type winding machines for capacitors, such as figure 1 As shown, it includes a stepping motor 1, a timing belt 2, a tension steel wheel 4, a foil pressing block 5, a foil feeding table 6, a paper clip 7, a winding needle 8, and an optical fiber 10. The winding needle 8 is provided with an aluminum foil guide groove 81.

[0020] The inventive point of the present invention is: it is provided with a paper backing device 3, a section of electrolytic paper A is inserted in the paper backing device 3, so that the insulation level of the joint part of the aluminum foil guide groove 81 of the winding needle 8 between the positive and negative aluminum foils is improved , and improve the ability of the capacitor to withstand voltage, temperature, and ripple, and directly increase the yield rate in production, thereby improving product quality and service life.

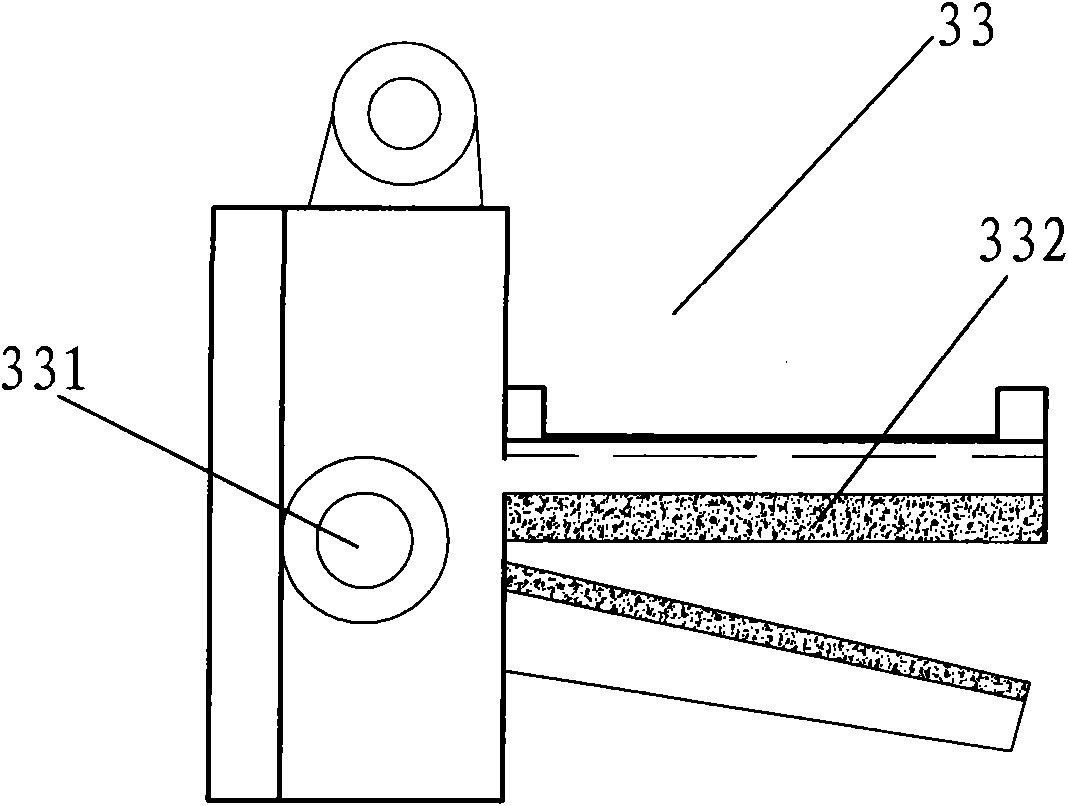

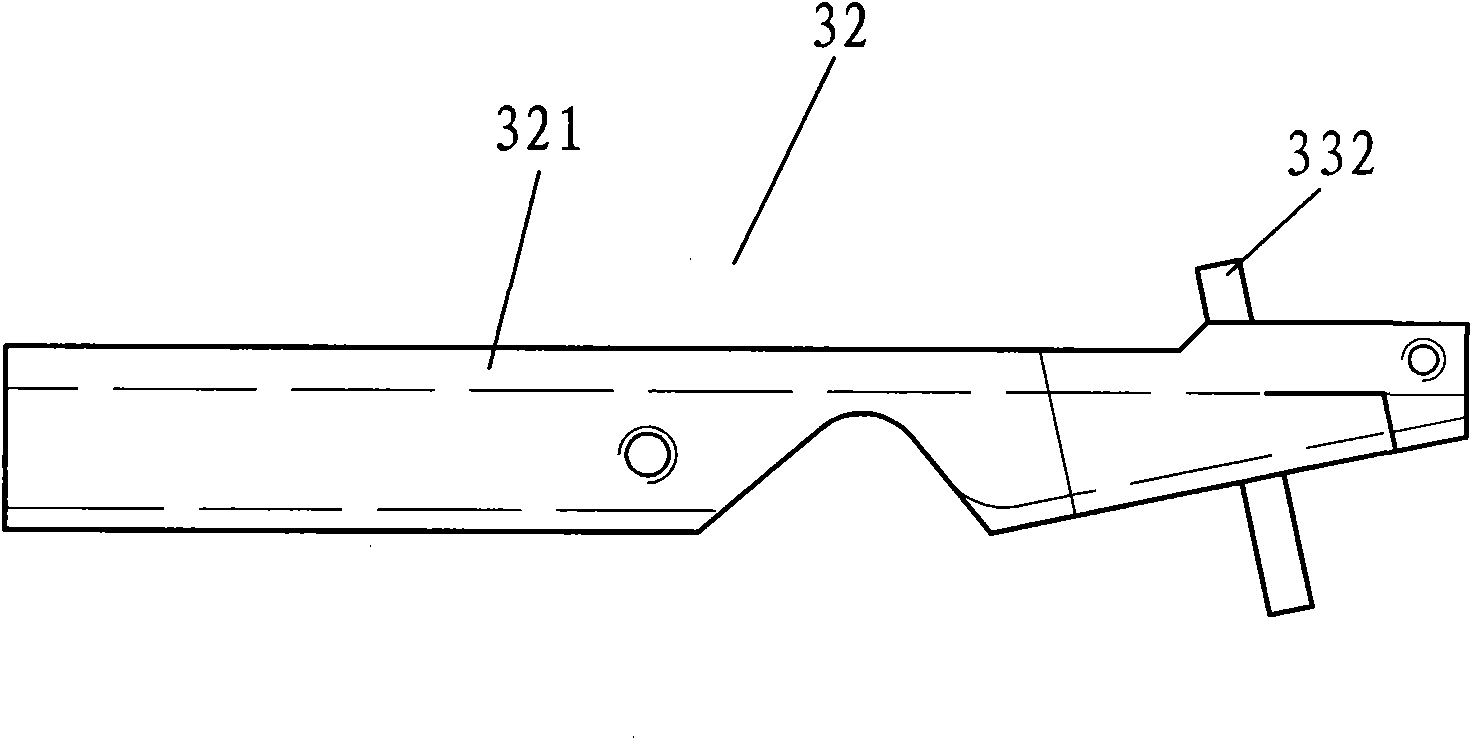

[0021] The paper pad device 3 is composed of electrolytic pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com