Method for manufacturing temperature resistant induction coil of induction cooker

A technology of induction coil and manufacturing method, which is applied in coil manufacturing, coil device, induction heating, etc., can solve the problems of high temperature that cannot withstand aluminum alloy melting, electromagnetic heating limitation, and failure to fundamentally improve the performance of temperature resistance, etc. The effect of low cost, shortened distance and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

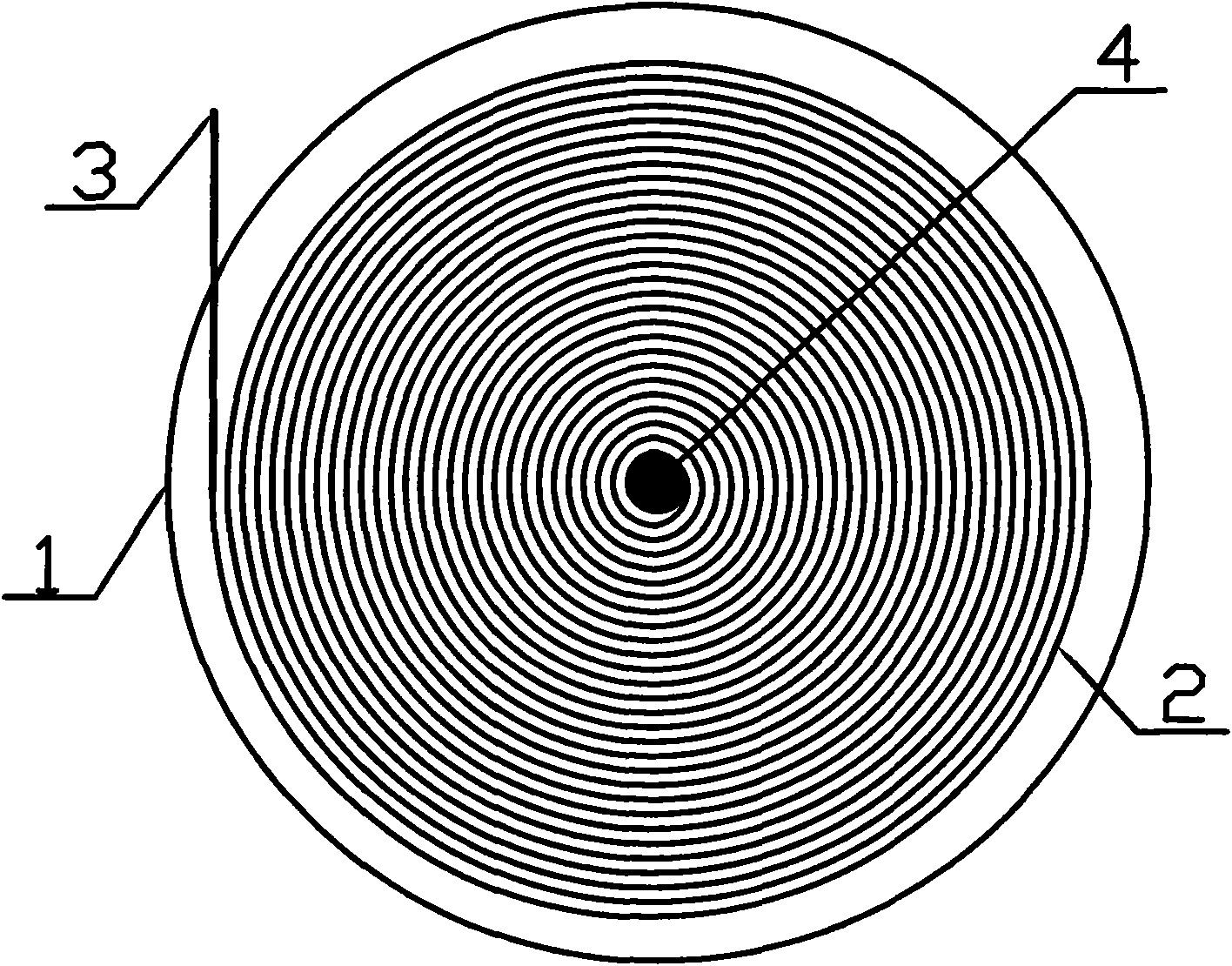

[0016] Refer to attached figure 1 , with figure 1 Describes the schematic diagram of an embodiment of the manufacturing method of the electromagnetic oven temperature-resistant induction coil provided by the present invention: the coil 2 is located in the porcelain plate 1, the copper wires in the coil 2 are all wrapped by ceramic materials, and the two ends of the coil 2 are external terminals respectively 3 and inside connector 4. Because the copper wires of the coil 2 are all wrapped by ceramic materials and then fired, the copper wires are still in a good insulating state at high temperatures. Since the ceramics can withstand high temperatures of thousands of degrees, the coil 2 has good temperature resistance.

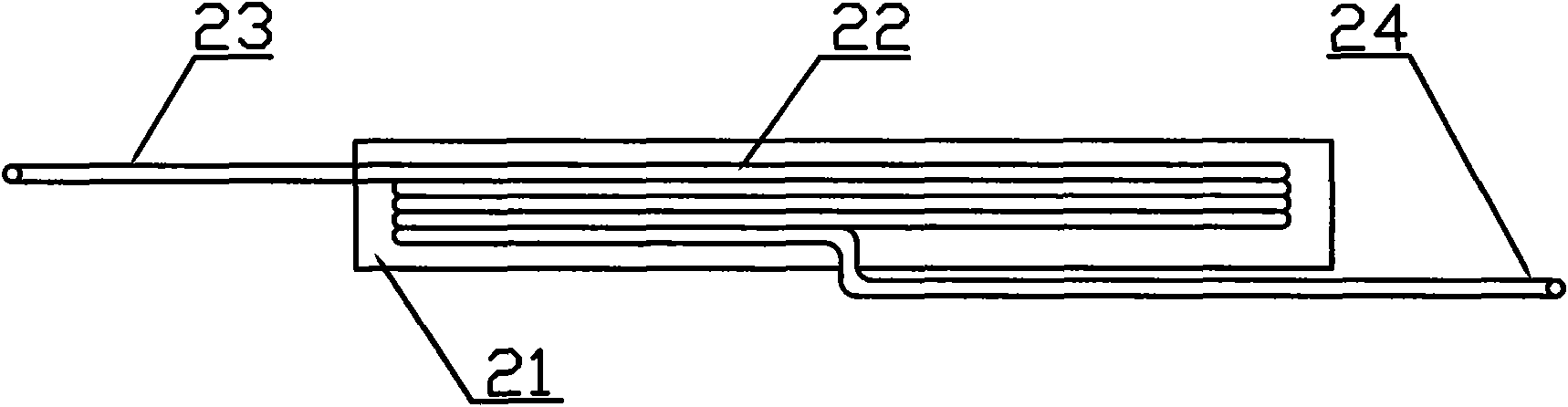

[0017] See attached figure 2 , with figure 2 It is a side view of an embodiment of the method for manufacturing a temperature-resistant induction coil for an electromagnetic oven provided by the present invention: after the copper wire of the coil 22 is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com