A method for producing hydrogen and sulphuric acid

A sulfuric acid, hydrogen technology, applied in chemical instruments and methods, hydrogen production, hydrogen, etc., can solve problems such as concentration that is not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] A major disadvantage in the prior art methods is the huge energy requirement for the decomposition of sulfuric acid, since it consumes roughly over 60% of the thermal energy for hydrogen production, while only less than 40% is consumed in the decomposition of water. The methods described in the cited Japanese Patent Publication avoid the decomposition of sulfuric acid, however, production according to them must be carried out in connection with a sulfuric acid plant because the sulfuric acid produced as it is is not a commodity.

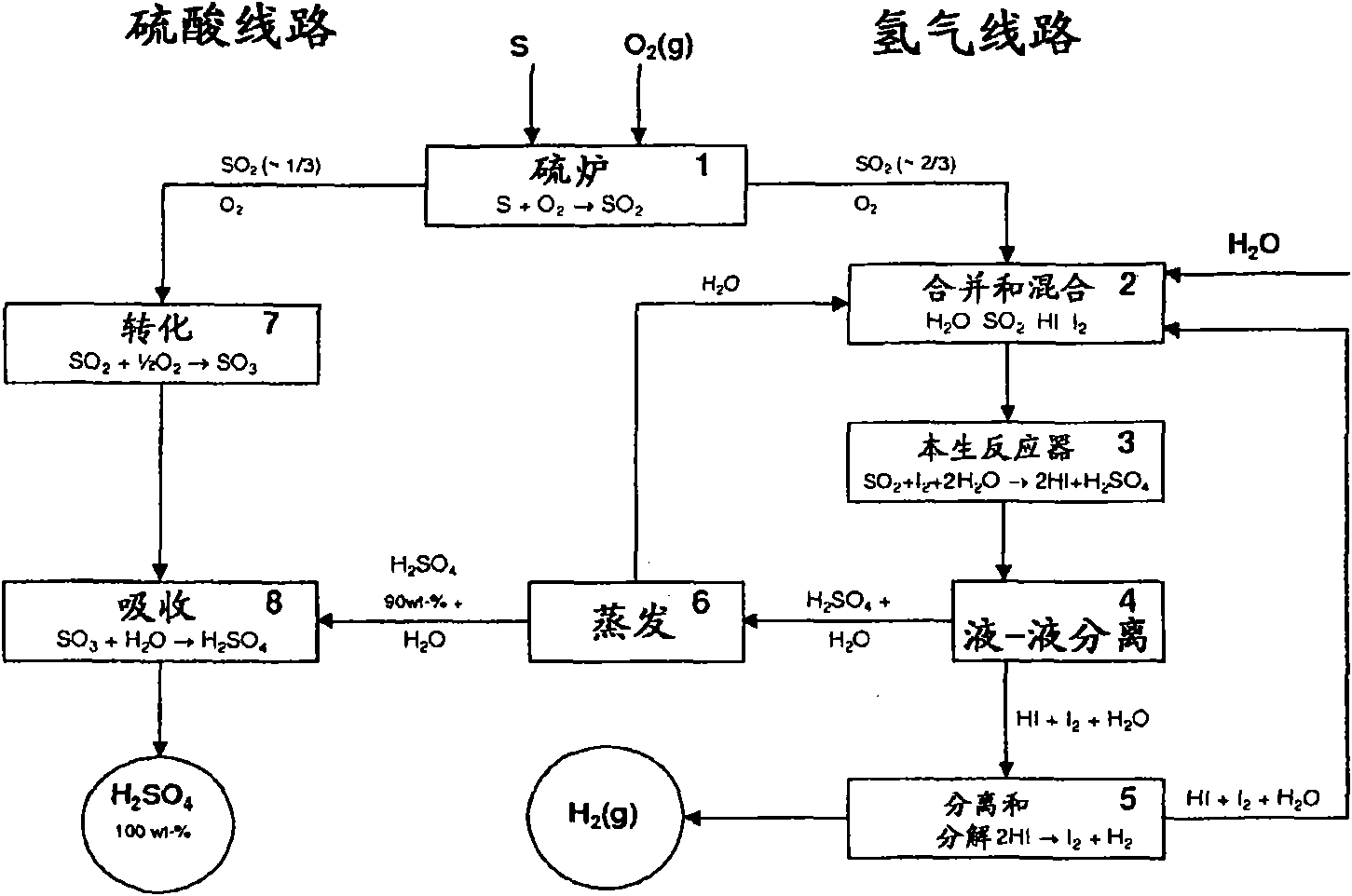

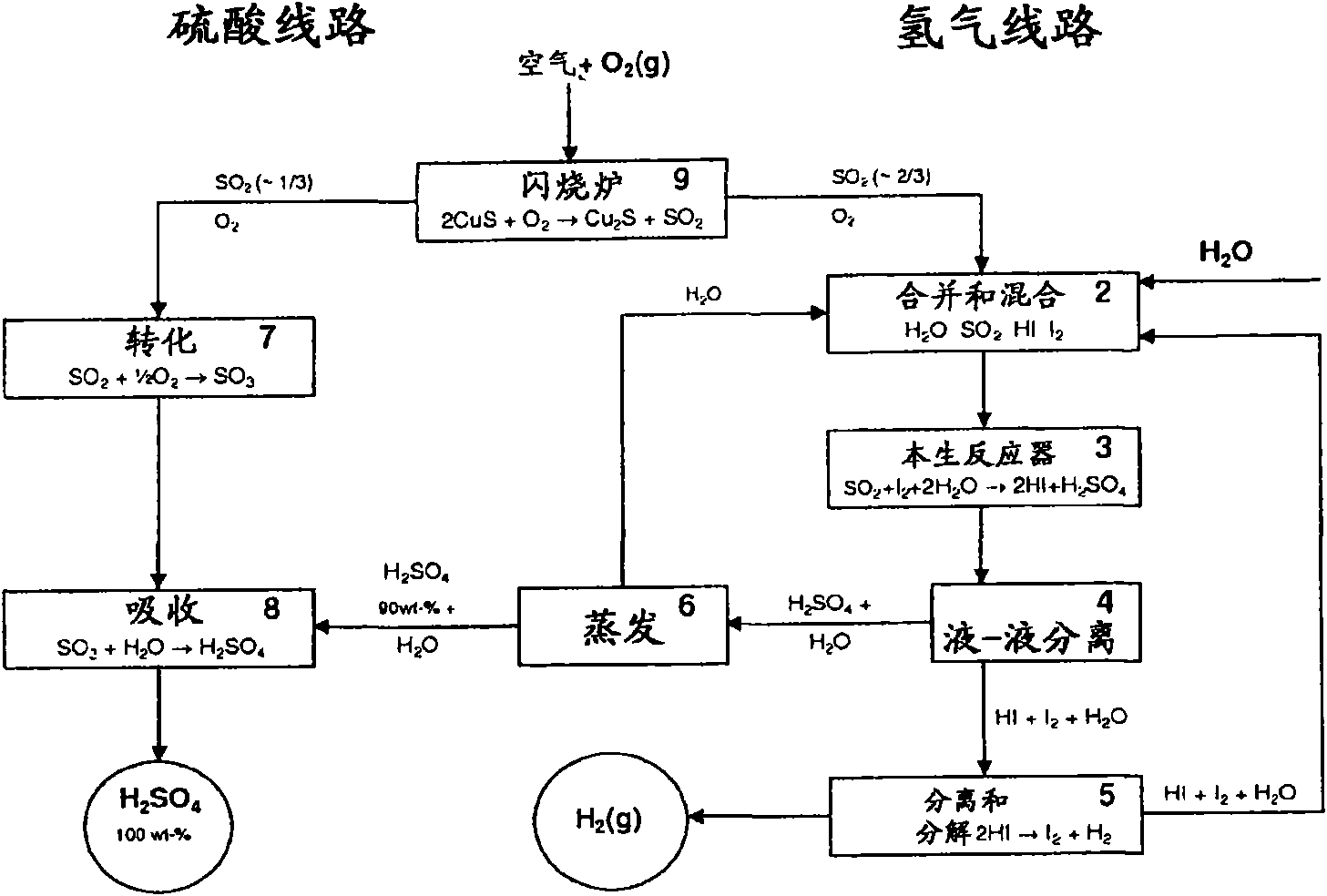

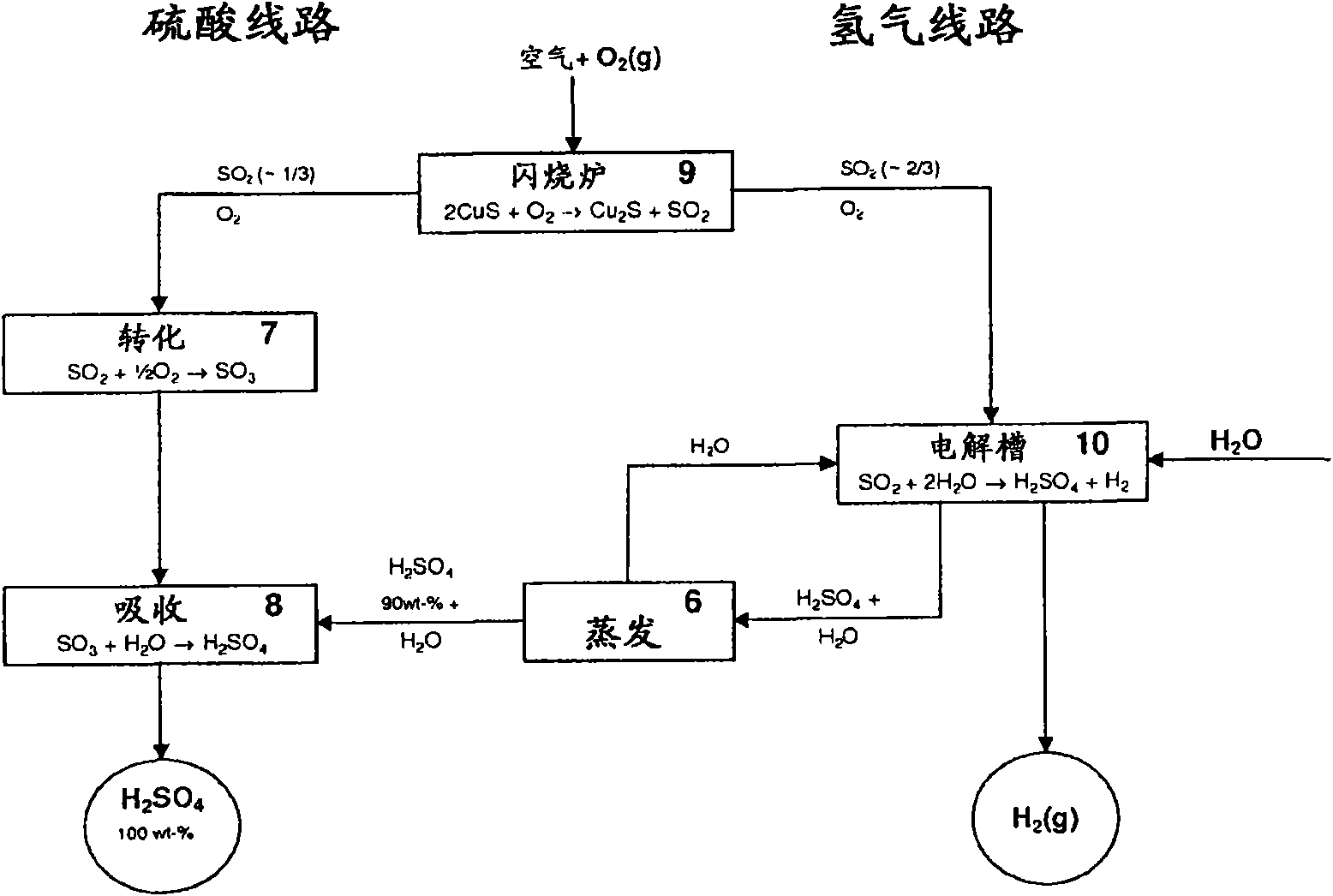

[0065] The invention according to the method reveals a new possibility to independently and cost-effectively produce both hydrogen and concentrated sulfuric acid (100%). In fact, the acid content of this concentrated sulfuric acid is between 97-100 wt%, although it is mentioned in this specification as 100 wt%. It is also possible to produce oleum by this method.

[0066] Some preferred process alternatives have been described according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com