Bi-component composite type metallic catalyst and application thereof

A metal catalyst and composite technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of low degradation efficiency and ineffective effect of free radical quencher Sensitivity and other issues, to achieve the effect of improving catalytic activity, excellent application prospects, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

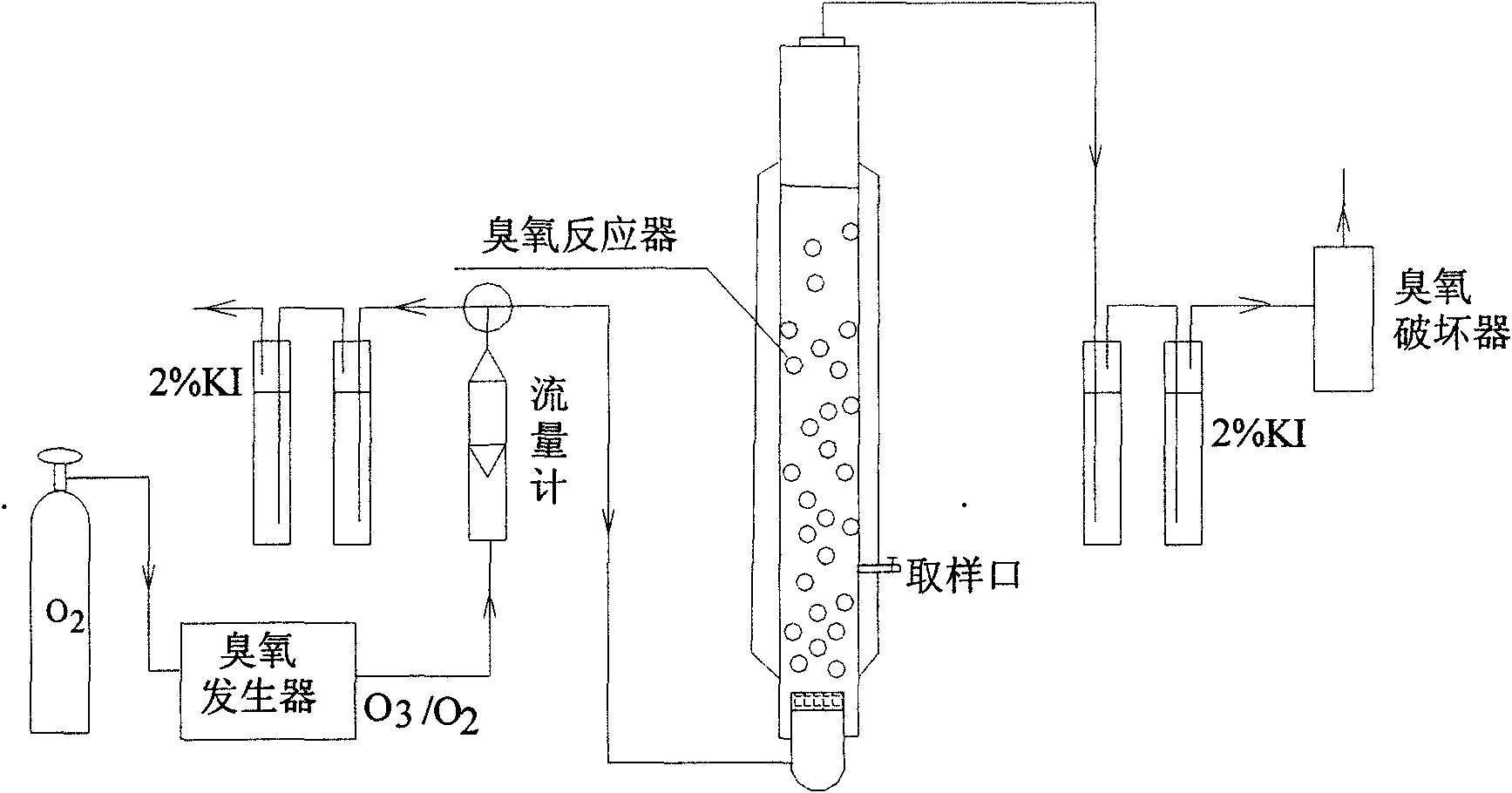

Method used

Image

Examples

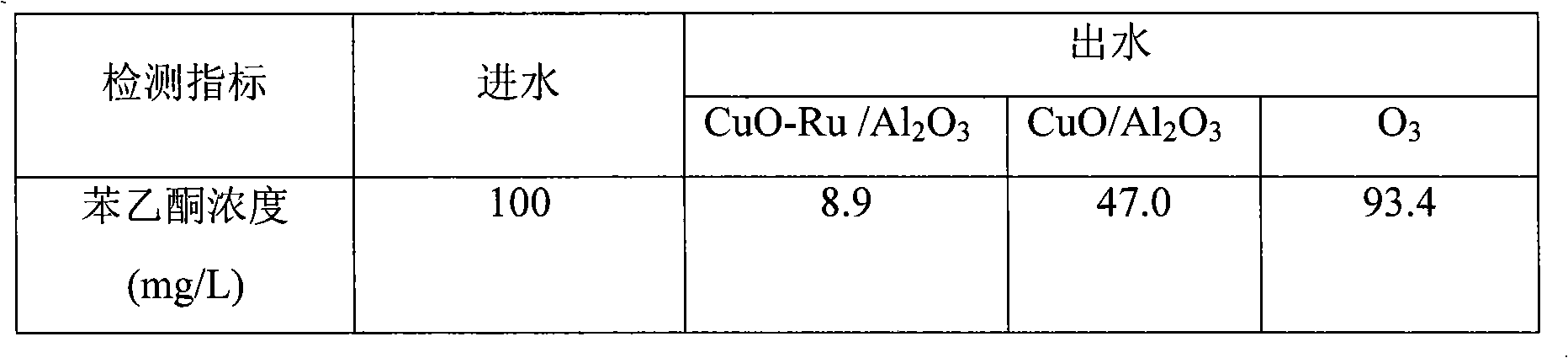

Embodiment 1

[0036] The copper nitrate trihydrate of 70g and the ruthenium trichloride hydrate of 1.5g are dissolved in water and made into a solution of 150ml, and then 80g of active aluminum oxide carrier (Sinopharm Group Chemical Reagent Co., Ltd., 20001661) is added to the same amount while stirring. Dip. After five hours of immersion, the resulting impregnation was dried at 80° C. for 2 hours. Then the above dried product was calcined in a muffle furnace at 430° C. for 10 hours to obtain a finished catalyst. CuO-Ru / Al 2 o 3 The appearance of the catalyst is a green active alumina sphere, the diameter d is about 3.5mm-5mm, and the density is about 150.9g / cm 3 .

[0037] Weigh 70g of copper nitrate trihydrate and dissolve it in water to form a 150ml solution, then impregnate 80g of active aluminum oxide carrier (Sinopharm Chemical Reagent Co., Ltd., 20001661) in equal amounts while stirring. After five hours of immersion, the resulting impregnation was dried at 80° C. for 2 hours. ...

Embodiment 2

[0046] The copper nitrate trihydrate of 75g and the ruthenium trichloride hydrate of 0.75g are dissolved in water and made into a solution of 150ml, and then 80g of active aluminum oxide carrier (Sinopharm Group Chemical Reagent Co., Ltd., 20001661) is added to the same amount while stirring. Dip. After impregnation for five hours, the obtained impregnation was dried at 90° C. for 3 hours. Then the above dried product was calcined in a muffle furnace at 450° C. for 12 hours to obtain the finished catalyst. CuO-Ru / Al 2 o 3 The appearance of the catalyst is a green active alumina sphere, the diameter d is about 3.5mm-5mm, and the density is about 150.6g / cm 3 .

[0047] Weigh 75g of copper nitrate trihydrate and dissolve it in water to form a 150ml solution, then impregnate 80g of active aluminum oxide carrier (Sinopharm Chemical Reagent Co., Ltd., 20001661) in equal amounts while stirring. After impregnation for five hours, the obtained impregnation was dried at 90° C. for ...

Embodiment 3

[0055] The copper nitrate trihydrate of 80g and the ruthenium trichloride hydrate of 0.5g are dissolved in water and made into a solution of 150ml, and then 80g of active aluminum oxide carrier (Sinopharm Group Chemical Reagent Co., Ltd., 20001661) is added to the same amount while stirring. Dip. After impregnation for five hours, the obtained impregnation was dried at 100° C. for 4 hours. Then the above dried product was calcined in a muffle furnace at 470° C. for 13 hours to obtain a finished catalyst. CuO-Ru / Al 2 o 3 The appearance of the catalyst is a green active alumina sphere, the diameter d is about 3.5mm-5mm, and the density is about 150.2g / cm 3 .

[0056] Weigh 80g of copper nitrate trihydrate and dissolve in water to form a 150ml solution, then impregnate 80g of active aluminum oxide carrier (Sinopharm Chemical Reagent Co., Ltd., 20001661) in equal amounts while stirring. After impregnation for five hours, the obtained impregnation was dried at 100° C. for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com