Method for raising diesel yield through gasoline-diesel fractionating towers

A fractionation tower, gasoline and diesel technology, applied in the direction of gasoline stabilization, etc., can solve problems such as water accumulation on the top, and achieve the effect of increasing diesel production, considerable benefits, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

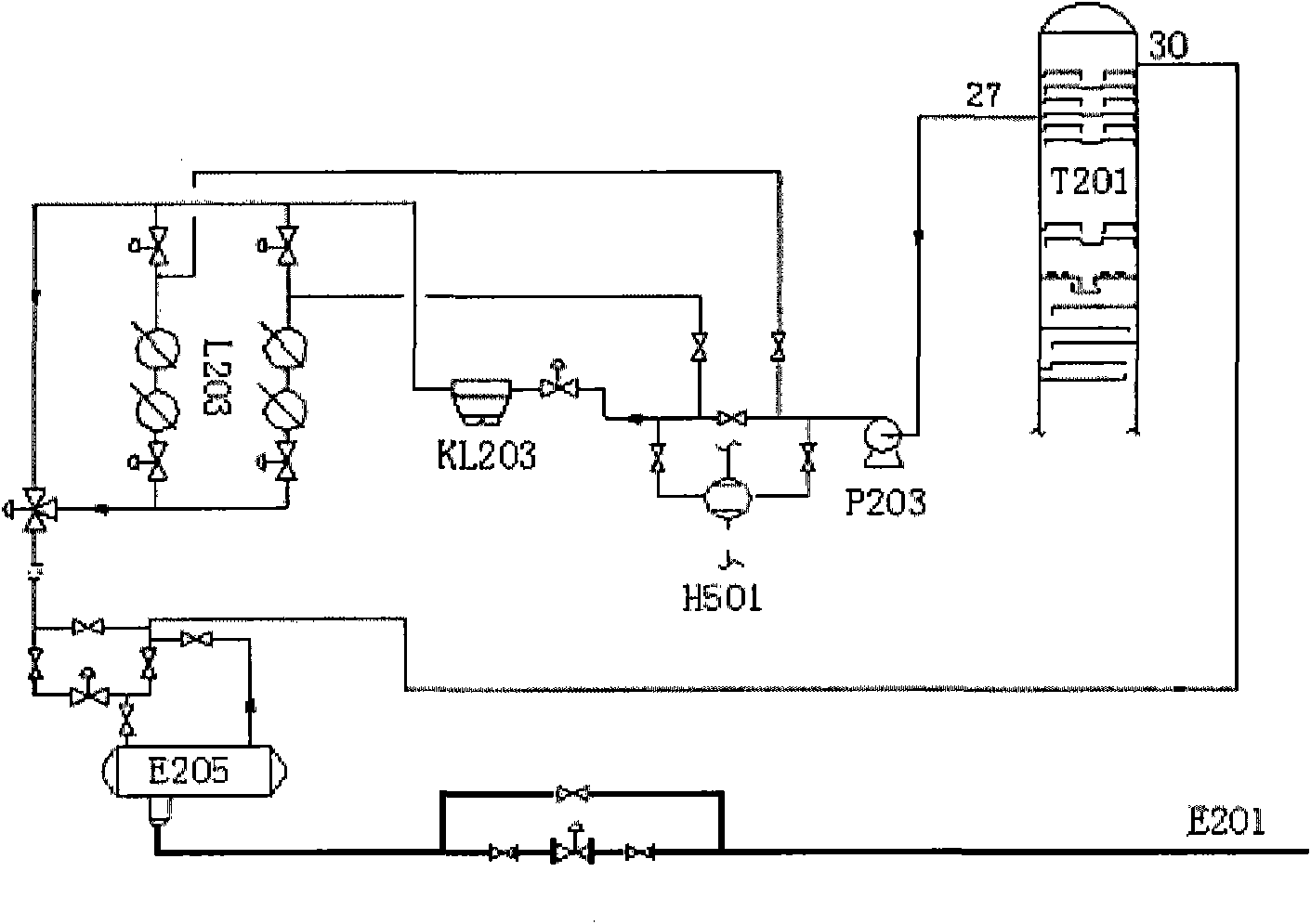

Image

Examples

Embodiment 1

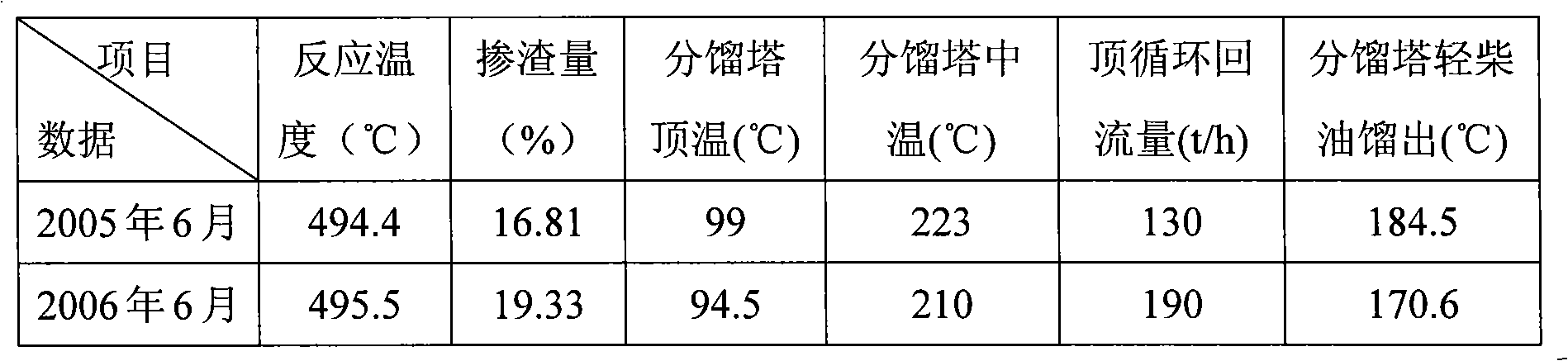

[0014] Table 1 Analysis of operating parameters before and after implementation

[0015]

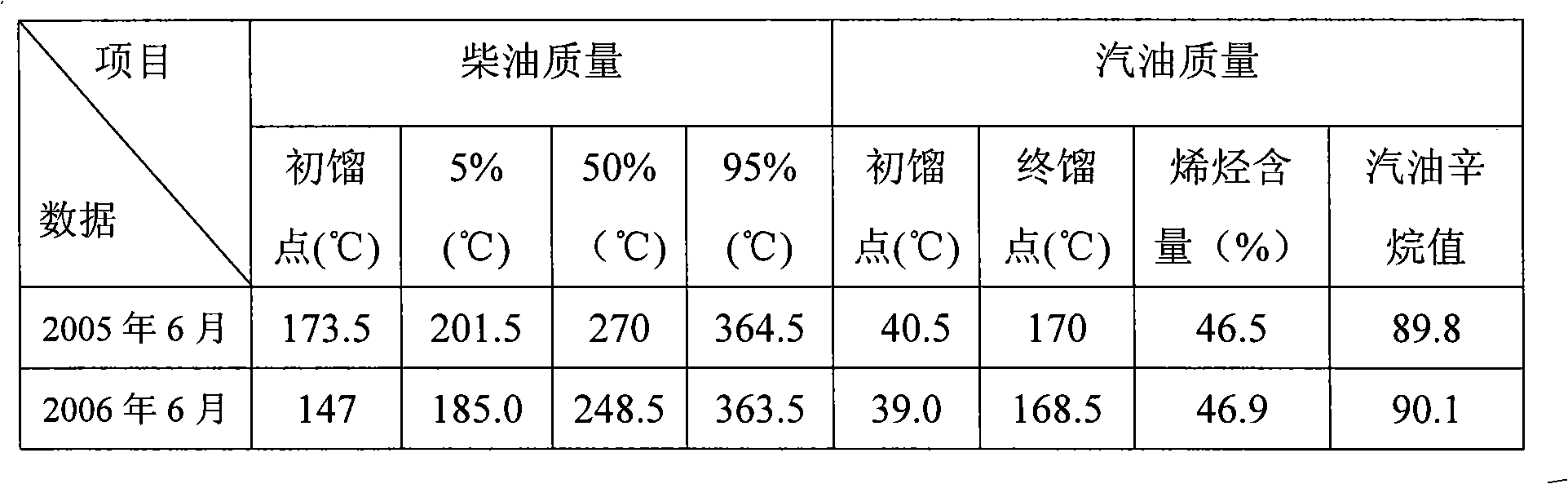

[0016] Table 2 Comparative analysis of diesel quality before and after implementation

[0017]

[0018] Under the condition that the reaction temperature and the amount of slag added are approximately constant, the top temperature and middle temperature of the fractionation tower will change significantly after the implementation of the technology, and the heat load will decrease as a whole. The diesel yield increased from 33.4% to 40.55%, the gasoline yield decreased from 43.17% to 36.74, and the diesel-gasoline ratio increased from 0.774 to 1.103.

Embodiment 2

[0020] Table 3 Analysis of operating parameters before and after implementation

[0021]

[0022] Table 4 Comparative analysis of diesel quality before and after implementation

[0023]

[0024] Under the condition that the reaction temperature and the amount of slag added are approximately constant, the top temperature and middle temperature of the fractionation tower will change significantly after the technology is implemented, and the overall heat load will decrease. The diesel yield increased from 33.27% to 40.55%, the gasoline yield decreased from 40.95% to 37.61, and the diesel-gasoline ratio increased from 0.812 to 1.078.

Embodiment 3

[0026] Table 5 Analysis of operating parameters before and after implementation

[0027]

[0028]

[0029] Table 6 Comparative analysis of diesel quality before and after implementation

[0030] Under the condition that the reaction temperature and the amount of slag added are approximately constant, the top temperature and middle temperature of the fractionation tower will change significantly after the technology is implemented, and the overall heat load will decrease. The diesel yield increased from 36.76% to 40.7%, the gasoline yield decreased from 41.26% to 35.23, and the diesel-gasoline ratio increased from 0.89 to 1.144.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com