Disk type flaking machine

A disc type flaker and slicing technology, which is applied in the direction of planer, pretreatment of molding materials, household components, etc., to achieve the effects of high production capacity, easy operation and convenient maintenance

Active Publication Date: 2010-12-01

云南永利发林业有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention aims to solve the problem of efficiently cutting bamboo chips or wood chips for the manufacture of bamboo structural boards, and provides a disc planer with reasonable and compact structure, simple operation, high production capacity, safety and reliability, and convenient maintenance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

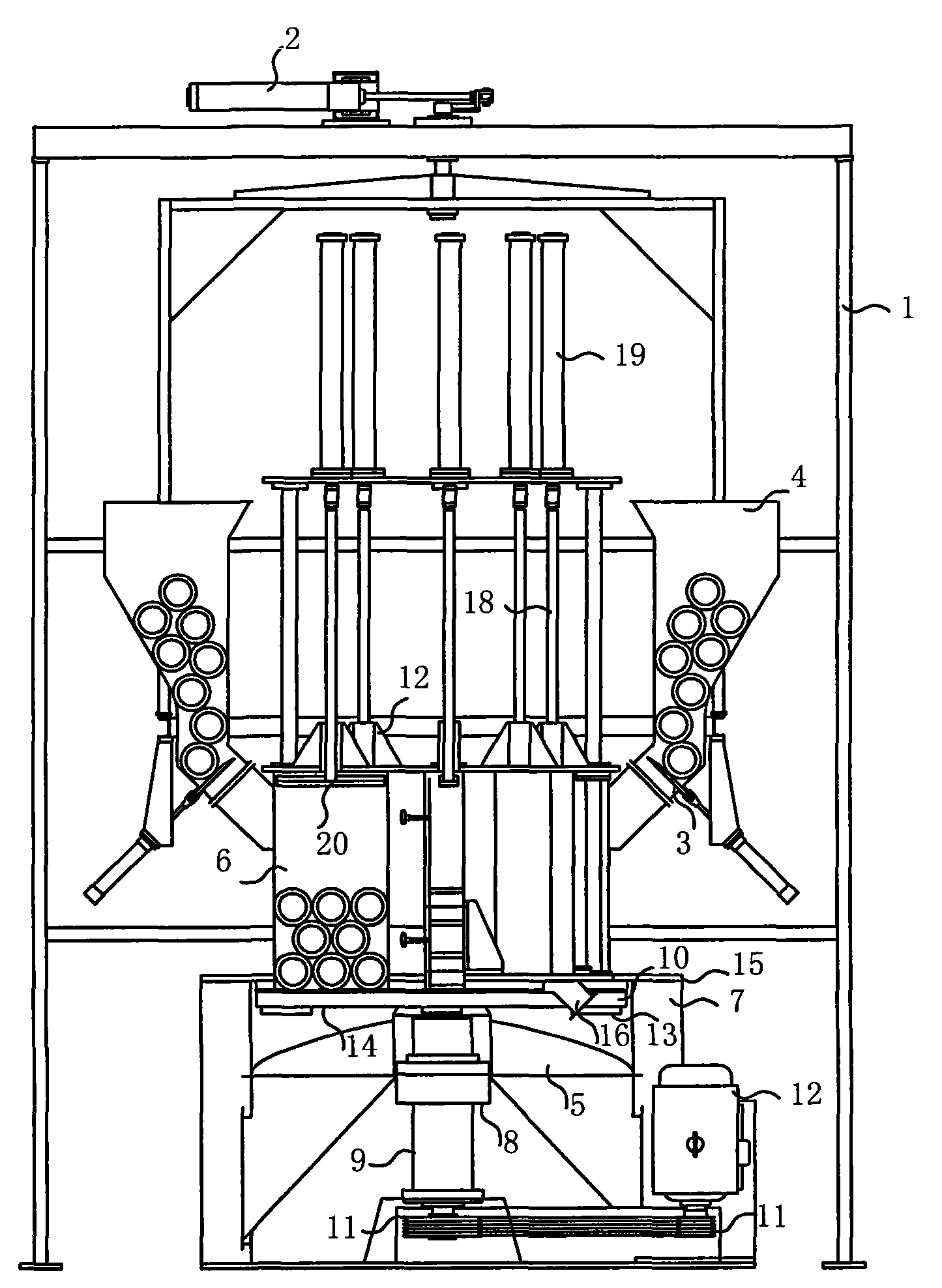

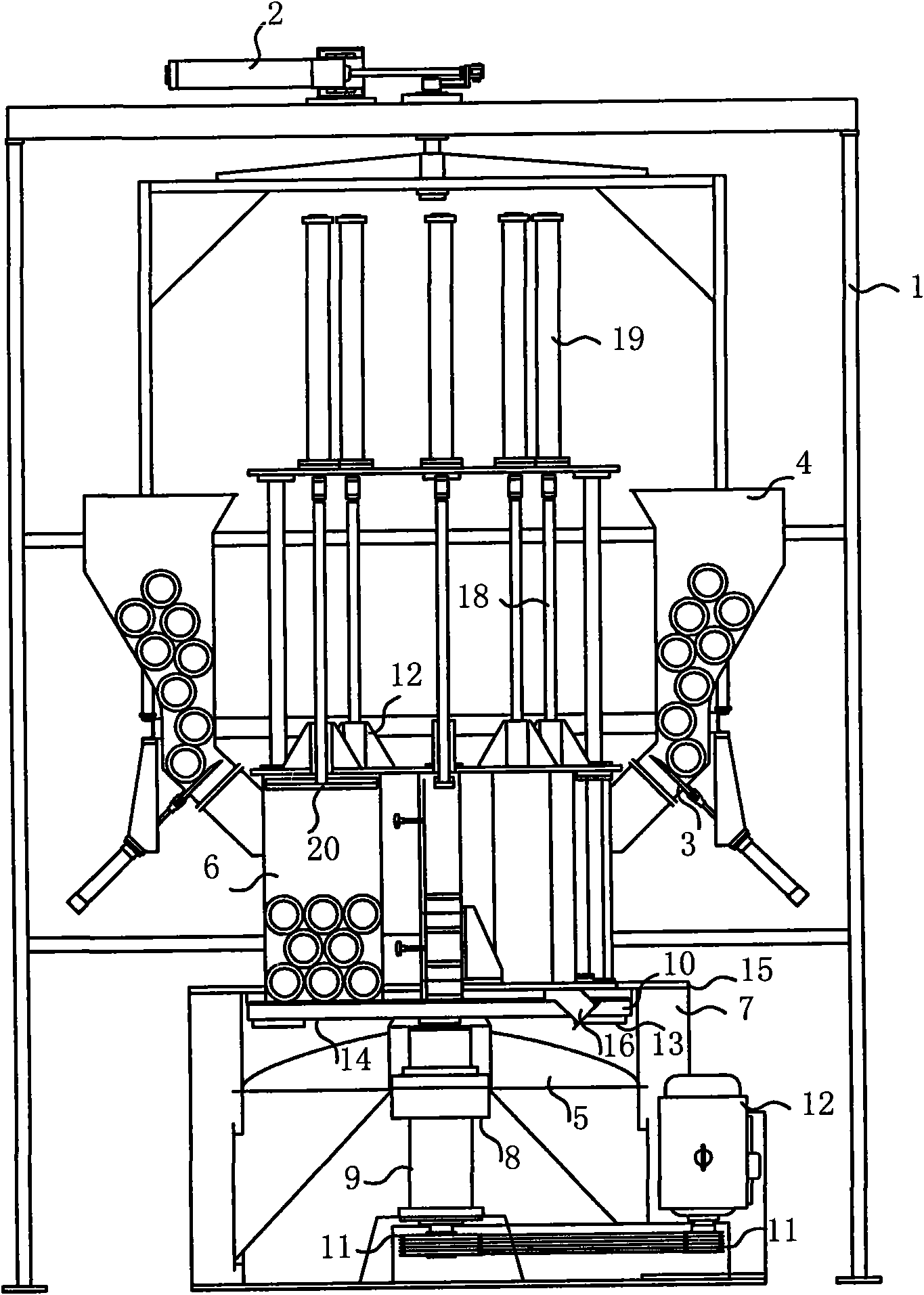

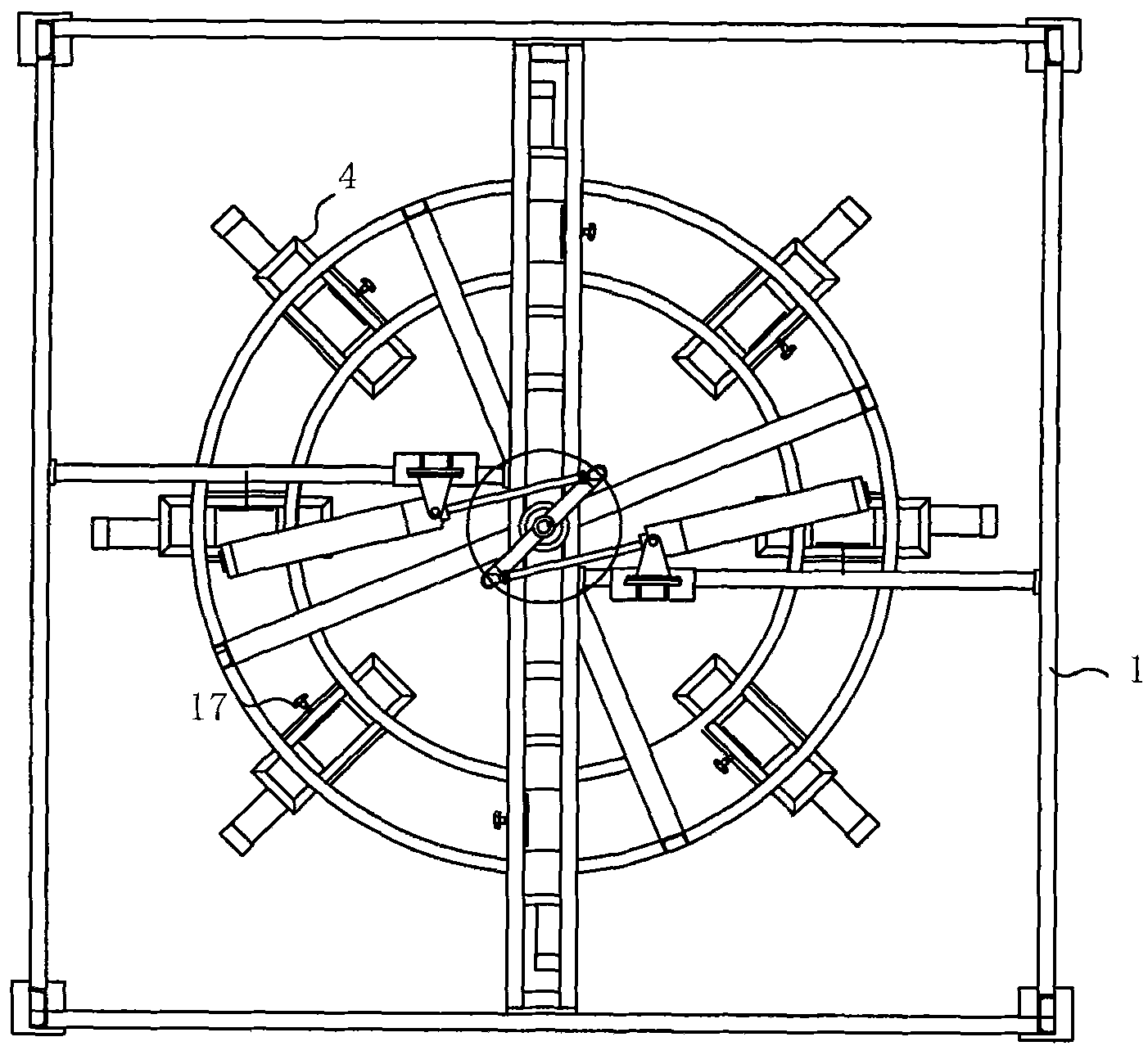

A disk type flaking machine relates to a slicing machinery apparatus, especially to a continuous cutting machine of bamboo chip or wood chip for making shaving board with orientated structure. The disk type flaking machine in the invention comprises a feeding system and a slicing system; the raw material is automatically fed to the slicing system to be sliced and the cutting chips are output through the feeding system; the apparatus comprises a pedestal, a cutter head combination, a supporting plate, a feeder, a mandril and a cylinder device. The apparatus in the invention is applied to the production line of the large bamboo chip container soleplate as a stock apparatus or the apparatus can be used as a single machine for producing the large bamboo chips. The machine is featured with compact and reasonable structure, simple and convenient operation, high production capacity and convenient maintenance and is safe and reliable.

Description

Disc flaker technical field The invention relates to a slicing mechanical device, in particular to a continuous cutting device for large bamboo or wood chips for making oriented particle boards. Background technique Oriented strand board is a board made by cutting small pieces of log or bamboo material, drying, sizing, directional paving, hot pressing and cutting. The surface layer of the board is arranged vertically, and the core layer is arranged horizontally. This criss-cross arrangement structure makes it have extremely high dimensional stability and strength, so it is widely used in construction, decoration, furniture, packaging and other fields. However, due to the consideration of environmental protection, blindly using wood as raw material is getting more and more restricted. Therefore, it is considered to use bamboo as an alternative raw material to further develop the structural panel business. Correspondingly, the equipment for producing structural panels also...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B27C1/04B27L11/02B27N1/00

Inventor 邱天祥

Owner 云南永利发林业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com