Slow-release solid salt inhibitor

A slow-release, solid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of frequent feeding, rapid drug activity failure, limited income, etc., to reduce feeding times, inhibit wellbore salt deposition, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

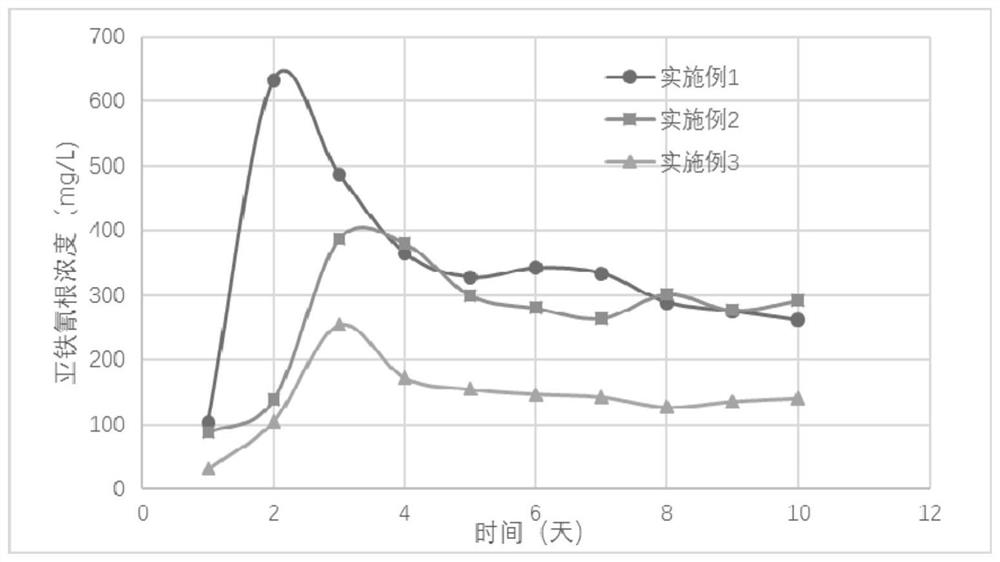

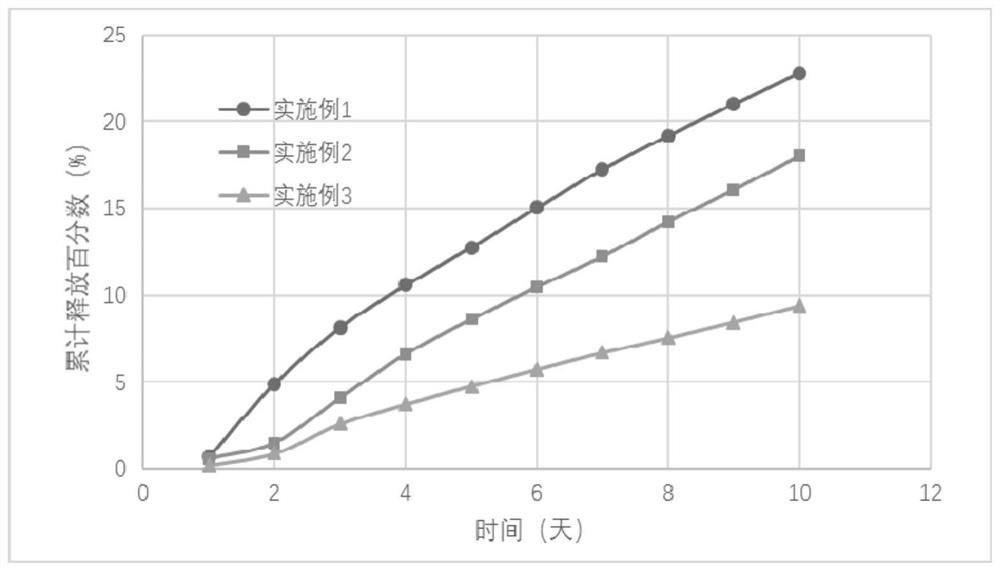

Embodiment 1

[0051] Weigh 100g of sodium ferrocyanide and dissolve it in a polyacrylic acid solution with a concentration of 30%, heat it in a water bath at 90 degrees and stir well, then add 10g of gelatin and stir and mix evenly again, wherein sodium ferrocyanide, gelatin and polyacrylic acid Acrylic acid accounts for 29.9%, 3%, and 59.7% of the total weight of the salt suppressant particles respectively. After mixing evenly for 1 hour, stop heating, and when it is cooled to about 70 degrees, use a spherical mold with a diameter of 2 cm to extrude and granulate, and cool to room temperature to obtain the core of the salt inhibitor particle.

[0052]Immerse the core of the salt suppressant particle in the modified urea-formaldehyde resin binder for 1 minute and take it out to obtain the particle with the binder on the surface. Mix the granules containing the adhesive on the surface with the coating material and add them to the evaporator, and distill at a temperature of 50°C for 90 minute...

Embodiment 2

[0054] Weigh 100g of sodium ferrocyanide and dissolve it in a polyacrylic acid solution with a concentration of 30%, heat it in a water bath at 90 degrees and stir well, then add 10g of gelatin and stir and mix evenly again, wherein sodium ferrocyanide, gelatin and polyacrylic acid Accounting for 29.9%, 3%, and 59.7% of the total weight of salt suppressant granules respectively. After mixing evenly for 1 hour, stop heating, and when it is cooled to about 70 degrees, use a spherical mold with a diameter of 2 cm to extrude and granulate, and cool to room temperature to obtain the core of the salt inhibitor particle.

[0055] Immerse the core of the salt suppressant particle in the modified urea-formaldehyde resin binder for 1 minute and take it out to obtain the particle with the binder on the surface. Mix the granules containing the adhesive on the surface with the coating material and add them to the evaporator, and distill at a temperature of 50°C for 90 minutes. The above-m...

Embodiment 3

[0057] Weigh 100g of sodium ferrocyanide and dissolve it in a polyacrylic acid solution with a concentration of 30%, heat it in a water bath at 90 degrees and stir well, then add 10g of gelatin and stir and mix evenly again, wherein sodium ferrocyanide, gelatin and polyacrylic acid They account for 30.4%, 3%, and 60.8% of the total weight of salt suppressant granules, respectively. After mixing evenly for 1 hour, stop heating, and when it is cooled to about 70 degrees, use a spherical mold with a diameter of 2 cm to extrude and granulate, and cool to room temperature to obtain the core of the salt inhibitor particle.

[0058] Immerse the core of the salt suppressant particle in the modified urea-formaldehyde resin binder for 1 minute and take it out to obtain the particle with the binder on the surface. Mix the granules containing the adhesive on the surface with the coating material and add them to the evaporator, and distill at a temperature of 50°C for 90 minutes. The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com